Method for preparing micro-fluidic/milli-fluidic chip by using detachable template

A technology for dismantling templates and chips, applied in laboratory containers, chemical instruments and methods, laboratory utensils, etc., can solve the problems of prolonging chip preparation cycle, expensive equipment and cost, substrate falling off, etc., to achieve pipeline crossing The effect of large adjustable range of angle, less labor-consuming and adjustable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

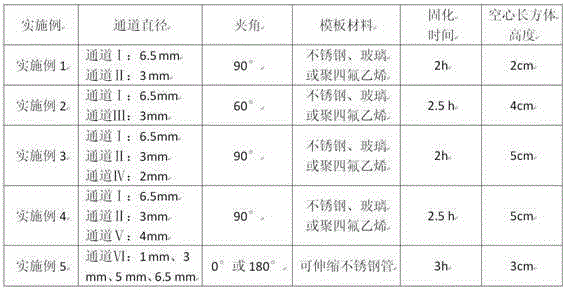

[0041] Example 1 is a T-shaped microchannel chip template made by using the method for preparing a micro / millifluidic chip using a detachable template of the present invention.

[0042] Place the cuboid-shaped glass sheet horizontally on the aluminum foil, fold the aluminum foil up along the sides of the glass sheet to wrap the four sides of the glass sheet, and wrap the glass sheet into a hollow cuboid with an upper opening to form a detachable mold prepolymer body container; pass the smooth surface stainless steel rod Ⅰ through the hollow cuboid along the long side of the hollow cuboid below the horizontal symmetrical centerline to form channel Ⅰ, pass one end of the smooth surface stainless steel rod Ⅱ through the aluminum foil of the hollow cuboid, and the other One end is bonded to the stainless steel rod Ⅰ, the adhesive is 502 glue or AB glue, so that the stainless steel rod Ⅱ and the stainless steel rod Ⅰ form an angle of 90°, the stainless steel rod Ⅱ forms a channel Ⅱ,...

Embodiment 2

[0046] Example 2 is a Y-shaped microchannel chip template made by using the method for preparing a micro / millifluidic chip using a detachable template of the present invention. Embodiment 2 is basically the same as Embodiment 1, the main difference being that the stainless steel rod II and the stainless steel rod I form an included angle of 60°, and the stainless steel rod II forms the channel III to form a Y-shaped channel template.

[0047] The specific parameters are shown in Table 1.

Embodiment 3

[0049] Example 3 is a cross-shaped microchannel chip template made by using the method for preparing a micro / millifluidic chip using a detachable template of the present invention. Embodiment 3 is basically the same as Embodiment 1. The main difference is that a stainless steel rod III symmetrical to the stainless steel rod II is added, and the stainless steel rod III forms an angle of 90° with the stainless steel rod I, and the stainless steel rod III forms a channel IV. Cross-shaped channel template.

[0050] The specific parameters are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com