Touch screen calibrating method and device

A calibration method and touch screen technology, applied in the direction of instrument, electrical digital data processing, data processing input/output process, etc., can solve the problem of irregularity and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

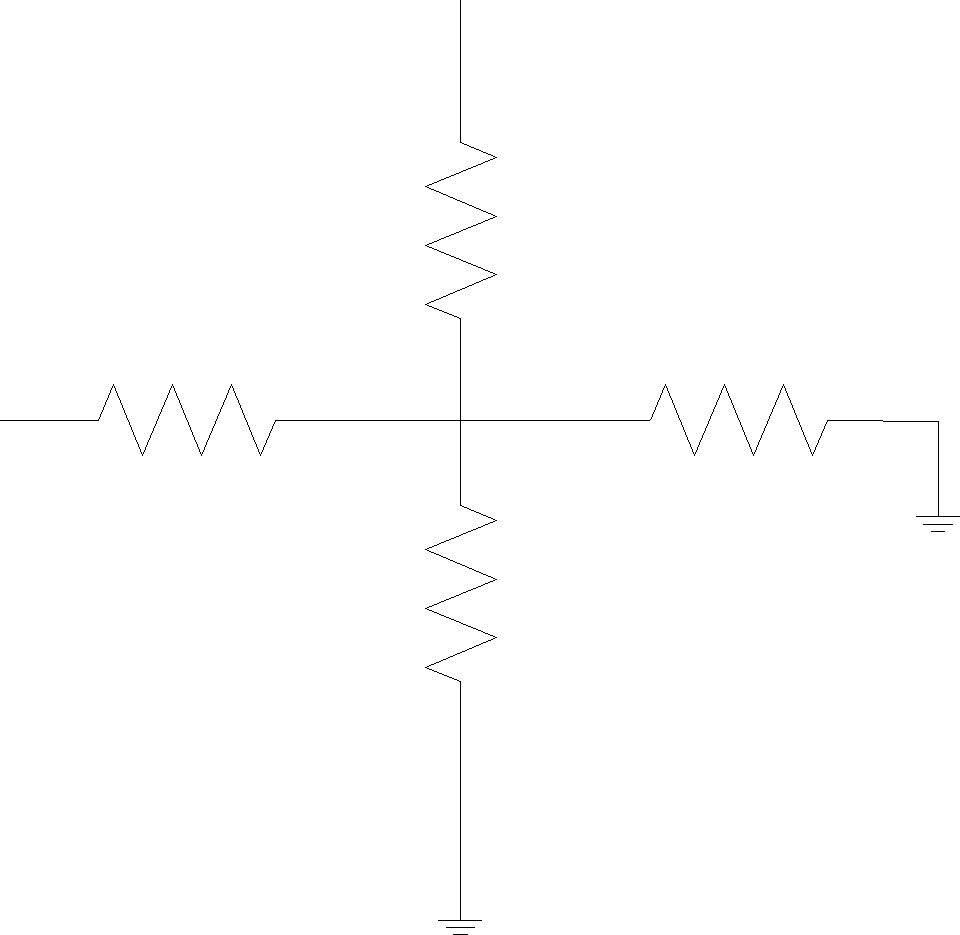

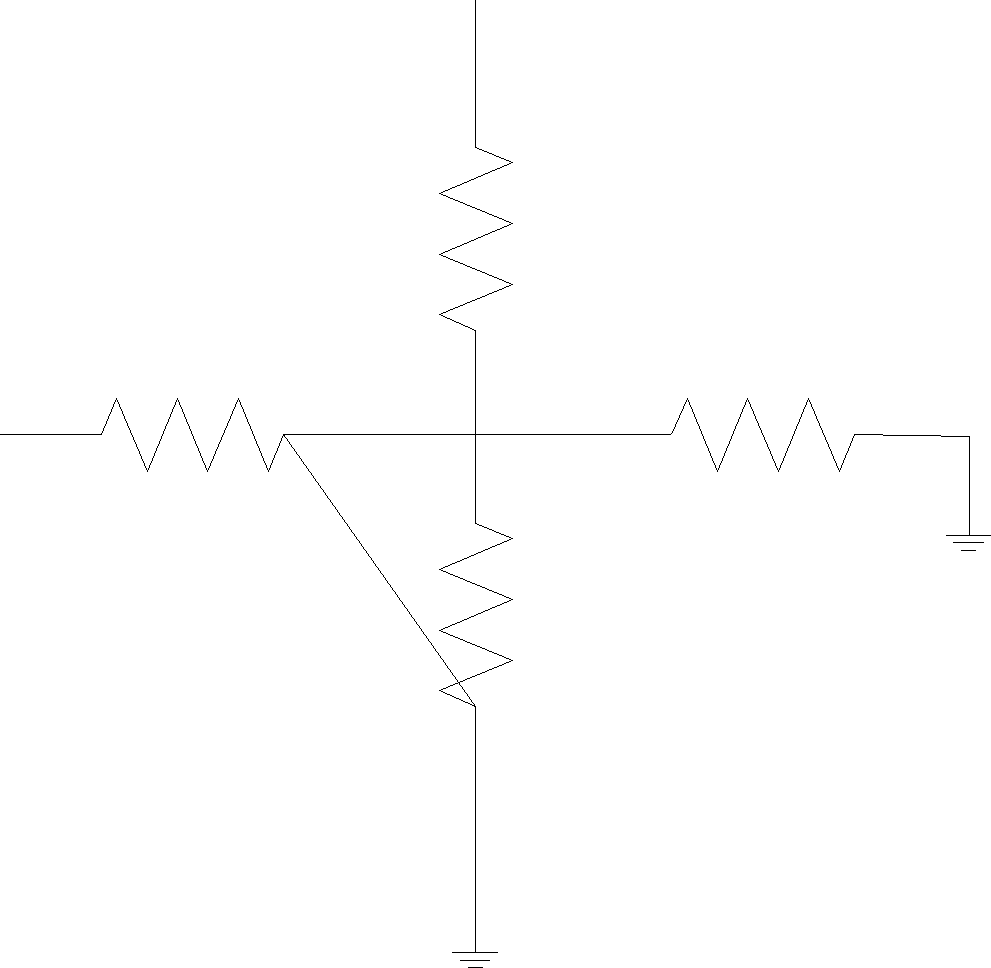

[0025] see Figure 4 , is a schematic flow chart of one embodiment of the touch screen calibration method of the present invention. In this embodiment, the touch screen calibration method includes:

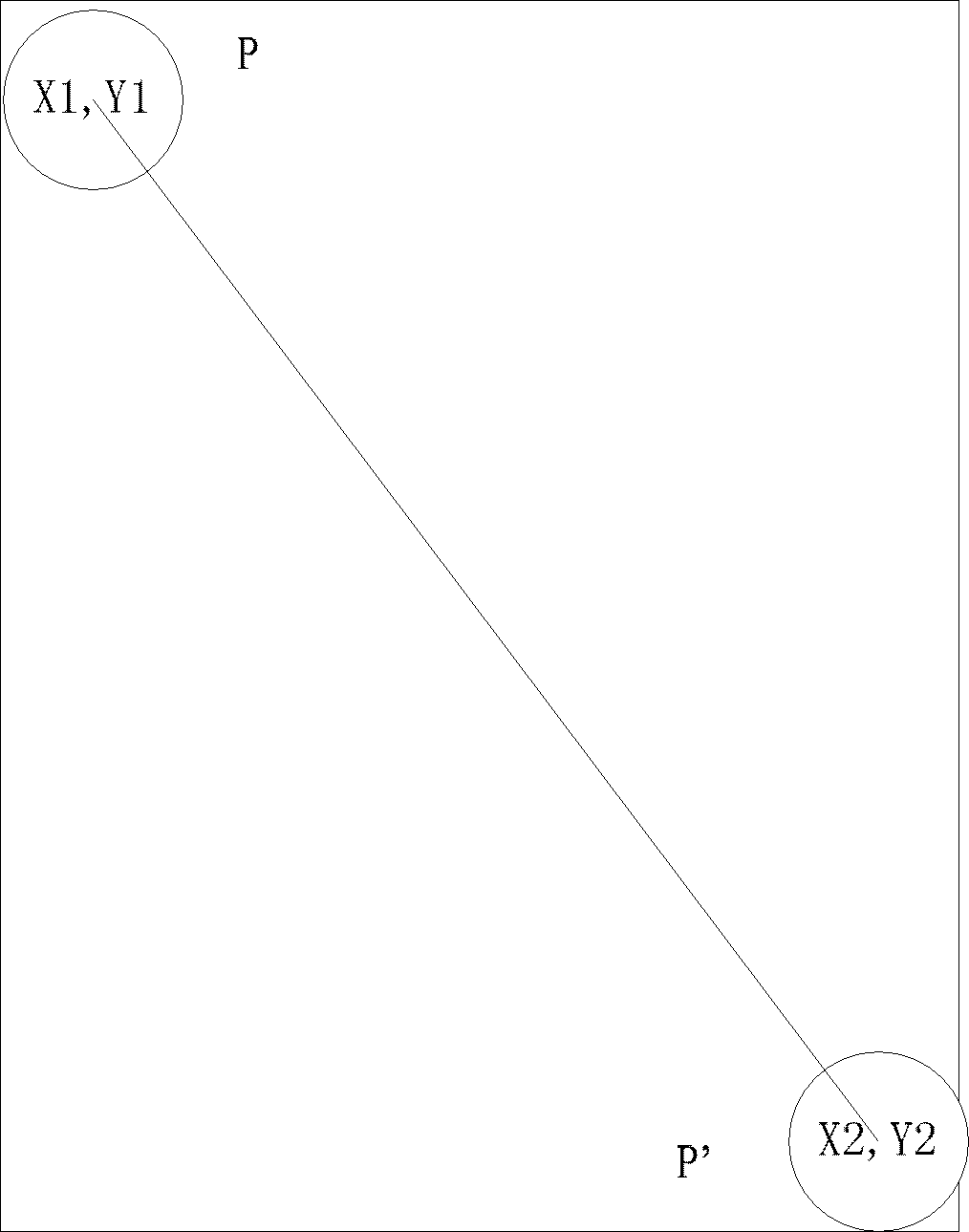

[0026] Step 401 , when the touch screen is touched to unlock, acquire the touch screen coordinates of the first touch point P1 and the second touch point P2 respectively. This step 401 is different from the prior art in that: when the user touches to unlock, operations such as selecting coordinates for touch screen calibration are performed synchronously in the background. The coordinate selection method of the first touch point P1 and the second touch point P2 can be determined according to the actual situation, for example, on a straight line where the two diagonal lines of the touch screen are located, or on a straight line parallel to the diagonal lines. , or select any two different points on the screen. At the same time, in order to ensure the accuracy of the calibration,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com