Metal mask for preventing falling of evaporation metal layer and manufacturing method

A technology of metal mask and manufacturing method, which is applied in the field of OLED, can solve the problems of roughness of the entire back surface, and achieve the effects of reducing defect rate, improving bonding force, and preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

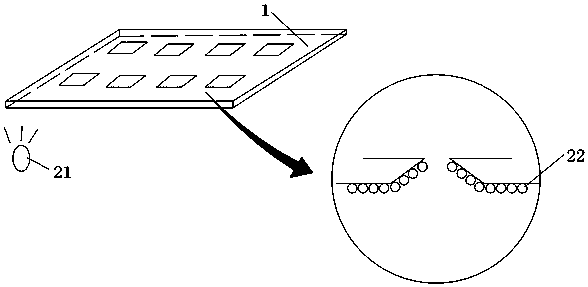

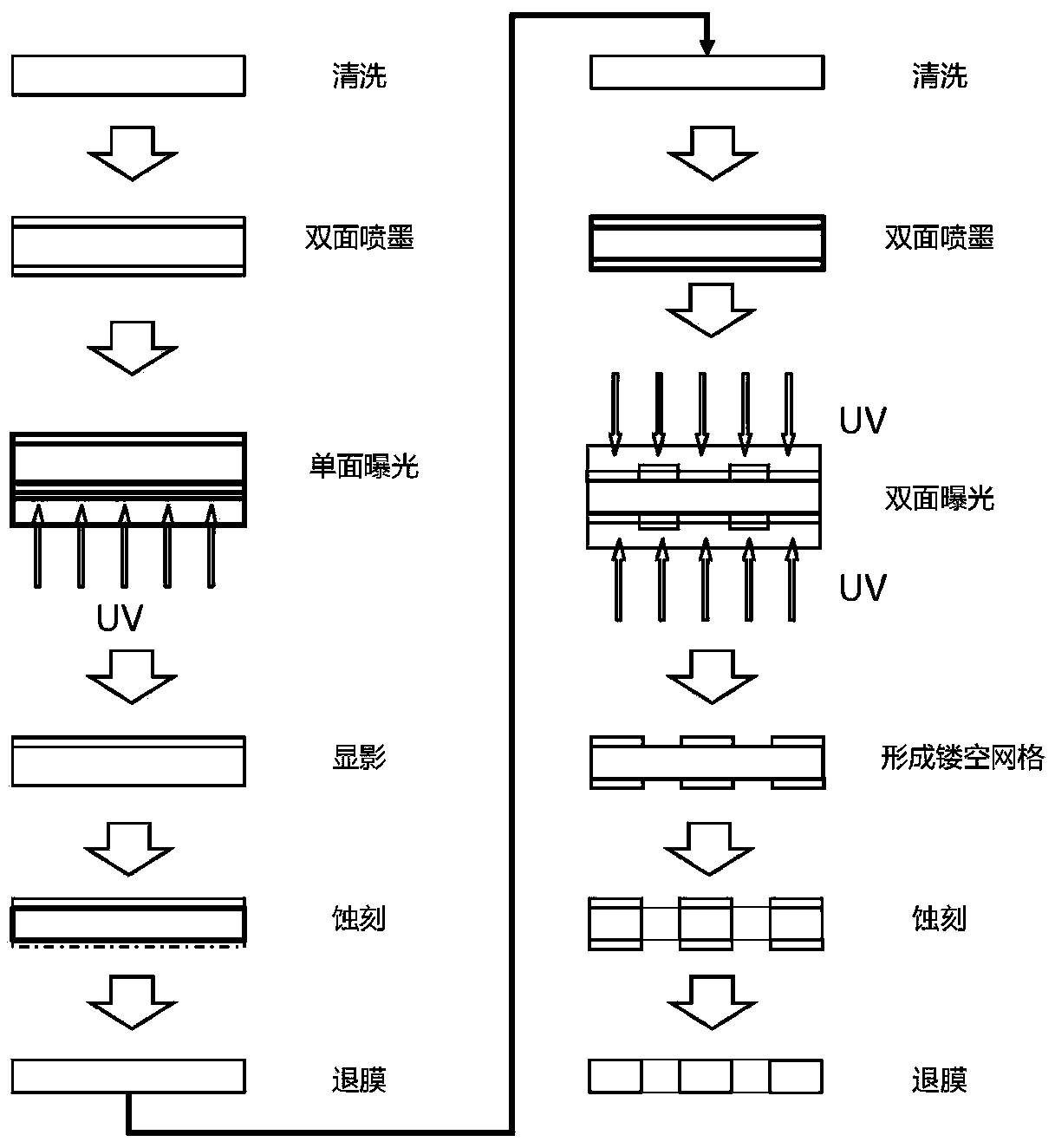

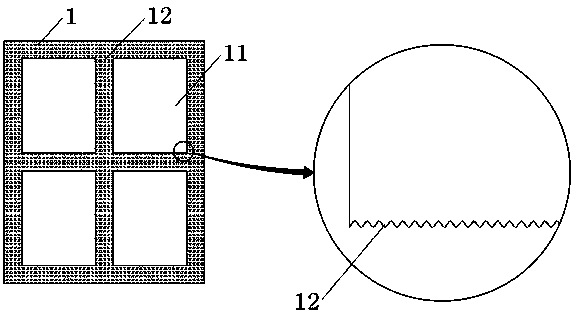

[0017] The process of the method for making a metal mask plate in an embodiment of the present invention to prevent the peeling of the evaporated metal layer is as follows: figure 2 As shown, the production method of this embodiment includes the following steps: (1) Cleaning: Use cleaning equipment to clean the sheet-shaped INVAR alloy material to remove oil stains on the surface of the INVAR alloy; (2) Inkjet: Use inkjet equipment to uniformly separate the ink Spray onto the upper and lower surfaces of the cleaned INVAR alloy, and the ink is dried on the two surfaces of the INVAR alloy to form an ink layer; (3) Single-sided exposure: use an exposure machine to irradiate UV light to the ink layer on one side of the INVAR alloy On the surface, the ink layer on this surface is completely irradiated by UV light to undergo photopolymerization; (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com