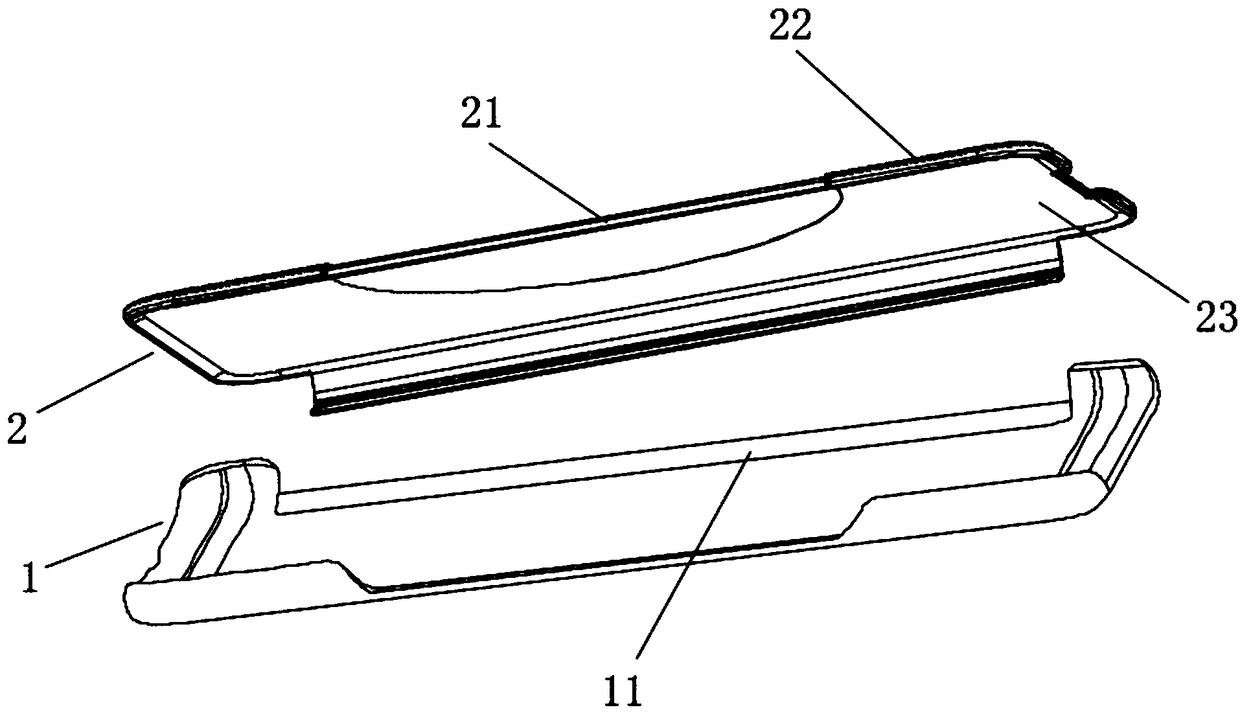

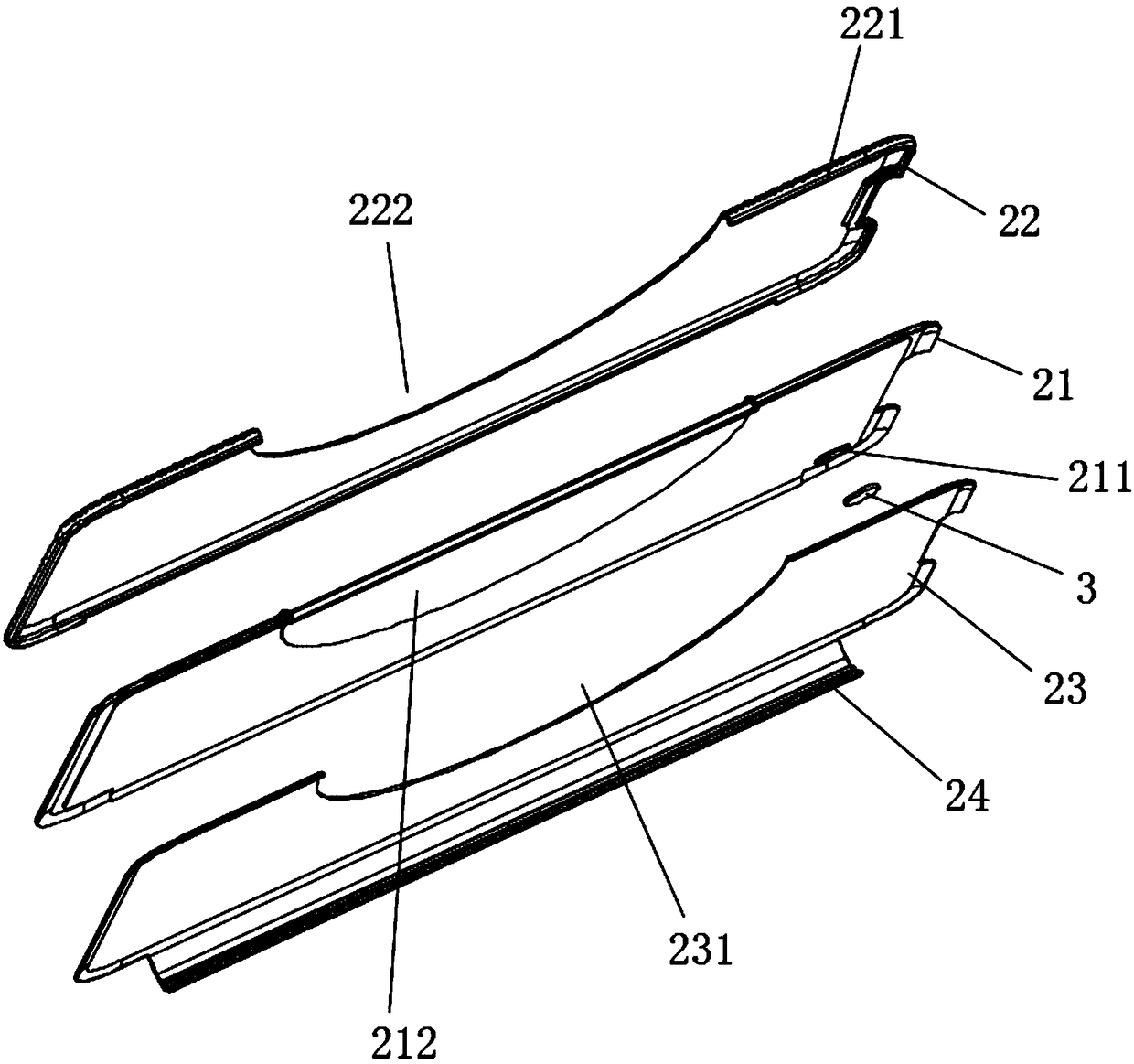

Preparation method and product of CX edgefolded leather sheath

A kind of edge leather and leather cover technology, which is applied to travel goods, other household appliances, clothing, etc., can solve problems such as easy to appear burrs, easy to deform, and uneven seams, and achieve the effect of improving product quality and high flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The present embodiment provides a kind of preparation method of CX hemming holster, comprises the following steps:

[0070] (1) Cutting: cut the PU leather and hot melt adhesive through the knife mold;

[0071] (2) Embossed

[0072] (2.1) Put the clean PU leather flat on the cx embossing mold and align it with the holes;

[0073] (2.2) Press the start button, the temperature of the upper mold is 120°-130°, the temperature of the lower mold is normal temperature, and the pressure is 0.5-0.7Mpa, the pre-pressing time is 1-3s, the pressurization time is 1-3s, and the embossing operation is completed;

[0074] (2.3) Take out the embossed PU leather and check whether it has clear embossing and consistent depth;

[0075] (3) Fabric re-cutting: According to the required shape, re-cut the PU leather material;

[0076] (4) fabric heat press veneer cover

[0077] (4.1) Put the cover into the cx press cover mold first, then put the recut PU leather on the cx press cover mold e...

Embodiment 2

[0113] The preparation method of the CX folded holster provided in this embodiment also includes the following steps between the step (8) and the step (11):

