Method for deep processing and treating starch for foods

A processing method and technology of a food processing device, which are applied in the directions of food mechanical processing, food ingredients, food extraction, etc., can solve the problems of reduced starch yield, hindered sweet potato unloading, and unsupported containers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

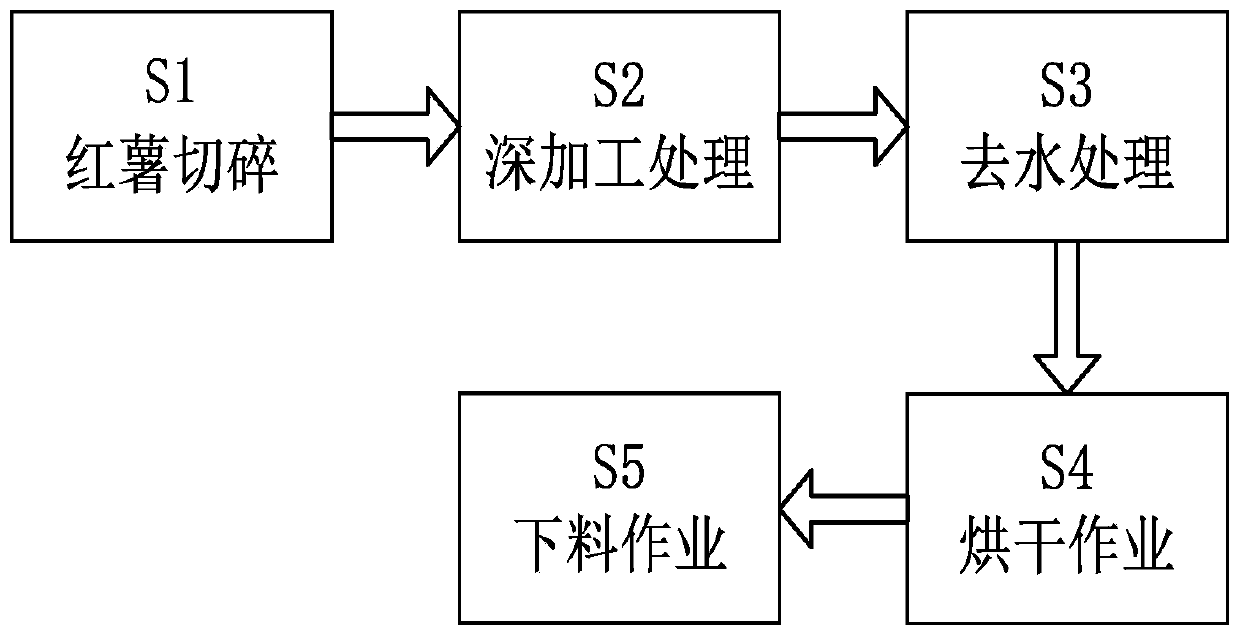

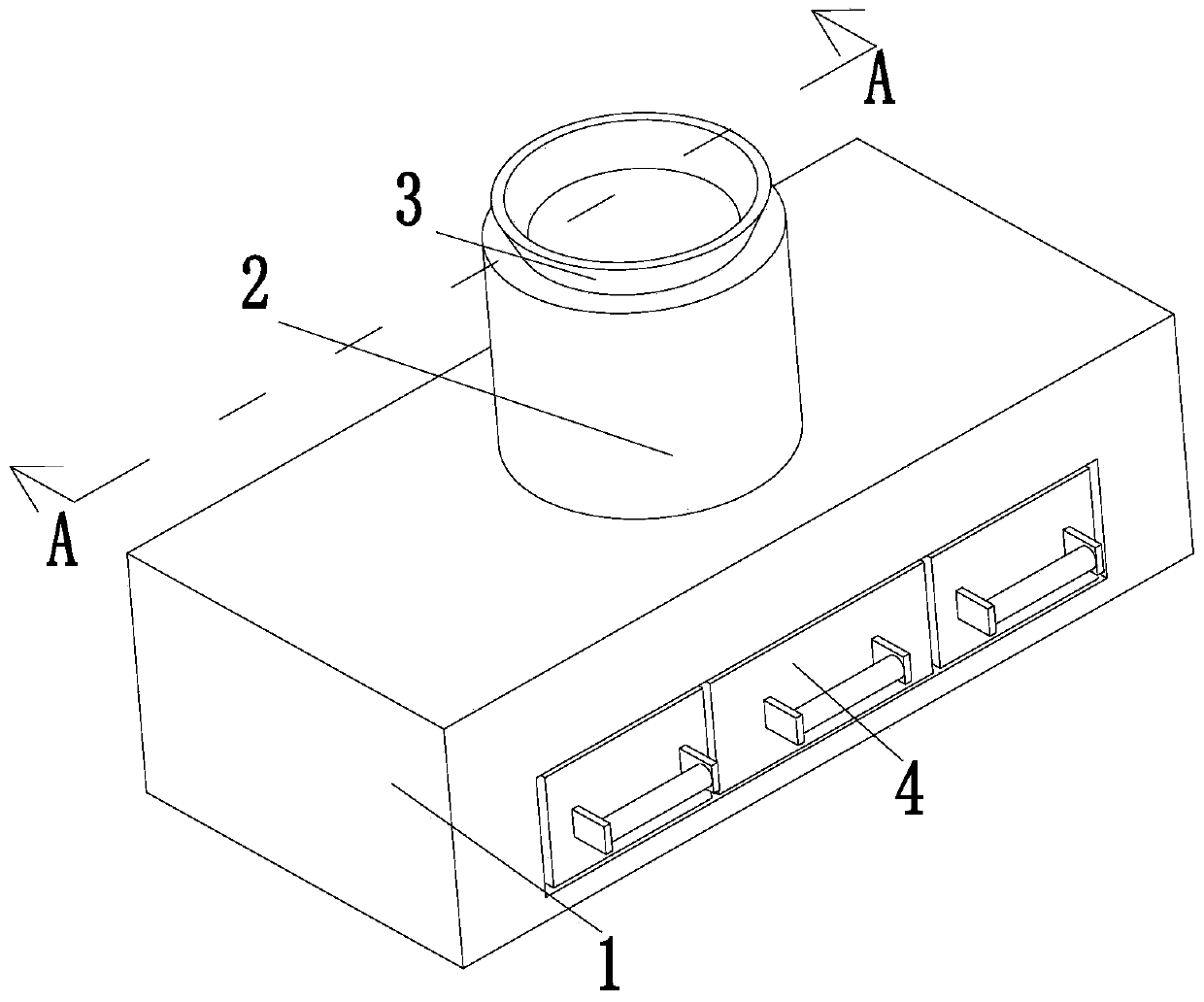

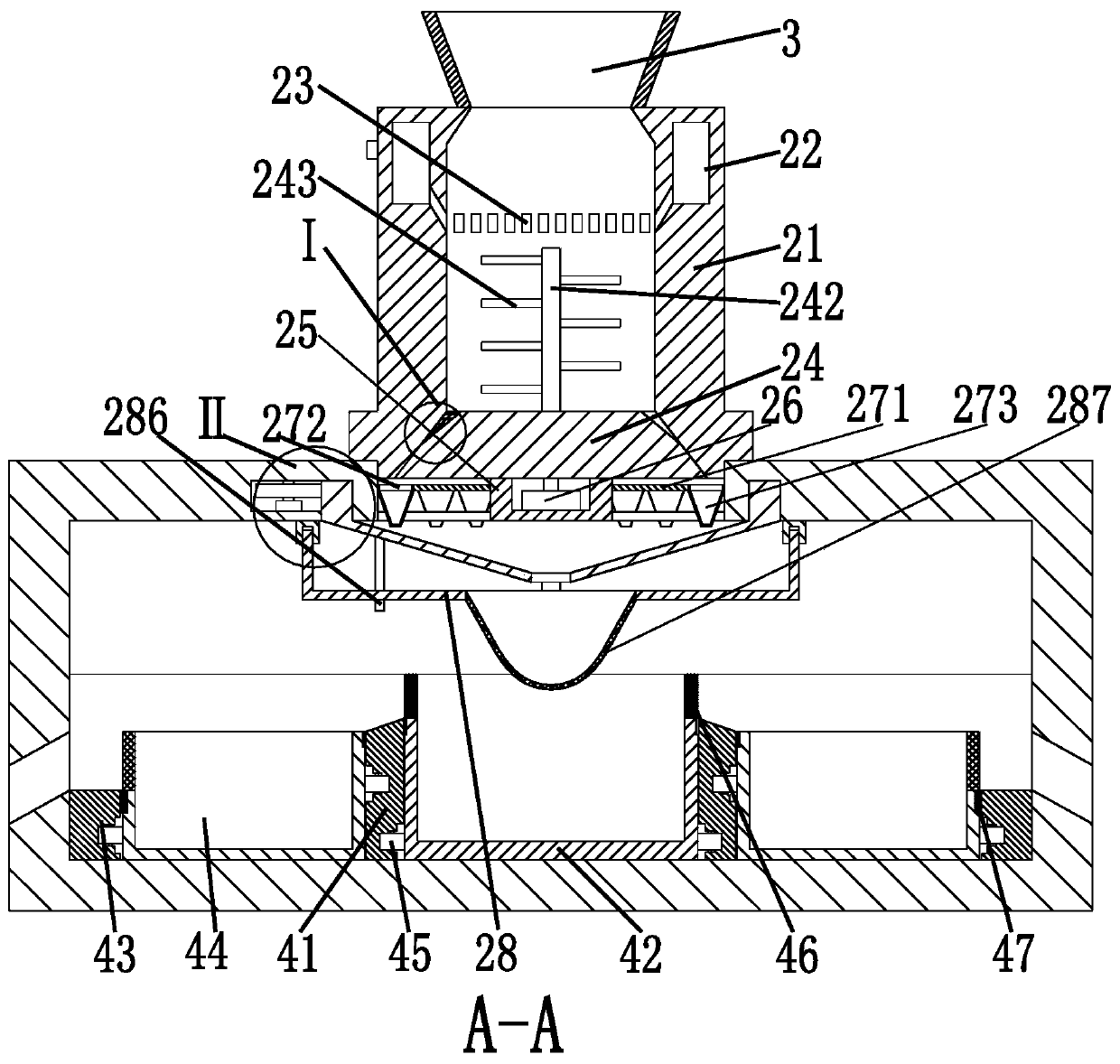

[0032] Such as Figure 1 to Figure 6 As shown, a food starch deep processing method, which uses a food processing device, the food processing device includes a blanking frame 1, a mincing unit 2, a feeding port 3 and a blanking unit 4, using the above food processing device The deep processing method of food also includes the following steps:

[0033] S1. Sweet potato chopping: peeling the sweet potato and cutting the sweet potato into pieces by manual or mechanical assistance;

[0034] S2, deep processing: through the mincing unit 2, the sweet potatoes chopped in step S1 are minced into slag, and then the filtered starch starch solution is introduced into the blanking frame 42;

[0035] S3, water removal treatment: remove the moisture on the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com