Wood board cutting device for wood processing

A cutting device and board technology, applied in wood processing equipment, manufacturing tools, sawing equipment, etc., can solve the problems of unable to compress wood boards, unable to collect wood chips, and low cutting efficiency, so as to achieve the effect of easy sawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

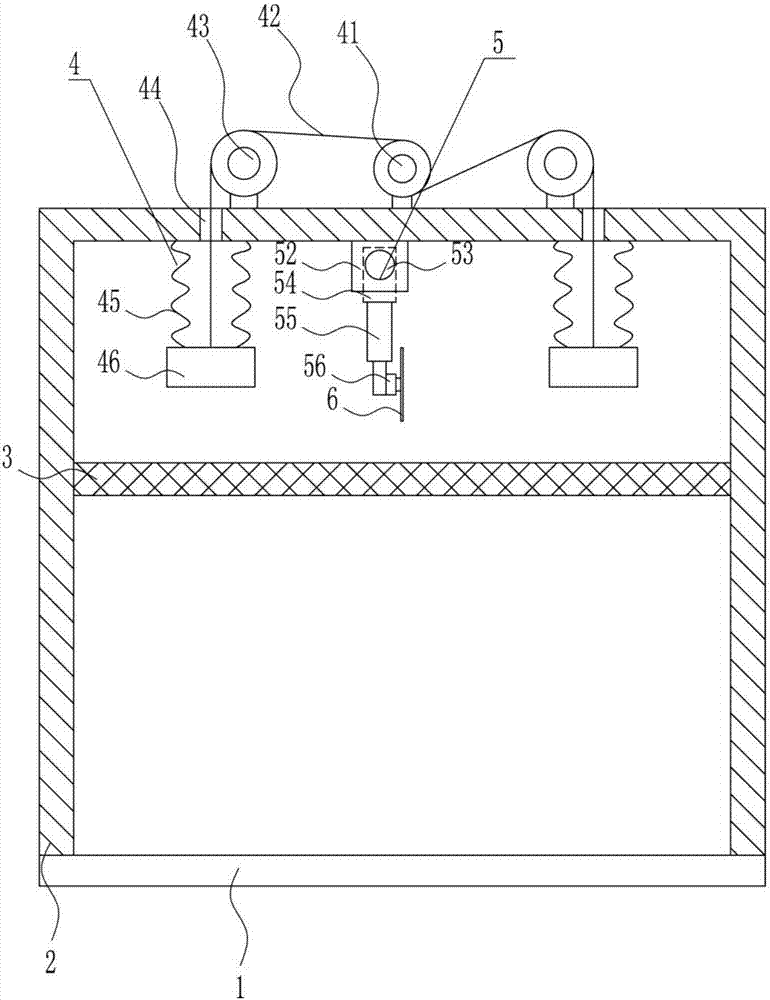

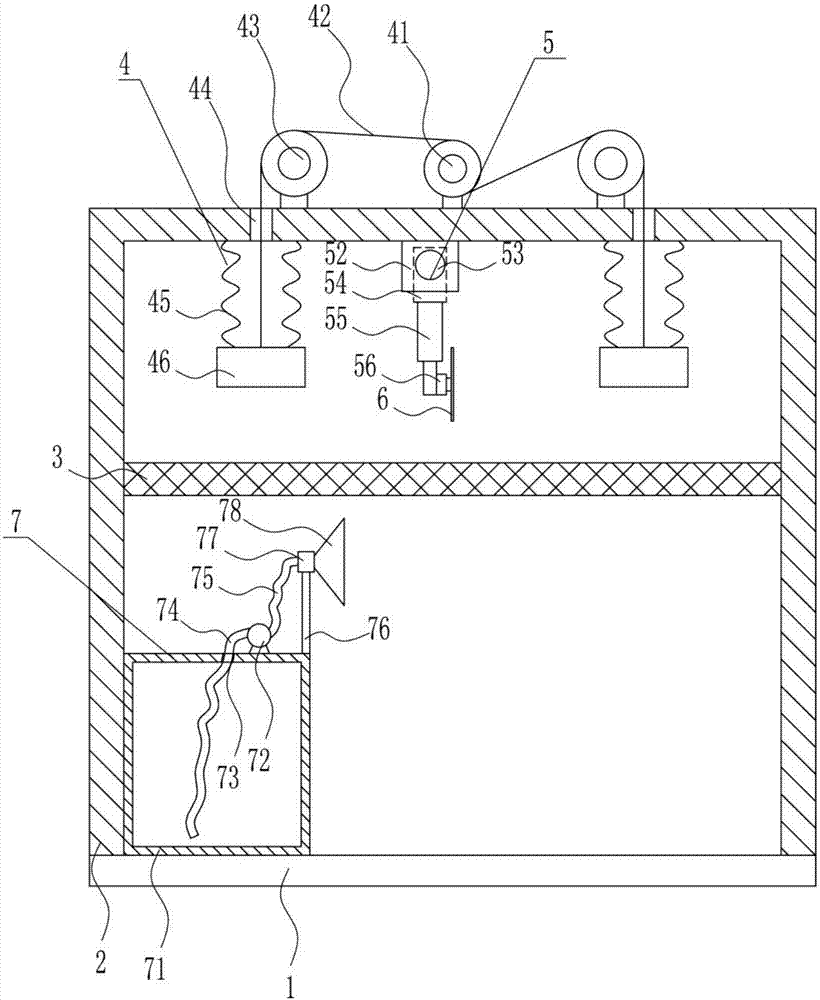

[0037] A plank cutting device for wood processing, such as Figure 1-6 As shown, it includes a base plate 1, an n-shaped frame 2, a mesh plate 3, a pressing mechanism 4, a cutting mechanism 5, and a saw disc 6. The top of the bottom plate 1 is provided with an n-shaped frame 2, and the inner middle of the n-shaped frame 2 is provided with a mesh plate. 3. A cutting mechanism 5 is arranged in the middle of the inner top of the n-shaped frame 2 , a pressing mechanism 4 is arranged symmetrically on the left and right sides of the inner top of the n-shaped frame 2 , and a saw disc 6 is arranged at the bottom of the cutting mechanism 5 .

Embodiment 2

[0039] A plank cutting device for wood processing, such as Figure 1-6 As shown, it includes a base plate 1, an n-shaped frame 2, a mesh plate 3, a pressing mechanism 4, a cutting mechanism 5, and a saw disc 6. The top of the bottom plate 1 is provided with an n-shaped frame 2, and the inner middle of the n-shaped frame 2 is provided with a mesh plate. 3. A cutting mechanism 5 is arranged in the middle of the inner top of the n-shaped frame 2 , a pressing mechanism 4 is arranged symmetrically on the left and right sides of the inner top of the n-shaped frame 2 , and a saw disc 6 is arranged at the bottom of the cutting mechanism 5 .

