Wood board sawing device for high-end equipment manufacturing

A technology for equipment and wood boards, which is applied in the field of wood board sawing devices for high-end equipment manufacturing, can solve problems such as reduced work efficiency, a large number of manpower, and deviation of viewing angles, and achieves the effect of convenient collection and less troublesome operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

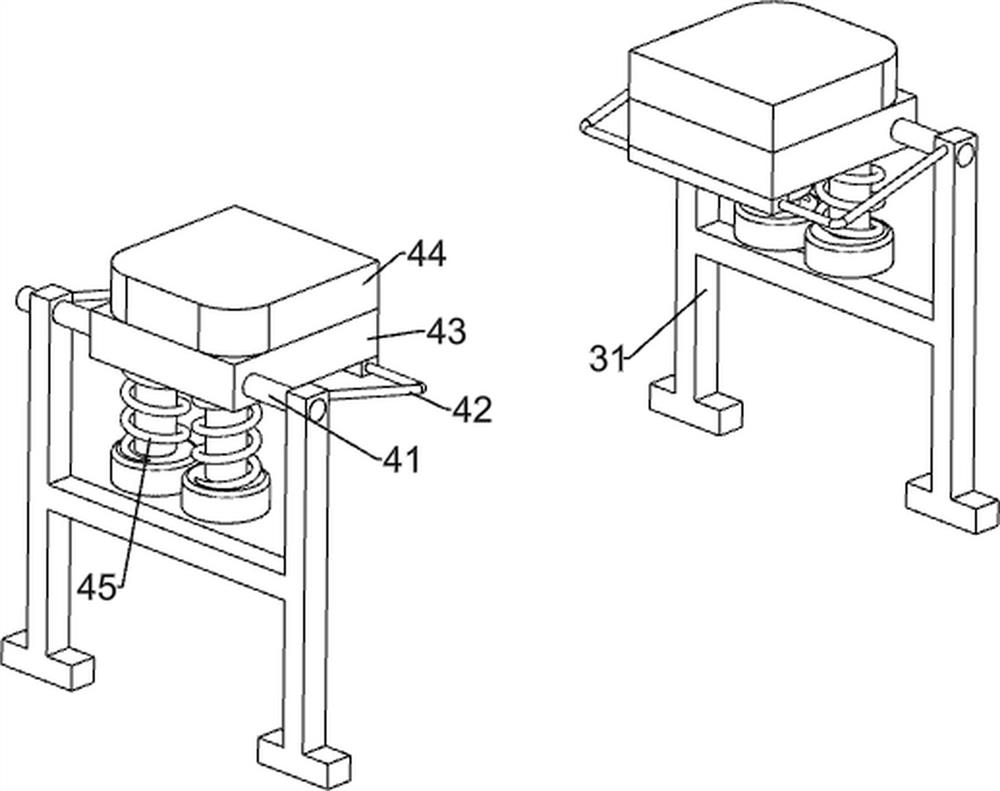

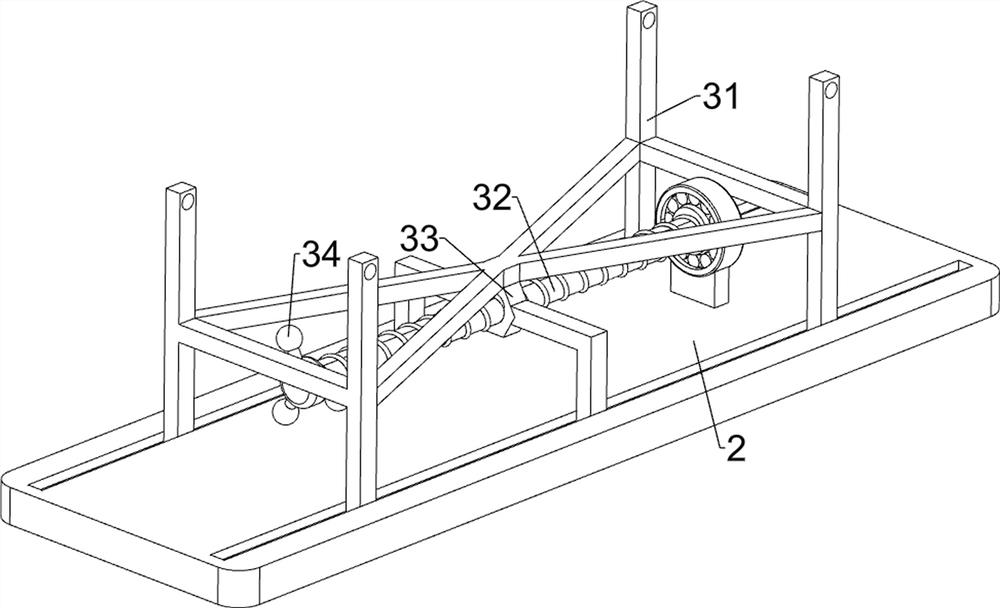

[0064] A plank sawing device for high-end equipment manufacturing, such as Figure 1-4 As shown, it includes a bottom plate 1, a saw blade 11, a sliding plate 2, a left and right moving component 3, a clamping component 4 and a cutting component 5. The upper right side of the bottom plate 1 is slidingly provided with a sliding plate 2, and the top of the sliding plate 2 slides There is a left and right moving assembly 3, a clamping assembly 4 is arranged on the top of the left and right moving assembly 3, a cutting assembly 5 is arranged on the bottom plate 1, and a saw blade 11 is arranged on the cutting assembly 5.

