Mica tape and preparation method thereof

A technology of mica tape and mica paper, applied in mica, quartz/glass/glass enamel, conductor and other directions, can solve the problem that mica tape is not high in fire resistance and tensile toughness, affects the fire resistance and insulation performance of cables, and has insufficient fire resistance of mica tape. and other problems, to achieve the effects of unstable product quality, reduced processing costs, and high refractory strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

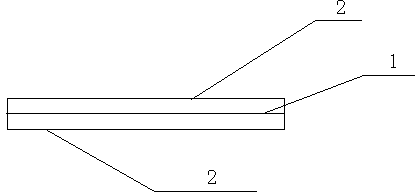

[0017] Such as figure 1 As shown, the mica tape includes mica paper 1 and glass fiber cloth 2, the upper and lower surfaces of the mica paper 1 are provided with glass fiber cloth 2, and the mica paper 1 and the glass fiber cloth 2 on the upper and lower surfaces are bonded together by glue, so The active ingredients in the above-mentioned rubber compound are adhesive silicone, diluent toluene and curing agent, the weight ratio of adhesive, diluent and curing agent is 3:20:1, the sum of the weight of adhesive, diluent and curing agent accounts for The weight percentage of material is 13-18%.

[0018] The preparation method of mica tape, comprises the following steps:

[0019] (1) Mix and stir the adhesive organic silica gel and diluent toluene, add a curing agent during the stirring process, fully dilute the obtained rubber material, and place the rubber material in the glue tank; the weight ratio of the adhesive, diluent and curing agent is 3 :20:1, the sum of the weight of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com