Self-adhesive sticker rapid blanking process

It is a kind of adhesive patch and fast technology, which is applied in metal processing and other directions. It can solve the problems of increased processing costs, irregular wafer diameters, and low mold usage, and achieves light weight, smooth outer contour, and high cutting speed. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

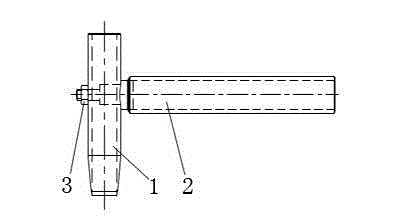

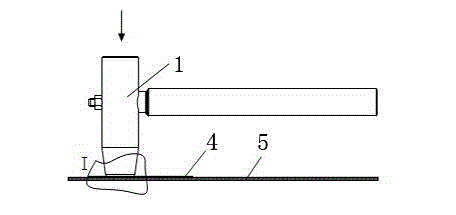

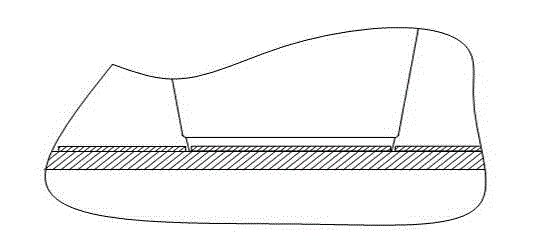

[0016] Self-adhesive patch rapid blanking process, using a blanking hammer to make the self-adhesive patch, the blanking hammer is composed of a punch 1 installed on the handle 2, the punch is a hollow structure, and the end is closed Cutting edge; place the self-adhesive paper 4 on the rubber pad 5, then hammer the self-adhesive paper with a blanking hammer, and cut the self-adhesive paper with the edge closed at the end of the punch to make it closed with the end of the punch The self-adhesive patch with the same cutting edge shape; the closed cutting edge shape and size of the punch end are different, and the self-adhesive patch of different shape and size matches the punch of different shape and size, only need to replace different punches head, you can make different self-adhesive patches. Punches and handles are fastened with nuts 3, easy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com