Active solvent for surface grain forming technology of wood products

A technology for wood-plastic products and active solvents, applied in the field of active solvents, can solve the problems that the pattern cannot be clearly and firmly attached, the pattern is deformed, and bubbles are easily generated, and achieves strong adhesion, realistic pattern effect, and wear resistance. Good results

Inactive Publication Date: 2013-11-13

GUILIN SHUKANG BUILDING MATERIAL

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The applicant found that the above process can also be used to coat patterns on the surface of wood-plastic composite products, and it is especially suitable for coating patterns on the surface of wood-plastic special-shaped products with uneven, complex curved surfaces, and dead angles. However, the applicant found that directly When the above-mentioned active solvent is used in the process of forming the surface texture of the wood-plastic product blank, the pattern on the printing film cannot be clearly and firmly attached to the wood-plastic composite product.

According to the applicant's analysis, the above phenomenon may be due to the fact that the internal structural pores of wood-plastic composite materials are larger than those of pure thermoplastic resin imitation wood materials, and the surface is smoother, and there are still some residual compounds on the surface of the filling powder. The reason why air bubbles are easy to be generated during the process, especially when dealing with PE and PP wood-plastic composite products, it is more likely to cause deformation and distortion of the texture pattern

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

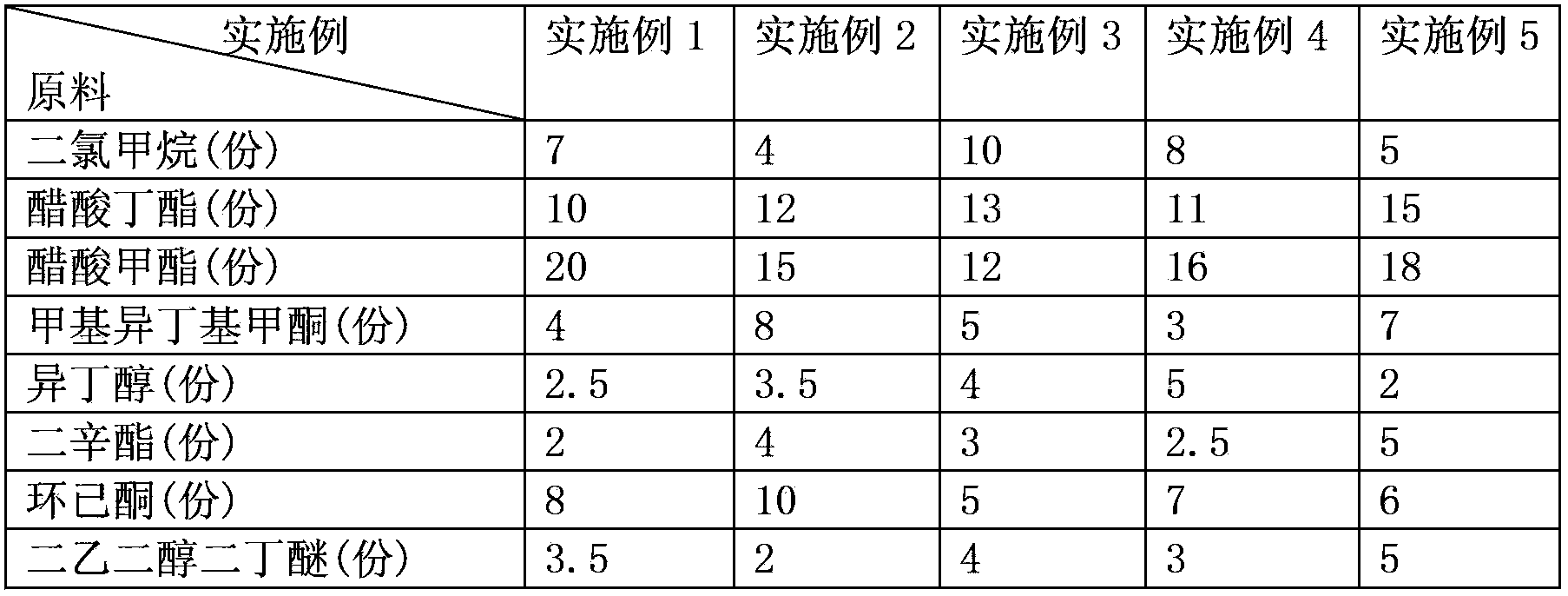

Embodiment 1

[0019] Weigh each raw material according to Table 1 below, mix evenly, and let stand for 30 minutes before use.

Embodiment 2

[0021] Weigh each raw material according to Table 1 below, mix evenly, and let stand for 30 minutes before use.

Embodiment 3

[0023] Weigh each raw material according to Table 1 below, mix evenly, and let stand for 30 minutes before use.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an active solvent for a surface grain forming technology of wood products, which is prepared by the following raw materials according to the weight ratio: 4-10% of dichloromethane, 10-15% of n-butyl acetate, 12-20% of methyl acetate, 3-8% of methyl isobuthyl ketone, 2-5% of isobutyl alcohol, 2-5% of dioctyl phthalate, 5-10% of cyclohexanone and 2-5% of diethylene glycol butyl ether. Compared with the prior art, patterns on a printed film can be clearly and firmly adhered onto the surface of a wood product blank during using the active solvent and the water pressure method overlying technology, so the prepared wood products have the realistic grain patterns and the smooth and clear surface. The surface hardness is high (4 H); the abrasion resistance is good, and the abrasion value g / 100 r is not greater than 0.01; and the adhesion is strong (grinding method 100 / 100).

Description

technical field [0001] The invention relates to wood-plastic composite material products, in particular to an active solvent used in the process of forming surface textures of wood-plastic products. Background technique [0002] At present, the surface texture treatment processes of wood-plastic composite products on the market mainly include: one-time direct extrusion texture, printing, high (heat) low temperature transfer printing, stickers, skinning, laminating, hand-painting, spraying and other processes, but these processes There are some deficiencies, among them: one-time direct extrusion of the texture is easy to distort the texture, and the color difference is serious, and it is easy to fade; the texture is relatively simple during printing processing, the operation process is complicated and the initial investment is large; Deformation of wood-plastic products, and because of the smooth surface of wood-plastic products, it is difficult to heat transfer, and the effe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08J7/00

Inventor 严秀芹陆绍荣徐觉明黄斌罗崇禧郭栋卢李勤谢超田卓文

Owner GUILIN SHUKANG BUILDING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com