Edge trimmer

A technology of trimming machine and frame, applied in metal processing and other directions, can solve the problems of high labor intensity, poor cutting effect and high scrap rate, and achieve the effect of reducing labor intensity, fast cutting speed and improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

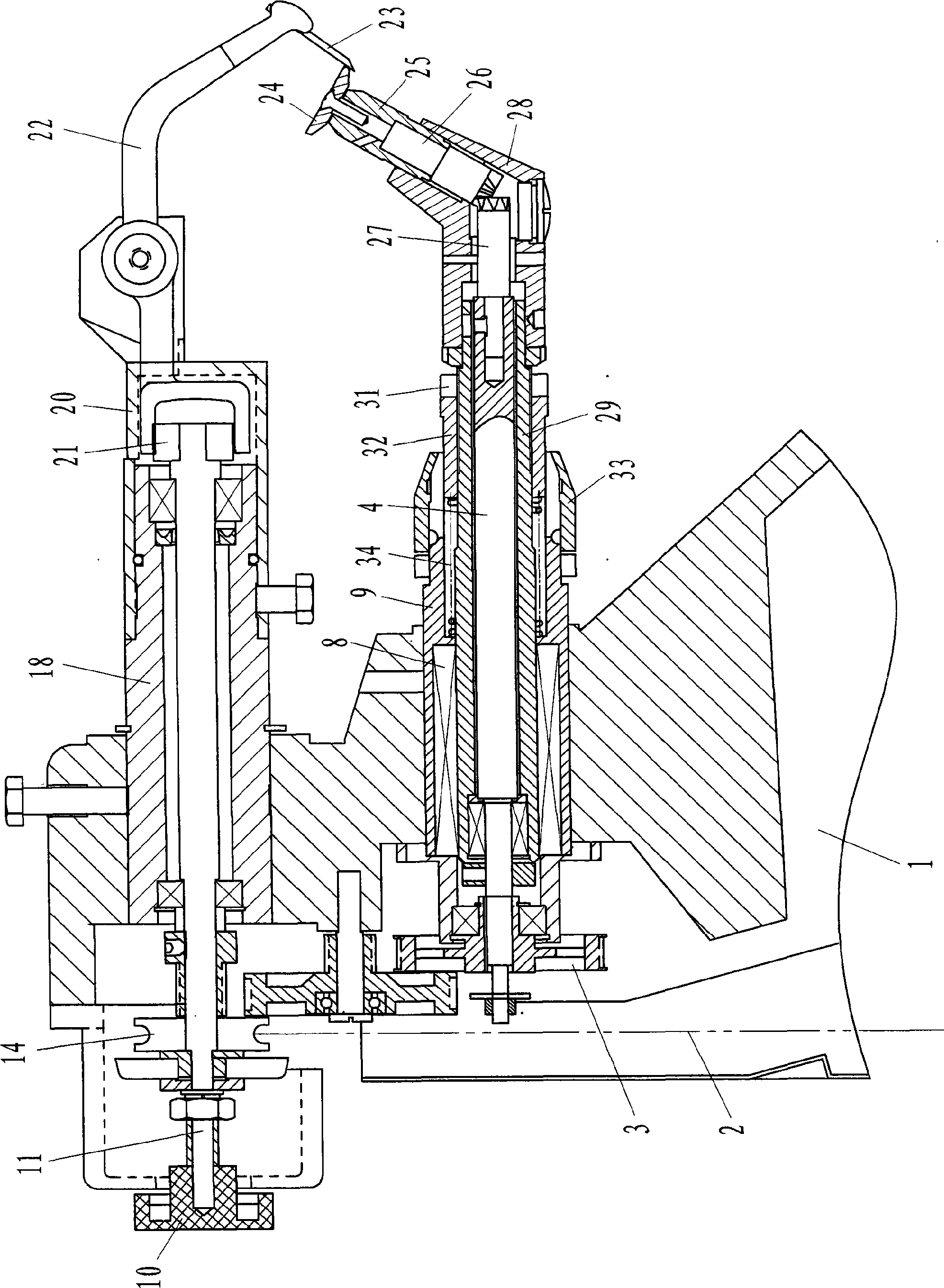

[0012] Example: see figure 1 , the present invention is to be provided with main shaft 11 on frame 1 top, and the lower transmission shaft 4 of synchronism is arranged below main shaft 11, and the upper blade 23 driven by main shaft 11 cuts the lower rotary blade 24 driven by lower transmission shaft 4 to complete the workpiece. For shearing and trimming, the hand pulley 10 is set near the end of the O-shaped belt pulley 14 on the main shaft 11 . Wherein the main shaft 11 is arranged in the main shaft seat 18 through bearings, the main shaft seat 18 is fixed on the frame 1 via locking screws, the outer end of the main shaft seat 18 is provided with a tool rest seat 20, and the tool rest seat 20 is provided with an eccentric wheel 21, eccentric The wheel 21 is connected to the outer end of the main shaft 11, and the tool rest rocking arm 22 is installed on the tool rest seat 20 via a bearing. The blade 23; the lower transmission shaft 4 is arranged in the sliding shaft 29 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com