Method and equipment for cleaning oxide skin on outer surface of copper pipe

A cleaning method and oxide skin technology, which is applied in the direction of workpiece surface treatment equipment, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems that are not suitable for large-scale manufacturing of copper pipes, and achieve small size deviation, less waste, and Good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

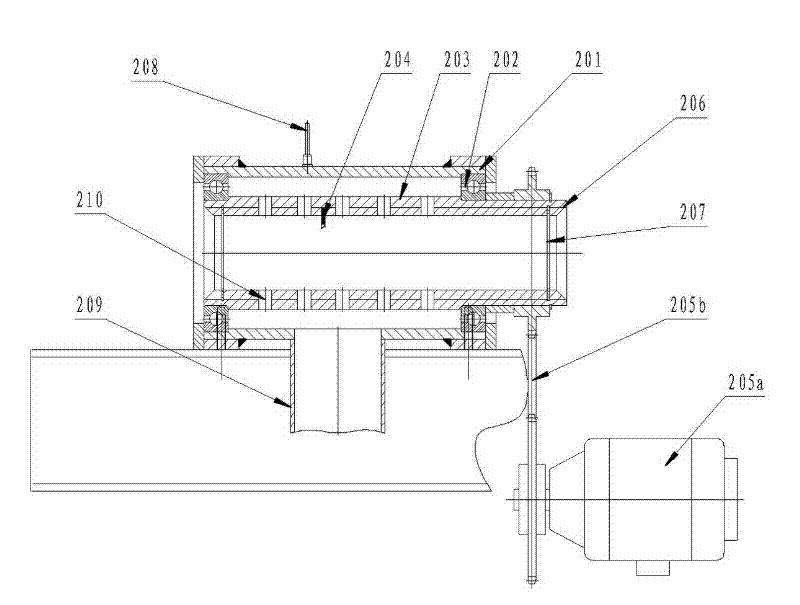

[0063] In this embodiment, the outer diameter of the copper pipe to be cleaned is 92mm.

[0064] For above-mentioned copper tube, in order to reach best cleaning effect, the design of cleaning equipment in the present embodiment is as follows:

[0065] The length of the first spring spiral brush in the rough brush device is 400 mm, the pitch of the first spring spiral brush is 25 mm, the diameter of the brush filament is 0.5 mm, the length of the brush filament is 23 mm, and the rotation speed is 500 rpm.

[0066] The length of the second spring spiral brush in the middle brush device is 400 mm, the pitch of the second spring spiral brush is 25 mm, the diameter of the brush filament is 0.3 mm, the length of the brush filament is 23 mm, and the rotation speed is 500 rpm; and the second The spacing between the second spring spiral brush and the first spring spiral brush is 450mm.

[0067] The length of the third spring spiral brush in the fine brush device is 400mm, the pitch o...

Embodiment 2

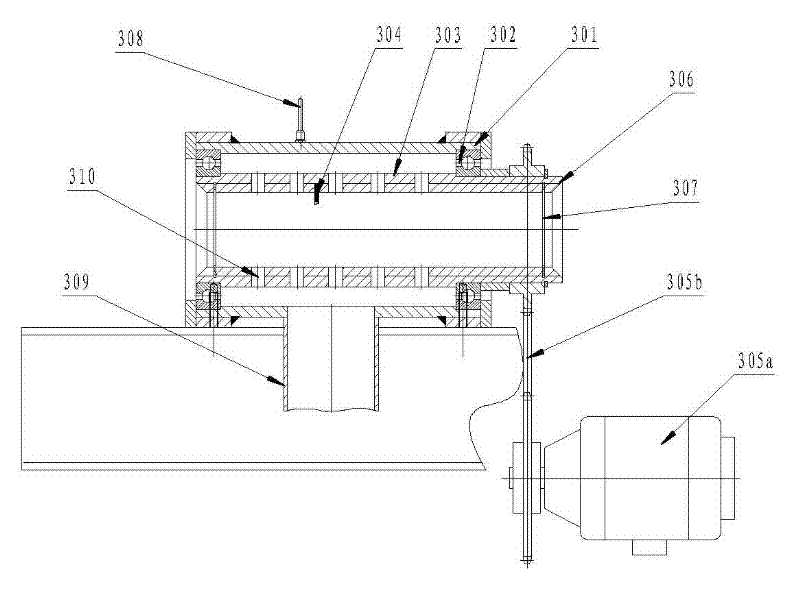

[0074] In this embodiment, the outer diameter of the copper pipe to be cleaned is 100mm.

[0075] For above-mentioned copper tube, in order to reach best cleaning effect, the design of cleaning equipment in the present embodiment is as follows:

[0076] The length of the first spring spiral brush in the rough brush device is 400mm, the pitch of the first spring spiral brush is 25mm, the diameter of the brush filament is 0.5mm, the length of the brush filament is 20mm, and the rotation speed is 500 rpm.

[0077] The length of the second spring spiral brush in the middle brush device is 400mm, the pitch of the second spring spiral brush is 25mm, the diameter of the brush filament is 0.3mm, the length of the brush filament is 20mm, and the rotation speed is 500 rpm; and the second spring The distance between the spiral brush and the first spring spiral brush is 450mm.

[0078] The length of the third spring spiral brush in the fine brush device is 400mm, the pitch of the third s...

Embodiment 3

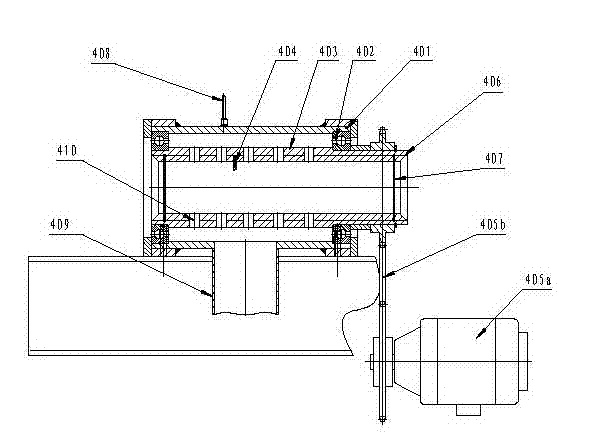

[0085] In this embodiment, the outer diameter of the copper pipe to be cleaned is 86 mm.

[0086] For above-mentioned copper tube, in order to reach best cleaning effect, the design of cleaning equipment in the present embodiment is as follows:

[0087] The length of the first spring spiral brush in the rough brush device is 400mm, the pitch of the first spring spiral brush is 25mm, the diameter of the brush filament is 0.5mm, the length of the brush filament is 25mm, and the rotation speed is 500 rpm.

[0088] The length of the second spring spiral brush in the middle brush device is 400mm, the pitch of the second spring spiral brush is 25mm, the diameter of the brush filament is 0.3mm, the length of the brush filament is 25mm, and the rotation speed is 500 rpm; and the second spring The distance between the spiral brush and the first spring spiral brush is 450mm.

[0089] The length of the third spring spiral brush in the fine brush device is 400mm, the pitch of the third s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com