Preparation method for medium-free printing air bubble film

A bubble film, medium-free technology, used in general parts of printing machinery, printing, printing machines, etc., can solve the problems of large amount of materials, waste of resources, and high production input costs, and achieve simple production technology, resource saving, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

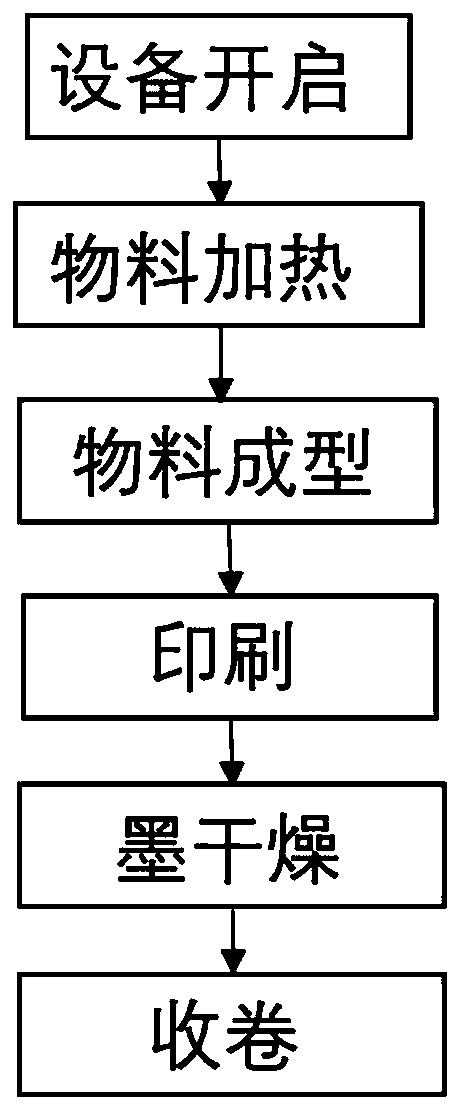

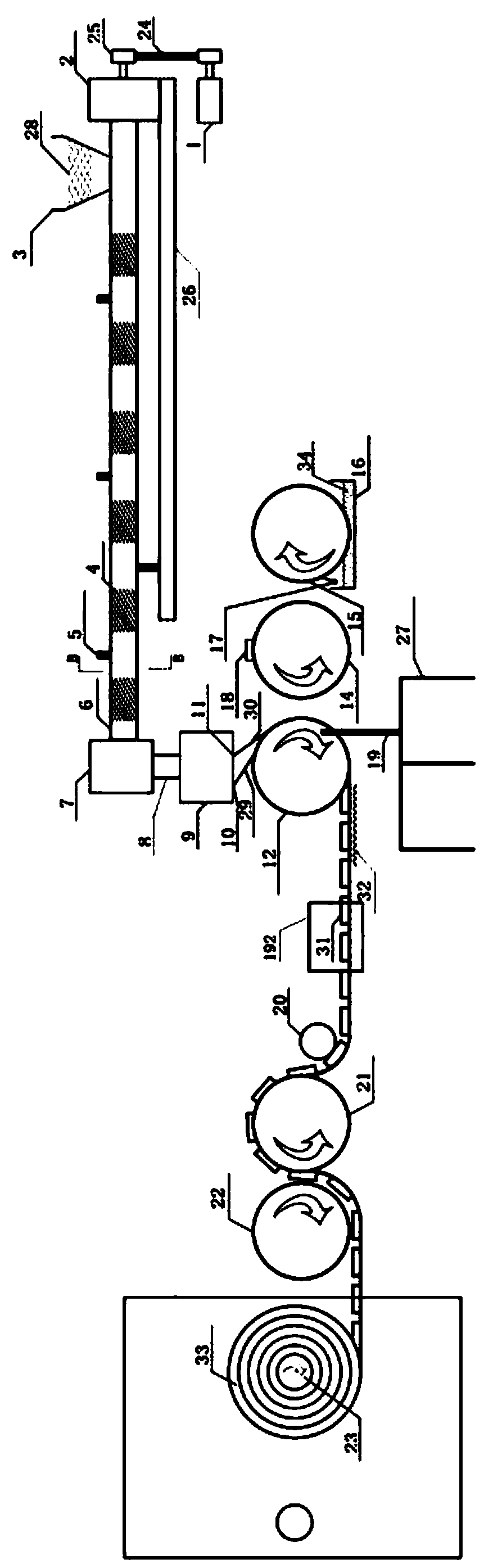

[0025] The preparation method of the non-media printing air bubble film involved in this embodiment is realized in the production equipment of the non-media printing air bubble film. Printing is carried out through the printing device in the process, and the specific production process is as follows:

[0026] (1) Device opening: Pour an appropriate amount of ink 34 into the ink container 16 and turn on the circulation pump 162, temperature controller I 171, ink volume controller 172 and viscosity controller 173, and then place the plastic template 18 engraved with text or pattern information Paste it on the printing roller 14, and then turn on the temperature control device to heat the barrel 6, filter 7, connecting pipe 8 and die head 9. The barrel 6 is heated in three stages, and the direction from the barrel 6 to the filter 7 is sequentially 1 stage, 2 stages, 3 stages, the temperature of stage 1 is 140-170 degrees, the temperature of stage 2 is 150-190 degrees, the tempera...

Embodiment 2

[0041] This embodiment relates to the specific preparation method of using polyethylene and water-based ink for non-medium printing bubble film, and the specific production process is as follows:

[0042] (1) Opening of the device: Pour an appropriate amount of water-based ink into the ink container 16 and turn on the circulation pump 162, temperature controller I 171, ink volume controller 172 and viscosity controller 173, and then place the plastic template 18 engraved with text or pattern information Paste it on the printing roller 14, and then turn on the temperature control device to heat the barrel 6, filter 7, connecting pipe 8 and die head 9. The barrel 6 is heated in three stages, and the direction from the barrel 6 to the filter 7 is sequentially 1 stage, 2 stages, 3 stages, the temperature of stage 1 is 140-170 degrees, the temperature of stage 2 is 150-190 degrees, the temperature of stage 3 is 210-230 degrees, the temperature of filter 7 is 220-230 degrees, The te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com