Silica gel sealing process for liquid silica gel injection mold

A technology of liquid silica gel and sealing process, applied in coating and other directions, can solve the problems of uneven wall thickness of silica gel, unattainable dimensional accuracy of tolerance, poor product adhesion, etc., to achieve uniform wall thickness and improve yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

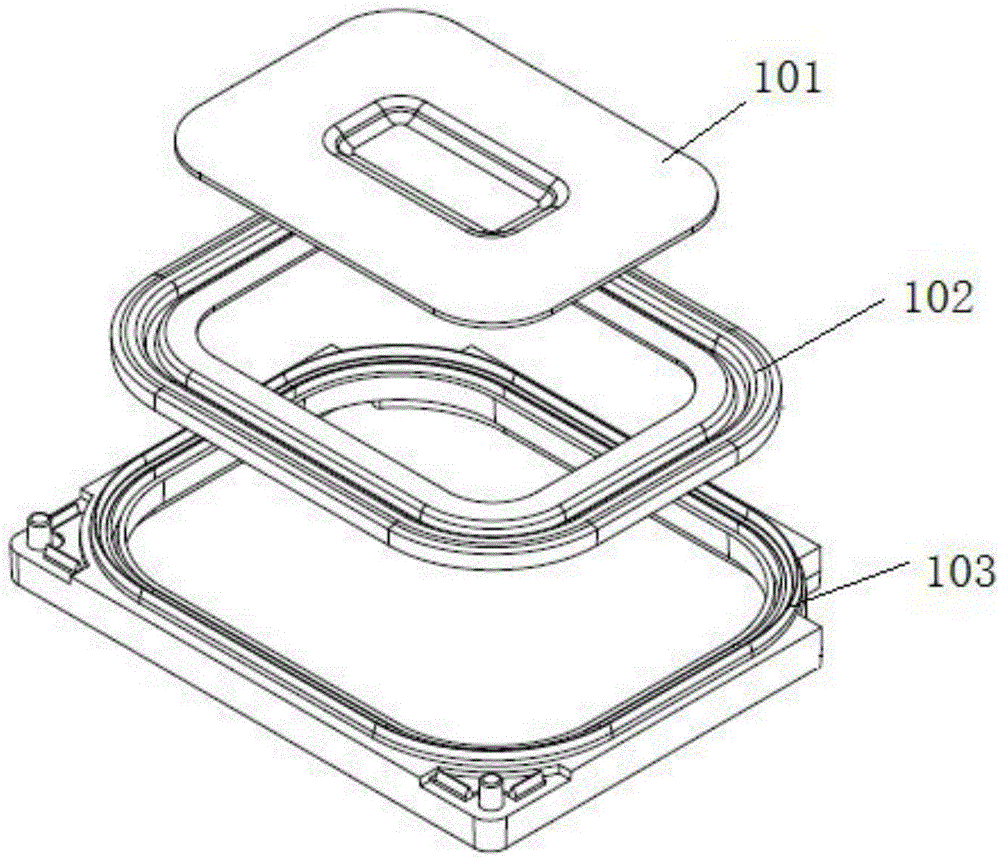

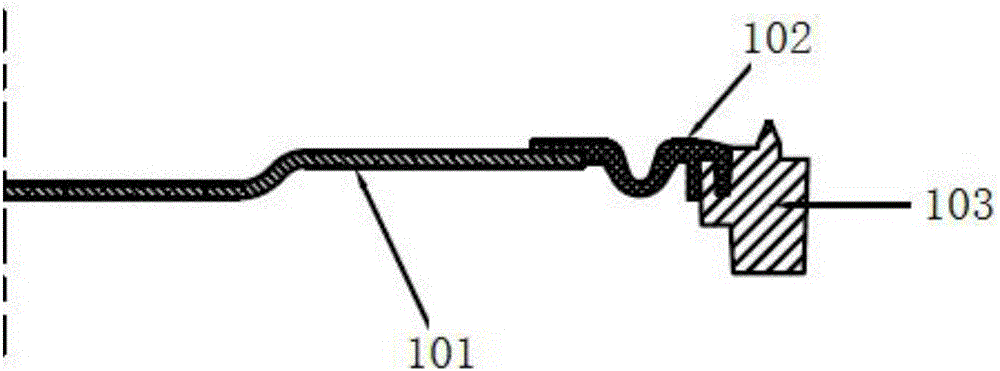

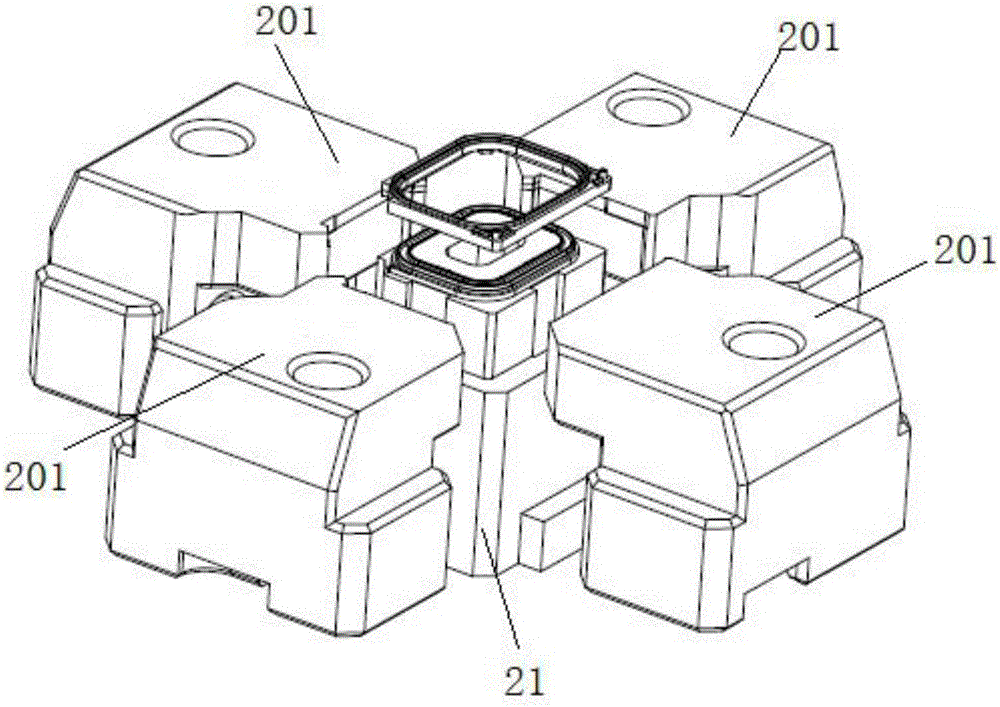

[0032] see Figure 3 to Figure 12 , the liquid silicone injection mold includes a male mold 21 and a female mold 22, the male mold 21 is located below the female mold 22, the inside of the male mold 21 is provided with a plurality of suction grooves 202, and the suction grooves 202 penetrate to the top surface of the male mold 21 , the top of the male mold 21 and the contact surface of the plastic frame 103 are provided with a first rib 203, the bottom of the female mold 22 and the contact surface of the plastic frame 103 are provided with a second rib 204, the first rib 203 and the second rib The cross-sectional shapes of the bits 204 are all triangular. A slider 201 is provided around the male mold 21, and the slider 201 presses the plastic frame 103 from the side.

[0033] Liquid silicone injection mold sealant process, including the following steps:

[0034] Step S1, surface-treating the FPC and the plastic frame;

[0035] Among them, the surface treatment method is pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com