Patents

Literature

31results about How to "Smooth and clean surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solder ball and method for producing same

InactiveUS6517602B2High degree of sphericityNarrow distributionPrinted circuit assemblingTransportation and packagingCrucibleSolder ball

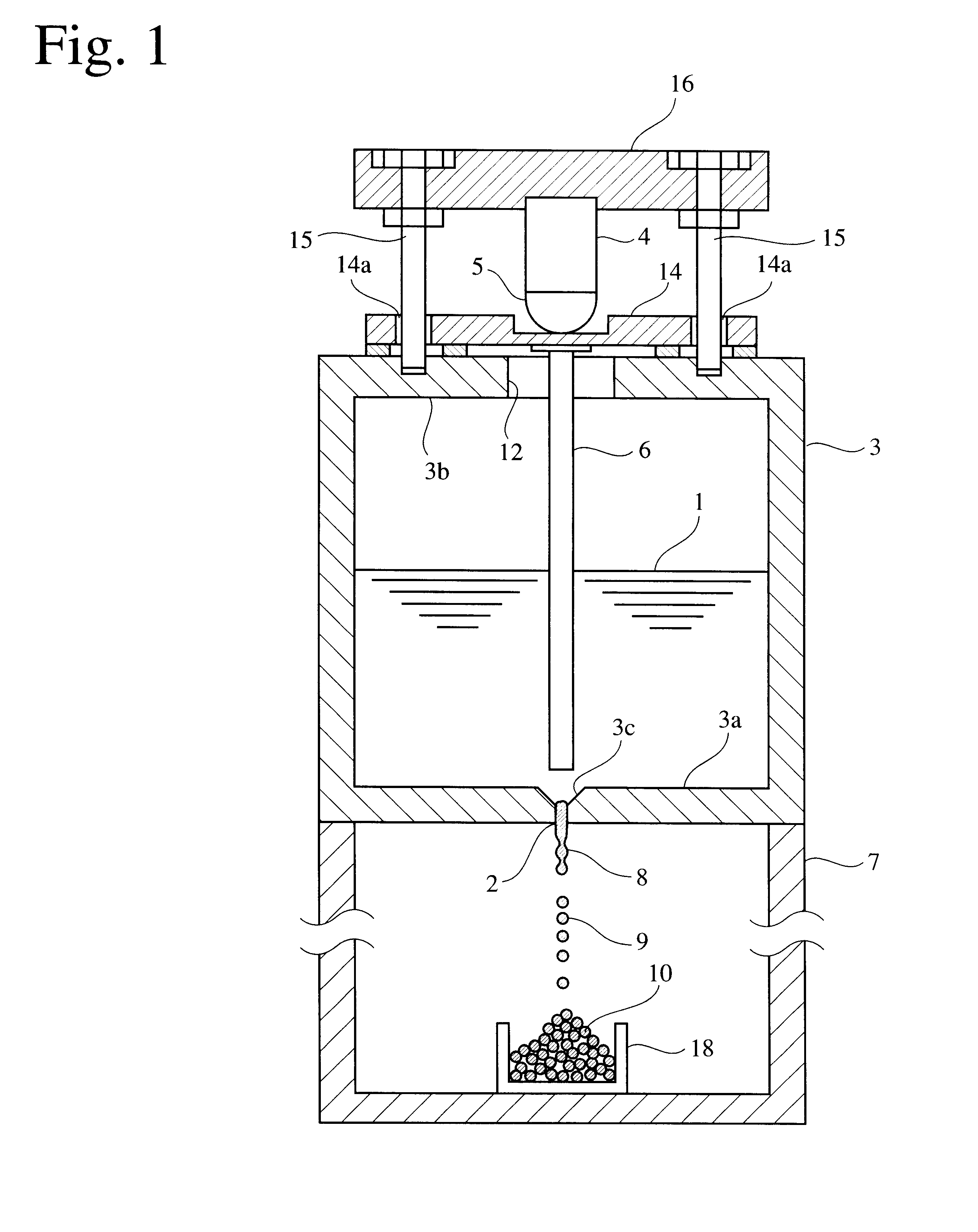

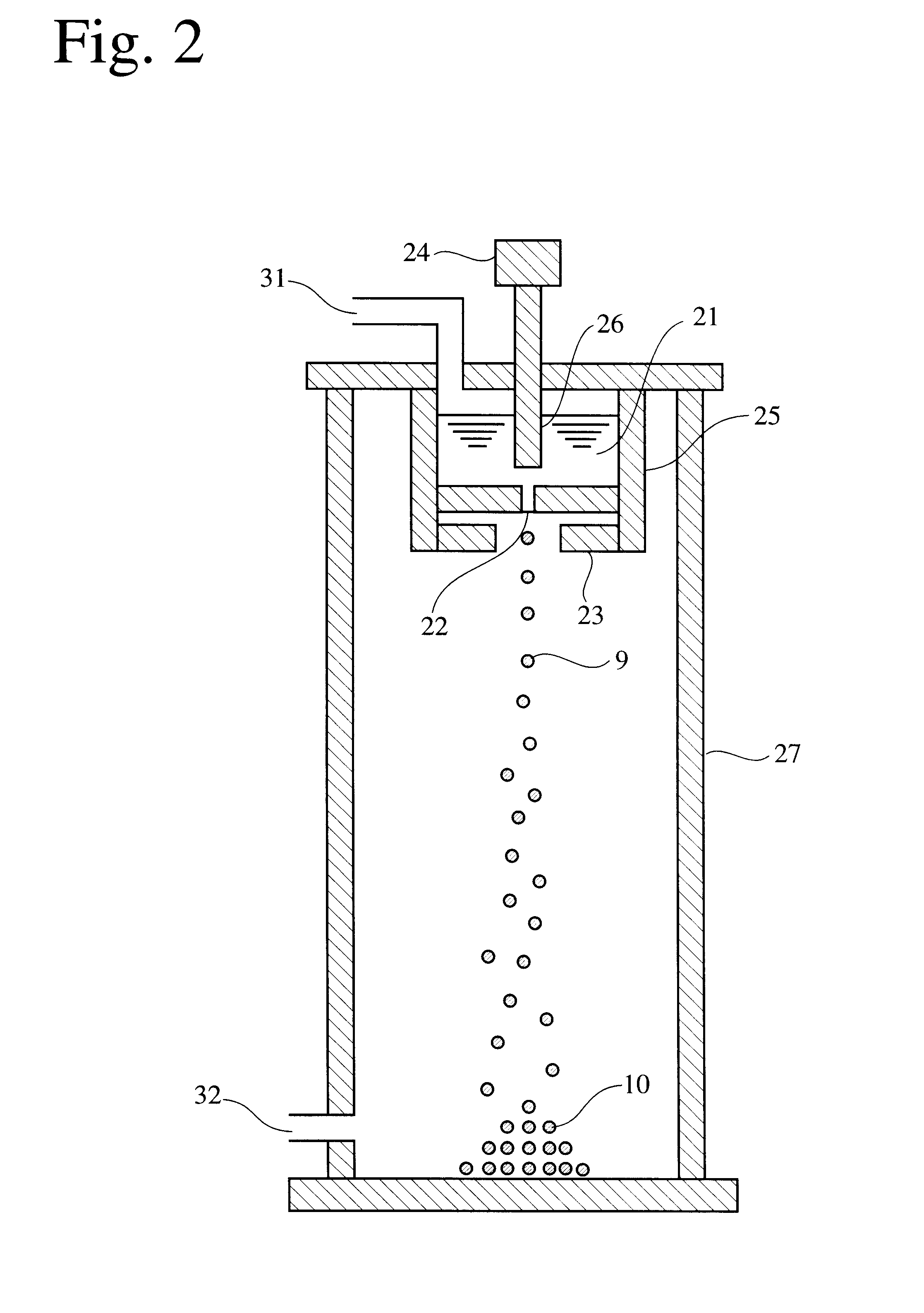

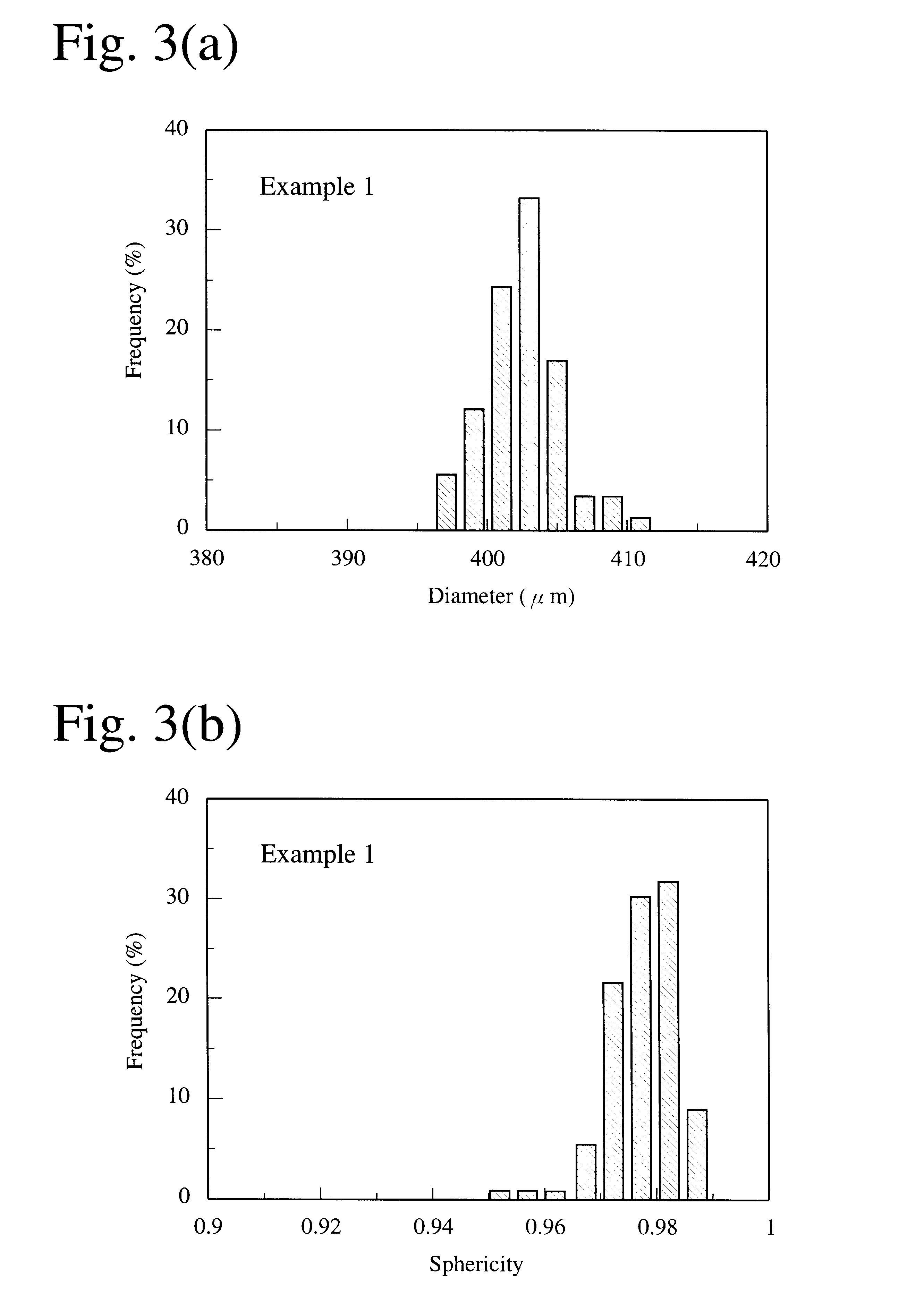

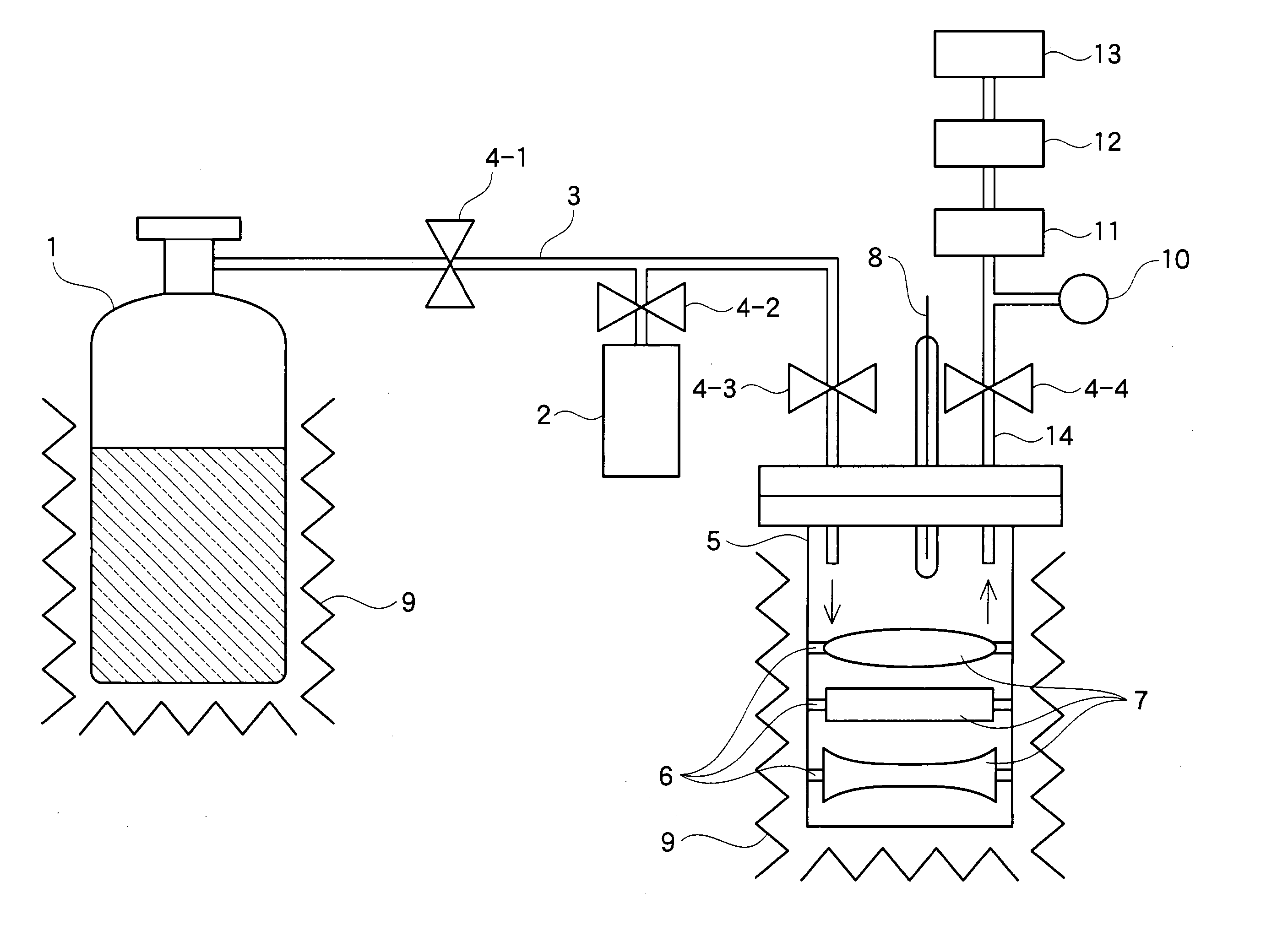

A solder ball having a diameter of 1.2 mm or less, a dispersion of a diameter distribution of 5% or less and sphericity of 0.95 or more, an area ratio of the maximum dendrite being 80% or less of a cross section including a center of the solder ball, comprises a first additional element of 0.5-8 mass % of Ag and / or 0.1-3 mass % of Cu, and 0.006-10 mass %, in total, of at least one second additional element selected from the group consisting of Bi, Ge, Ni, P, Mn, Au, Pd, Pt, S, In and Sb, the balance being substantially Sn. The solder ball is produced by a uniform droplet-spraying method comprising the steps of vibrating a melt of a solder alloy in a crucible under pressure to force the melt to drop through orifices of the crucible; permitting the melt dropping through the orifices to become spherical droplets in a non-oxidizing gas atmosphere; and rapidly solidifying them.

Owner:DUKSAN HI METAL

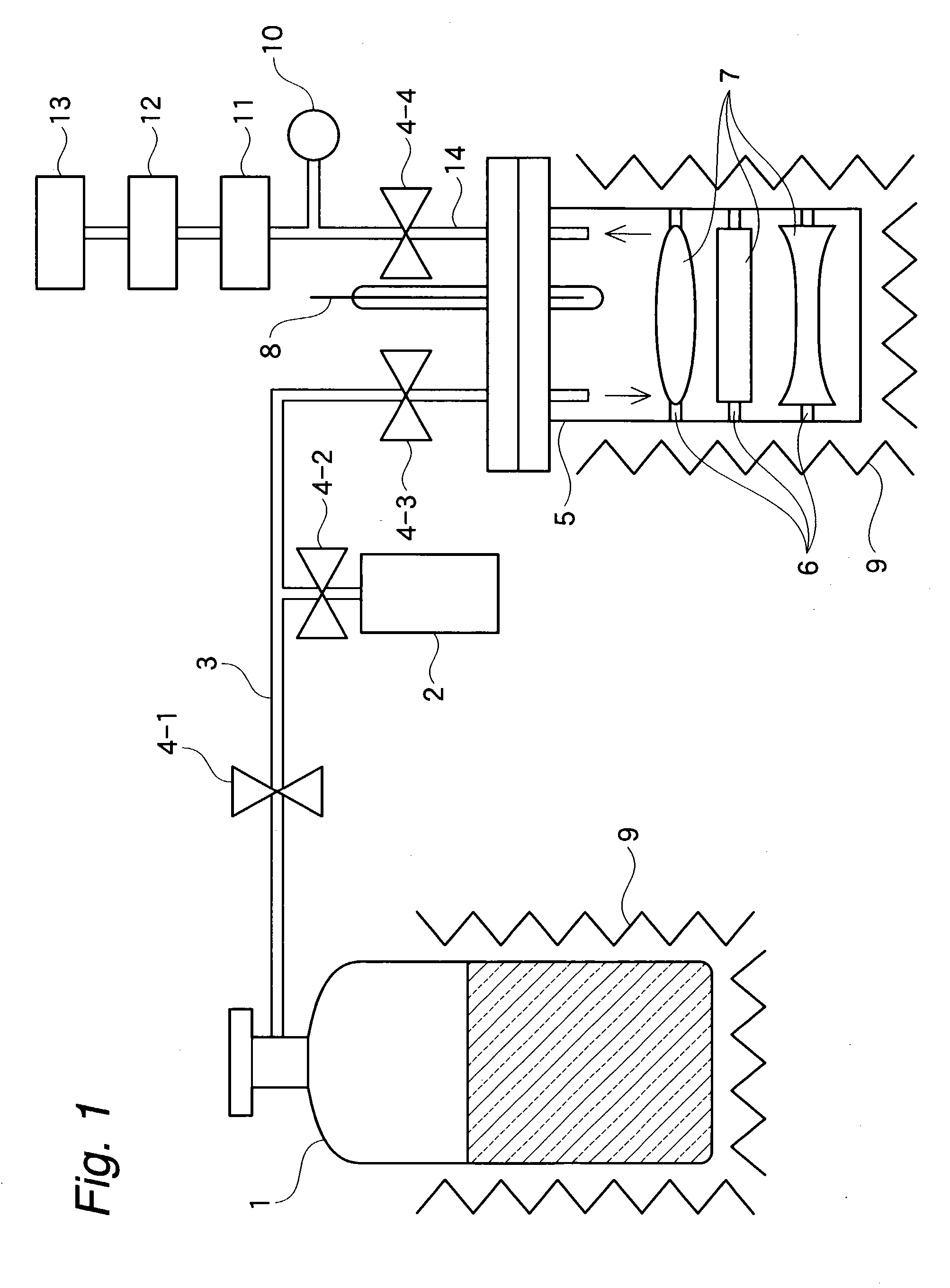

Fluorination treatment apparatus, process for producing fluorination treated substance, and fluorination treated substance

InactiveUS20040006249A1Substance reductionHigh light transmittanceLavatory sanitorySolid state diffusion coatingReaction stepNuclear chemistry

According to the invention, a fluorination treated substance remarkably reduced in the light absorption loss of a substance to be treated, such as a fluoride thin film, a fluorination treatment apparatus capable of producing the fluorination treated substance, and a process for producing a fluorination treated substance can be provided. Disclosed is a process for producing a fluorination treated substance, comprising an enclosure step of enclosing a substance to be treated in a reactor and a fluorination reaction step of introducing a fluorine gas into the reactor to bring the substance to be treated into contact with the fluorine gas and thereby carry out fluorination reaction.

