Removing method for residual liquid on back of tellurium-cadmium-mercury liquid phase epitaxial thin film

A technology of liquid phase epitaxy and epitaxial thin film, which is applied in the direction of liquid phase epitaxy layer growth, chemical instruments and methods, crystal growth, etc., and can solve problems such as lower yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

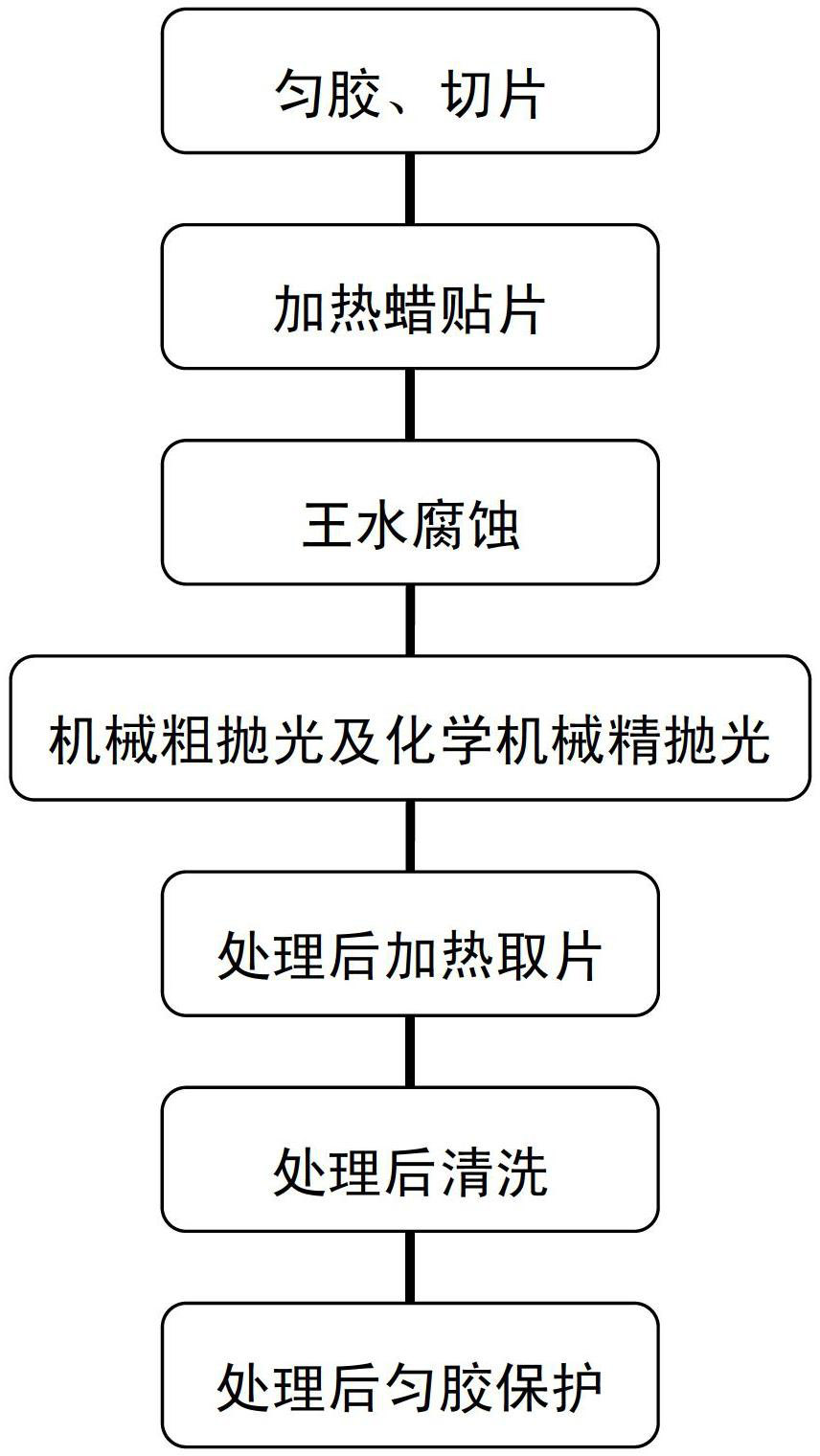

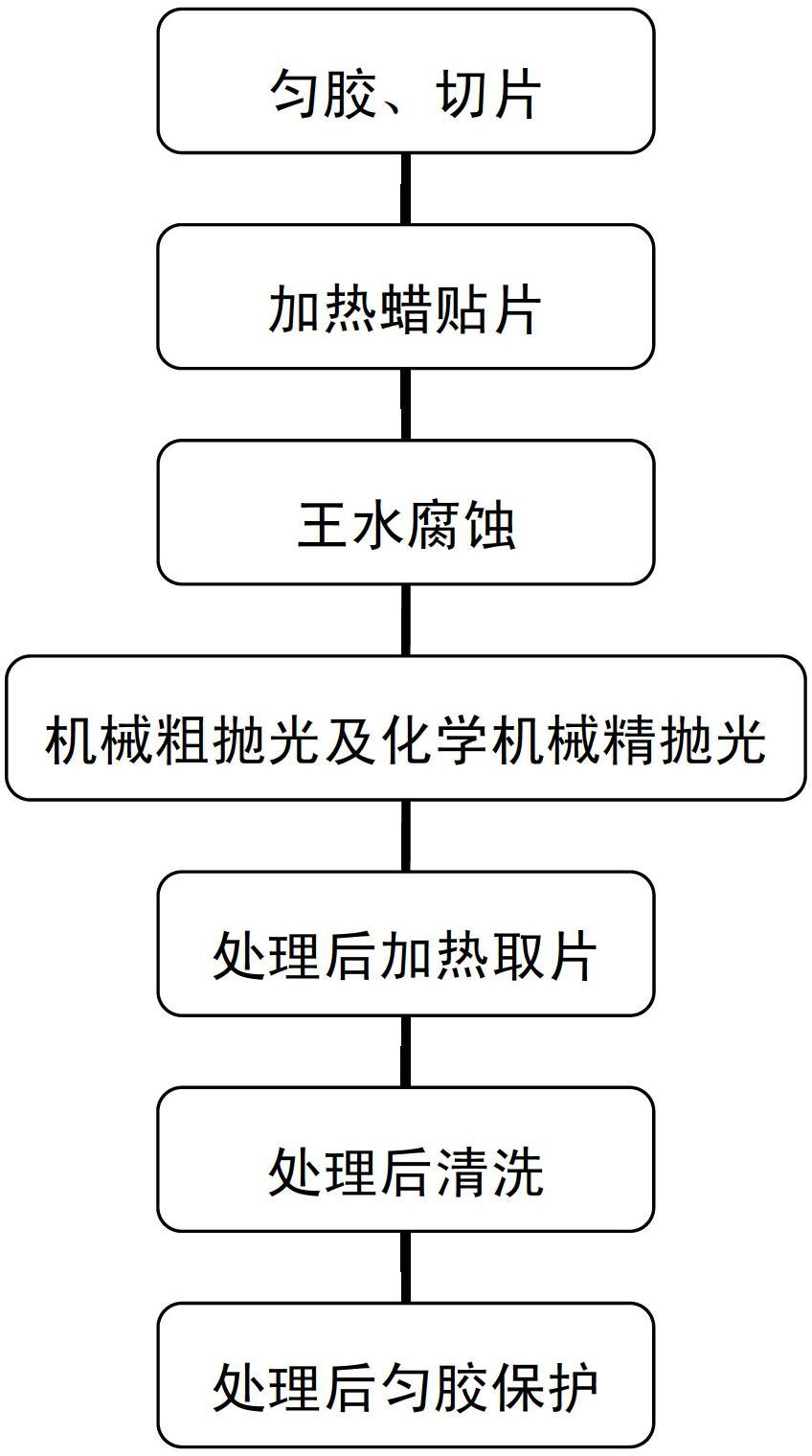

[0015] See below in conjunction with accompanying drawing to the concrete implementation flow process of the present invention figure 1 To elaborate further:

[0016] 1. The uniform glue mainly plays the role of protecting the surface of the epitaxial film. In this treatment method, the process of