Technology for controlling laser cutting power and speed when detonating cord is peeled off by laser

A technology of laser cutting and cutting speed, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as affecting the process, large flanging at the incision on the surface of the detonating cord, and not reaching the cutting depth of the detonating cord , to achieve the effect of smooth surface removal and no burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

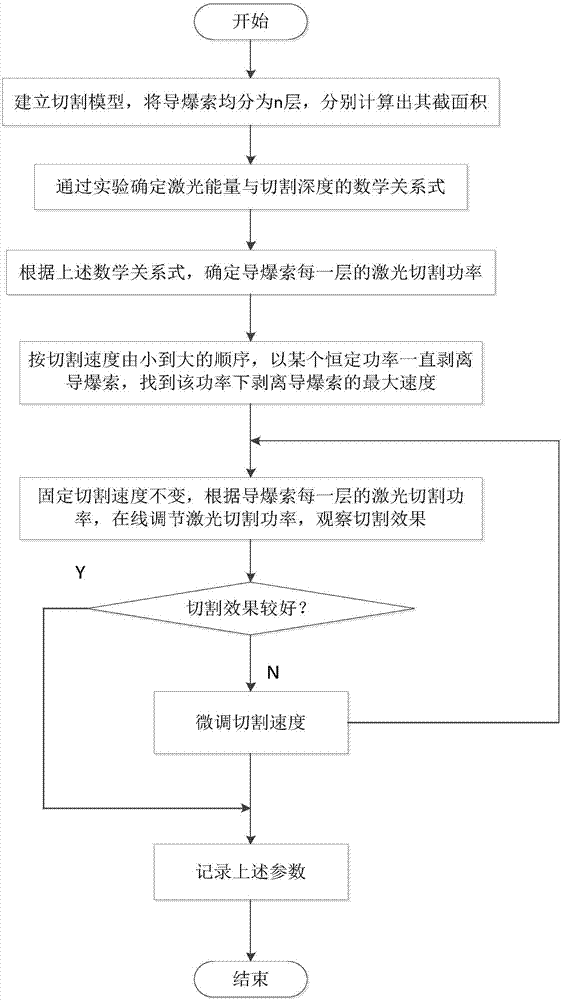

[0015] The implementation process of the present invention will be described in detail below in conjunction with the accompanying drawings.

