Feeding platform of swing arm type cutting machine

A technology of feeding platform and cutting machine, applied in metal processing and other directions, can solve the problems of fast cutting speed, time-consuming and laborious, and reduced feeding efficiency of the cutting machine, and achieve the effect of improving cutting efficiency, improving safety performance, and reducing standby time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

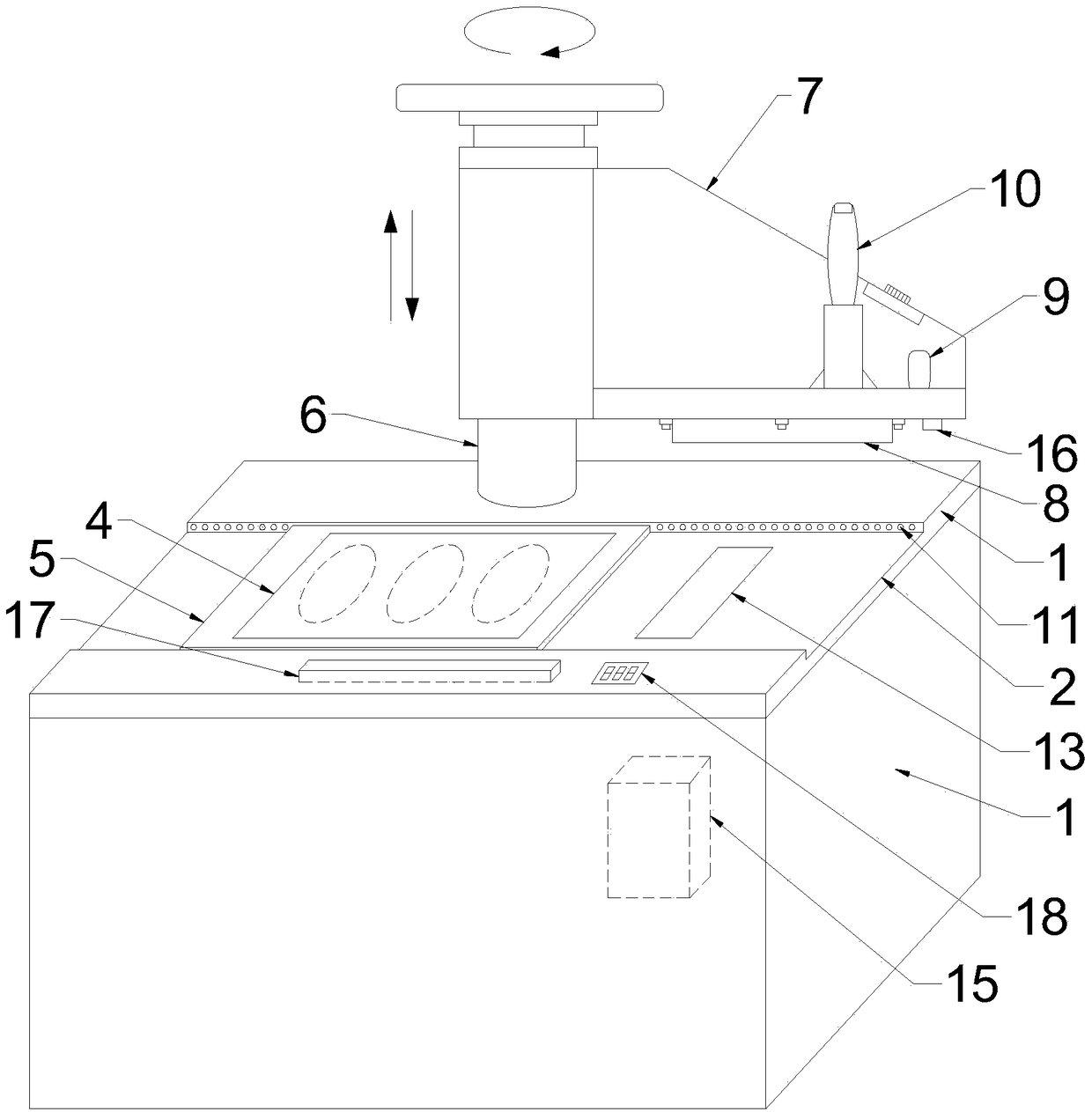

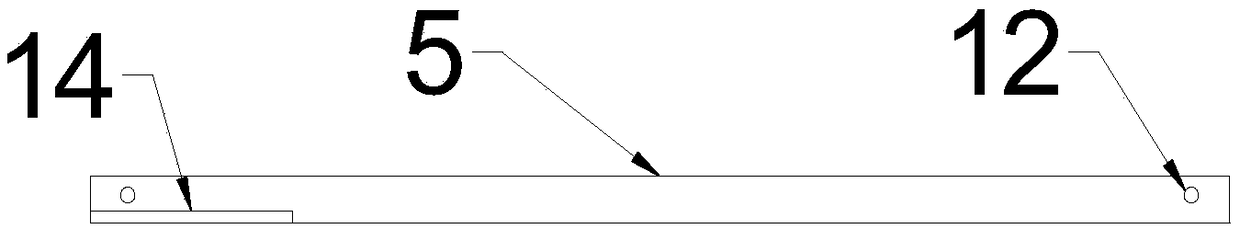

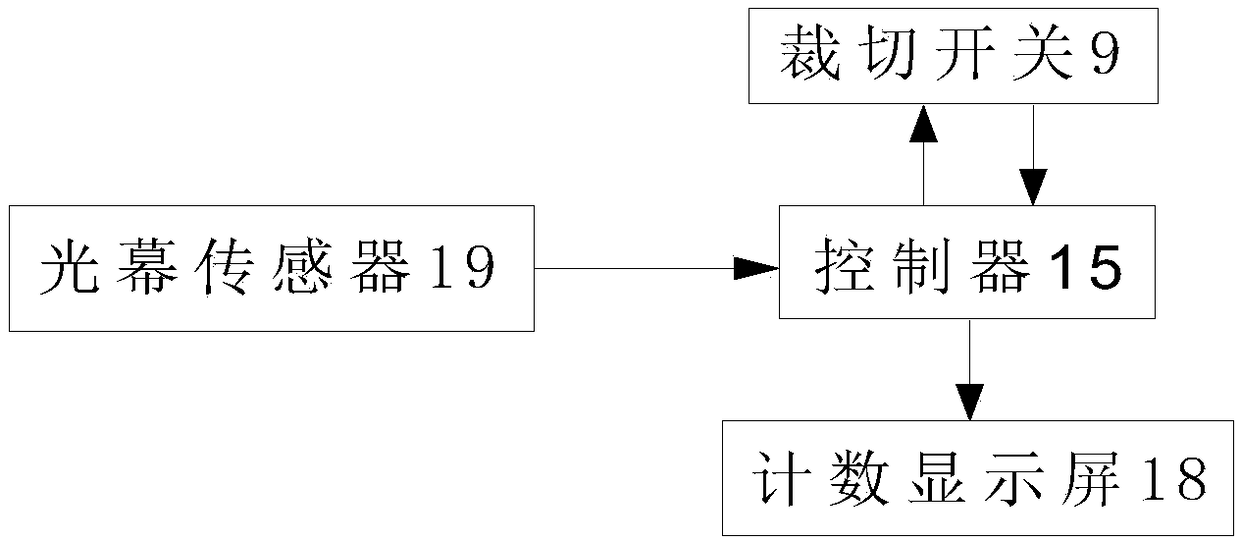

[0022] Such as figure 1 As shown, a feeding platform of a swing arm type cutting machine includes a horizontal workbench 2 located at the upper end of the body 1 of the swing arm type cutting machine. The left end of 2 runs through to the right end of the workbench 2. The feeding trough 3 is embedded with a pressing plate 5 for placing the sheet 4 to be cut. The width of the pressing plate 5 matches the width of the feeding trough 3. The pressing plate 5 can be fed along the The groove 3 is used for horizontal translation; the workbench 2 is provided with a mounting groove, and a column 6 is arranged in the mounting groove, and a swing arm 7 is installed on the upper side of the column 6, and the swing arm 7 can rotate around the column 6 and perform lifting movement, and the swing arm The bottom of 7 is removably equipped with cutting die 8, and the upper side of swing arm 7 is provided with cutting switch 9 and handle 10. Such as figure 1 As shown, the sheet can be cut int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com