External wall tile manufacturing system and external wall tile manufacturing method

A technology for exterior walls and wall bricks, which is applied to the production system and field of exterior wall bricks, can solve problems affecting the quality and service life of buildings, heavy weight of exterior wall bricks, unsafe factors, etc., and achieves good flattening effect and supporting effect. Good, smooth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

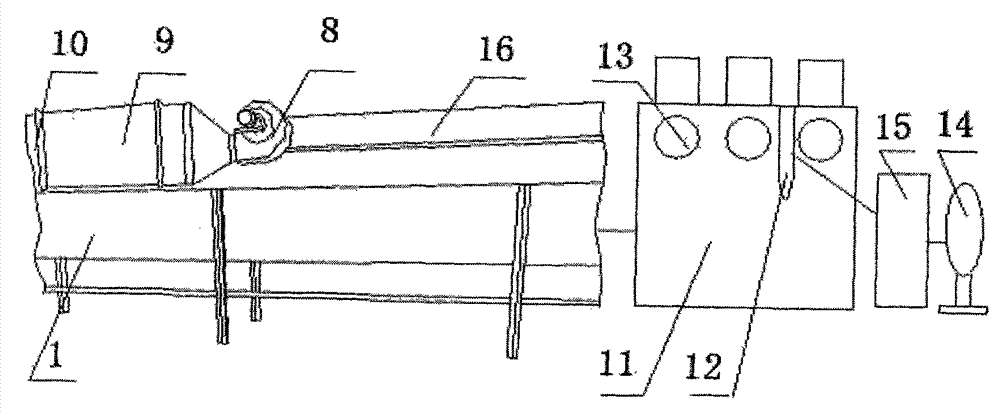

[0041] A system for making exterior wall bricks, comprising: a conveyor for making exterior wall bricks, the conveyor for making exterior wall bricks is connected to a paint spraying device, the paint spraying device is connected to a drying device, and the drying device is connected to an exterior wall brick The receiving device for making wall bricks, the receiving device for making outer wall bricks is connected to the cutting machine through the bottom plate of the outer wall bricks, the cutting machine is used in conjunction with the forging press, and the forging press is used in conjunction with the gluing device for making outer wall bricks .