Owner:SHOWA DENKO KK +1

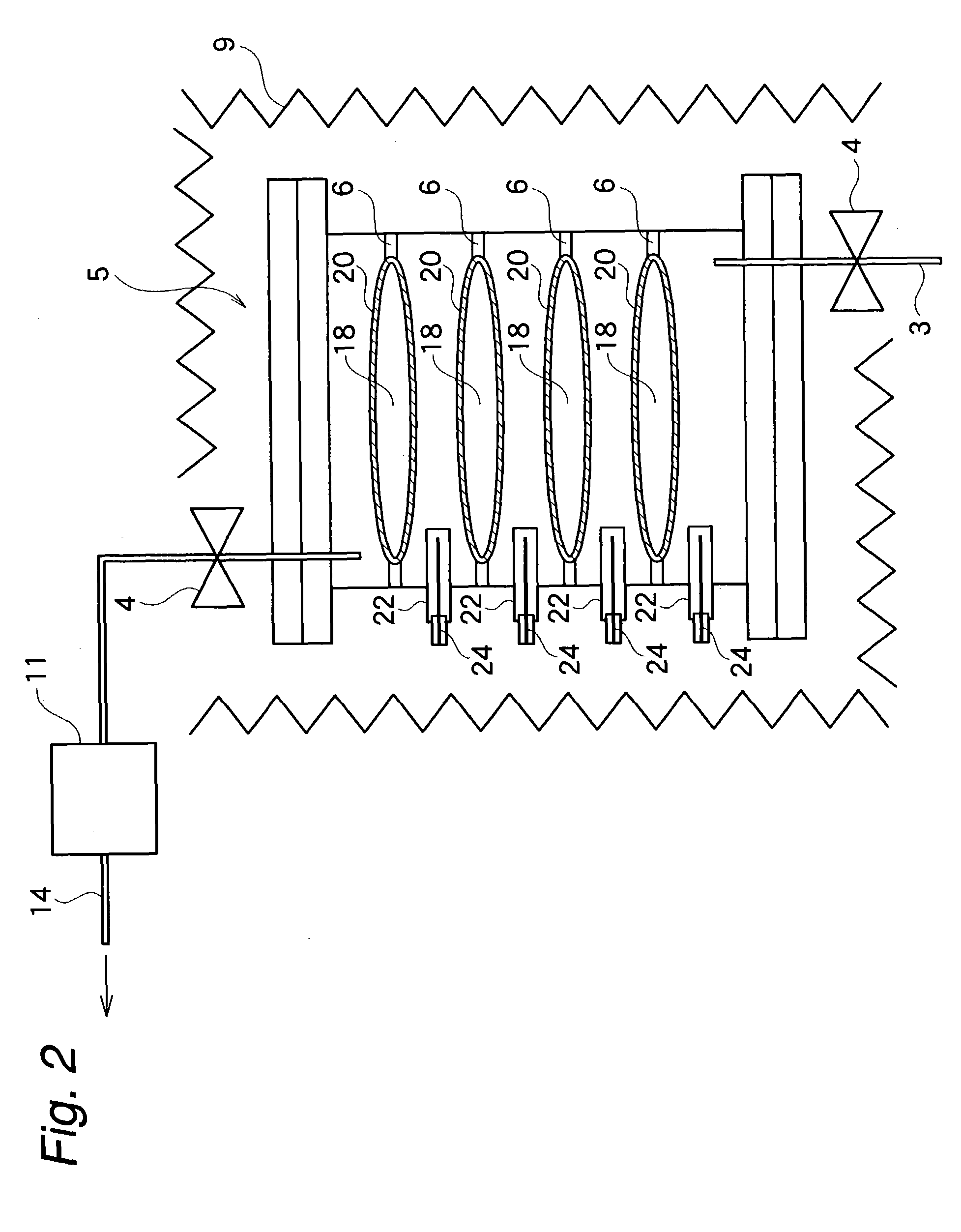

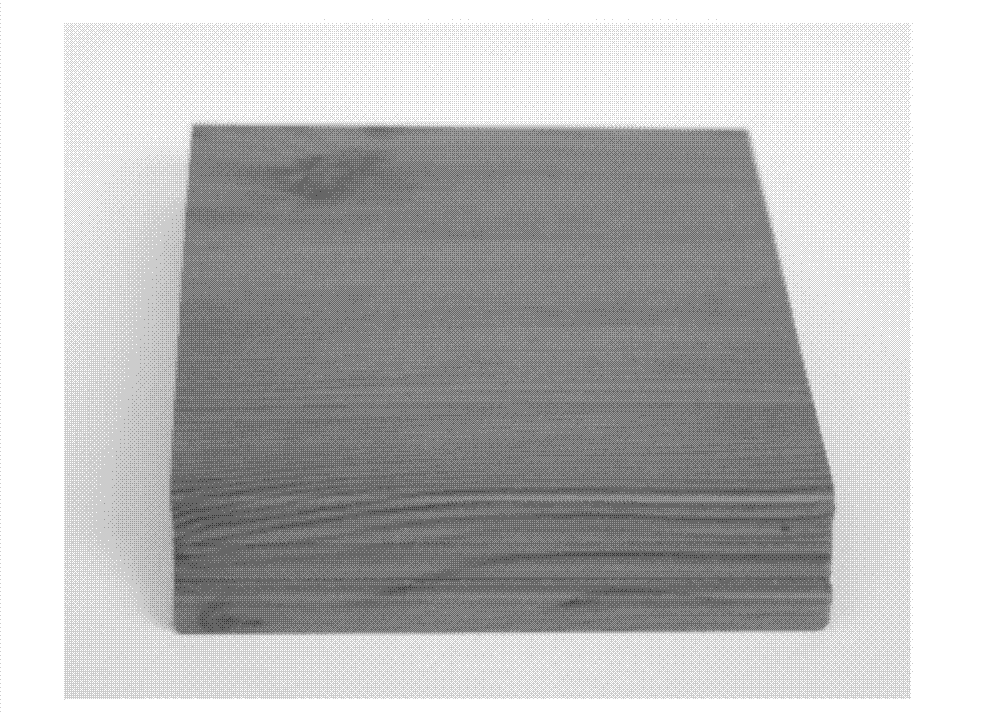

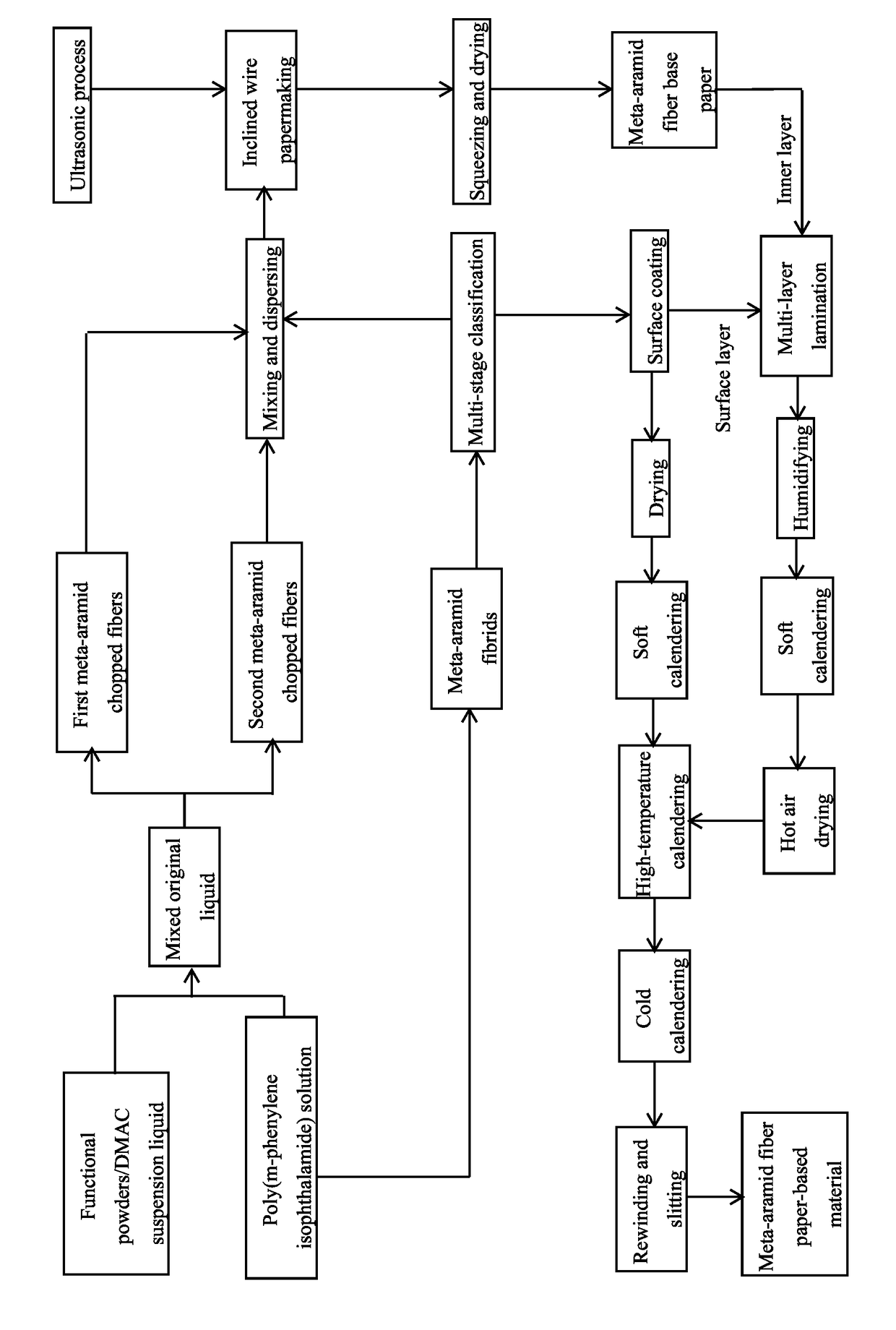

Method for producing meta-aramid fiber paper-based material

ActiveUS20170073896A1High whitenessExcellent characteristicsSpecial paperFlame-proof filament manufacturePapermakingPhenylene

A method for producing a meta-aramid fiber paper-based material includes steps of: adding functional powders into a first poly(m-phenylene isophthalamide) solution, and obtaining a homogeneous mixed solution; through a dry spinning method, obtaining meta-aramid chopped fibers; through a second poly(m-phenylene isophthalamide) solution, obtaining meta-aramid fibrids; processing the fibrids with a multi-stage classification, selecting the fibrids having an appropriate mesh number and combining in proportion; mixing the chopped fibers and the fibrids, and relieving until uniform; forming a paper through an ultralow concentration inclined wire forming machine with an ultrasonic process and a wet-papermaking process; after squeezing and drying, obtaining a meta-aramid fiber base paper, and then processing with surface coating; and, after multi-stage calendering, rewinding and slitting, obtaining the high-performance meta-aramid fiber paper-based material. The paper-based material has a thickness of 1.5-30 mil, a high whiteness, a smooth and even surface, excellent characteristics, and a good performance stability.