[0065] When it is necessary to saw the board, the board can be placed on the clamping assembly 4, use the left and right moving assembly 3 to adjust the placement position of the board, start the cutting assembly 5, and push the sliding plate 2 to move backward to perform the sawing process of the board. When finished, the cutting assembly 5 is closed.

[0066]...

Embodiment 2

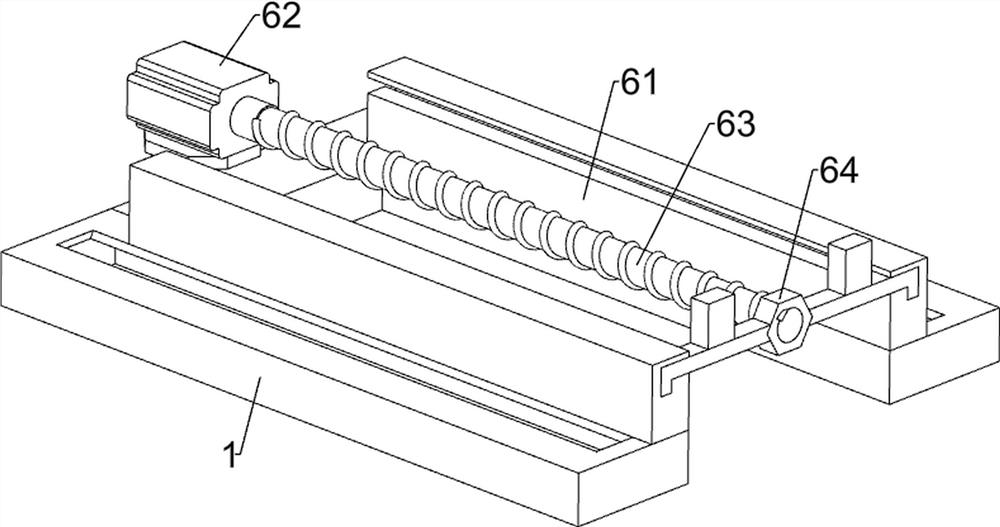

[0073] On the basis of Example 1, such as figure 1 , Figure 5 , Image 6 with Figure 7 As shown, the automatic advance assembly 6 is also included, and the automatic advance assembly 6 includes a chute plate 61, a second motor 62, a second screw mandrel 63 and a second nut 64, and two slides are arranged on the left and right sides of the base plate 1. Slot plate 61, bottom plate 1 upper rear side is provided with second motor 62, is provided with second screw mandrel 63 on the output shaft of second motor 62, is connected with second nut 64 by thread on the second screw mandrel 63, and second nut 64 It is slidably connected with the chute plates 61 on both sides.

[0074] When a larger plank needs to be sawed off, the automatic advance assembly 6 can be used instead of manual operation to start the second motor 62, the second motor 62 rotates to drive the second screw mandrel 63 to rotate, and the second screw mandrel 63 rotates to drive the second nut 64 moves forward,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com