evenly gluing with thin glue is adopted twice. The speed is 200 for the first 3 seconds, and 2000 rpm for the next 30 seconds.

[0017] 2. The aqua regia corrosion mainly plays the role of partially crisping and loosening the residual liquid on the back of the epitaxial film and partially removing the residual liquid. Due to the traditional CdZnTe polishing technology, it is easy to throw the epitaxial film of the residual liquid on the back under high pressure, but the residual liquid on the back cannot be removed when the pressure is small. Therefore, aqua regia corrosion is the core process of this invention.

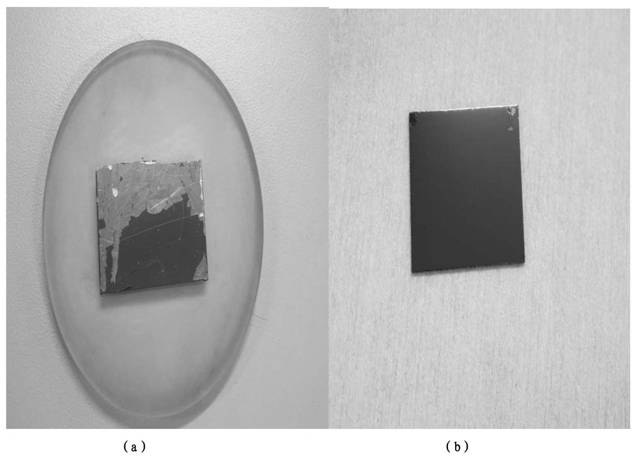

[0018] 3. The mercury cadmium telluride epitaxial layer on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com