Patents

Literature

35results about How to "Efficient split" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

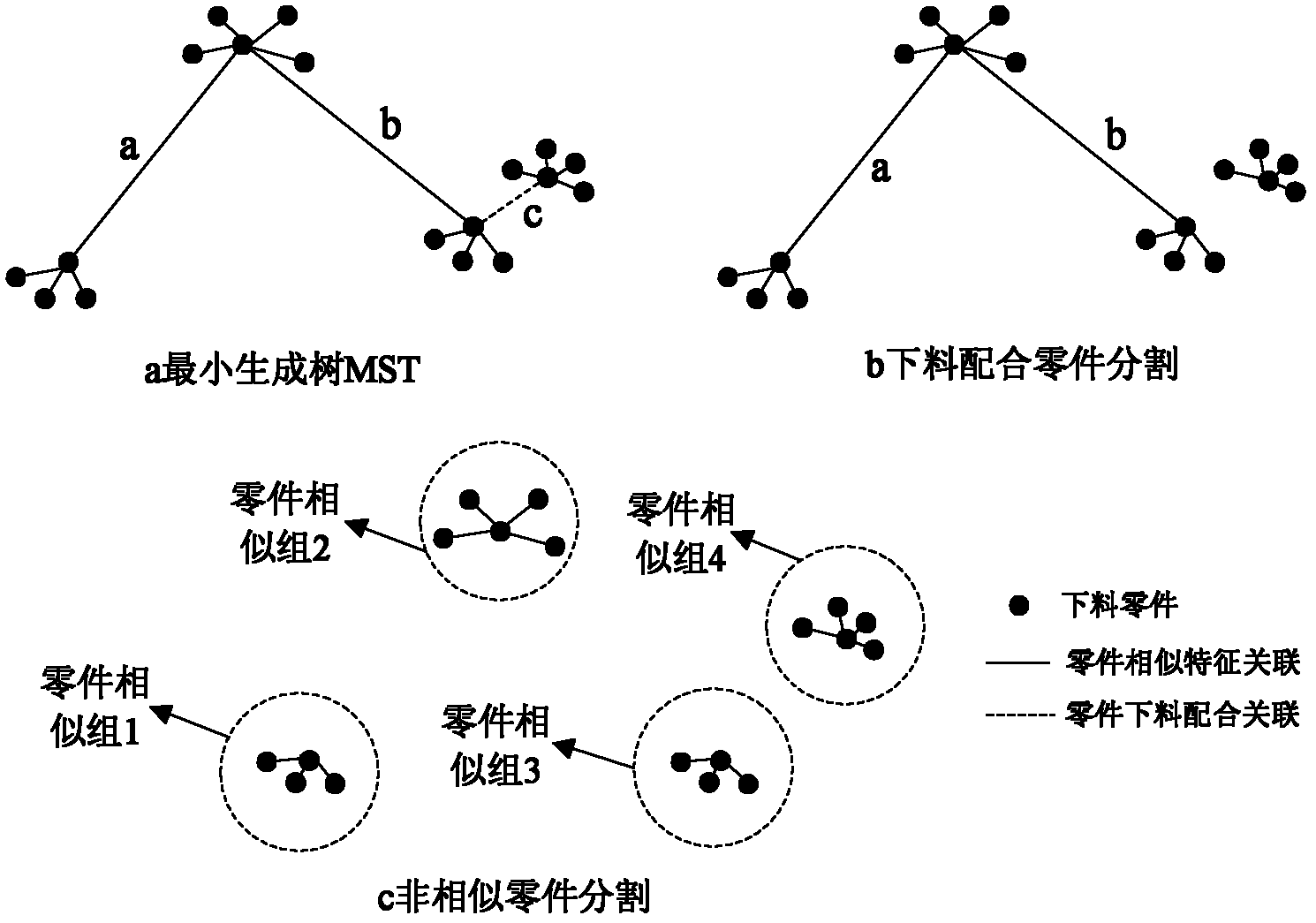

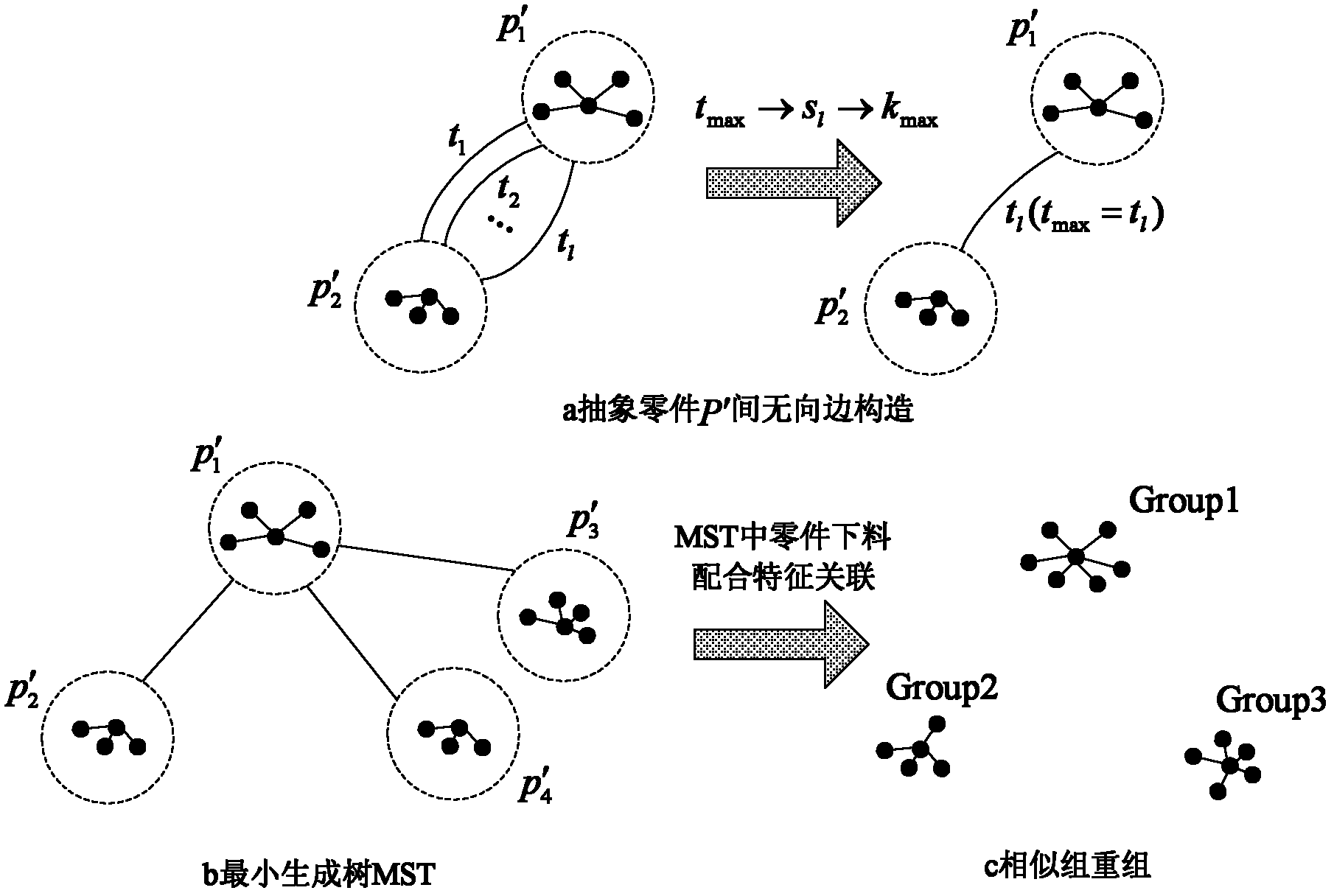

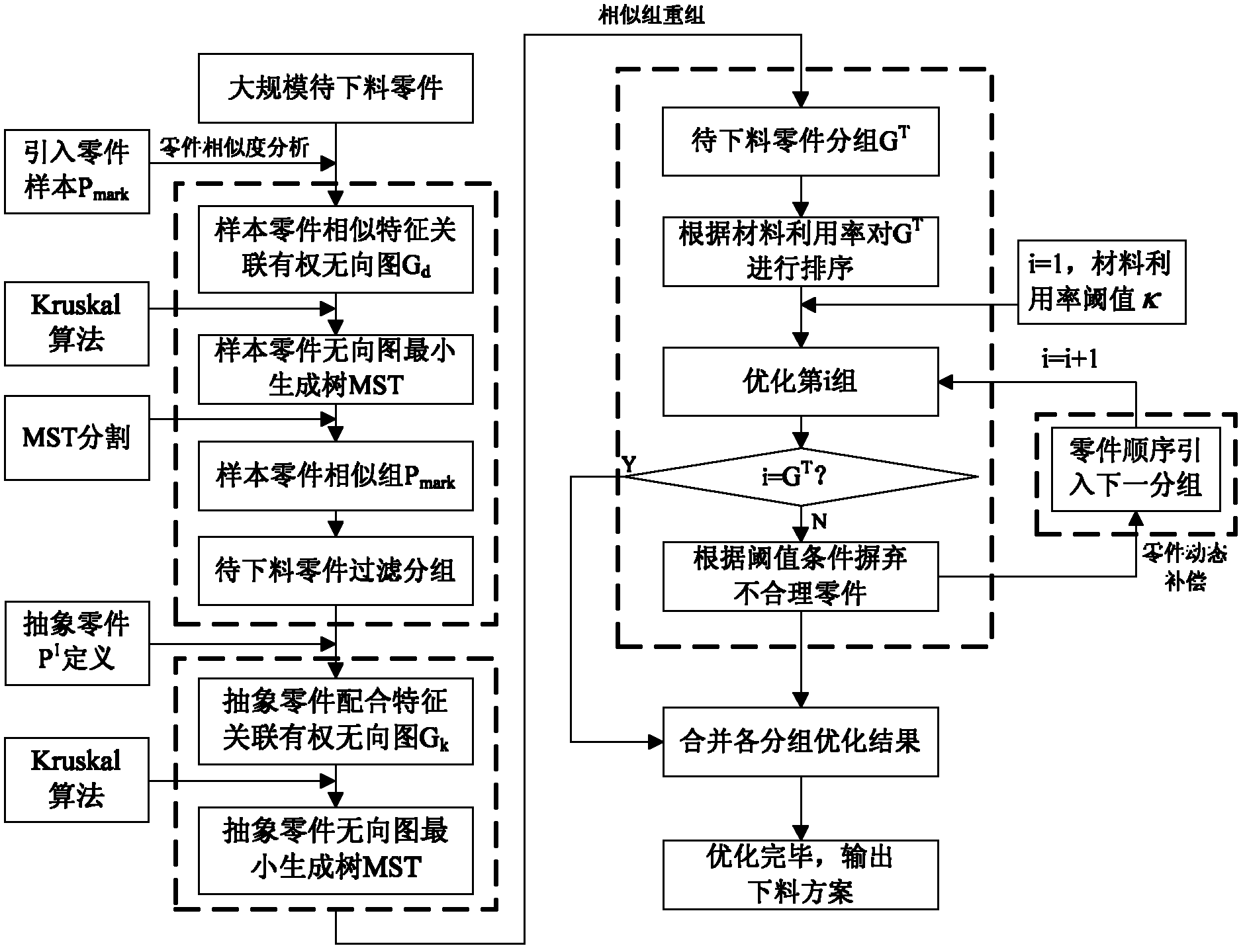

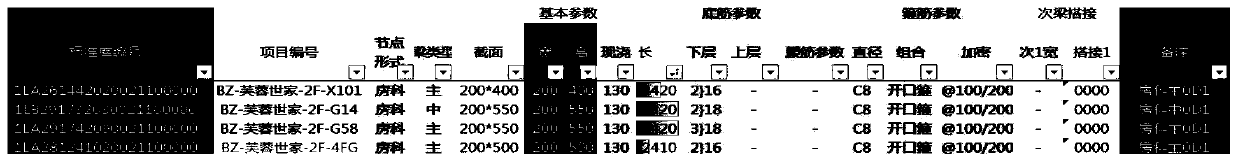

Large-scale grouping optimizing method of parts based on feed characteristic

InactiveCN102254067AOptimal Compensation RealizationOptimal Utilization ImprovementSystems intergating technologiesSpecial data processing applicationsCluster algorithmComputer science

The invention discloses a large-scale grouping optimizing method of parts based on a feeding characteristic. The large-scale grouping optimizing method of parts comprises the specific steps of: (1) grouping the parts based on the similarity characteristic to obtain different similar part groups, and putting each part into a similar part group; (2) regrouping the parts based on the feed fit characteristic, wherein each regrouped similar part group corresponds to a feed optimizing subproblem; and (3) optimizing and compensating the parts, dynamically compensating the distribution of groups of parts in the optimizing process, and finally combining the optimization results of all the groups to obtain a feeding scheme of the original problem. The large-scale grouping optimizing method of parts can be used for grouping parts adaptively, obtaining reasonable and stable part groups, avoiding influence of a specific clustering algorithm on the grouping result, and alleviating the contradiction of the algorithm between time efficiency and material utilization rate.

