Wood processing machine

A technology for processing machinery and wood, which is applied to wood processing appliances, multi-purpose machinery, manufacturing tools, etc., and can solve the problems that the processing method cannot meet the production needs, the long boards that are decomposed into equal parts, and the long boards are frequently used, etc. To achieve the same length and width, improve work efficiency, buffer cutting force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific figures.

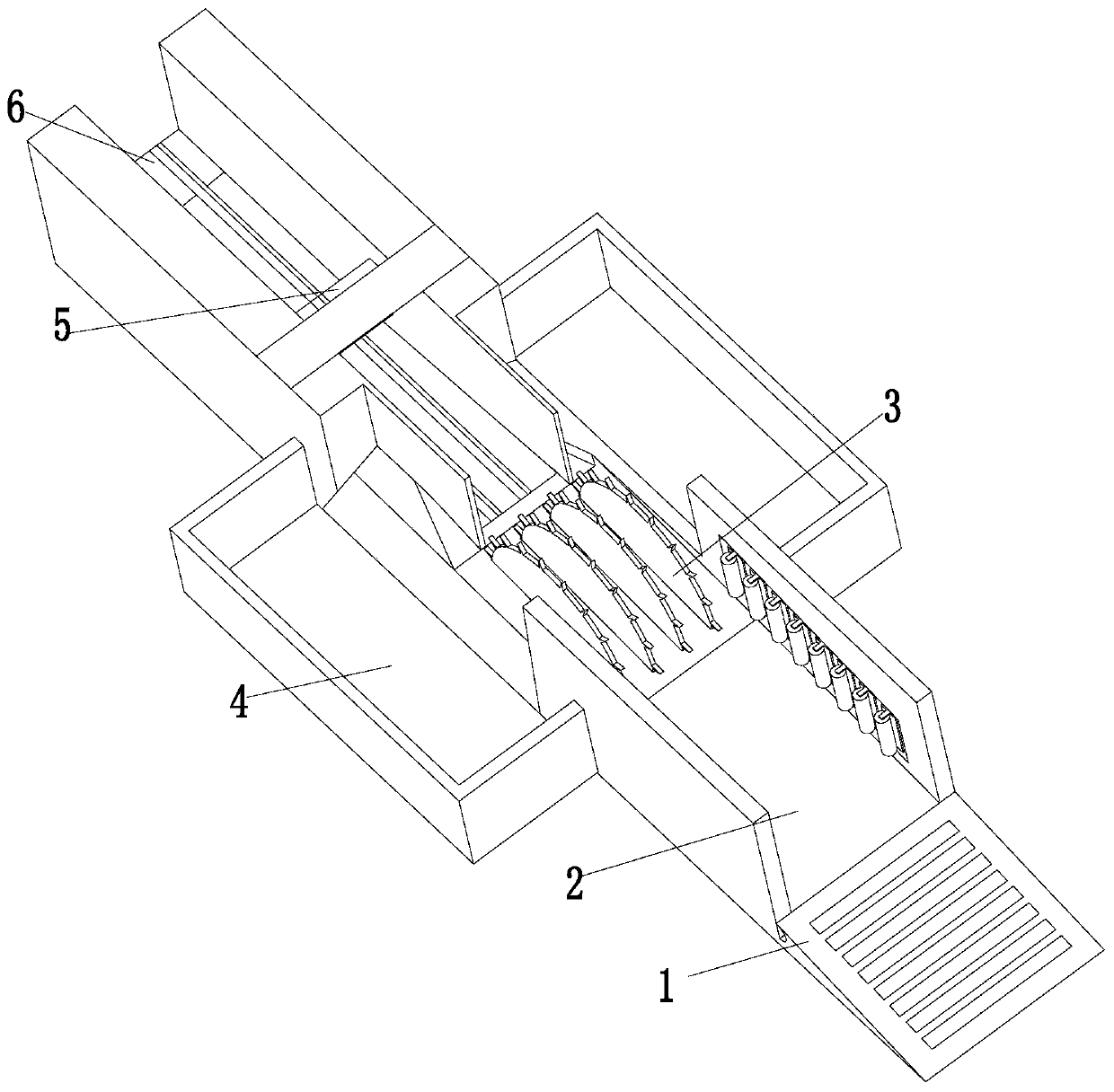

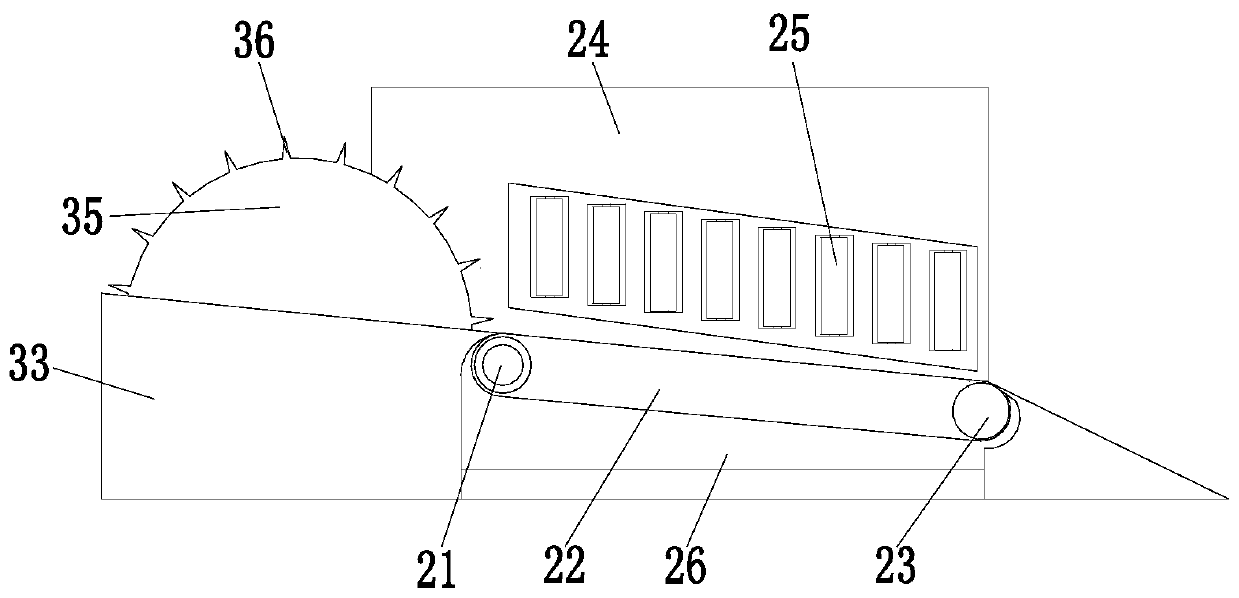

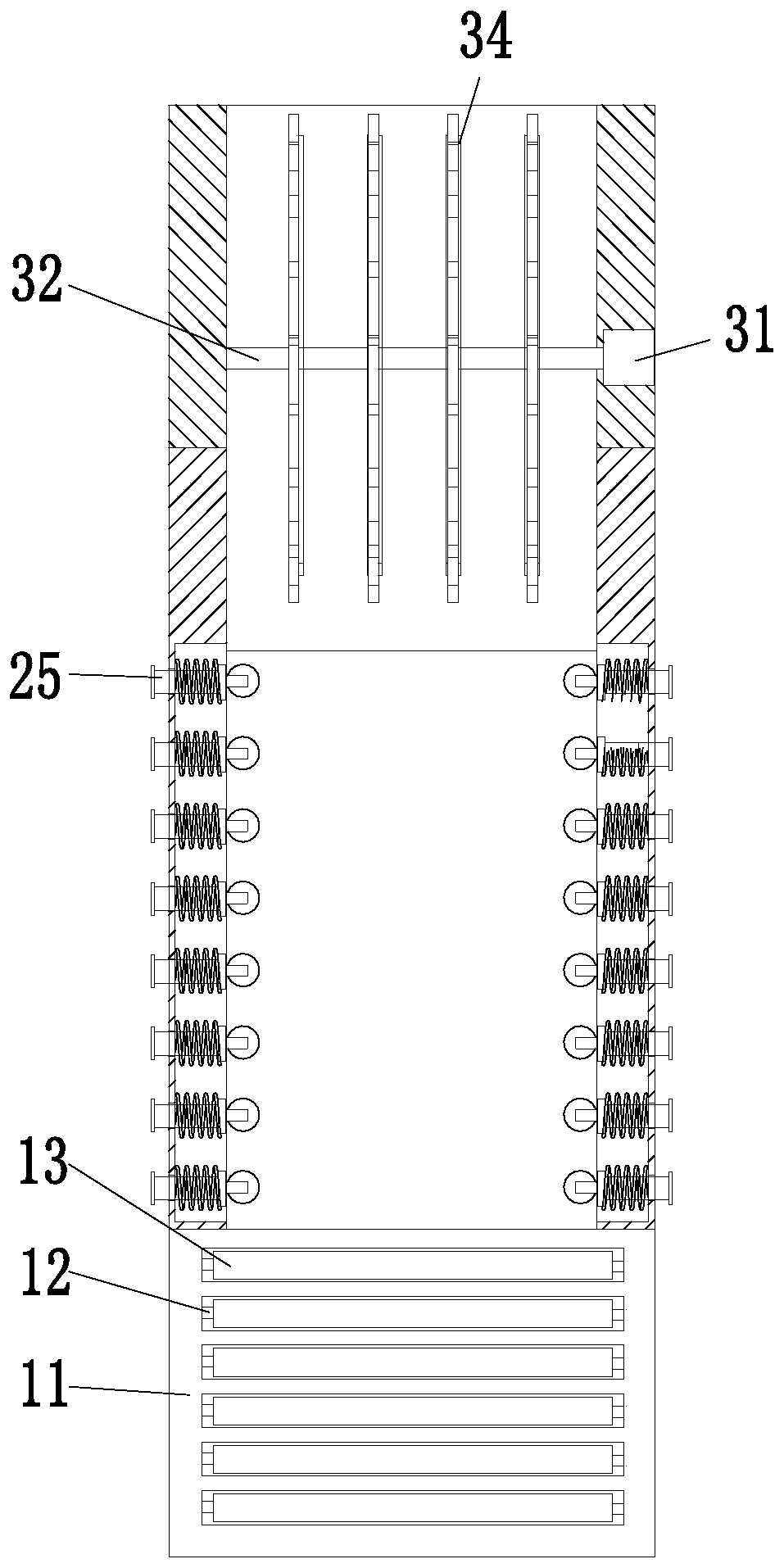

[0026] like Figure 1 to Figure 6 As shown in the figure, a wood processing machine includes a triangular feeder 1, a conveying device 2, a longitudinal sawing device 3, a scrap collection frame 4, a transverse cutting mechanism 5 and a discharge opening 6. The left end of the triangular feeder 1 A conveying device 2 is installed, a longitudinal sawing device 3 is installed at the left end of the conveying device 2, a scrap collecting frame 4 is installed symmetrically at the front and rear ends of the longitudinal sawing device 3, and a transverse cutting mechanism 5 is installed at the left end of the longitudinal sawing device 3. The transverse cutting mechanism 5 The left end is equipped with a feeding port 6; the wood is fed from the triangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com