Novel environment-friendly round iron rod tapping machine

A technology of tapping machine and iron rod, applied in the field of tapping machine, can solve problems such as manual injury, and achieve the effects of reducing burden, improving work efficiency and reducing operation trouble.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

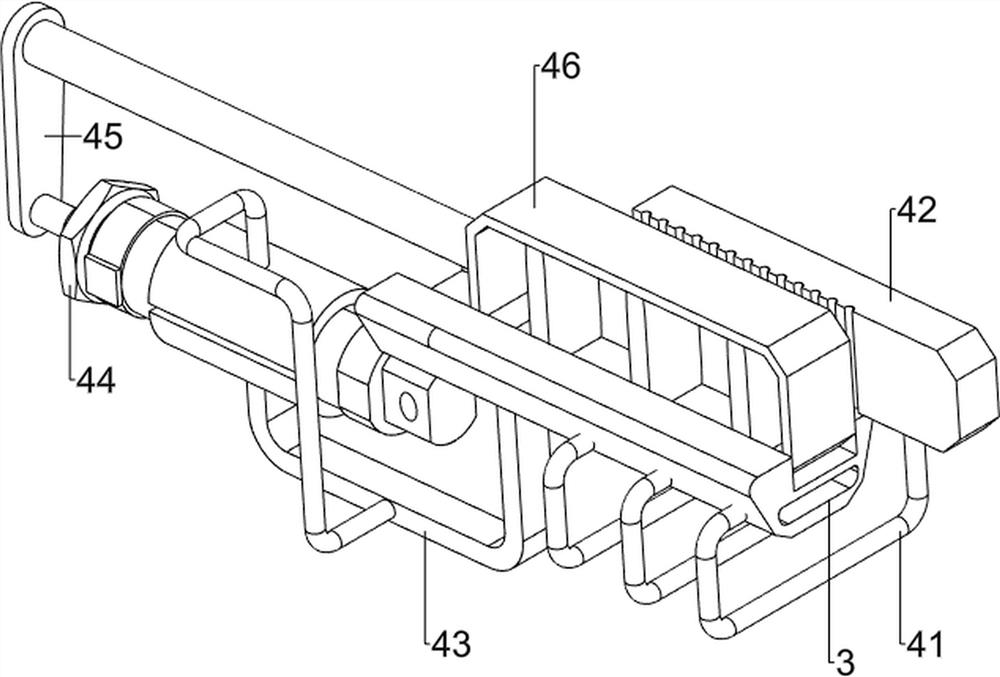

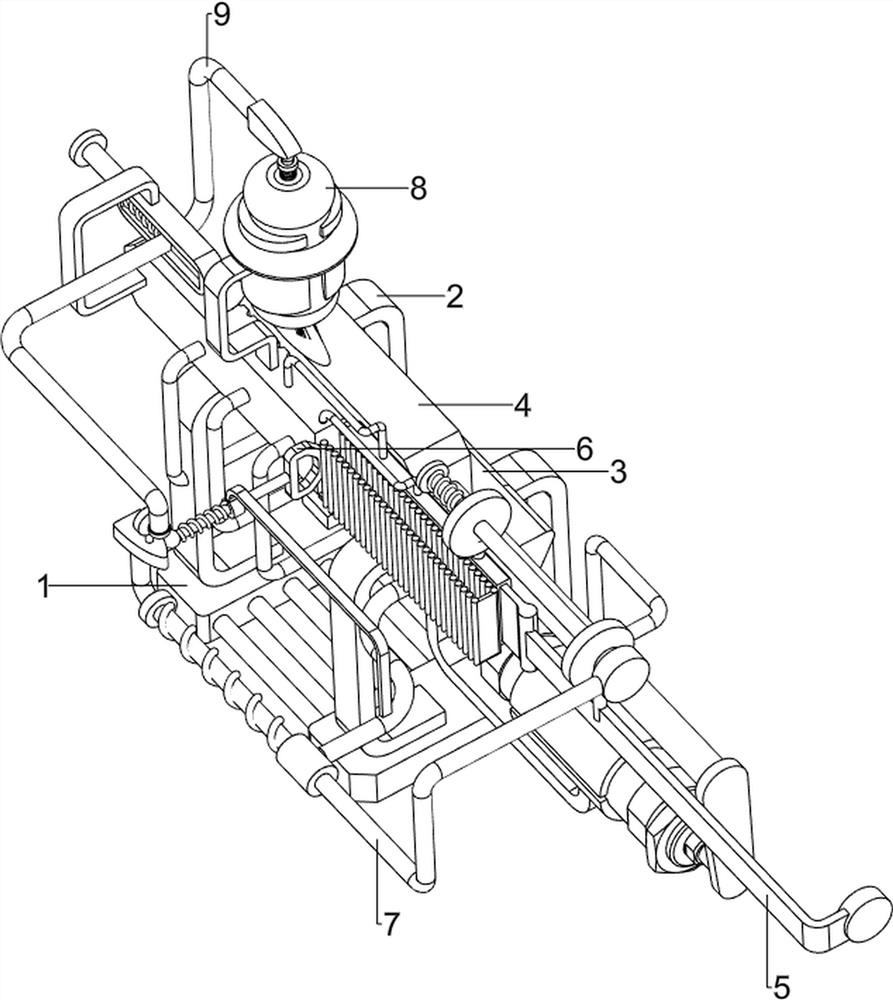

[0028] A new type of environmental protection round iron rod tapping machine, such as figure 1 and figure 2 As shown, it includes a base plate 1, a first support seat 2, a sliding support frame 3 and a tapping mechanism 4. The upper, front, and rear sides of the base plate 1 are symmetrically connected with the first support base 2, and the first support base 2 is connected with A sliding support frame 3 is provided, and a tapping mechanism 4 is arranged on the sliding support frame 3 .

[0029] When it is necessary to tap the round iron rod, the round iron rod is put into the tapping mechanism 4, then start the tapping mechanism 4, and the tapping mechanism 4 will tap the round iron rod. After completion, control the tapping mechanism 4 to reset, then repeat the above operations, when all the round iron rods have been tapped, close the tapping mechanism 4 and get final product.

