Efficient stick section cutting machine

A technology of a cutting machine and a wooden stick, which is applied to sawing components, sawing equipment, wood processing appliances, etc., can solve problems such as low cutting efficiency of wooden sticks, and achieve the effect of high processing efficiency and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

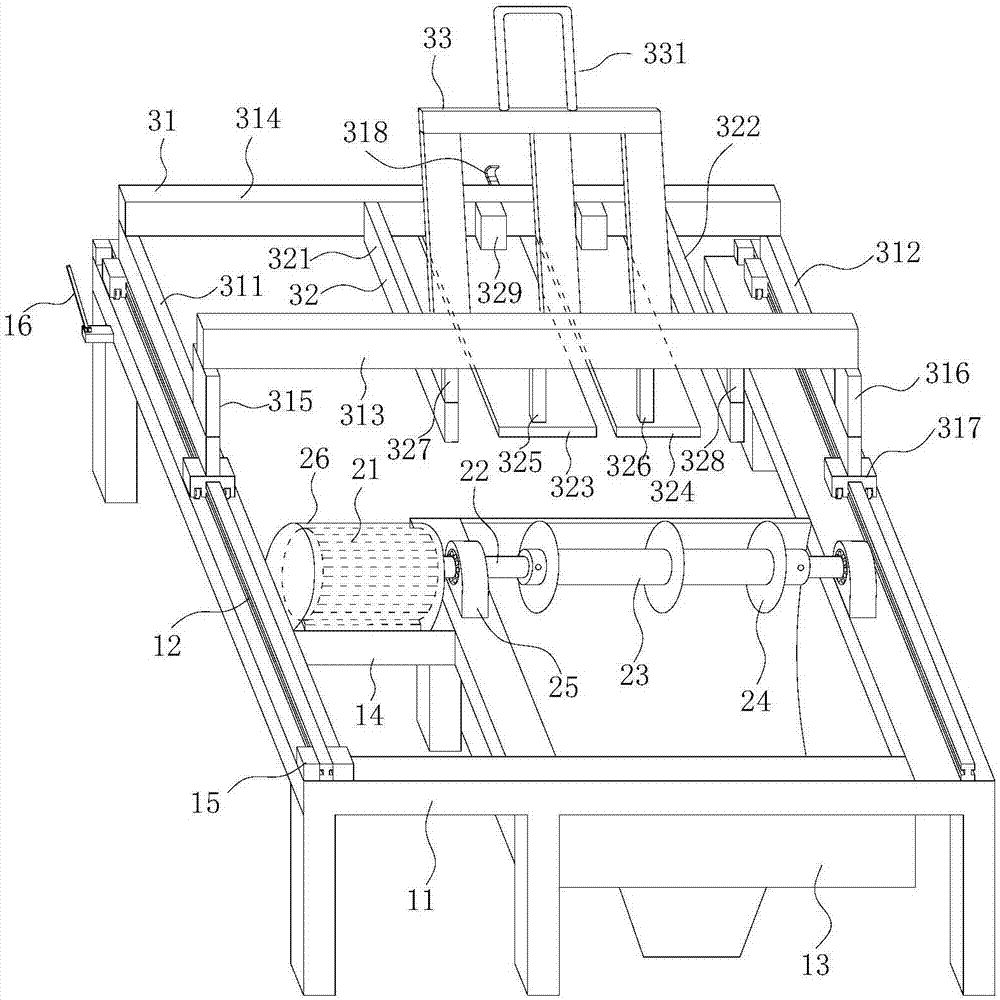

[0021] refer to figure 1 As shown, a high-efficiency stick cutting machine includes a frame, a cutting device and a feeding device. The frame includes a support frame 11, two guide rails 12 for slidingly connecting the feeding device and a chip collection bin 13. The upper part of the support frame 11 is provided with a horizontal support plate 14, and the upper part of the support frame 11 is respectively fixed with two horizontally aligned bearing seats 25, bearings are installed in the bearing seats 25, and the support frame 11 is provided with a mechanism for limiting the movement of the feeding device. Limiting piece 16, the limiting piece 16 is hinged on the support frame 11, when operating the wooden stick into the loading frame, the limiting piece 16 is rotated to the position that can limit the movement of the feeding device, which can limit t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com