Embodiment 2

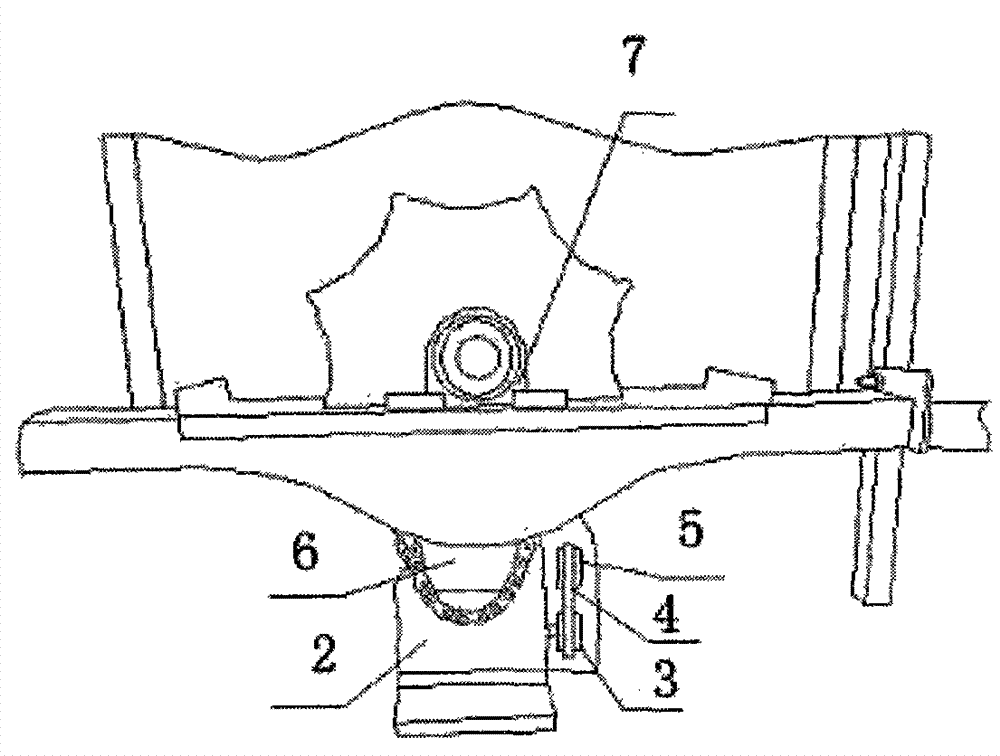

[0043] In the exterior wall brick production system described in Example 1, the drying device includes an insulated box 1, the bottom of the insulated box is connected to a conveyor belt system, and the conveyor belt system includes an insulated box motor 2. The thermal insulation box motor is connected to the thermal insulation box driving sprocket 3, and the thermal insulation box driving sprocket is connected to the thermal insulation box driven sprocket 5 through the thermal insulation box chain 4, and the thermal insulation box driven sprocket is connected to the thermal insulation box gearbox 6 , the incubator gearbox is connected to the incubator drive main sprocket, the incubator drive main sprocket is connected to the incubator drive slave sprocket through the incubator chain, and the incubator drive slave sprocket passes through the incubator shaft Connect the incubator conveyor belt gear, the incubator conveyor belt gear is connected to the incubator conveyor belt 7;...

Embodiment 3

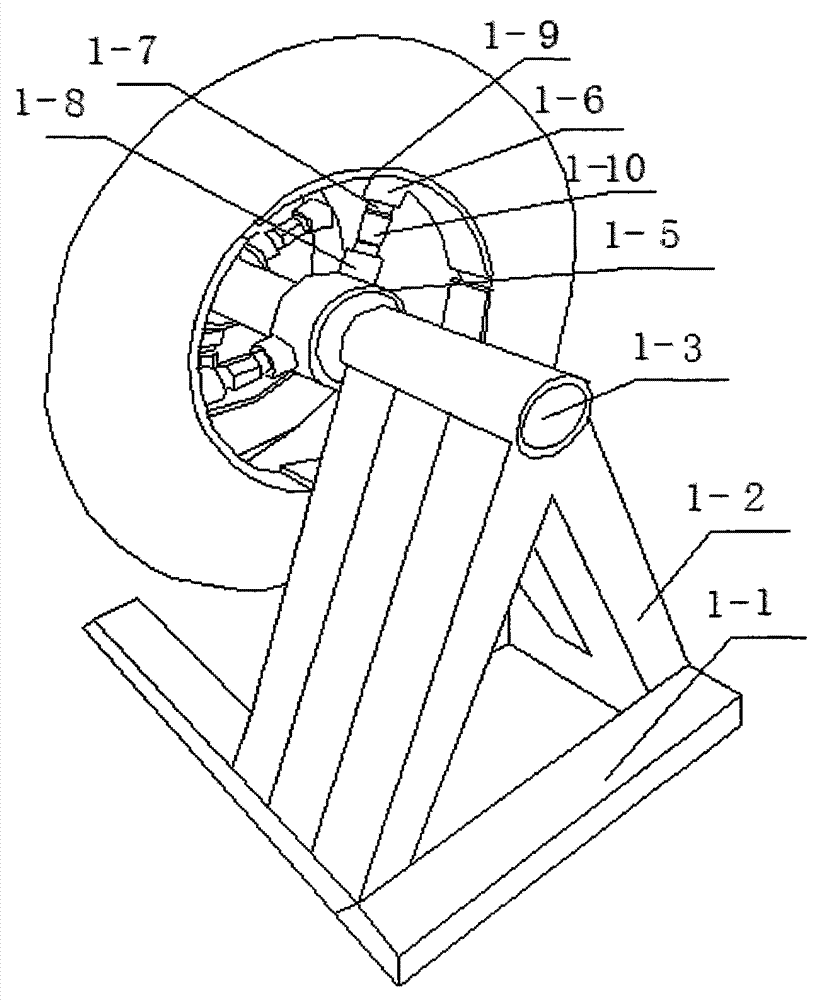

[0045] In the exterior wall brick production system described in Embodiment 1, the exterior wall brick production and conveying device includes a base 1-1, the base is connected to a triangular support 1-2, and the triangular support is connected to a fixed shaft 1-3, The fixed shaft is connected to the rotating ring 1-5 through the bearing 1-4, and the rotating ring is connected to a group of inner support sleeves 1-6, and the angle between the inner support sleeves is 120°. The inner support sleeve has an internal positive thread, and the inner support sleeve is connected to the locking support screw 1-7 through the positive thread. One end of the locking support screw is a positive thread, and the other end is a reverse thread. The support screw is connected to the outer support sleeve 1-8 through a reverse thread, the outer support sleeve has an internal reverse thread, the outer support sleeve is connected to the support ring 1-9, and the middle part of the locking support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com