Device for cutting multilayer cloth by one time with high efficiency

A one-time, high-efficiency technology, applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of inconsistent cloth specifications and shapes, unsuitable for mass production, low strength of cutting tools, etc., to achieve high cutting speed and saving. Labor cost, the effect of consistent specifications and shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

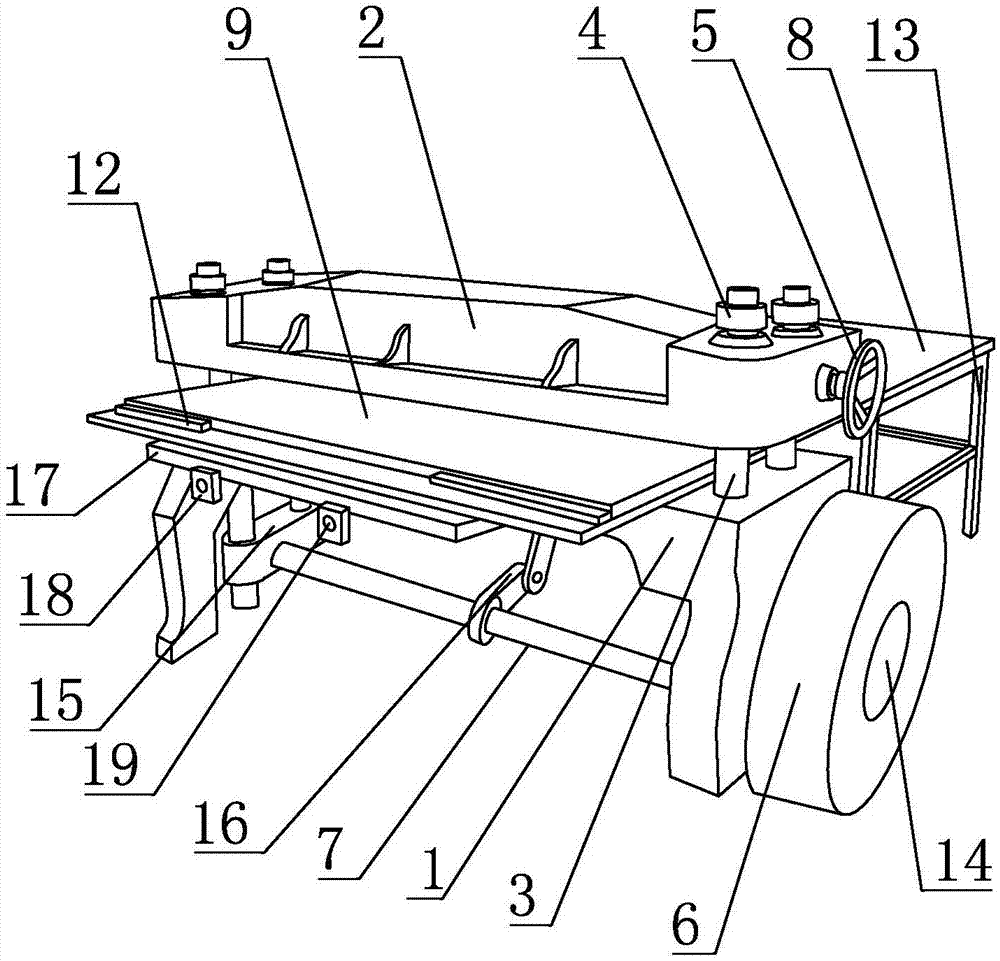

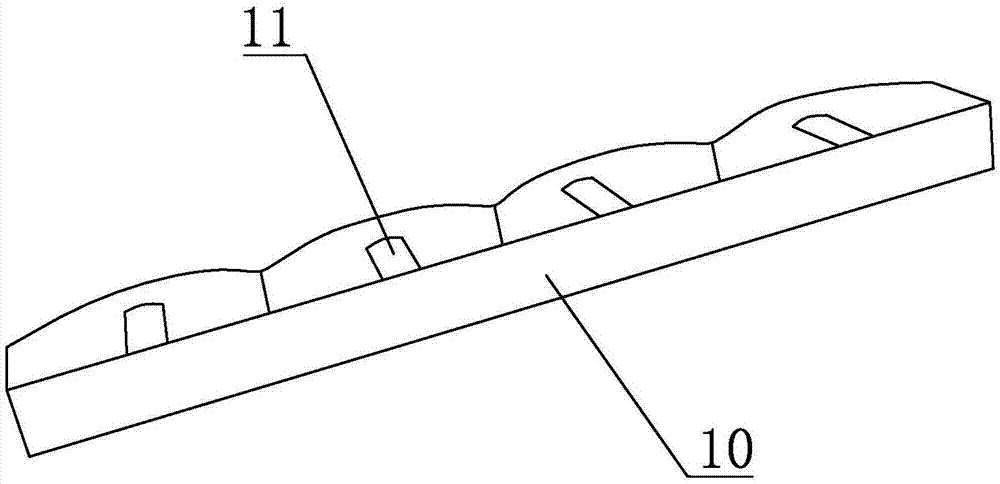

[0018] refer to Figures 1 to 2 , a high-efficiency one-time cutting device for multi-layer fabrics, including a frame 1 and a press plate 2, guide rods 3 are provided at both ends of the frame 1, and the two ends of the press plate 2 are respectively fixed on the guide rods 3 and can pass through The nut 4 at the top of the guide rod 3 and the runners 5 at both ends of the pressure plate 2 adjust the height. The guide rod 3 is driven up and down by the drive device 6 on the outside of the two ends of the frame 1. The lower parts of the guide rod 3 at both ends are connected by the connecting rod 7, and the frame 1 is provided with a bottom plate 8 that can move back and forth, and a backing plate 9 is fixed on the bottom plate 8; a die-cutting edge 10 is placed on the cloth to be cut under the press plate 2, and the die-cutting edge 10 is set in a closed shape and lower The side edge is sharp, and its inner side is welded with multiple reinforcing plates 11. The height from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com