Owner:YANTAI METASTAR SPECIAL PAPER

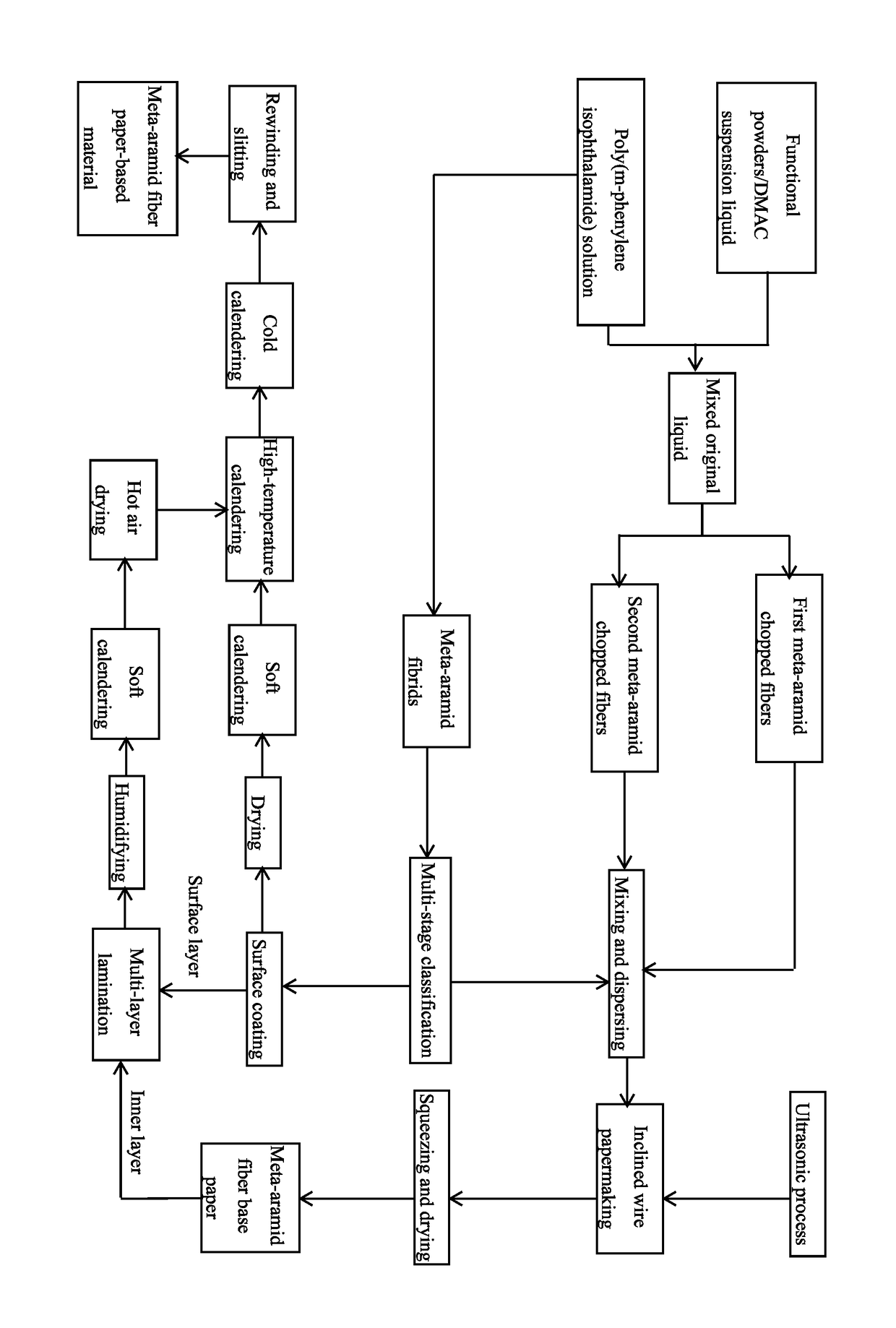

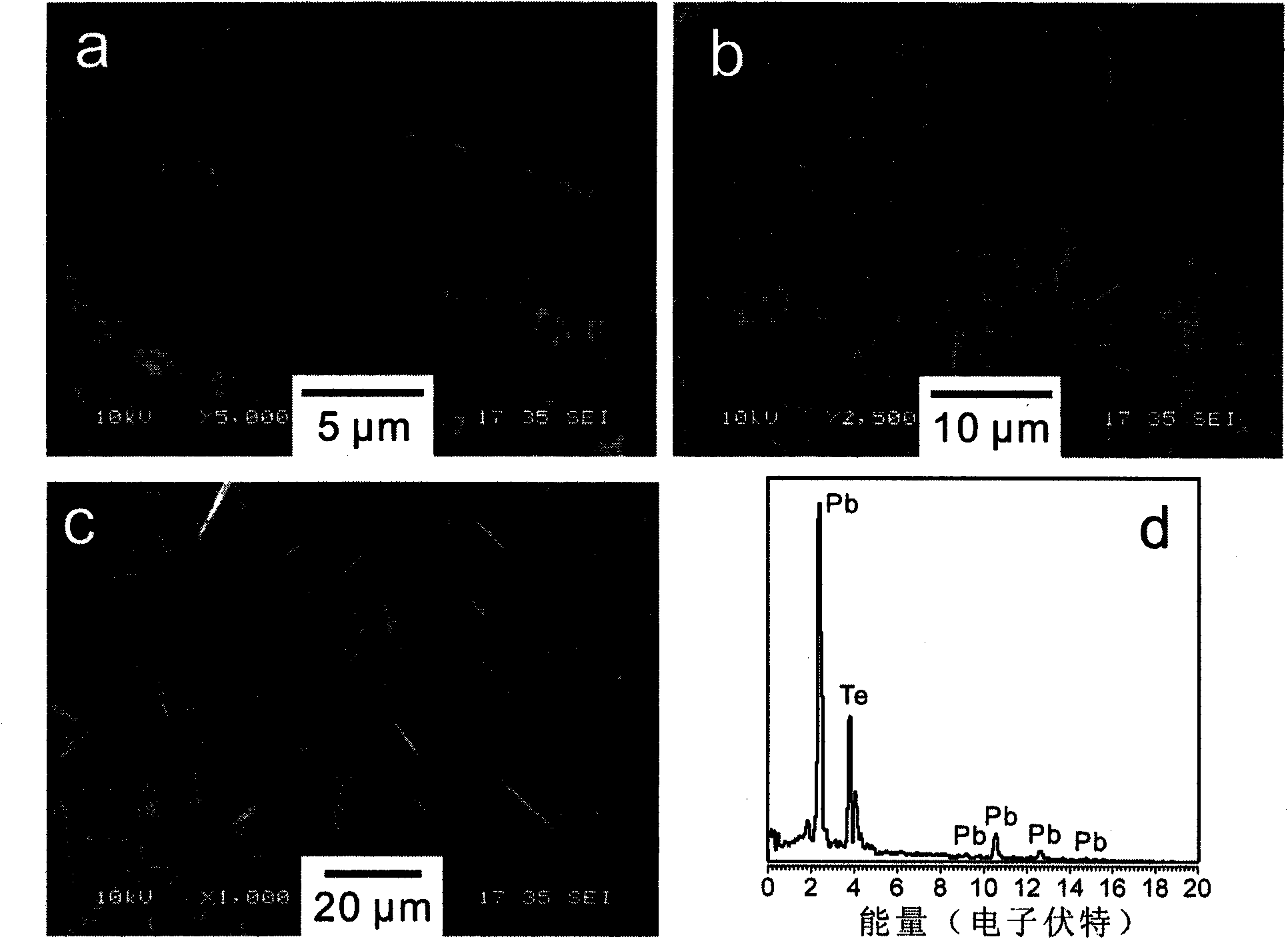

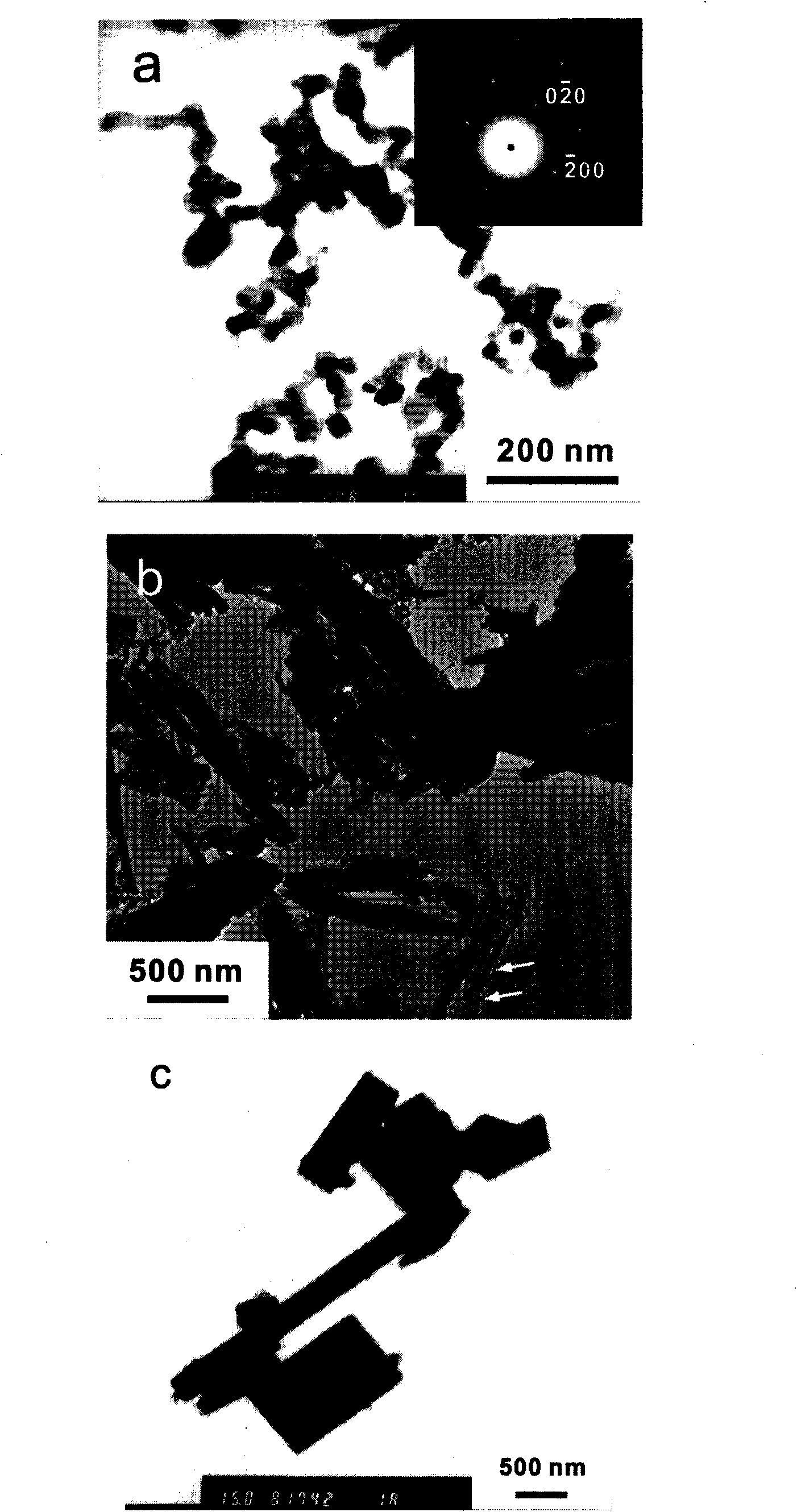

Preparation method of lead telluride nano crystal and micron crystal

InactiveCN101602495AHigh crystallinityHigh purityPolycrystalline material growthSingle crystal growth detailsThermoelectric materialsLead salt

The invention relates to a preparation method of lead telluride nano crystal and micron crystal, belonging to the thermoelectric material technical field. In the method, soluble lead salt and compound containing tellurium are taken as raw materials, borohydride of alkali metal is taken as reducing agent, mixed hydroxides are adopted as reaction medium, and reaction is carried out for 0.5-12h at 170-200 DEG C at normal atmosphere, thus obtaining the PbTe nano crystal and micron crystal. The preparation method related in the invention has the characteristics of simple device and process, low cost and high reaction speed and is easy for industrialized production. The invention can obtain nano and micron PbTe products in different appearances by simply controlling reaction time. The obtained product has good crystallinity, and the surface is clean and smoother, thus having potential application value in preparation of nano and micro thermoelectric devices.

Owner:TONGJI UNIV

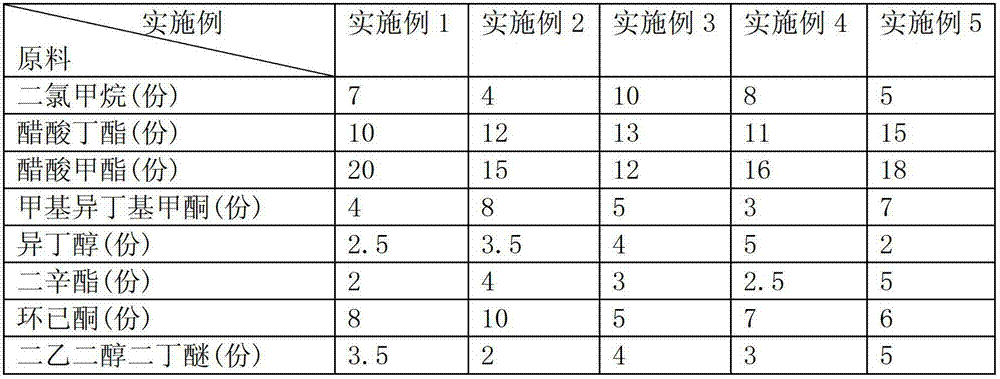

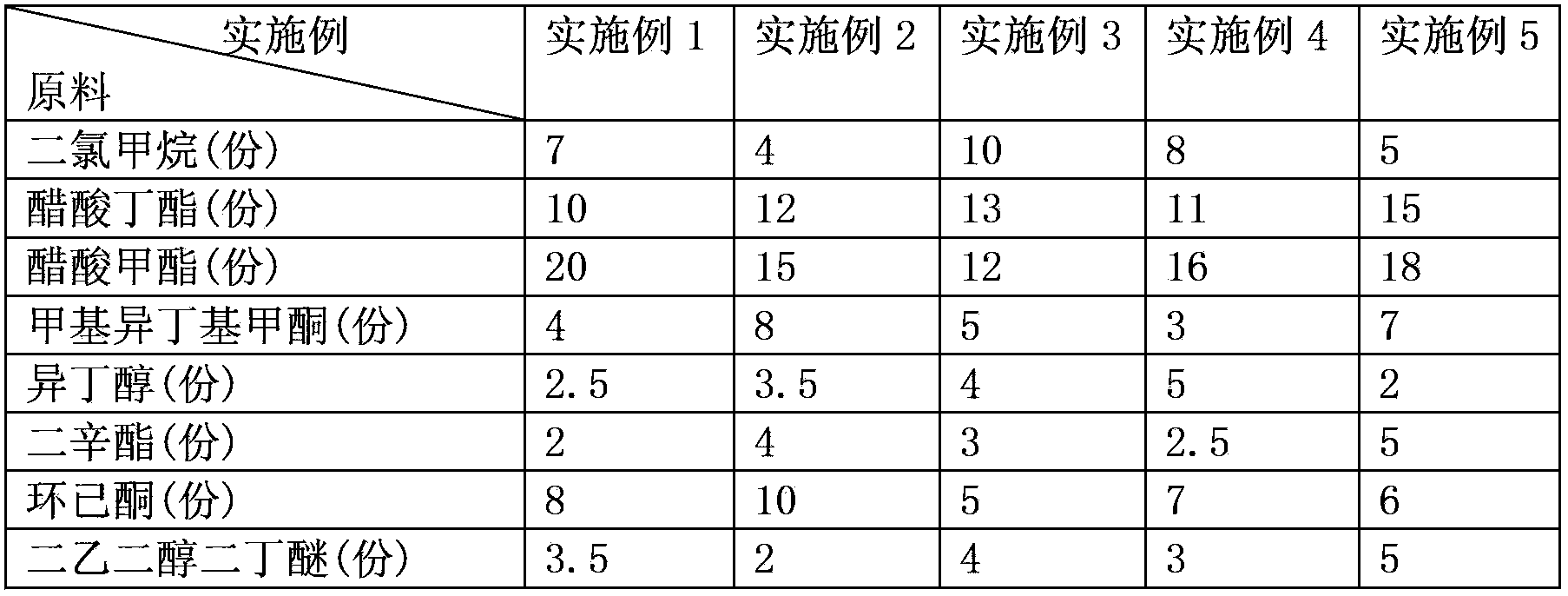

Active solvent for surface grain forming technology of wood products

The invention discloses an active solvent for a surface grain forming technology of wood products, which is prepared by the following raw materials according to the weight ratio: 4-10% of dichloromethane, 10-15% of n-butyl acetate, 12-20% of methyl acetate, 3-8% of methyl isobuthyl ketone, 2-5% of isobutyl alcohol, 2-5% of dioctyl phthalate, 5-10% of cyclohexanone and 2-5% of diethylene glycol butyl ether. Compared with the prior art, patterns on a printed film can be clearly and firmly adhered onto the surface of a wood product blank during using the active solvent and the water pressure method overlying technology, so the prepared wood products have the realistic grain patterns and the smooth and clear surface. The surface hardness is high (4 H); the abrasion resistance is good, and the abrasion value g / 100 r is not greater than 0.01; and the adhesion is strong (grinding method 100 / 100).

Owner:GUILIN SHUKANG BUILDING MATERIAL

Potato fertility improving method for carrying out straw field changing and returning on newly-prepared farmland

InactiveCN103875409AGrowth inhibitionLow costPlant protective coveringsSoil-working methodsEconomic benefitsSolanum tuberosum

The invention discloses a potato fertility improving method for carrying out straw field changing and returning on newly-prepared farmland. The potato fertility improving method includes the steps of selecting the newly-prepared farmland to carry out straw field changing and returning to plant potatoes, rapidly improving the fertility of soil of the newly-prepared farmland through straw and potato straw, deeply plowing the newly-prepared farmland in the mid-to-late September to enable the thickness of the plowed layer to be larger than 25 cm, ditching furrows according to the potato planting technology, leveling the farmland, applying base fertilizers which include, by mass, 10 kg-15 kg per mu of urea, 30 kg-50 kg per mu of calcium magnesium phosphate fertilizers and 40 kg-50 kg per mu of potassium sulfate at a time, planting the potatoes with the standard of 5000 holes-6000 holes per mu, covering ridges with prepared straw with the standard of 400 kg-600 kg per mu, conventionally managing the planted potatoes, harvesting the potatoes in the mid-to-late April next year, and carrying out cyclic operation of farming work such as preparing next-stubble crop planting and the like. The potato fertility improving method is high in economic benefit, after the potatoes are harvested, the potato straw and the decayed straw serve as organic materials to be directly returned to the farmland, and the good effects on the rapid fertility improvement and the physical and chemical property improvement of the soil of the newly-prepared farmland are achieved.

Owner:CHANGSHA ENVIRONMENTAL PROTECTION COLLEGE +3

Double-faced organic silicon polyimide film dry mica paper tape and preparation method thereof

InactiveCN103514978AGood flexibilityGood wrapping performancePlastic/resin/waxes insulatorsInsulated cablesAcetic acidPaper tape

The invention relates to a cable fire-resistant insulation material, and particularly relates to a double-faced organic silicon polyimide film dry mica paper tape which comprises mica paper and polyimide films. The polyimide films are arranged on upper and lower surfaces of the mica paper. The mica paper and the polyimide films on upper and lower surfaces are bonded together through glue materials. Each glue material consists of organic silicon resin, a modified additive, an additive, toluene and ethyl acetate. The weight ratio of the organic silicon resin, the modified additive, the additive, the toluene to the ethyl acetate is 10:0.6:0.24:18:12. The glue material content in the mica tape is 3 to 9 g / square meter. The thickness of the mica paper is 0.035 to 0.065mm. The thickness of each polyimide film is 0.03 to 0.035mm. The preparation method of the double-faced organic silicon polyimide film dry mica paper tape has the steps of glue material configuring, dip coating, compositing, drying, cooling, rewinding and slitting. The product has the advantages of easy manufacture, good fire-resistant insulation performance, strong shock-resistant performance and low processing cost.

Owner:扬州新奇特电缆材料有限公司

Fine Treatment Agent and Fine Treatment Method Using Same

InactiveUS20080029487A1Reduce in quantitySmooth and clean surfaceDecorative surface effectsSolid-state devicesHydrogen fluorideSilicon oxide

A fine treatment agent according to the present invention is a fine treatment agent for the fine treatment of a multilayer film, including a tungsten film and a silicon oxide film comprising at least one from among hydrogen fluoride, nitric acid, ammonium fluoride and ammonium chloride. Thus, a fine treatment agent which makes fine treatment on a multilayer film, including a tungsten film and a silicon oxide film, possible by controlling the etching rate and a fine treatment method using the same can be provided.