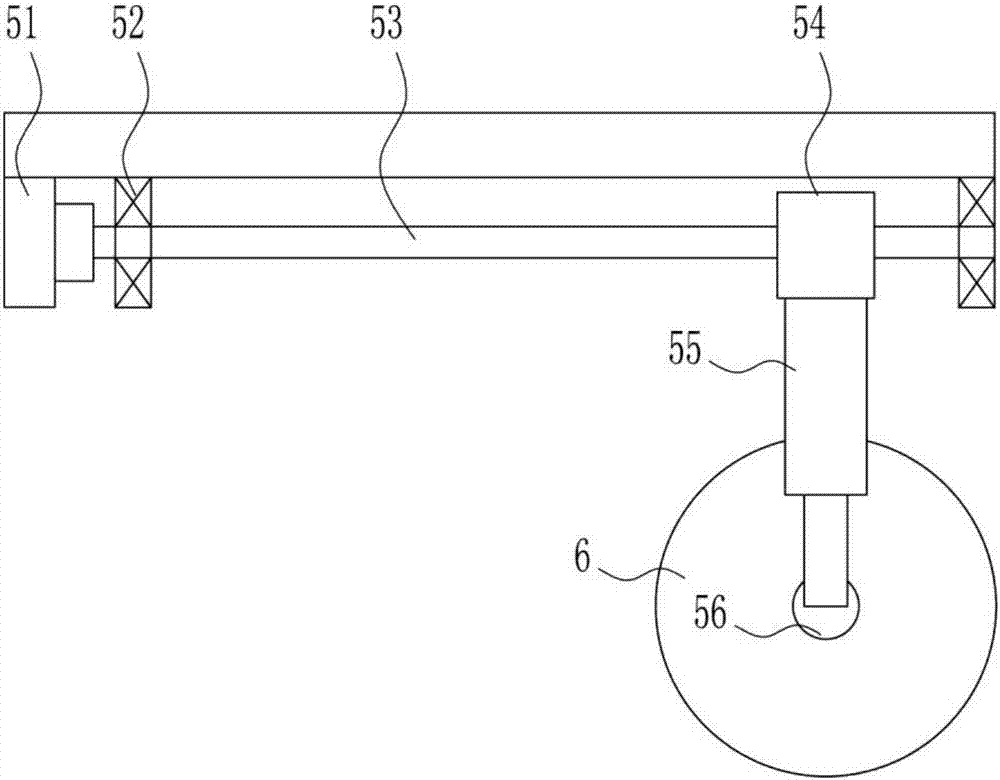

[0040] Pressing mechanism 4 comprises the first electric reel 41, the first backguy 42, pulley 43, the first spring 45 and pressing block 46, is provided with the first electric reel 41 in the middle of the outer top of n-shaped frame 2, the first The electric reel 41 is wound with the first backguy 42, and the top of the n-shaped frame 2 is symm...

Embodiment 3

[0042] A plank cutting device for wood processing, such as Figure 1-6 As shown, it includes a base plate 1, an n-shaped frame 2, a mesh plate 3, a pressing mechanism 4, a cutting mechanism 5, and a saw disc 6. The top of the bottom plate 1 is provided with an n-shaped frame 2, and the inner middle of the n-shaped frame 2 is provided with a mesh plate. 3. A cutting mechanism 5 is arranged in the middle of the inner top of the n-shaped frame 2 , a pressing mechanism 4 is arranged symmetrically on the left and right sides of the inner top of the n-shaped frame 2 , and a saw disc 6 is arranged at the bottom of the cutting mechanism 5 .

[0043] Pressing mechanism 4 comprises the first electric reel 41, the first backguy 42, pulley 43, the first spring 45 and pressing block 46, is provided with the first electric reel 41 in the middle of the outer top of n-shaped frame 2, the first The electric reel 41 is wound with the first backguy 42, and the top of the n-shaped frame 2 is symm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com