Turnover device for power battery raw material production line

A technology of flipping device and power battery, applied in packaging, transportation and packaging, final product manufacturing, etc., can solve problems such as affecting blanking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

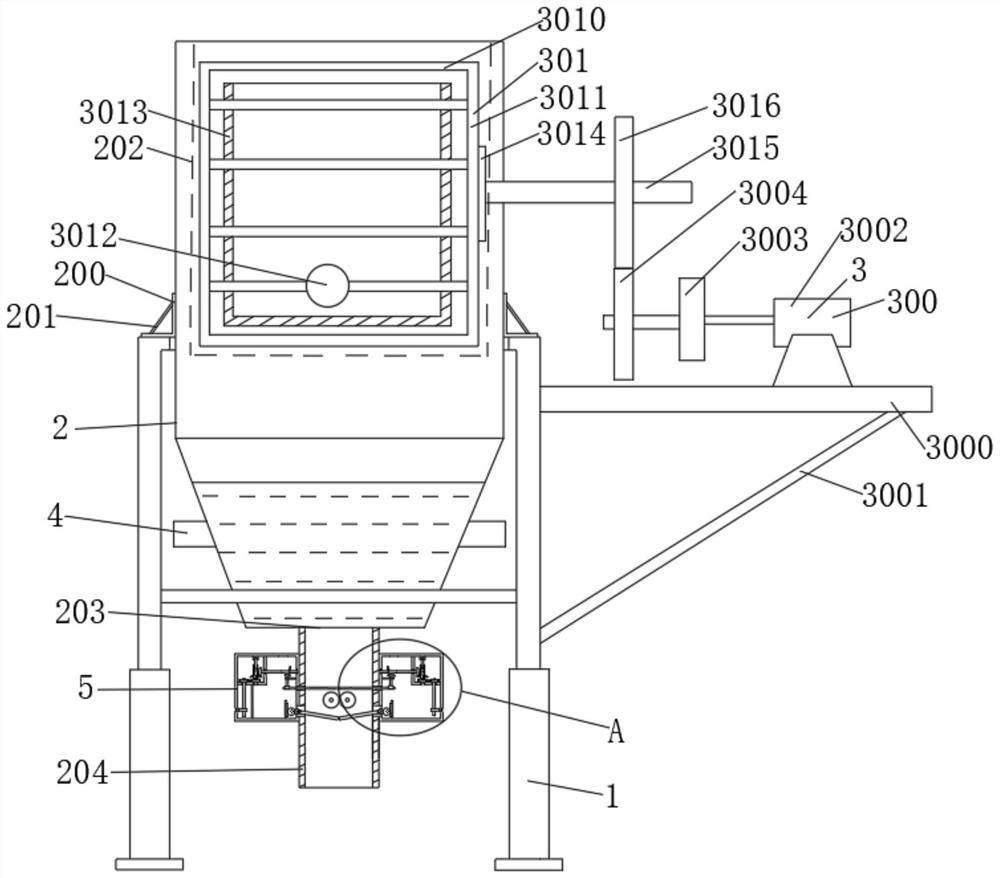

[0033] The embodiment of the present invention provides an overturning device for a power battery raw material production line, such as Figure 1-5 As shown, a bracket 1 is included, and a lower material bin 2 is arranged on the bracket 1 , a turning mechanism 3 is arranged inside the lower material bin 2 , and an air hammer 4 is arranged on the lower material bin 2 .

[0034] Preferably, the support 1 includes a lifting cylinder 100 and a support leg 101 from bottom to top, the support leg 101 is sleeved in the lifting cylinder 100, and the support leg 101 is provided with a sixth driving member, so The sixth driving member is used to drive the support leg 101 to slide along the lifting cylinder 100 .

[0035] The working principle and beneficial effects of the above technical solution are: when in use, due to the action of the air hammer 4, the outer wall of the lower hopper 2 is knocked, thereby promoting the battery raw materials attached to the inner wall of the lower hop...

Embodiment 2

[0037] On the basis of the above-mentioned embodiment 1, the support 1 and the lower silo 2 are connected by an angle steel 200, and the angle steel 200 is provided with several uniformly arranged reinforcing ribs 201;

[0038] A material box inlet 202 is provided on the lower material bin 2;

[0039] The turnover mechanism 3 includes a turnover drive mechanism 300 and a turnover actuator 301, the turnover drive mechanism 300 is arranged on the support 1, the turnover actuator 301 is arranged in the lower bin 2, and the turnover drive The mechanism 300 is used to drive the turning actuator 301 to turn over;

[0040] The overturning drive mechanism 300 includes a mounting plate 3000, the mounting plate 3000 is fixedly connected to the support 1, and an auxiliary support rod 3001 is arranged obliquely between the mounting plate 3000 and the support 1, and the mounting plate 3000 The top is fixedly connected with a turning motor 3002, and the output shaft of the turning motor 30...

