Solvent-free preparation method of polymer microspheres

A solvent-free, polymer-free technology, applied in the field of solvent-free preparation of polymer microspheres, achieves the effects of simplified preparation process, fast polymerization rate and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

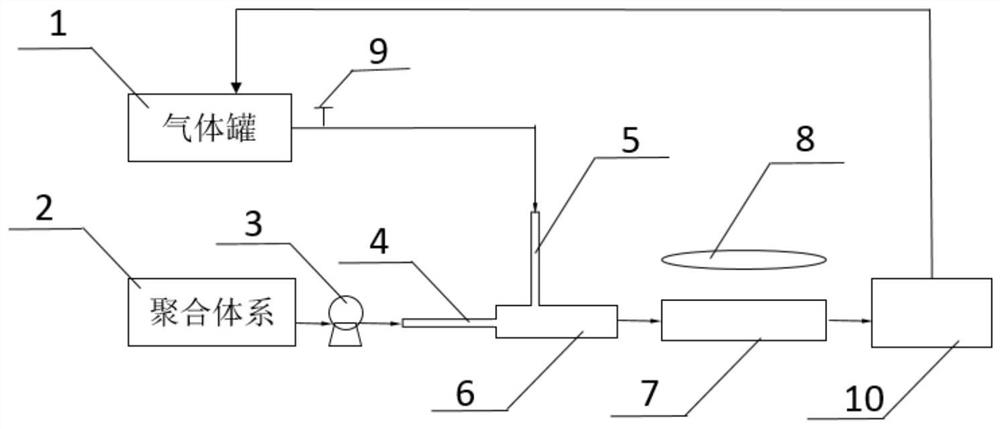

[0044] A solvent-free preparation method of polymer microspheres, using figure 1 The reaction apparatus shown in the polymerization reaction, figure 1 The device shown in is a reaction device using photopolymerization, and the specific structure is:

[0045] Comprising a mixing unit 2, a feed pump 3, a first pipeline 4, a gas input control unit, a second pipeline 5, a dispersion unit 6, a microchannel reactor polymerization unit 7 and a product collection tank 10; the gas input control The unit includes a gas tank 1 and a gas flow control meter 9; the microchannel reactor polymerization unit 7 is a microchannel reactor, and the microchannel reactor adopts a transparent quartz glass pipeline with a photoinitiating source 8 above the microchannel reactor ;

[0046] The mixing unit 2 is connected to the feed pump 3, the feed pump 3 is connected to the dispersing unit 6 through a first pipeline 4, and a gas inlet is also provided on the dispersing unit 6, the The gas inlet is c...

Embodiment 2

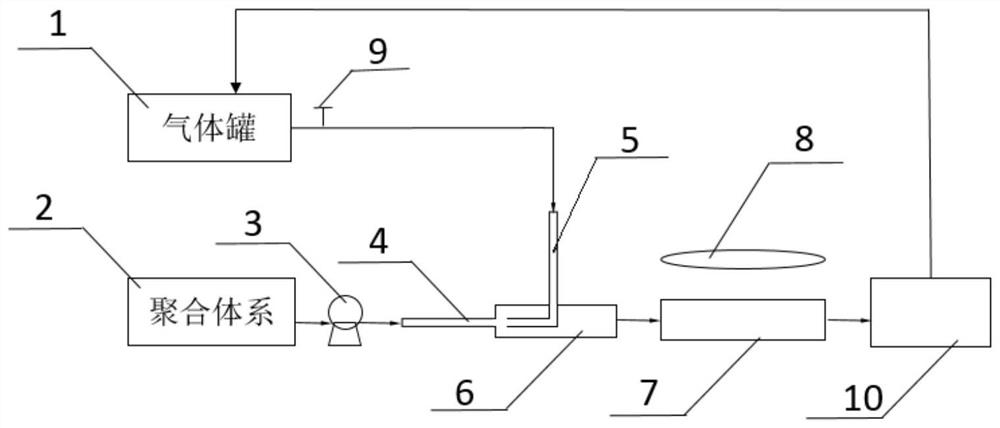

[0053] A solvent-free preparation method of polymer microspheres, using figure 2 The reaction apparatus shown in the polymerization reaction, figure 2 The device shown in is a reaction device using photopolymerization, and the specific structure is the same as that of Example 1, except that the gas in the second pipeline 5 in this embodiment is carried out horizontally with the polymerization system in the dispersion unit 6. Convergence defines that the gas at this time performs impact movement on the polymerization system.

Embodiment 3

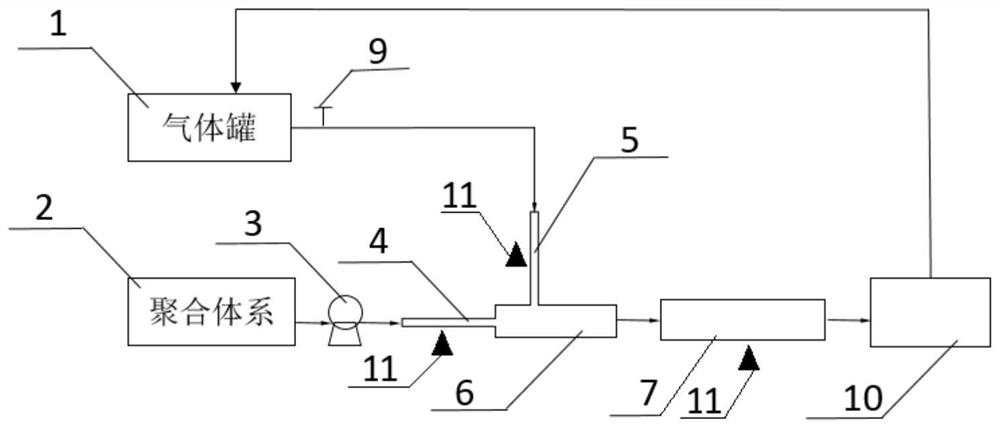

[0055] A solvent-free preparation method of polymer microspheres, using image 3 The reaction apparatus shown in the polymerization reaction, image 3 The device shown in is a reaction device that adopts thermal polymerization. The difference between the specific structure and the device in Example 1 is that the microchannel reactor polymerization unit 7 adopts thermal polymerization, and all pipelines are made of stainless steel. The microchannel reactor The microchannel pipeline in the polymerization unit 7, the first pipeline 4, and the second pipeline 5 are all made of stainless steel, and a temperature control element 11 is arranged outside the pipeline;

[0056] Wherein, the diameter of the microchannel of the polymerization unit 7 of the microchannel reactor is 1-5 mm, and the length is 20-100 m.

[0057] In addition, in some embodiments, the above-mentioned pipe made of stainless steel is also wrapped with an insulating layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com