Preparation method of high-quality metal nanodot array

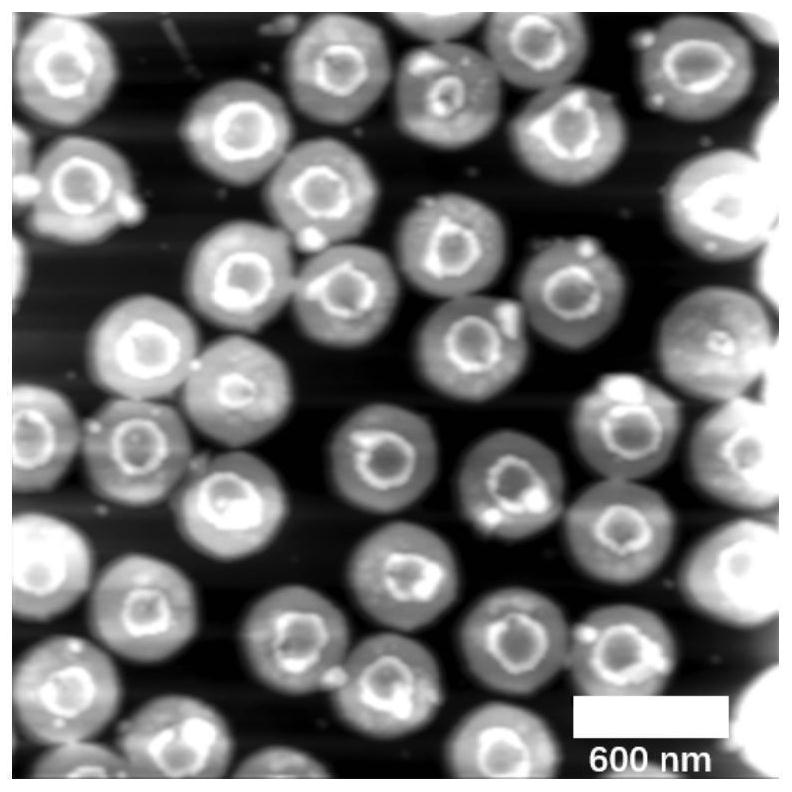

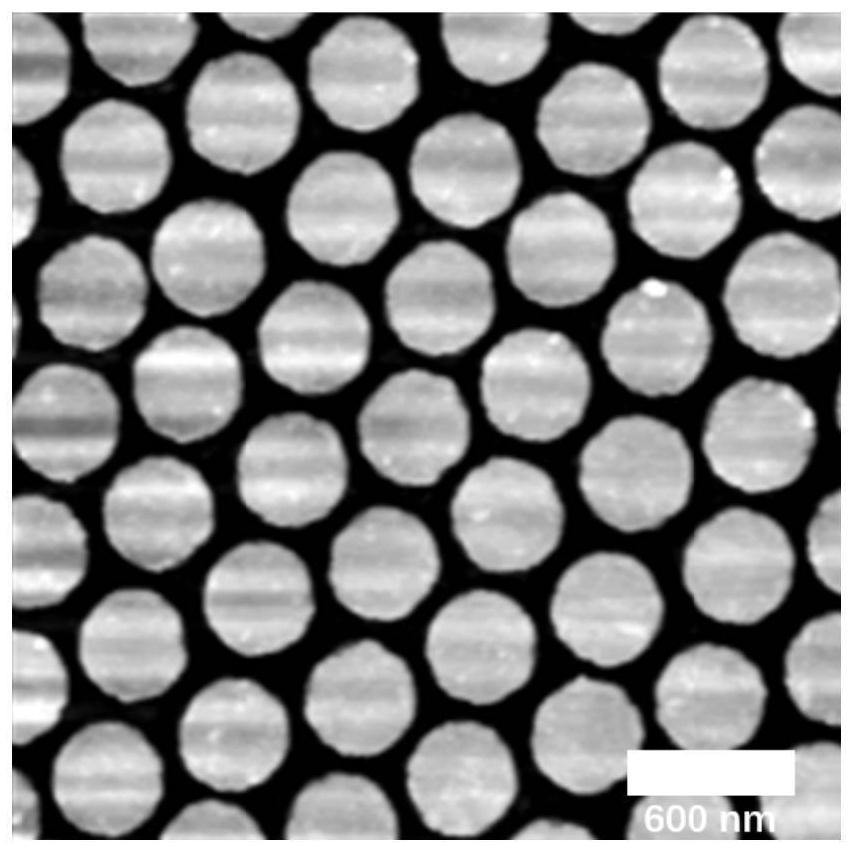

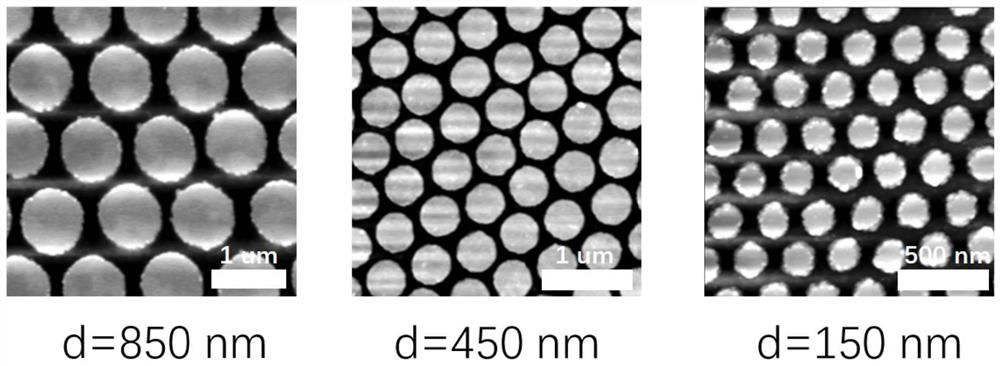

A metal nano-dot array technology, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problem that PS residues are difficult to wash off, the surface of nano-dots is sunken, and it is difficult to obtain ideal and high-quality nano-dots. point array etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a high-quality metal nano-dot array of this embodiment comprises the following steps:

[0033] S1: Preparation of metal cobalt thin film on the substrate by magnetron sputtering process: select Si single crystal substrate in (001) direction, prepare Co thin film on the substrate by magnetron sputtering method, the thickness of the film is 60nm, and then obtain The samples were ultrasonically cleaned with alcohol for 3 min and dried with nitrogen gas. The metal thin film is prepared by magnetron sputtering, which can improve the bonding force between the metal thin film and the substrate, and avoid damage to the nano-dot structure during the ultrasonic cleaning process. The preparation parameters of magnetron sputtering are as follows:

[0034] DC current (mA) temperature(℃) Argon pressure (mTorr) 50 30 4

[0035] S2: Prepare an anti-etching protective layer by thermal evaporation on the surface of the Co film prepared in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com