Owner:STELLA CHEMIFA CORP

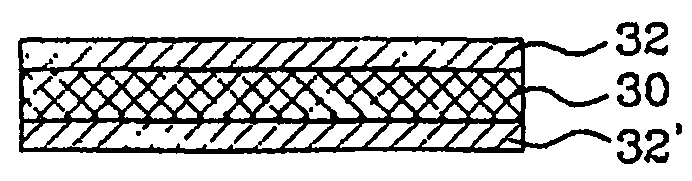

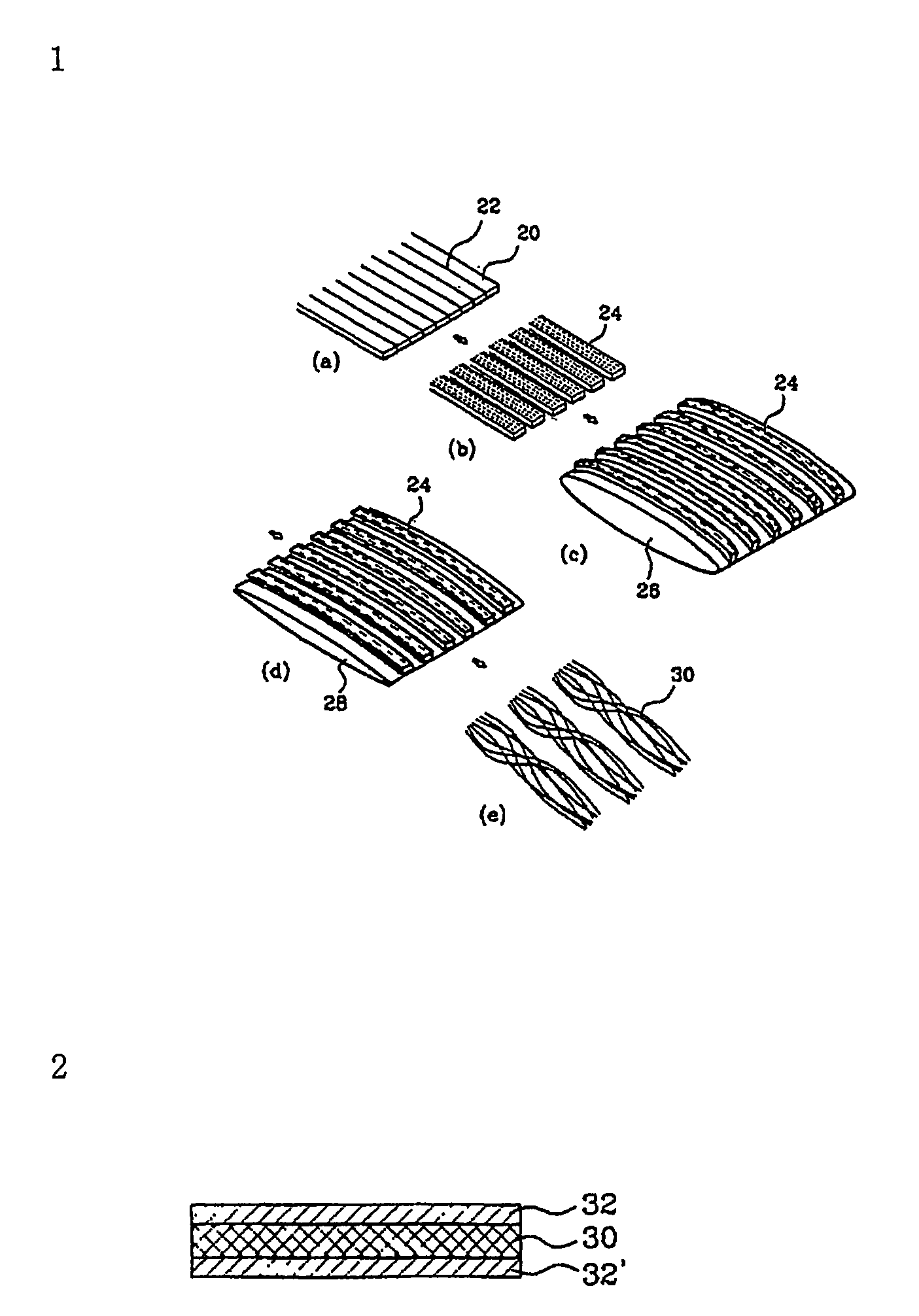

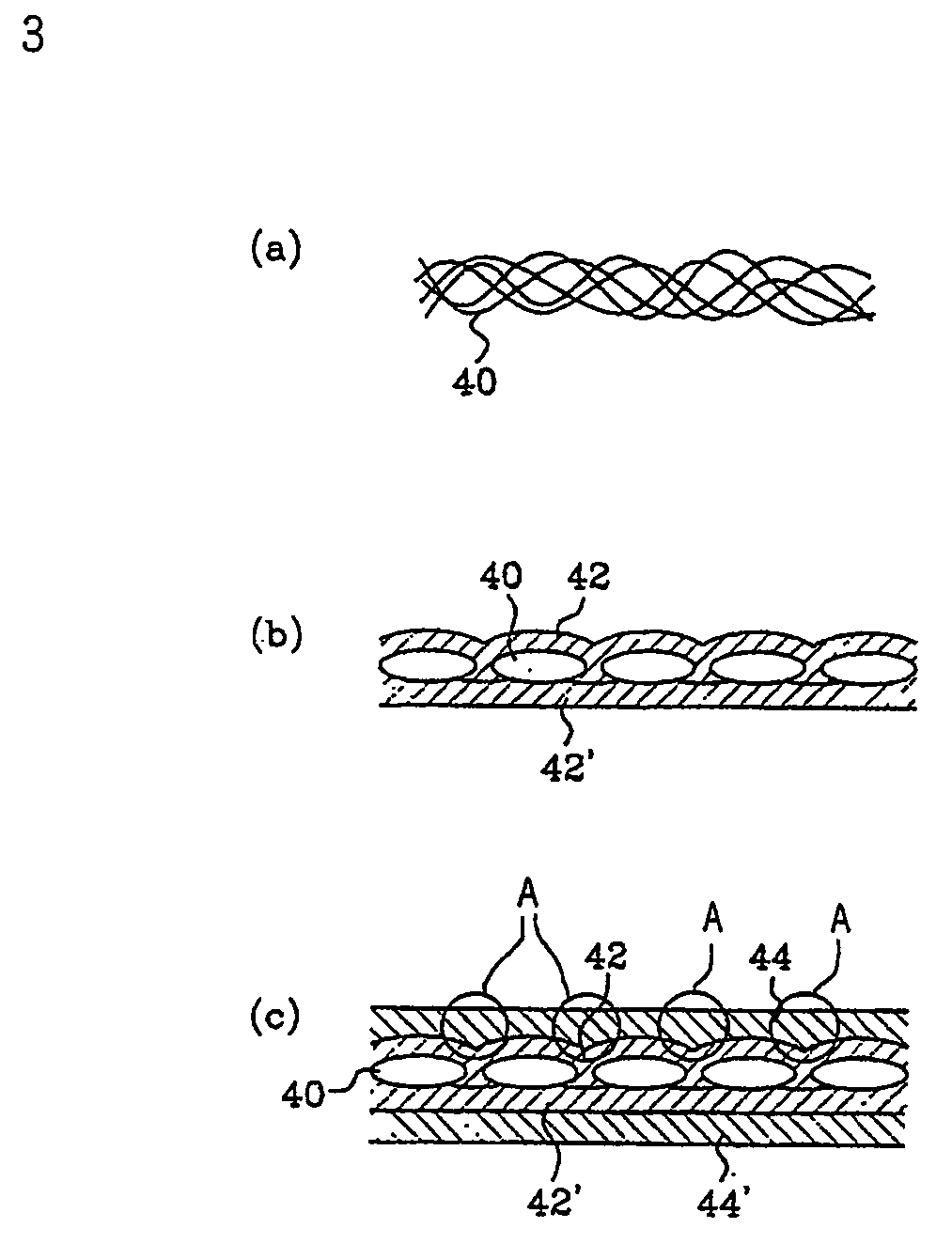

Tarpaulin by using polyolefin group split yarn and method thereof

InactiveUS20070010152A1Economical priceEasy to processSynthetic resin layered productsConstructions elementsYarnPolyolefin

The present invention relates to a tarpaulin by using a polyolefin group resin which is comprised of a polyolefin group woven cloth layer in which a polyolefin group resin is split, drawn and weaved and a polyolefin group resin coating layer manufactured by stacking the polyolefin group resin on both sides of the polyolefin group woven cloth, the tarpaulin comprising a polyolefin group yarn for constructing the polyolefin group woven cloth, the polyolefin group yam is split with a predetermined width and number, drawn by 7-8 times through a drawing plate, split firstly, performed secondly by a heat setting through a setting plate, twisted and then weaved, and the polyolefin group resin coating layer including a first polyolefin group resin coating layer caoted with a predetermined thickness and color and a second polyolefin group resin coating layer manufacured by stacking a melting polyolefin group resin on the first polyolefin group resin coating layer.

Owner:KWON HYUK CHONG

Nanostructured Working Electrode of an Electrochemical Sensor, Method of Manufacturing Thereof and Sensor Containing This Working Electrode

InactiveUS20080169191A1Transfer become impossibleAllows preparationImmobilised enzymesMaterial nanotechnologyOptoelectronicsNanostructure

A nanostructured working electrode of an electrochemical sensor wherein the working electrode is composed of a material in the form of a film and is inserted onto the sensor. The electrode can be prepared from materials the use of which was impossible in the working electrodes known in the art (e.g. metals of defined purity). A method of manufacturing of the nanostructured working electrode and an electrochemical sensor containing the nanostructured electrode is disclosed

Owner:BVT TECH +1

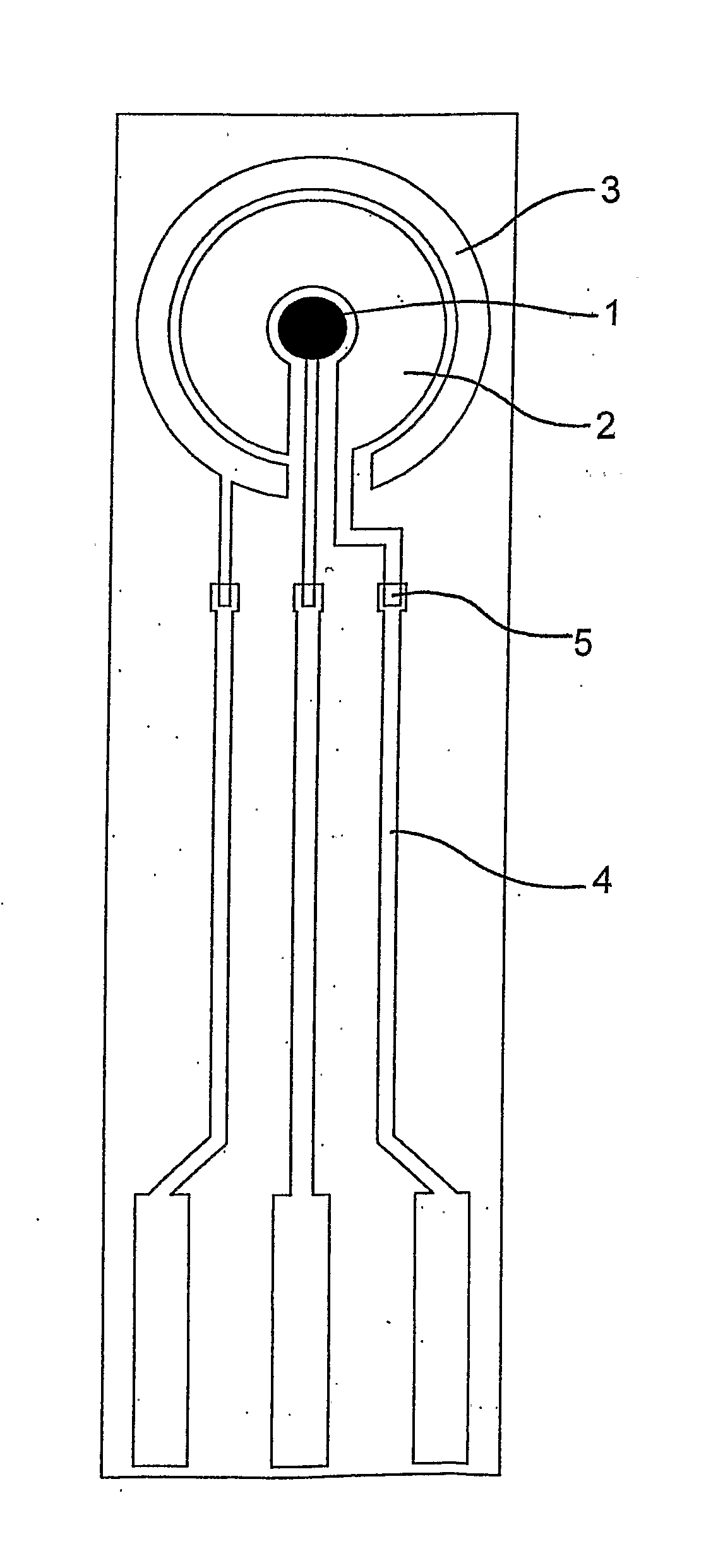

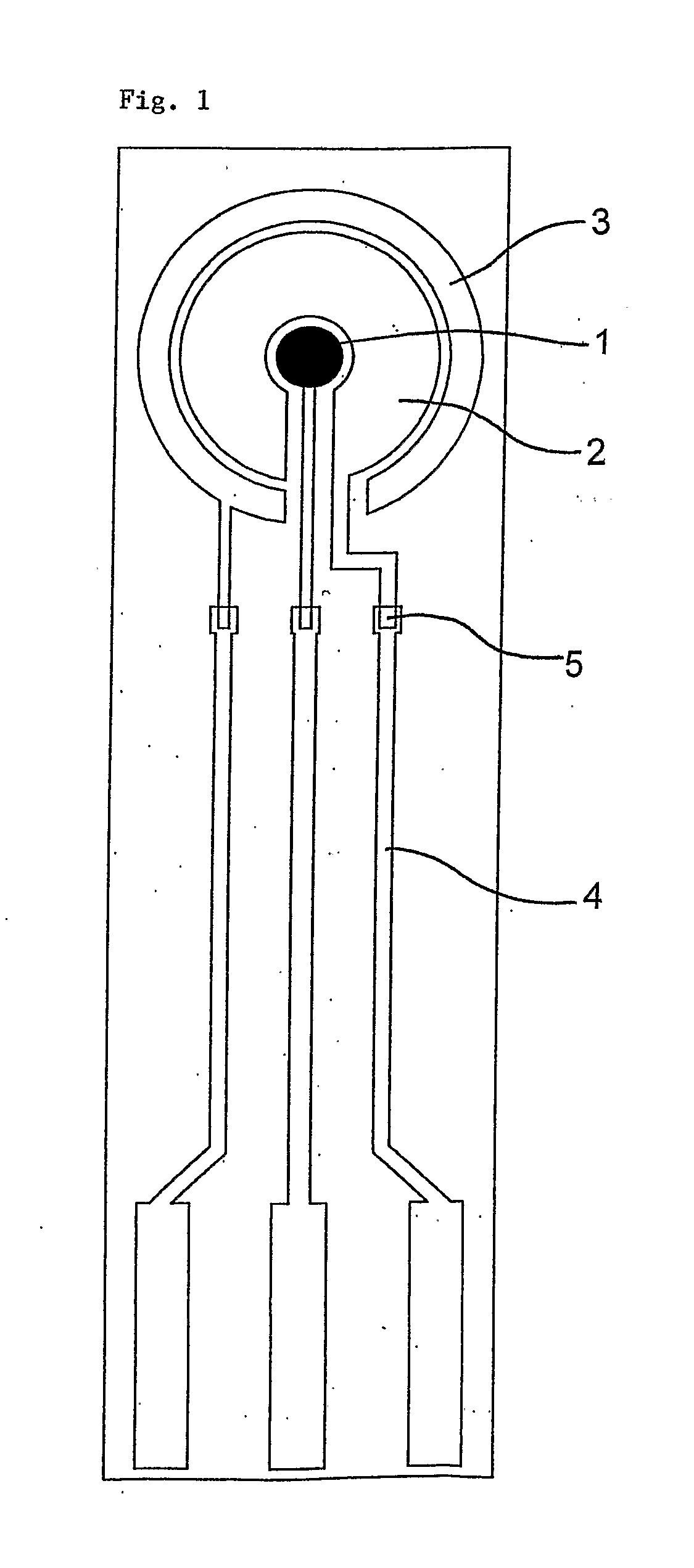

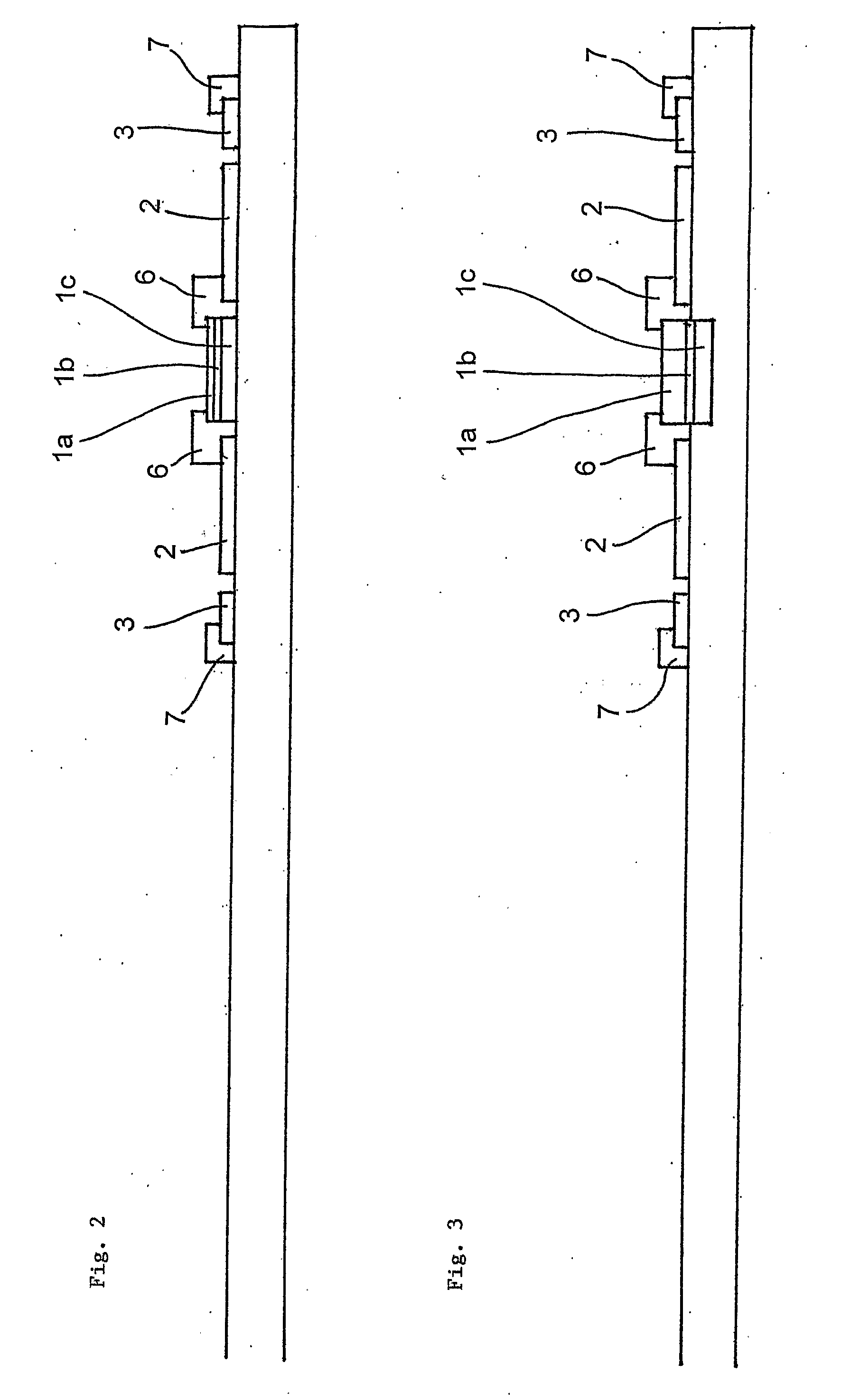

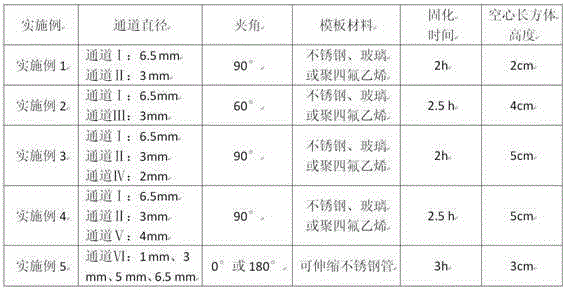

Method for preparing micro-fluidic/milli-fluidic chip by using detachable template

The invention provides a method for preparing a micro-fluidic / milli-fluidic chip by using a detachable template. The method comprises steps as follows: a, a detachable container is prepared; b, a pipeline is reserved, and the template is prepared; c, a prepolymer is poured and a die is solidified; d, an aluminum foil, a glass sheet and the template of the die are detached, and a micro-fluidic / milli-fluidic chip blank is obtained; e, the micro-fluidic / milli-fluidic chip blank is cut, and the micro-fluidic / milli-fluidic chip is obtained. The method has the characteristics that the processing technology is simple, controllability is high, and the stability of the obtained chip is good.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