Embodiment 3

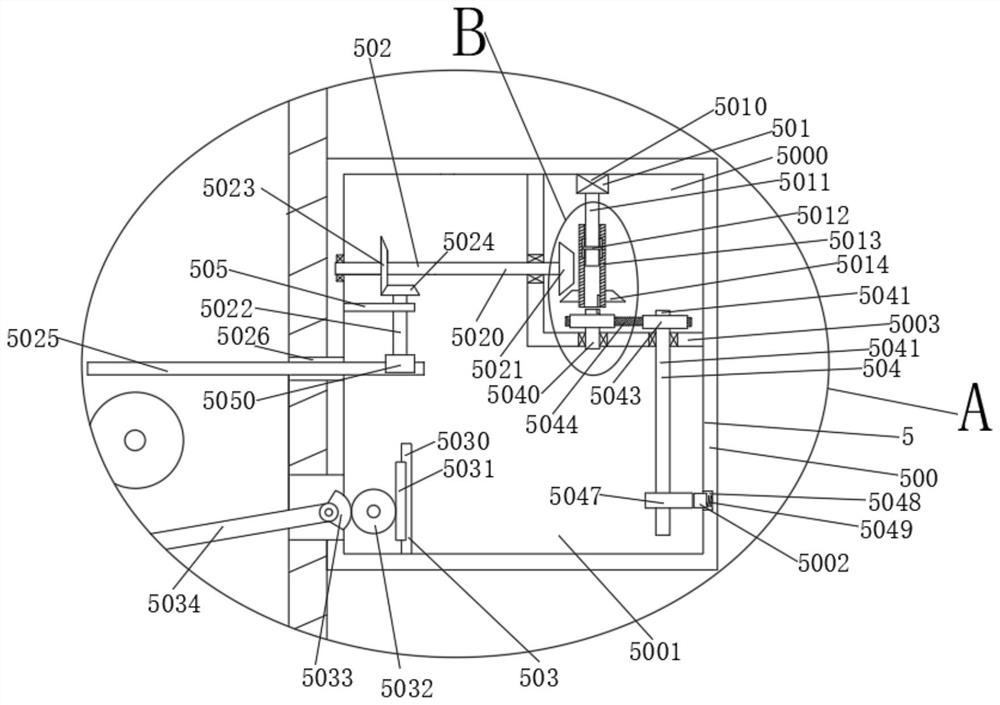

[0045] On the basis of Embodiment 1 or 2, a discharge port 203 is provided at the bottom of the lower hopper 2, and a discharge channel 204 is fixedly connected to the discharge port 203, and discharge channels 204 are provided on both sides of the discharge channel 204. Material auxiliary mechanism 5;

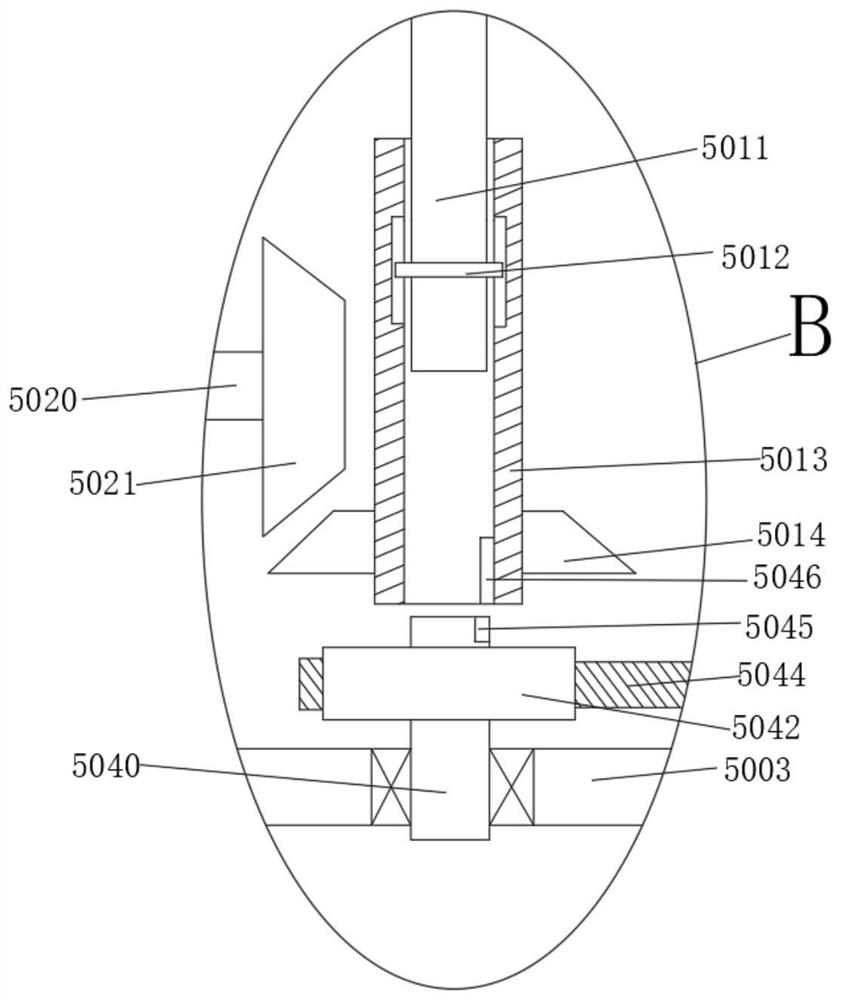

[0046] The auxiliary discharge mechanism 5 includes a mechanism casing 500 symmetrically arranged with respect to the discharge channel 204, the mechanism casing 500 is divided into a drive chamber 5000 and an execution chamber 5001 by a plate body 5003, and the mechanism casing 500 Auxiliary mechanism driver 501, channel switch assembly 502, discharge adjustment assembly 503 and crushing trigger assembly 504 are provided inside. The auxiliary mechanism driver 501 is placed in the drive chamber 5000, the channel switch assembly 502, outlet The material adjustment assembly 503 and the crushing trigger assembly 504 are placed in the execution cavity 5001, the channel switch asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com