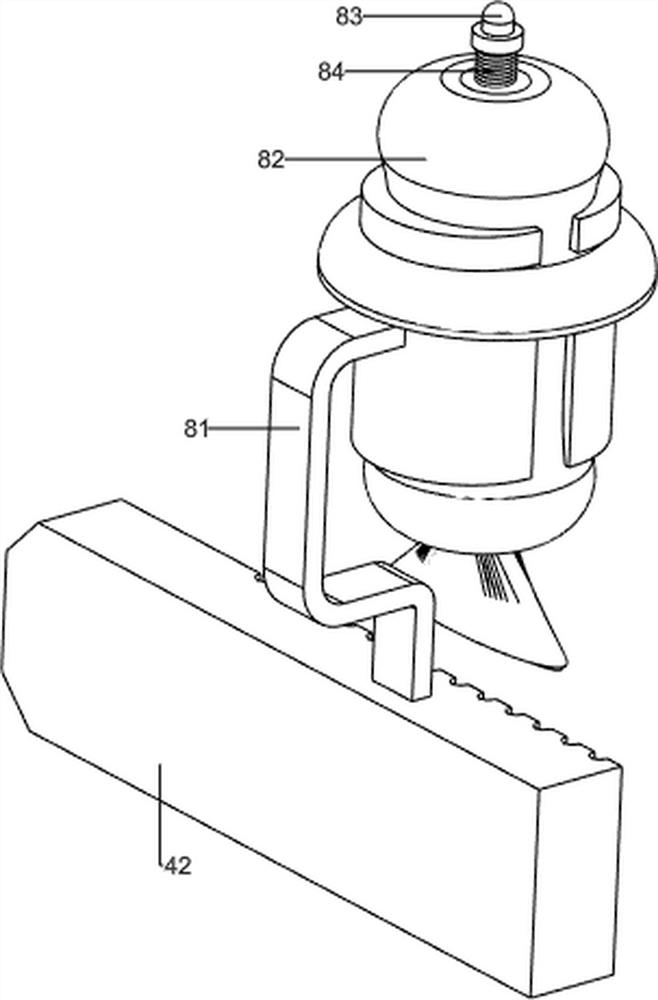

[0030] The tapping mechanism 4 includes a first connecting column 41, a thread rolling plate 4...

Embodiment 2

[0033] On the basis of Example 1, such as figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, it also includes a material-discharging opening and closing mechanism 5, and the material-discharging opening and closing mechanism 5 includes a second connecting column 51, a fixed frame 52, a sliding slat 53, a first round block bracket 54, a first sliding column 55, a second Two round block frames 56, the first spring 57 and the discharge frame 58, the upper side of the thread rolling plate 42 is connected with the second connecting column 51, and the front lower side of the second connecting column 51 is welded with a fixed frame 52, inside the fixed frame 52 The sliding type is provided with a sliding slat 53, the sliding slat 53 cooperates with the auxiliary push plate 45, the upper side of the sliding slat 53 is connected with a first round block support 54, and the first round block support 54 is welded with a first sliding column 55 , the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com