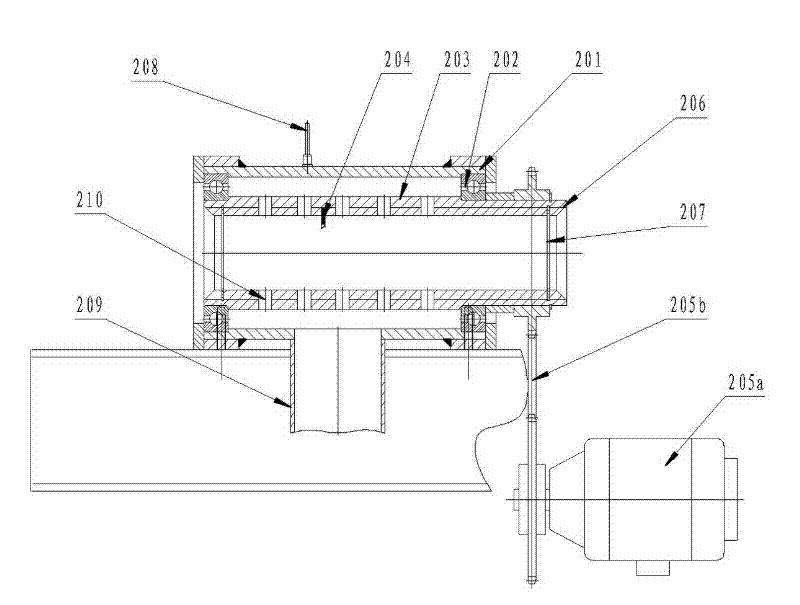

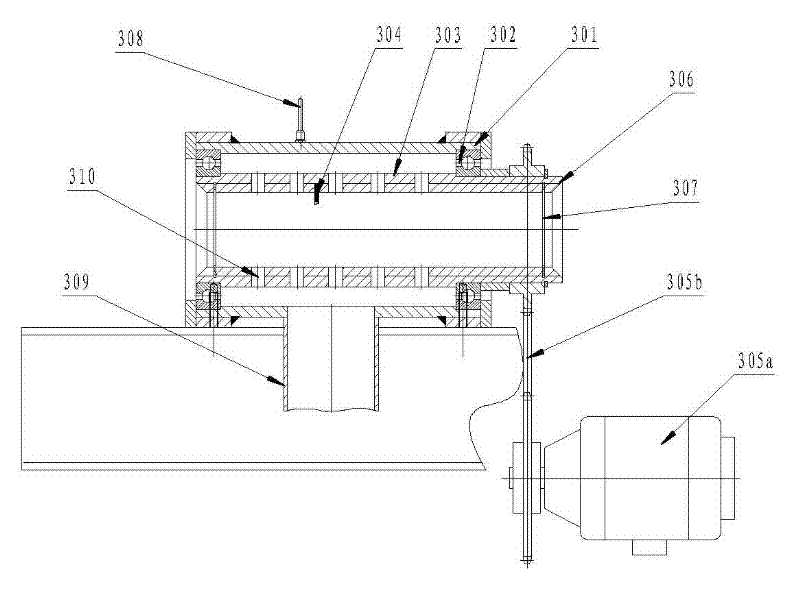

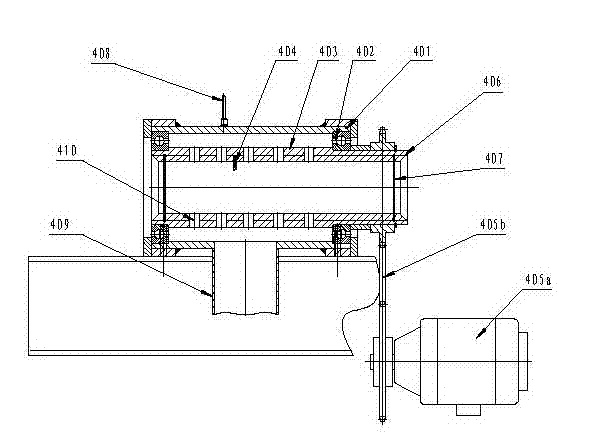

Method and equipment for cleaning oxide skin on outer surface of copper pipe

ActiveCN102000706BReduce generationImprove yieldHollow article cleaningWork treatment devicesSurface oxidationEngineering

The invention discloses method and equipment for cleaning an oxide skin on the outer surface of a copper pipe, wherein the method comprises the step of: continuously passing through a pipe blank of the copper pipe through a rough brushing device, a medium brushing device and a fine brushing device which are arranged coaxially for respectively sequentially carrying out primary brushing, medium brushing and fine brushing on the outer surface of the pipe blank of the copper pipe to realize primary brushing, medium brushing and fine brushing on the surface of the pipe blank, and removing the oxide skin. The equipment mainly comprises a stand, and the rough brushing device, the medium brushing device and the fine brushing device which are arranged on the stand at intervals. Copper powder wastegenerated in the method is greatly reduced, and the predicted yield can reach 99.5 percent; and the equipment is convenient for use and has good cleaning effect on the oxide skin on the surface of the pipe blank.

Owner:SHANGHAI LONGYANG PRECISE COMPOUND COPPER TUBE CO LTD

Polishing composition for IC copper barrier layer CMP and preparation method thereof

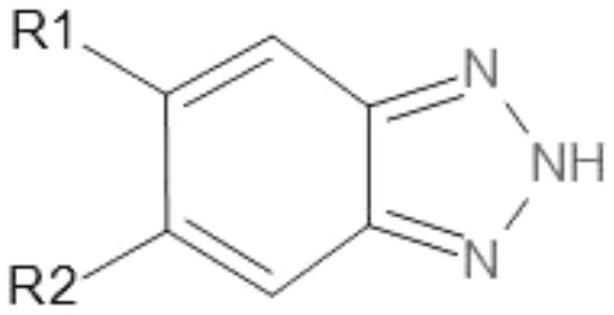

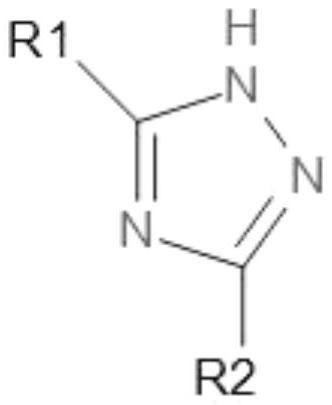

InactiveCN112175525ANot easy to reuniteHigh surface finishSolid-state devicesSemiconductor/solid-state device manufacturingOrganic solventCopper interconnect

The invention discloses a polishing composition for an IC copper barrier layer CMP. The polishing composition is prepared by the following method: sequentially adding a dispersing agent, a corrosion inhibitor, a wetting agent, an organic solvent and an oxidizing agent into a grinding material while stirring, adding a defoaming agent, and adjusting the pH value of the solution by using a pH regulator. The polishing composition can be used for chemical mechanical polishing of a copper interconnection barrier layer, surface pollutant particles, surface butterfly-shaped recesses and metal corrosion after polishing are all effectively controlled, the requirements of 28 nanometers and below processes can be met, and the polishing composition has a good application prospect.

Owner:常州时创新材料有限公司

Manufacturing method of natural bamboo-fiber hemostatic gauze

InactiveCN107281534ASmooth and clean surfaceWell-proportionedSurgical adhesivesPharmaceutical delivery mechanismFiberMedicine

The invention relates to the field of medical supplies, and particularly relates to a manufacturing method of water-soluble bamboo-fiber hemostatic gauze. The method comprises five procedures of pretreatment, an alkali reaction, an ether reaction, washing treatment and post treatment. The manufacturing method is a method for producing hemostatic gauze, which is simple in production process, relatively few in the kinds of used raw materials and reagents, and further better in effects, particularly in degradation effects.