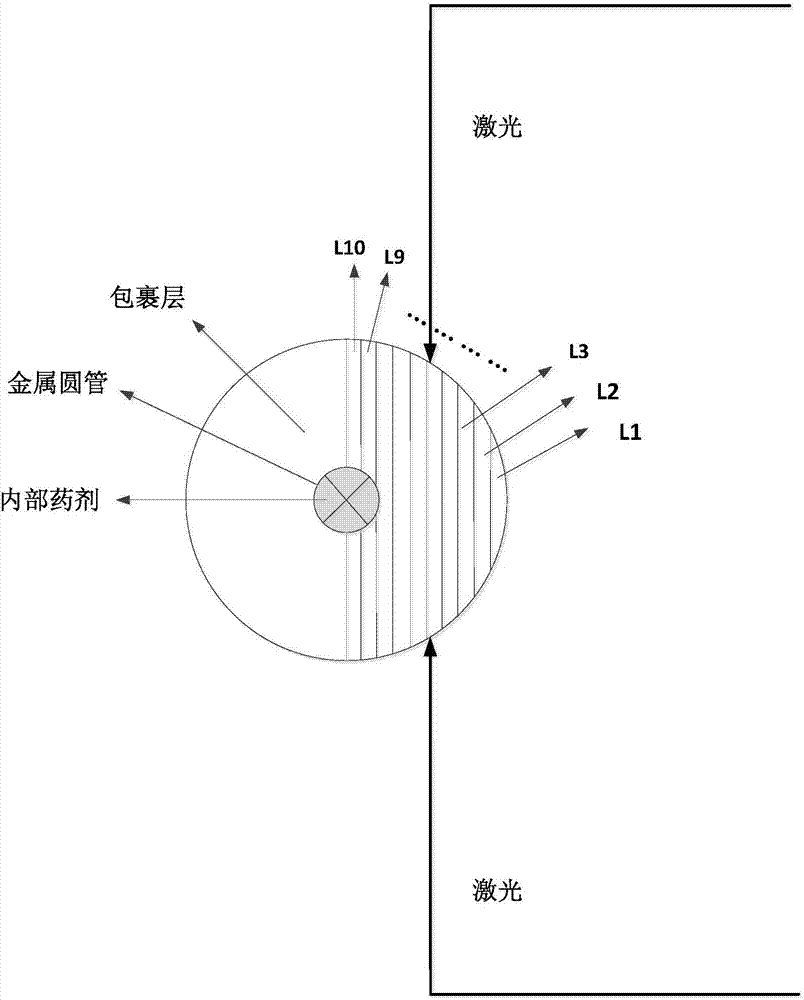

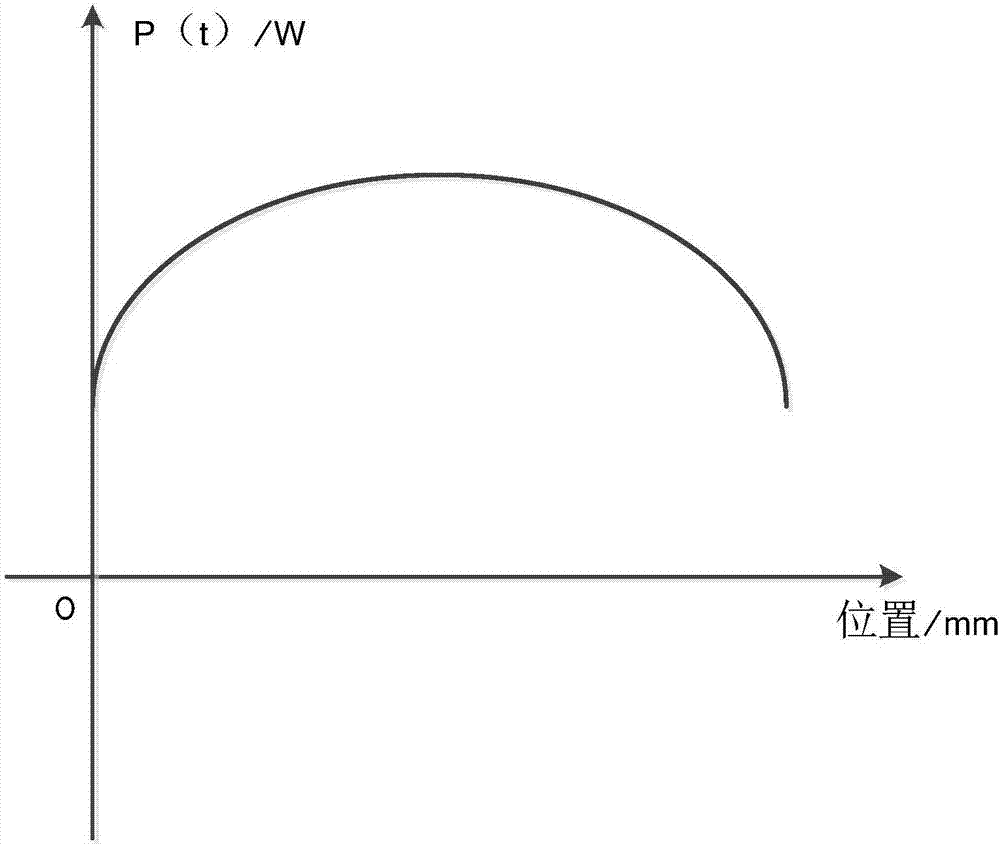

[0016] figure 1 It is the detonating cord cutting model diagram of the laser cutting power and speed control technology when the laser strips the detonating cord according to the present invention. Taking the detonating cord with a diameter of 8mm as an example, its cross section is divided into 20 layers, respectively L1 , L2, L3...L20, the thickness of each layer is 0.4mm. After that, the cross-sectional area S1, S1, S3...S20 of each layer is calculated. Assuming that the laser cutting power is proportional to its cross-sectional area, the laser power for cutting each layer can be roughly determined. When the cutting speed is fixed, the time for laser cutting each layer is the same. Assuming that the time for cutting each layer is T1, every time T1, the laser cutting power is changed according to the cross-sectional area ratio.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com