EVA film hob cutting device of thin-film solar cell

A technology of solar cells and hobs, applied in metal processing, etc., can solve problems such as low production efficiency, difficult to control dimensional accuracy, and inability to be suitable for automated production lines, and achieve the effects of convenient installation and adjustment, high straightness, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

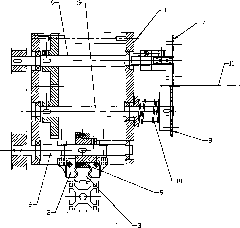

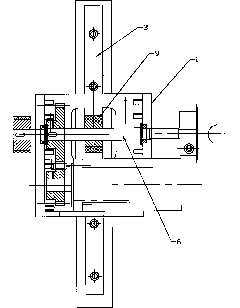

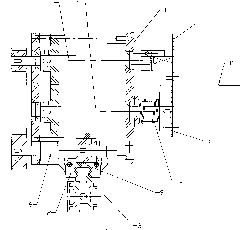

[0014] As shown in the figure, the device includes a knife holder 1 for installing cutting tools, a slider 2 is fixedly connected to the bottom of the knife holder, and the slider and the fixed linear guide rail 3 below are positioned in cooperation with each other, so that the slider and the knife The frame can move along the linear guide rail; the upper cutter shaft 4, the lower cutter shaft 5 and the rubber wheel shaft 6 perpendicular to the direction of the linear guide rail are installed on the tool holder 1; The wheel shafts are driven by synchronous wheels, and the upper and lower cutter shafts are driven by gears. The end of the same side of the upper cutter shaft 4 and the lower cutter shaft 5 is respectively equipped with an upper hob 7 and a lower hob 8 that can rotate with the upper and lower cutter shafts, and the lower hob 8 can move within a certain range along its axial direction , while spring 10 is installed on the lower cutter shaft, it can make the blade of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com