Owner:宣晓星

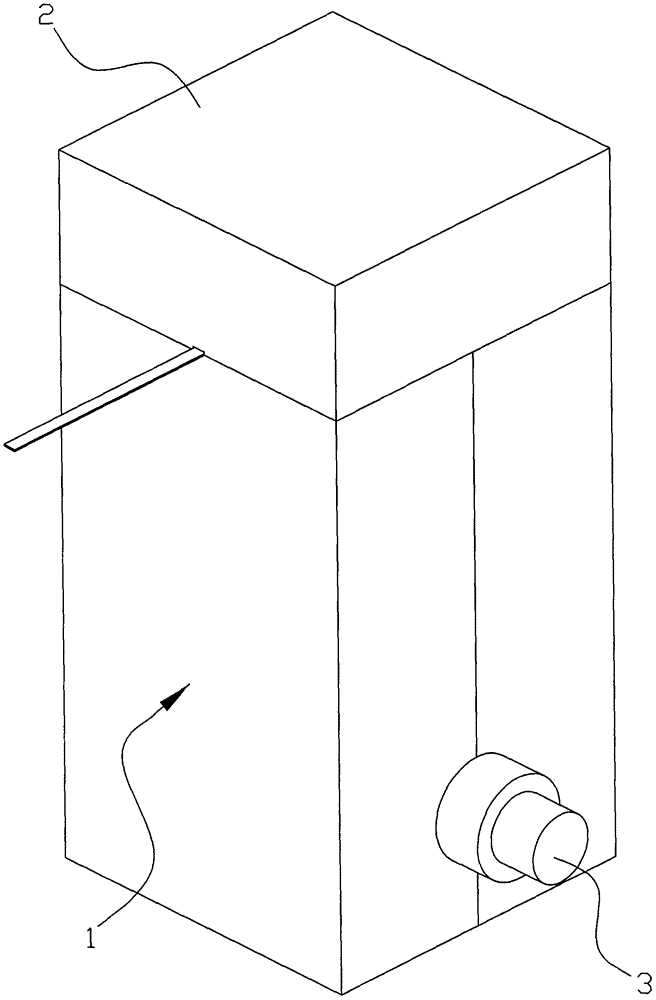

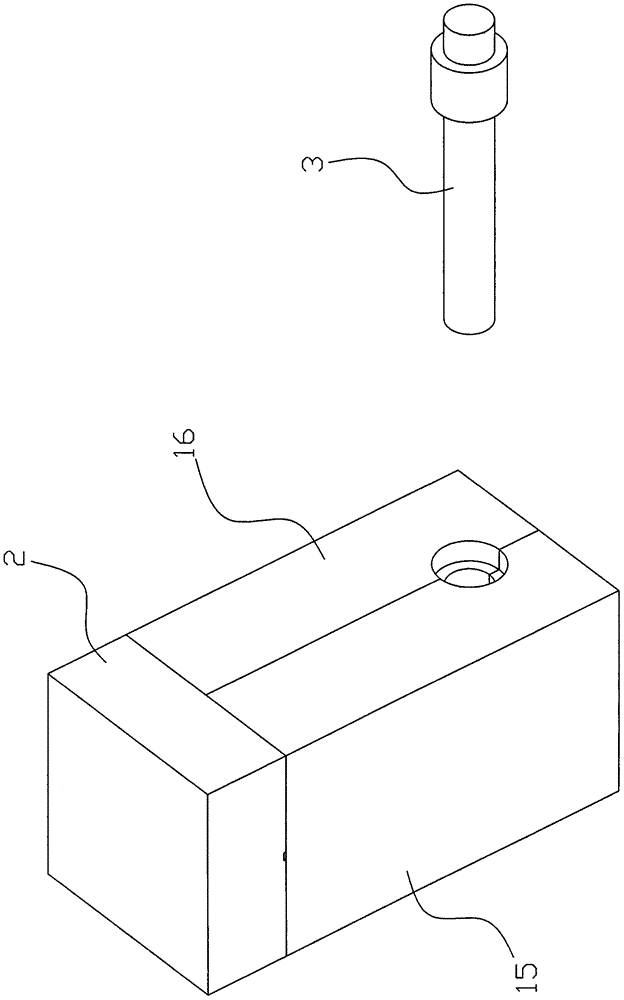

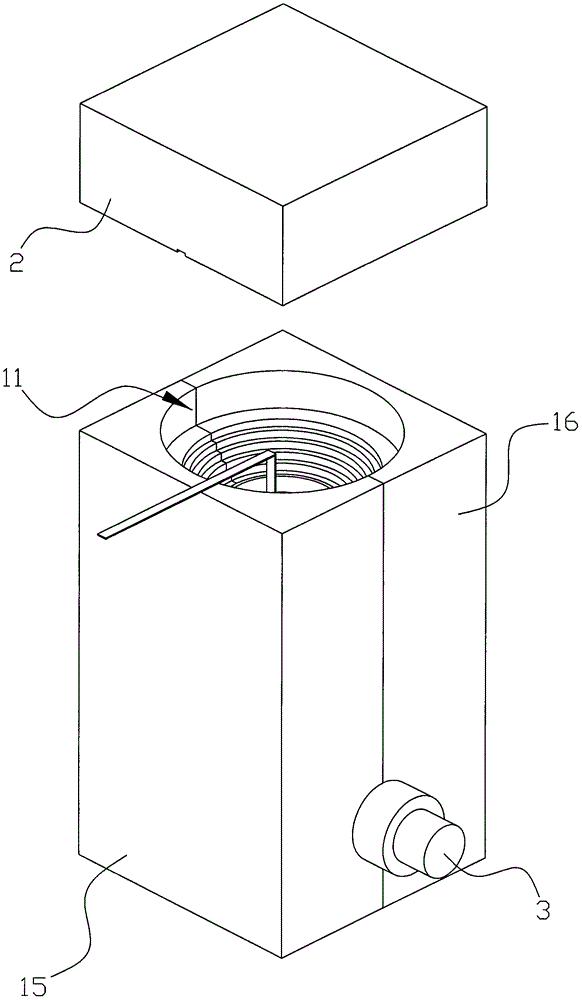

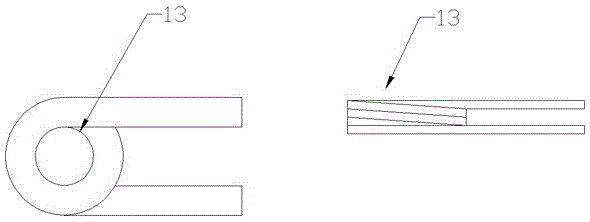

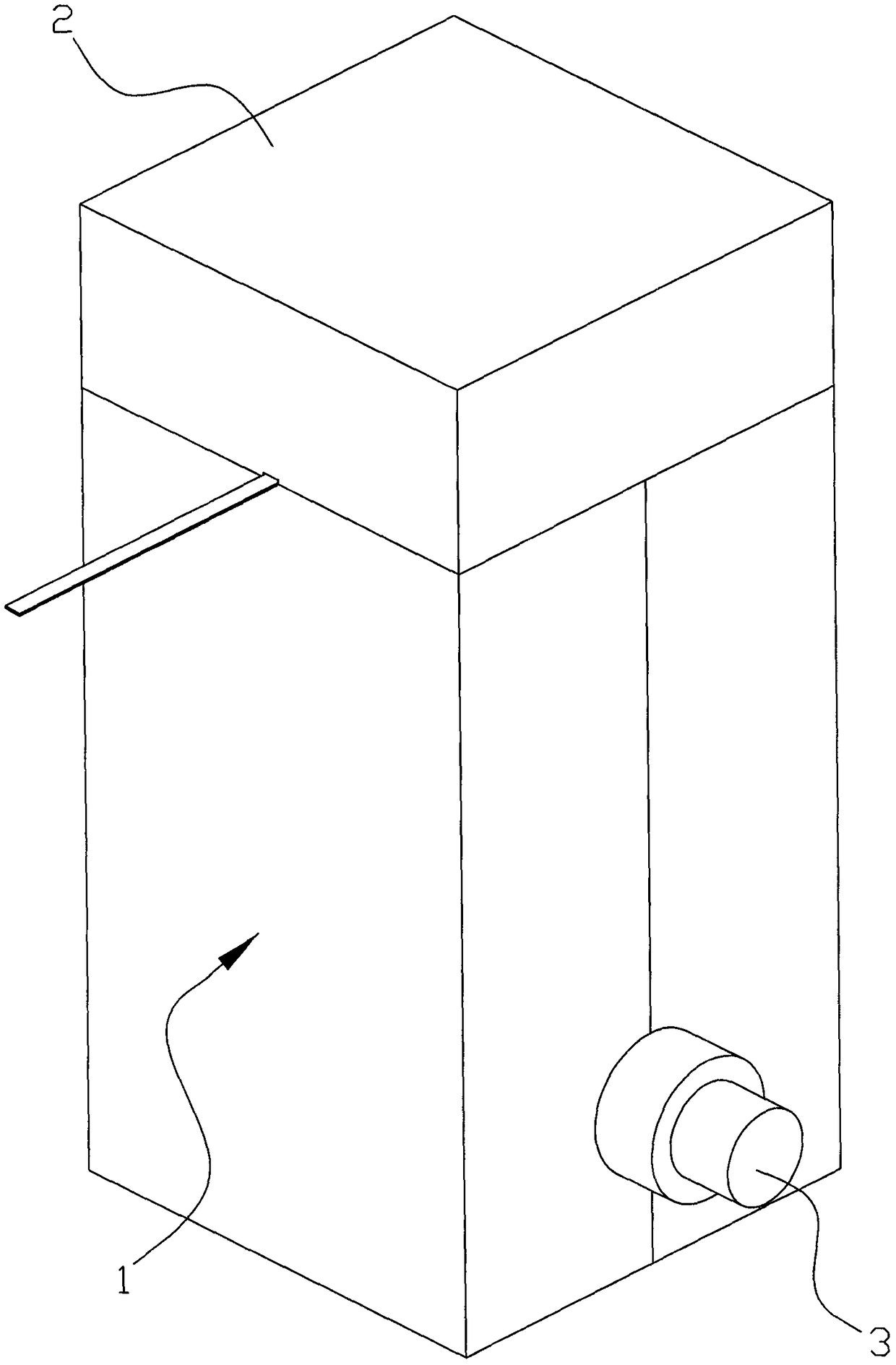

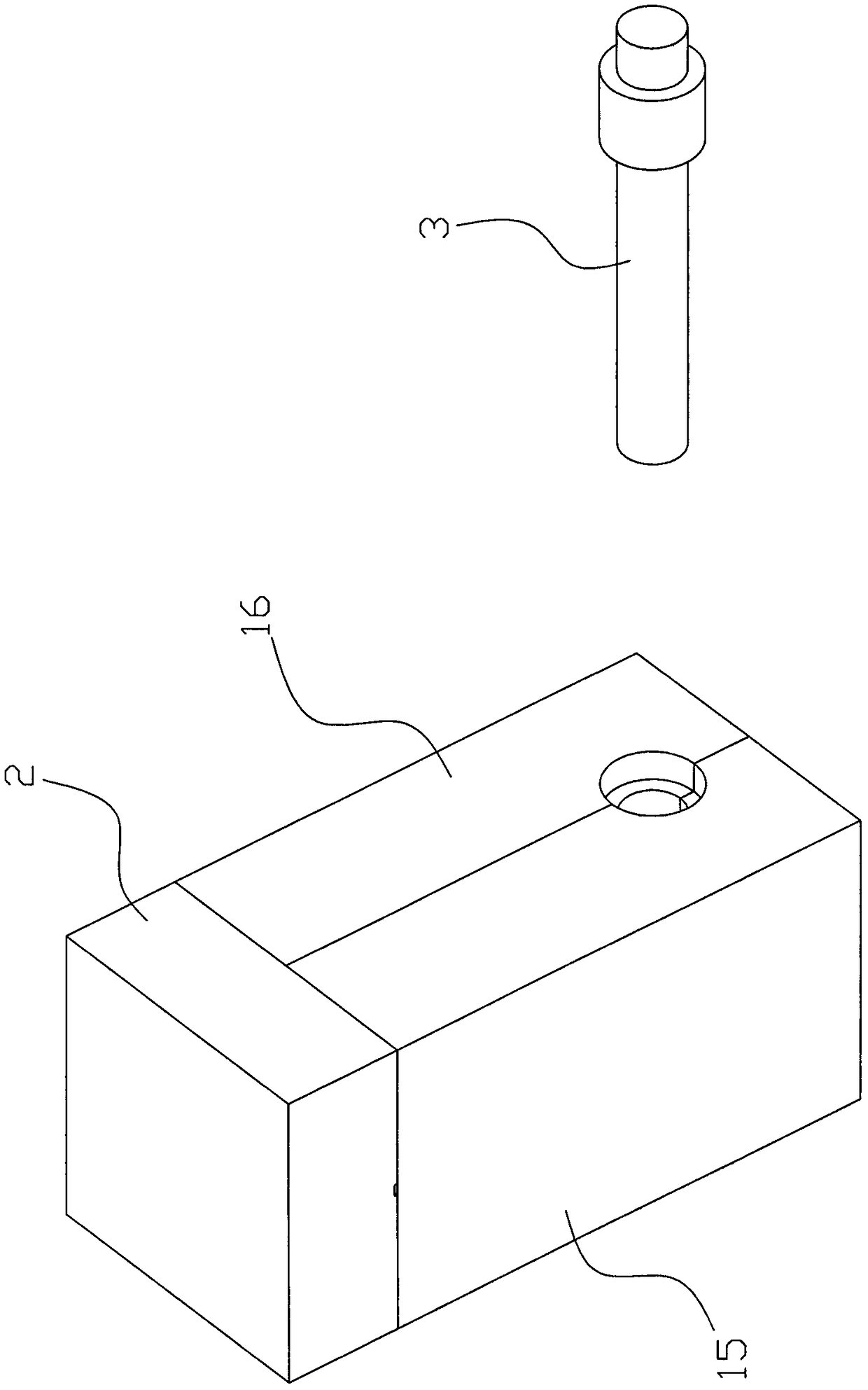

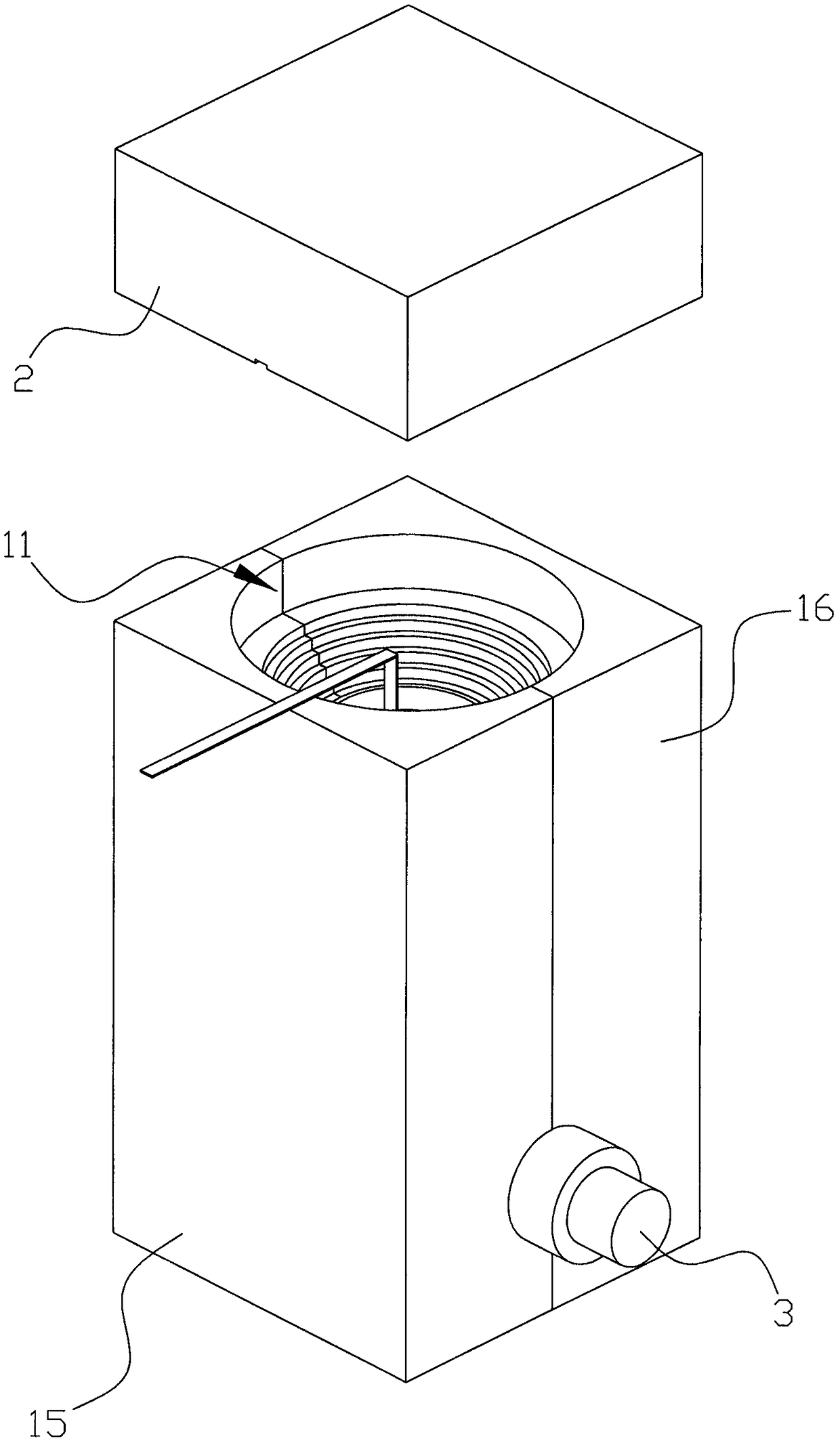

Welding die for welding powder

InactiveCN106078014AImprove welding qualitySmooth and clean surfaceWelding/cutting auxillary devicesAuxillary welding devicesSlagStepping level

The invention provides a welding die for welding powder. The welding die comprises a die body and a die cover, the die cover detachably covers the die body, the die body is internally provided with a reaction cavity and a welding cavity, the reaction cavity is located above the welding cavity, the bottom of the reaction cavity is communicated with the welding cavity through a drainage trough, and the bottom face of the reaction cavity is provided with a metal spacer for preventing the welding powder in the reaction cavity from falling into the welding cavity before welding. The welding die is characterized in that the inner wall of the reaction cavity is provided with an annular step-level trough capable of retaining welding slag obtained after a reaction in the reaction cavity on the inner wall of the reaction cavity, and the diameter of the annular step-level trough is sequentially increased from bottom to top. The reaction cavity is composed of an upper reaction cavity body and a lower reaction cavity body, the top of the lower reaction cavity body is communicated with the upper reaction cavity body, the bottom of the lower reaction cavity body is communicated with the drainage trough, the annular step-level trough is located on the inner wall of the upper reaction cavity body, and the metal spacer is placed at the communicating position of the upper reaction cavity body and the lower reaction cavity body. The welding die has the advantages that the welding slag can be effectively prevented from entering a welding piece along with the molten welding powder, and welding quality is good.

Owner:宁波高新区远创科技有限公司

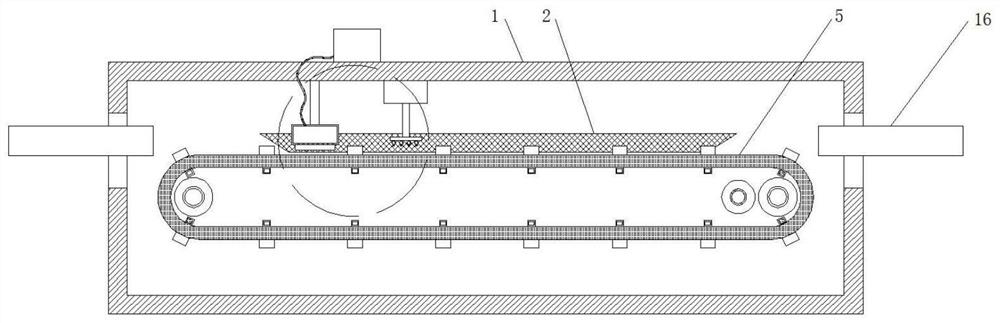

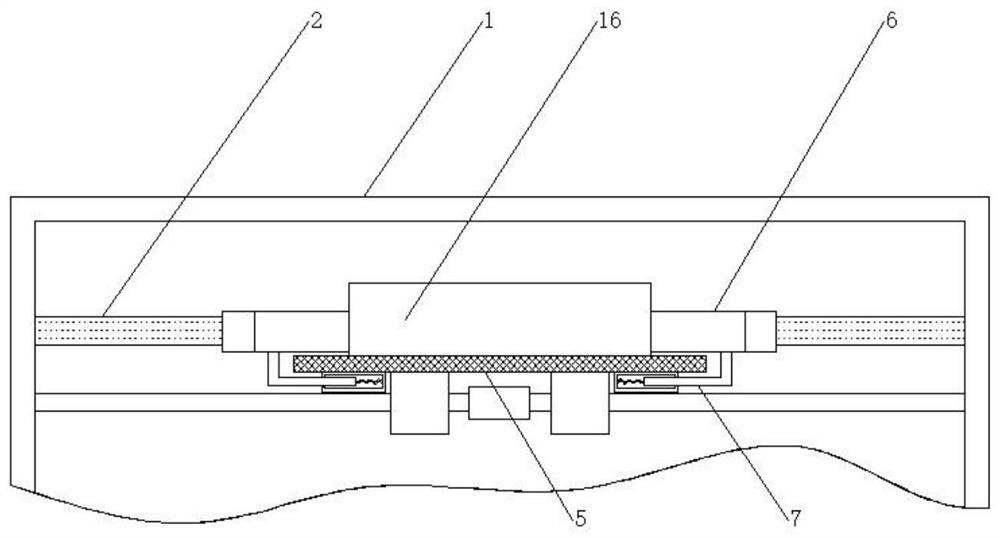

Environment-friendly intelligent spraying device for household goods processing

InactiveCN113262918AEasy to processSmooth and clean surfaceDirt cleaningCleaning using toolsStructural engineeringIndustrial engineering

The invention belongs to the technical field of spraying devices, and particularly relates to an environment-friendly intelligent spraying device for household goods processing. The environment-friendly intelligent spraying device comprises a paint spraying box, two sets of first fixing plates symmetrically distributed along the central axis of the paint spraying box are fixed on the inner wall of the paint spraying box, and the two sets of first fixing plates are provided with cleaning mechanisms fixed with the inner wall of the top of the paint spraying box; a paint spraying mechanism fixed to the inner wall of the top of the paint spraying box is arranged on one side of each cleaning mechanism, a conveying belt of an annular structure is arranged below each paint spraying mechanism, clamping mechanisms distributed at equal intervals in the length direction of the conveying belt are arranged on the outer ring of the conveying belt, each clamping mechanism comprises two sets of pushing blocks symmetrically distributed along the central axis of the paint spraying box, and each pushing block is of a trapezoidal structure; and a telescopic mechanism fixed to the inner ring of the conveying belt is fixed to the bottom of each pushing block. According to the environment-friendly intelligent spraying device for household goods processing, a wood board can be rapidly clamped and fixed, so that the surface of the wood board is cleaned, the working efficiency is improved, and the labor intensity of workers is reduced.

Owner:安徽德帝智能科技股份有限公司

Formula for preparing vinyl

The invention relates to the technical field of vinyl production, in particular to a formula for manufacturing vinyl, which is used for realizing the purpose that the produced vinyl has good supporting strength under the condition of good softness, so that the vinyl is not difficult to support due to over-softness. The technical scheme provided by the invention is as follows: the composition is prepared from the following raw materials in percentage by weight: 8-8.5% of dioctyl terephthalate; 4 to 4.5% of a PVC viscosity reducer; 9%-9.5% of DNTXIB (Dinitrotoluene 1-1.5% of hot oil; 1.8%-2.2% of phenol-free calcium zinc; 0.1 to 0.3 percent of dimethyl silicone oil; 33 to 33.5 percent of PVC (Polyvinyl Chloride) paste resin; 20.5 to 21% of PVC (Polyvinyl Chloride) paste resin; and 20.5-21% of PVC mixed resin, wherein the sum of the percentage contents of all the components is 100%.

Owner:云阳县优多科技有限公司

Fine treatment agent and fine treatment method using same

InactiveUS7727415B2Reduce in quantitySmooth and clean surfaceSolid-state devicesSemiconductor/solid-state device manufacturingHydrogen fluorideSilicon oxide

A fine treatment agent according to the present invention is a fine treatment agent for the fine treatment of a multilayer film, including a tungsten film and a silicon oxide film comprising at least one from among hydrogen fluoride, nitric acid, ammonium fluoride and ammonium chloride. Thus, a fine treatment agent which makes fine treatment on a multilayer film, including a tungsten film and a silicon oxide film, possible by controlling the etching rate and a fine treatment method using the same can be provided.

Owner:STELLA CHEMIFA CORP

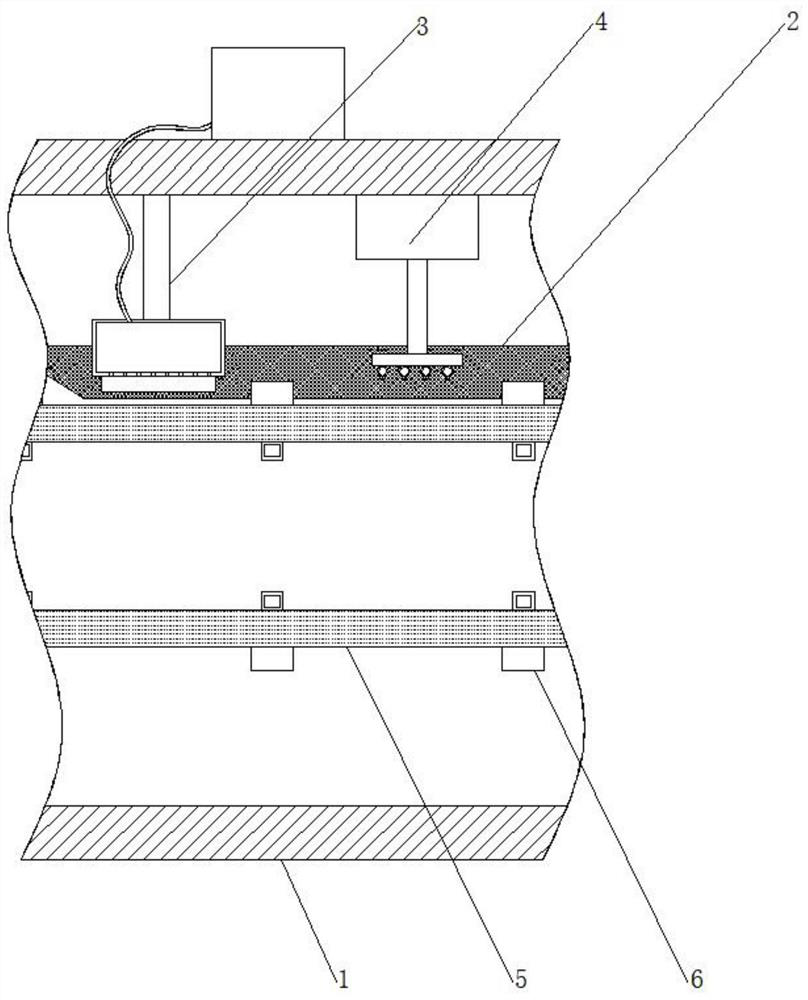

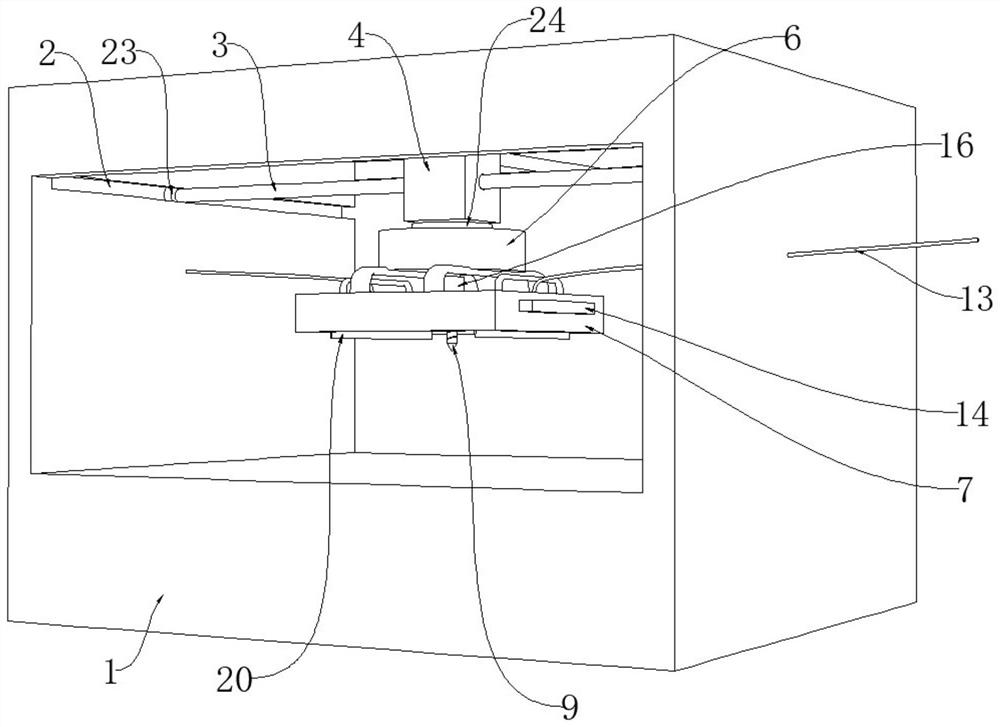

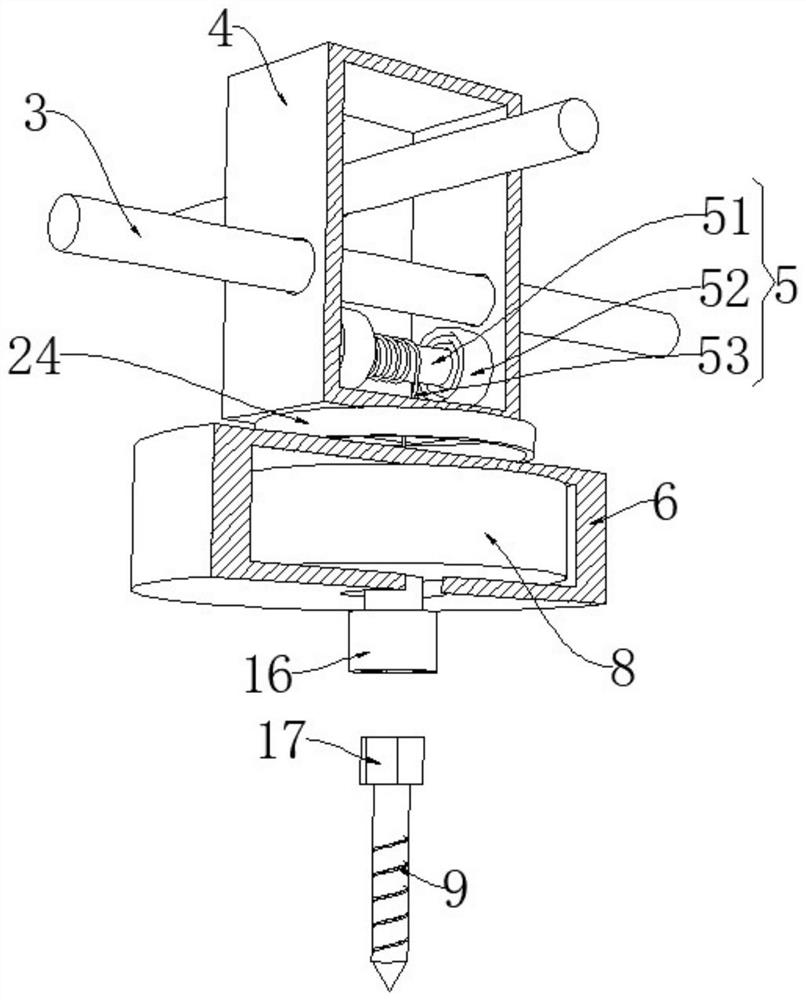

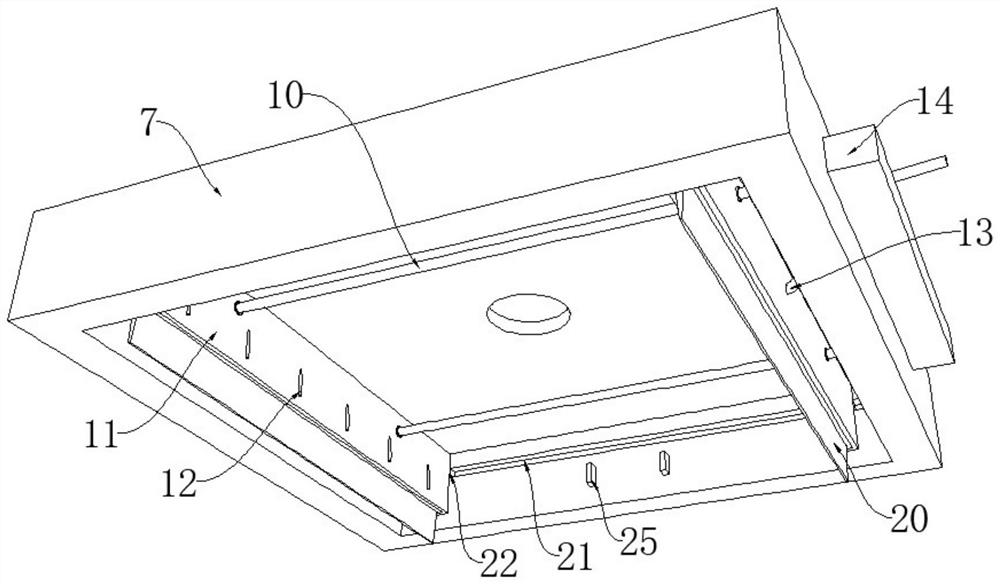

Drilling device with cleaning function for circuit board processing and using method