[0114] (9) Fabric recutting

[0115] (9.1) Place the pressed product with the lining facing up on the cx correction die, and the hole position of the product should be hung on the positioning column of the cx correction die;

[0116] (9.2) Press the start button to complete the fabric re-cutting operation;

[0117] (9.3) Take out the product and take out the waste;

[0118] (10) Embossing the lining LOGO: Put the product flat into the prepared positioning, and emboss at a temperature of 175-185° for 0.8-1.5s to complete the embossing of the lining LOGO.

Embodiment 3

[0120] The preparation method of the CX folded holster provided in this embodiment also includes the following steps:

[0121] (12) High cycle pressure shell

[0122] (12.1) Put the finished leather case into the cx shell mold;

[0123] (12.2) After the hand leaves the machine work surface, the right foot presses down the right lift, and the left foot presses the left high switch;

[0124] (12.3) After the high cycle indicator light jumps up, let go of the high cycle switch on the left foot first, the temperature of the upper mold is 120-140°, the high cycle is 7-9s, then slowly put it down, and take out the product;

[0125] (12.4) Put the paper card holder in the product to make the leather case finalize;

[0126] (13) Check the magnetic flux: check the magnetic flux of the holster. The front side of the full-check magnetic flux is above 28 gauss, that is, the magnet is an N pole; the back side of the full-check magnetic flux is below 10 gauss, that is, the magnet is an S ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com