PendingCN114800685AEasy to moveEasy drillingDirt cleaningPrinted circuit manufactureDust controlThreaded rod

The invention discloses a circuit board processing drilling device with a cleaning function and a using method, and belongs to the technical field of drilling, the circuit board processing drilling device comprises a working box, guide grooves are formed in the periphery of an inner cavity of the working box, sliding rods are slidably connected to inner cavities of the guide grooves, and the surfaces of the sliding rods are sleeved with box bodies; through cooperation of a sliding rod and a box body, the box body can move freely in the working box in the horizontal direction, meanwhile, through cooperation of a traction shrinkage assembly, a drill bit is moved up and down, drilling treatment can be conveniently conducted on circuit boards at different positions in the working box, and then through a dust collection pipe and a hose, the dust collection efficiency is improved. Chippings generated by drilling of a drill bit are conveniently discharged out of a working box, the surface of a circuit board is smooth and clean during drilling, meanwhile, a driving assembly is used for driving a positive and negative threaded rod to rotate, a movable frame is conveniently moved during drilling, comprehensive dust removal is conducted on the top of the circuit board, and the working efficiency is improved. The problem that a traditional drilling device for circuit board machining cannot synchronously remove dust is solved.

Owner:SHENZHEN BOMIN ELECTRONICS

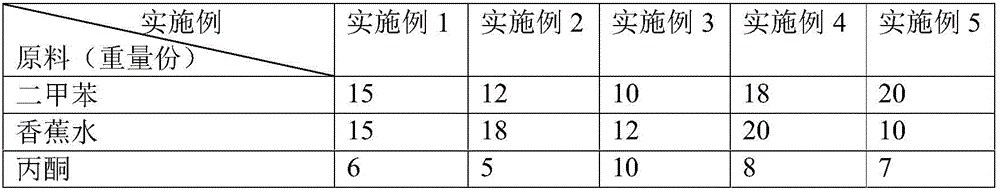

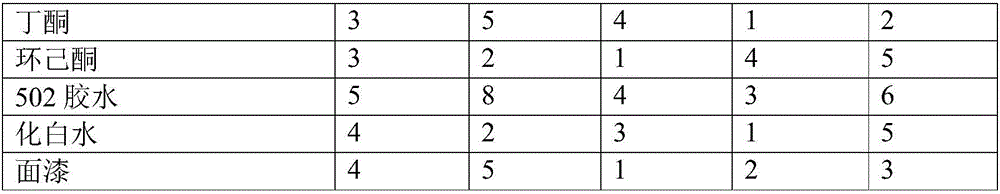

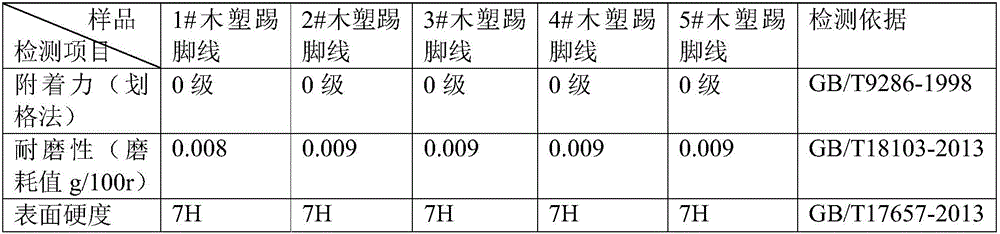

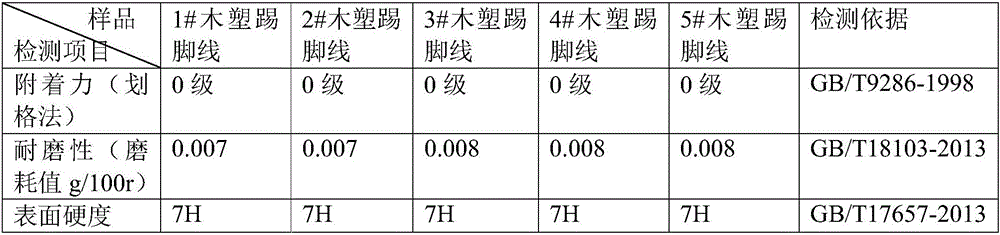

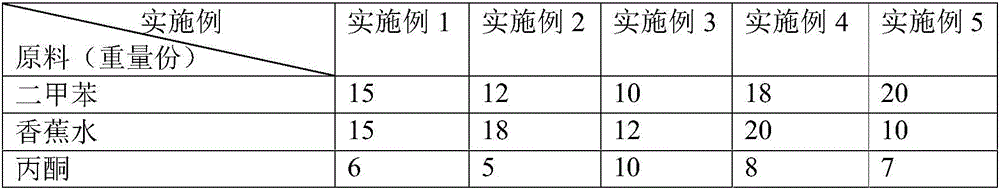

Special active solvent for making surface textures of PVC (polyvinyl chloride) wood-plastic product

InactiveCN105924662ARealistic texture pattern effectSmooth and clean surfaceChemistryAdhesion process

The invention discloses a special active solvent for making surface textures of a PVC (polyvinyl chloride) wood-plastic product. The special active solvent is prepared from the following raw materials in parts by weight: 10 to 20 parts of dimethylbenzene, 10 to 20 parts of banana oil, 5 to 10 parts of acetone, 1 to 5 parts of butanone, 1 to 5 parts of cyclohexanone, 3 to 8 parts of 502 glue, 1 to 5 parts of haze remover and 1 to 5 parts of finish paint. Compared with the prior art, the special active solvent for making the surface textures of the PVC wood-plastic product has the advantages that when the active solvent is combined with a hydraulic pressure covering adhesion process, a pattern on a printed film can be clearly and firmly attached to the surface of a wood-plastic product blank with the adhesion force of 0 level, a texture pattern on the surface of the obtained wood-plastic product is vivid, the surface is smooth and clean, and a paint film of the obtained product is higher in hardness (capable of reaching 6H or more than 6H) and wear resistance (the wear value g / 100r is less than or equal to 0.01).

Owner:GUILIN SHUKANG BUILDING MATERIAL

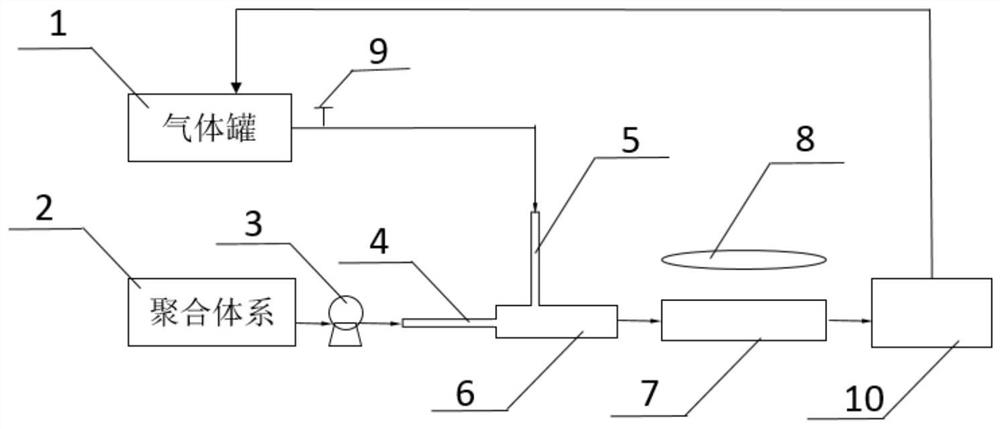

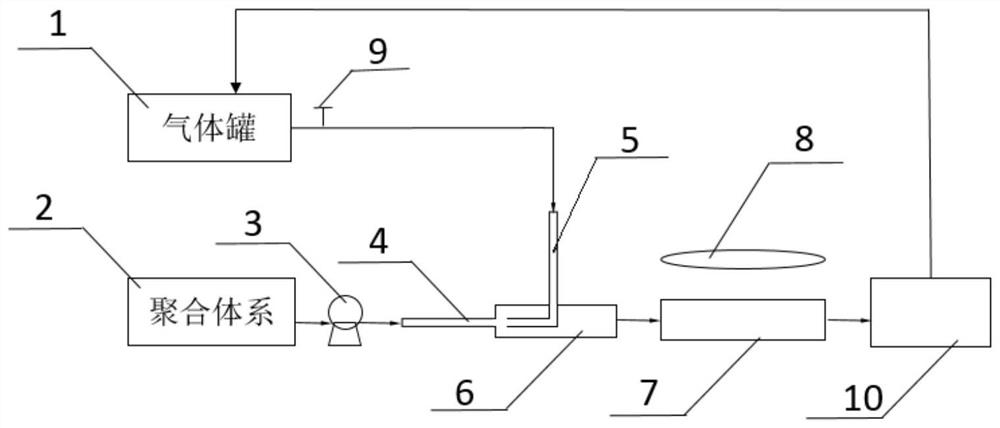

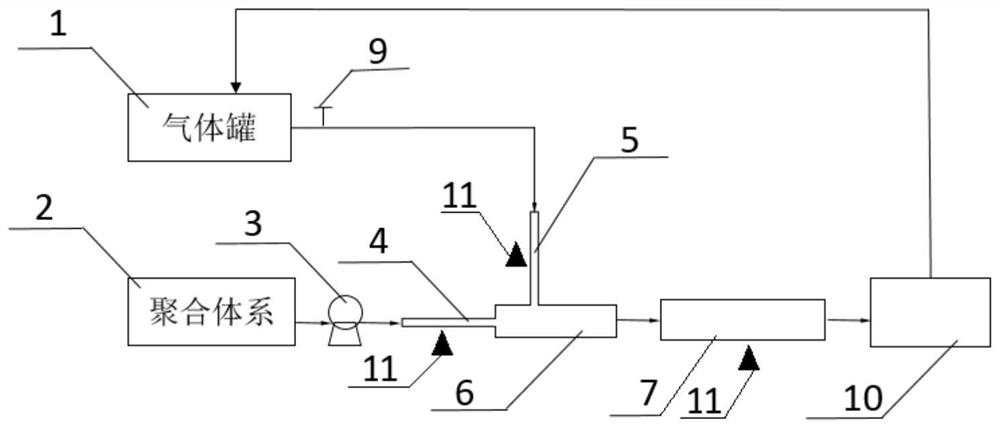

Solvent-free preparation method of polymer microspheres

PendingCN113941301AParticle size controllableAvoid wall stickingChemical/physical/physico-chemical microreactorsMicroballoon preparationPolymer scienceMicrosphere

The invention relates to a solvent-free preparation method of polymer microspheres. The method comprises the following step of: uniformly dispersing a continuously introduced solvent-free polymerization system in a container under the impact or cutting of continuously input gas, and at the same time, under the flow of the gas, and driving the dispersed polymerization system to enter a micro-channel reactor to carry out polymerization reaction so as to prepare the polymer microspheres. The method provided by the invention can realize solvent-free preparation of the polymer microspheres; the prepared microspheres are colorless and transparent, smooth and clean in surface, uniform in particle size; and the method is free of post-treatment and suitable for preparation of most polymer microspheres. According to the method, the wall sticking phenomenon of the polymerization system is avoided, and the polymer microspheres are prepared through rapid polymerization by means of photopolymerization or thermal polymerization.

Owner:南京极速优源感光材料研究院有限公司

Method for producing meta-aramid fiber paper-based material

ActiveUS10011951B2Increases the whiteness and the aging resistanceImprove the stability of actionFlame-proof filament manufactureSpecial paperPaper basedAramides

A method for producing a meta-aramid fiber paper-based material includes steps of: adding functional powders into a first poly(m-phenylene isophthalamide) solution, and obtaining a homogeneous mixed solution; through a dry spinning method, obtaining meta-aramid chopped fibers; through a second poly(m-phenylene isophthalamide) solution, obtaining meta-aramid fibrids; processing the fibrids with a multi-stage classification, selecting the fibrids having an appropriate mesh number and combining in proportion; mixing the chopped fibers and the fibrids, and relieving until uniform; forming a paper through an ultralow concentration inclined wire forming machine with an ultrasonic process and a wet-papermaking process; after squeezing and drying, obtaining a meta-aramid fiber base paper, and then processing with surface coating; and, after multi-stage calendering, rewinding and slitting, obtaining the high-performance meta-aramid fiber paper-based material. The paper-based material has a thickness of 1.5-30 mil, a high whiteness, a smooth and even surface, excellent characteristics, and a good performance stability.

Owner:YANTAI METASTAR SPECIAL PAPER

A kind of manufacturing method of special structure cellulose paper

ActiveCN109137625BChange courseReduce tar contentChemical/chemomechanical pulpDamping devicesCelluloseFiber

The invention discloses a manufacturing method of specially structured cellulose paper. The manufacturing method specifically includes: weighting certain amounts of bleaching sulfate wood pulp, cottonpulp and chemical fiber; disintegrating the bleaching sulfate wood pulp, the cotton pulp and the chemical fiber, and beating the bleaching sulfate wood pulp, the cotton pulp and the chemical fiber respectively; putting the beaten bleaching sulfate wood pulp, cotton pulp and chemical fiber into blending bins, blending, adding auxiliary chemicals, and mixing uniformly to obtain mixed pulp; subjecting the mixed pulp to shaping by a wet papermaking method through an inclined wire former, forming specially structured paper surfaces, subjecting the specially structured paper to humidifying treatment, and cutting to obtain finished products; adopting an ultrasonic atomizing humidifier to humidify the paper before cutting. The manufacturing method of the specially structured cellulose paper has the advantages that specific surface areas of the specially structured cellulose paper are enlarged by specially-embossed grooves, travelling paths of smoke in groove filter sticks are changed, inertial collision and diffused deposition of smoke particulate matters in the groove filter sticks are improved, good smoke particulate matter filtering effect is realized, and tar content in cigarette smoke can be reduced effectively.

Owner:WELBON SPECIAL MATERIALS CO LTD

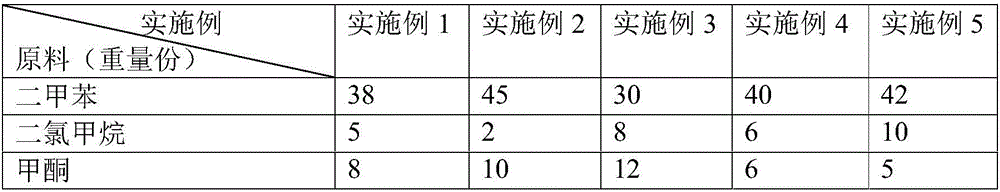

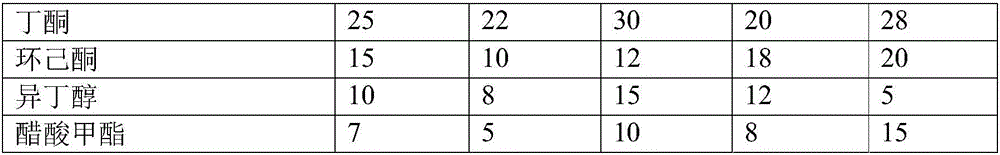

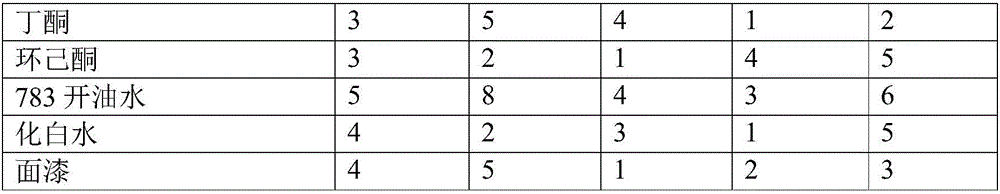

Special active solvent for producing grains on surface of PP (Polypropylene) wood plastic product

The invention discloses a special active solvent for producing grains on the surface of a PP (Polypropylene) wood plastic product. The special active solvent is prepared from the following raw materials in weight proportion: 30 to 45g of dimethylbenzene, 2 to 10g of dichloromethane, 5 to 12g of ketone, 20 to 30g of butanone, 10 to 20g of cyclohexanone, 5 to 15g of isobutanol and 5 to 15g of methyl acetate. Compared with the prior art, the invention provides the special active solvent for specially producing the grains on the surface of the PP wood plastic product; when the active solvent is combined with a hydraulic fracturing attaching process, patterns on a printed film are clear and are firmly attached to the surface of a wood plastic product blank, and an adhesive force reaches 0 grade; the obtained grains on the surface of the wood plastic product are realistic in effect, and are smooth and clean in surface; in addition, a film of the obtained product is higher in hardness (can reach 6H or higher) and is better in wear resistance (a wear value g / 100r is smaller than or equal to 0.01).

Owner:GUILIN SHUKANG BUILDING MATERIAL

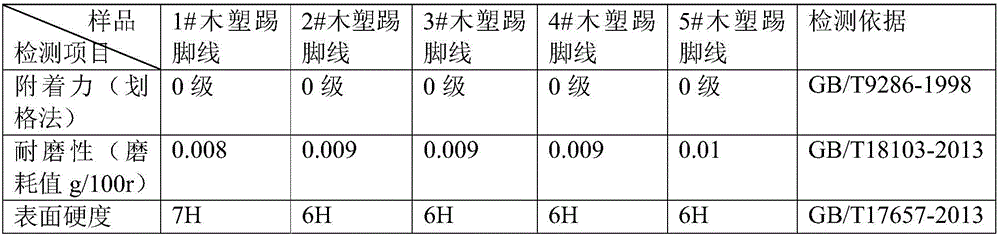

Dedicated active solvent for forming surface texture of PVC wood-plastic product

The invention discloses a dedicated active solvent for forming the surface texture of a PVC wood-plastic product. The dedicated active solvent is prepared from, by weight, 10-20 parts of xylene, 10-20 parts of lacquer thinner, 5-10 parts of acetone, 1-5 parts of butanone, 1-5 parts of cyclohexanone, 3-8 parts of isophorone, 1-5 parts of haze remover and 1-5 parts of finishing coat. Compared with the prior art, the dedicated active solvent has the advantages that when the dedicated active solvent is combined with the hydraulic pressure method adhering process, patterns on a printing membrane can be clear and firmly attached to the surface of a wood-plastic product blank, adhesive force reaches grade 0, texture patterns on the surface of the obtained wood-plastic product look real, the surface is smooth and clean, the paint film hardness of the product is higher and can be 6 H or more, and wear resistance is higher (wear value g / 100 r<=0.01).

Owner:GUILIN SHUKANG BUILDING MATERIAL

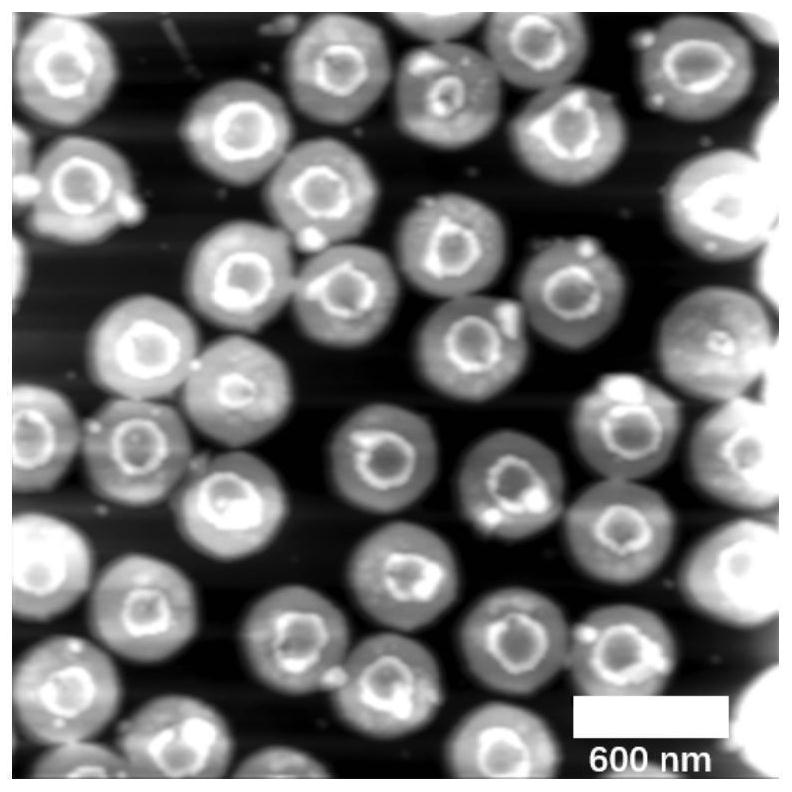

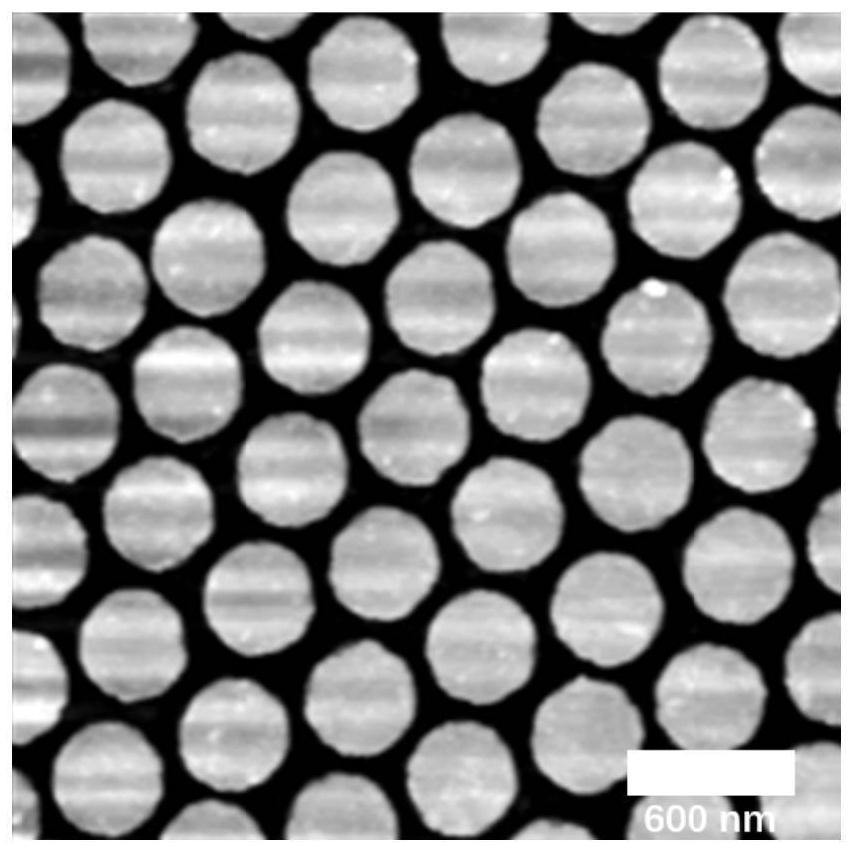

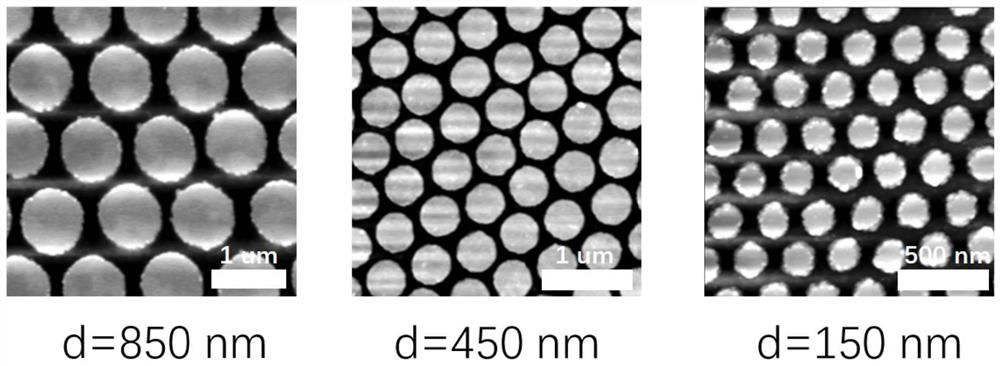

Preparation method of high-quality metal nanodot array

PendingCN114411105AEasy to prepareSmooth and clean surfaceVacuum evaporation coatingSputtering coatingNanodotEtching

The invention relates to a preparation method of a high-quality metal nanodot array. The preparation method comprises the following steps: S1, preparing a metal film on a substrate by adopting a magnetron sputtering process; s2, an anti-etching protection layer is prepared on the surface of the metal film prepared in the step S1 through thermal evaporation; and S3, preparing the high-quality metal nanodot array by adopting a polystyrene bead auxiliary ion etching method. Compared with the prior art, the preparation method has the advantages that the metal film is effectively protected by preparing the anti-etching protection layer, direct contact between the metal film and the PS beads is avoided, interface reaction is avoided, damage to the surface of the metal film caused by physical etching is avoided, and the high-quality and high-density ordered nano-dot array structure is prepared; the surface of the nanodot is smooth and clean, impurity residues are avoided, and the center is not sunken.

Owner:SOUTH CHINA NORMAL UNIVERSITY

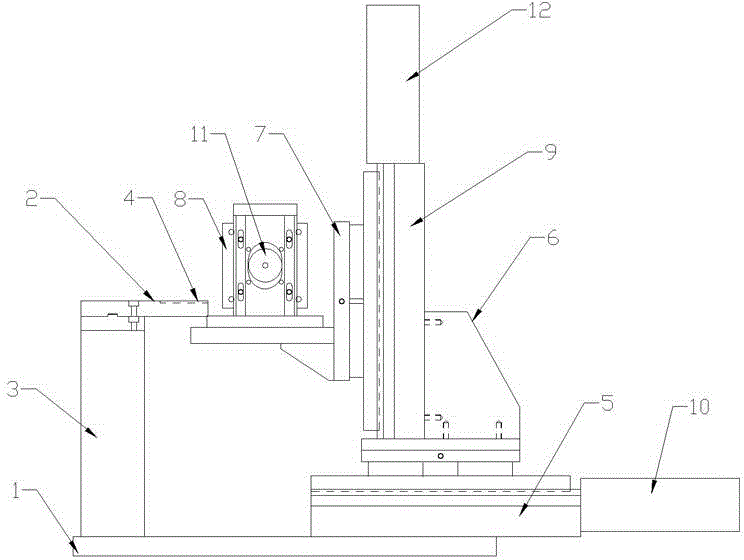

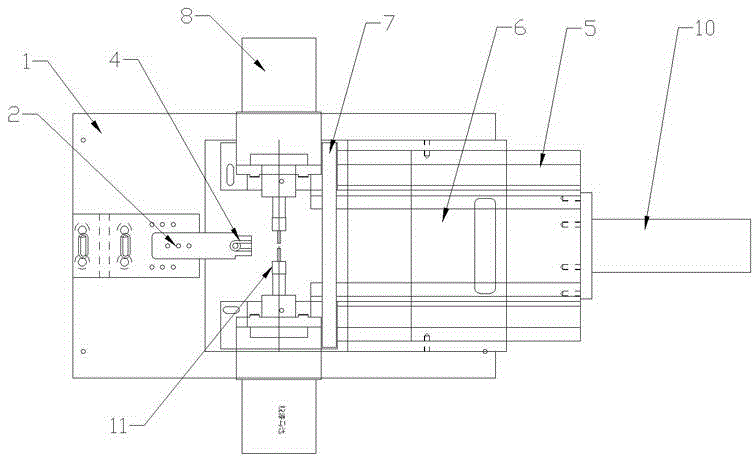

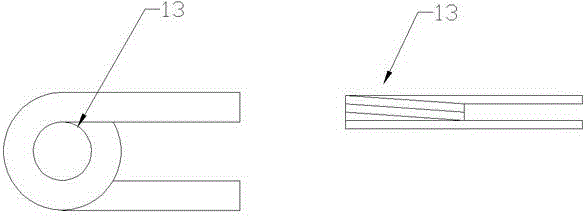

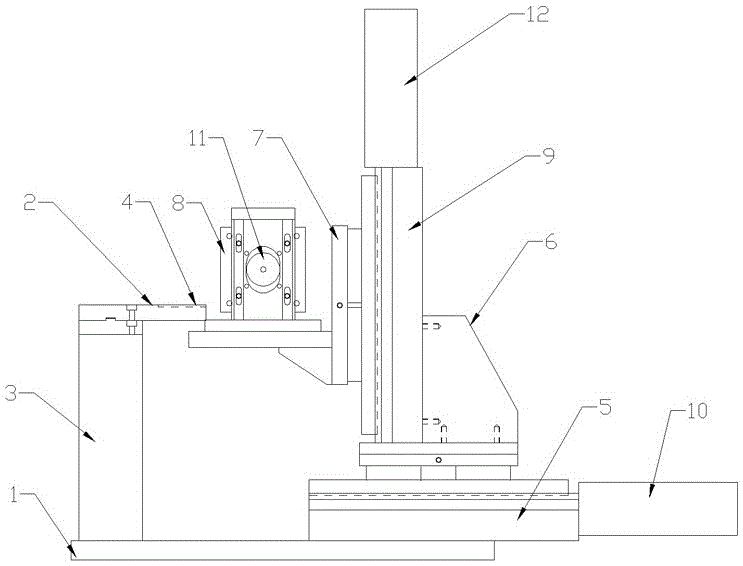

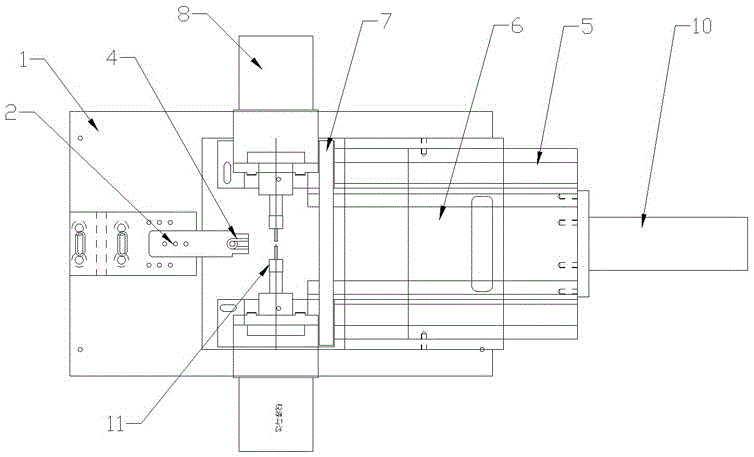

Single-face skiving machine for pin of inductance coil

ActiveCN104526033AHigh degree of automationSmooth and clean surfaceTransformers/inductances coils/windings/connectionsFeeding apparatusVehicle frameMilling cutter

The invention relates to a single-face skiving machine for a pin of an inductance coil, belonging to the technical field of inductance coil production equipment. The single-face skiving machine structurally comprises a base, an inductance coil placement clamping mold, a skiving mechanism and an electrical control system, wherein the inductance coil placement clamping mold is mounted on a side pillar on the left side of the base; the skiving mechanism comprises a machine seat, a big vehicle frame, a small vehicle frame and two milling cutter motors; the machine seat is fixed above the right end of the base; the big vehicle frame is in relative sliding connection with the machine seat through a horizontal sliding rail; two horizontal stretching crossbeams are arranged at the middle lower part of the left side of a vertical plate of the small vehicle frame, each milling cutter motor with a main shaft provided with a milling cutter is arranged above each horizontal stretching crossbeam, and a vertical sliding rail is arranged on the right side of the vertical plate and is in sliding connection with upper and lower chutes of an upright post part of the big vehicle frame. The single-face skiving machine is high in automation degree, smart in structural design, easy to operate and high in working efficiency and can be used for skiving single surfaces of pins of different inductance coils without damaging matrixes of the pins, and the surface is smooth and clean.

Owner:资兴市弘电电子科技有限公司

Inductance Coil Pin Single Side Thinning Machine

ActiveCN104526033BHigh degree of automationSmooth and clean surfaceTransformers/inductances coils/windings/connectionsFeeding apparatusVehicle frameMilling cutter

The invention relates to a single-face skiving machine for a pin of an inductance coil, belonging to the technical field of inductance coil production equipment. The single-face skiving machine structurally comprises a base, an inductance coil placement clamping mold, a skiving mechanism and an electrical control system, wherein the inductance coil placement clamping mold is mounted on a side pillar on the left side of the base; the skiving mechanism comprises a machine seat, a big vehicle frame, a small vehicle frame and two milling cutter motors; the machine seat is fixed above the right end of the base; the big vehicle frame is in relative sliding connection with the machine seat through a horizontal sliding rail; two horizontal stretching crossbeams are arranged at the middle lower part of the left side of a vertical plate of the small vehicle frame, each milling cutter motor with a main shaft provided with a milling cutter is arranged above each horizontal stretching crossbeam, and a vertical sliding rail is arranged on the right side of the vertical plate and is in sliding connection with upper and lower chutes of an upright post part of the big vehicle frame. The single-face skiving machine is high in automation degree, smart in structural design, easy to operate and high in working efficiency and can be used for skiving single surfaces of pins of different inductance coils without damaging matrixes of the pins, and the surface is smooth and clean.

Owner:资兴市弘电电子科技有限公司

Welding molds for welding powder

InactiveCN106078014BAvoid enteringPrevent overflowWelding/cutting auxillary devicesAuxillary welding devicesSlagEngineering

The invention provides a welding die for welding powder. The welding die comprises a die body and a die cover, the die cover detachably covers the die body, the die body is internally provided with a reaction cavity and a welding cavity, the reaction cavity is located above the welding cavity, the bottom of the reaction cavity is communicated with the welding cavity through a drainage trough, and the bottom face of the reaction cavity is provided with a metal spacer for preventing the welding powder in the reaction cavity from falling into the welding cavity before welding. The welding die is characterized in that the inner wall of the reaction cavity is provided with an annular step-level trough capable of retaining welding slag obtained after a reaction in the reaction cavity on the inner wall of the reaction cavity, and the diameter of the annular step-level trough is sequentially increased from bottom to top. The reaction cavity is composed of an upper reaction cavity body and a lower reaction cavity body, the top of the lower reaction cavity body is communicated with the upper reaction cavity body, the bottom of the lower reaction cavity body is communicated with the drainage trough, the annular step-level trough is located on the inner wall of the upper reaction cavity body, and the metal spacer is placed at the communicating position of the upper reaction cavity body and the lower reaction cavity body. The welding die has the advantages that the welding slag can be effectively prevented from entering a welding piece along with the molten welding powder, and welding quality is good.

Owner:宁波高新区远创科技有限公司

Active solvent for surface grain forming technology of wood products

The invention discloses an active solvent for a surface grain forming technology of wood products, which is prepared by the following raw materials according to the weight ratio: 4-10% of dichloromethane, 10-15% of n-butyl acetate, 12-20% of methyl acetate, 3-8% of methyl isobuthyl ketone, 2-5% of isobutyl alcohol, 2-5% of dioctyl phthalate, 5-10% of cyclohexanone and 2-5% of diethylene glycol butyl ether. Compared with the prior art, patterns on a printed film can be clearly and firmly adhered onto the surface of a wood product blank during using the active solvent and the water pressure method overlying technology, so the prepared wood products have the realistic grain patterns and the smooth and clear surface. The surface hardness is high (4 H); the abrasion resistance is good, and the abrasion value g / 100 r is not greater than 0.01; and the adhesion is strong (grinding method 100 / 100).

Owner:GUILIN SHUKANG BUILDING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com