Owner:CHONGQING UNIV

Parametric modeling design method for fabricated building

PendingCN110110442AImprove work efficiencyPut an end to omissionsGeometric CADSpecial data processing applicationsCollision detectionShop drawing

The invention provides a parametric modeling design method for a fabricated building, which comprises the following steps of: extracting parameters: splitting each component from a CAD structure construction drawing of the building, representing each different component with different parameters, and extracting parameter information of each component; inputting parameters: storing the parameter information of each component into a database, and inputting the parameter information into UG software to form a three-dimensional model of each component; assembling collision: correspondingly assembling three-dimensional models of a plurality of adjacent components in UG software, and carrying out collision detection and collision adjustment on the components; wherein the three-dimensional modelof the qualified standard component is converted into a two-dimensional drawing; a plurality of standard components are used for jointly forming the fabricated building. By using the method disclosedby the invention, the structure construction drawing of the house can be efficiently split into a plurality of standard components, the two-dimensional drawing of each standard component can be accurately given out in detail, and the material list for production and manufacturing can be accurately calculated as soon as possible.

Owner:中民筑友房屋科技集团有限公司

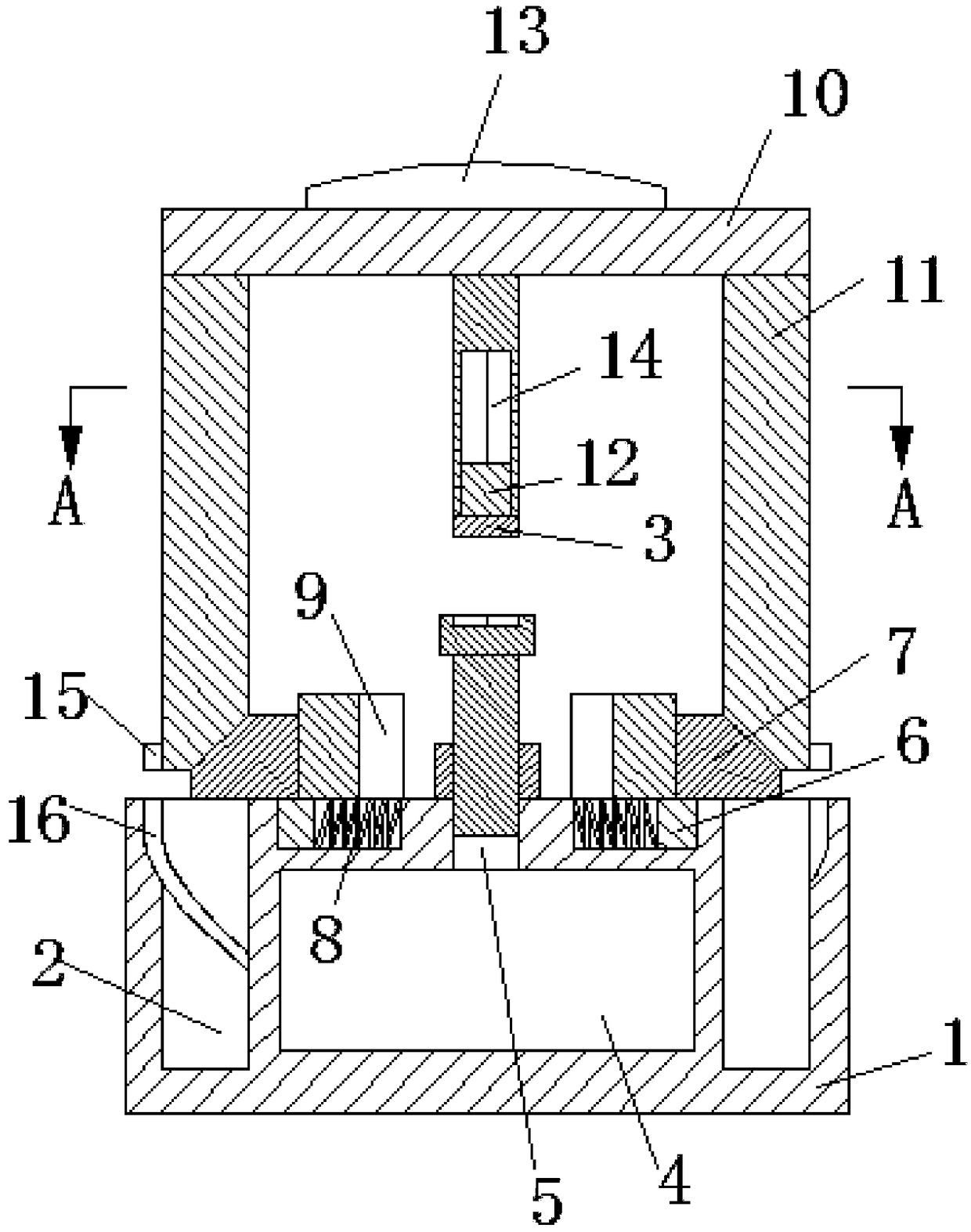

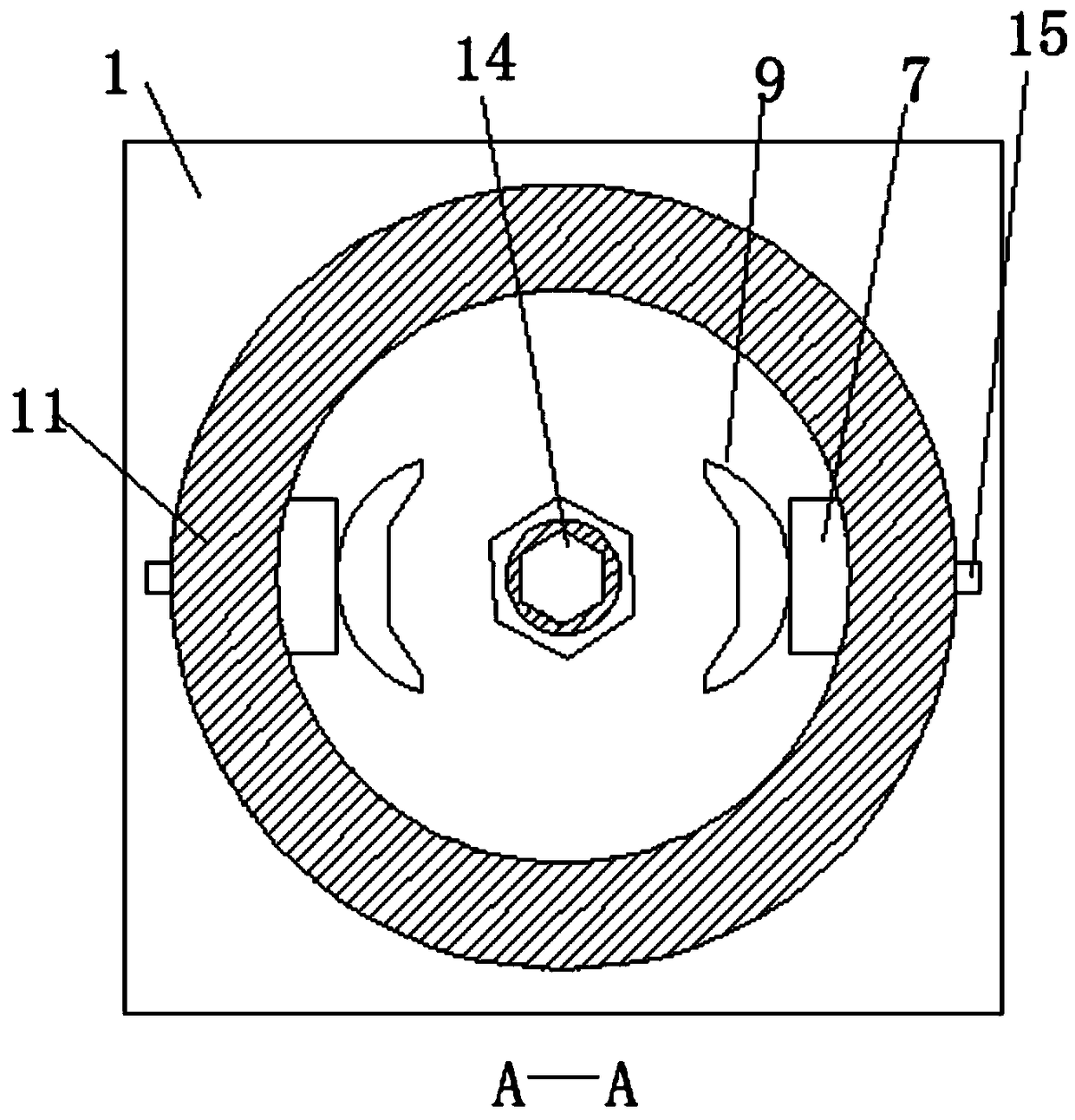

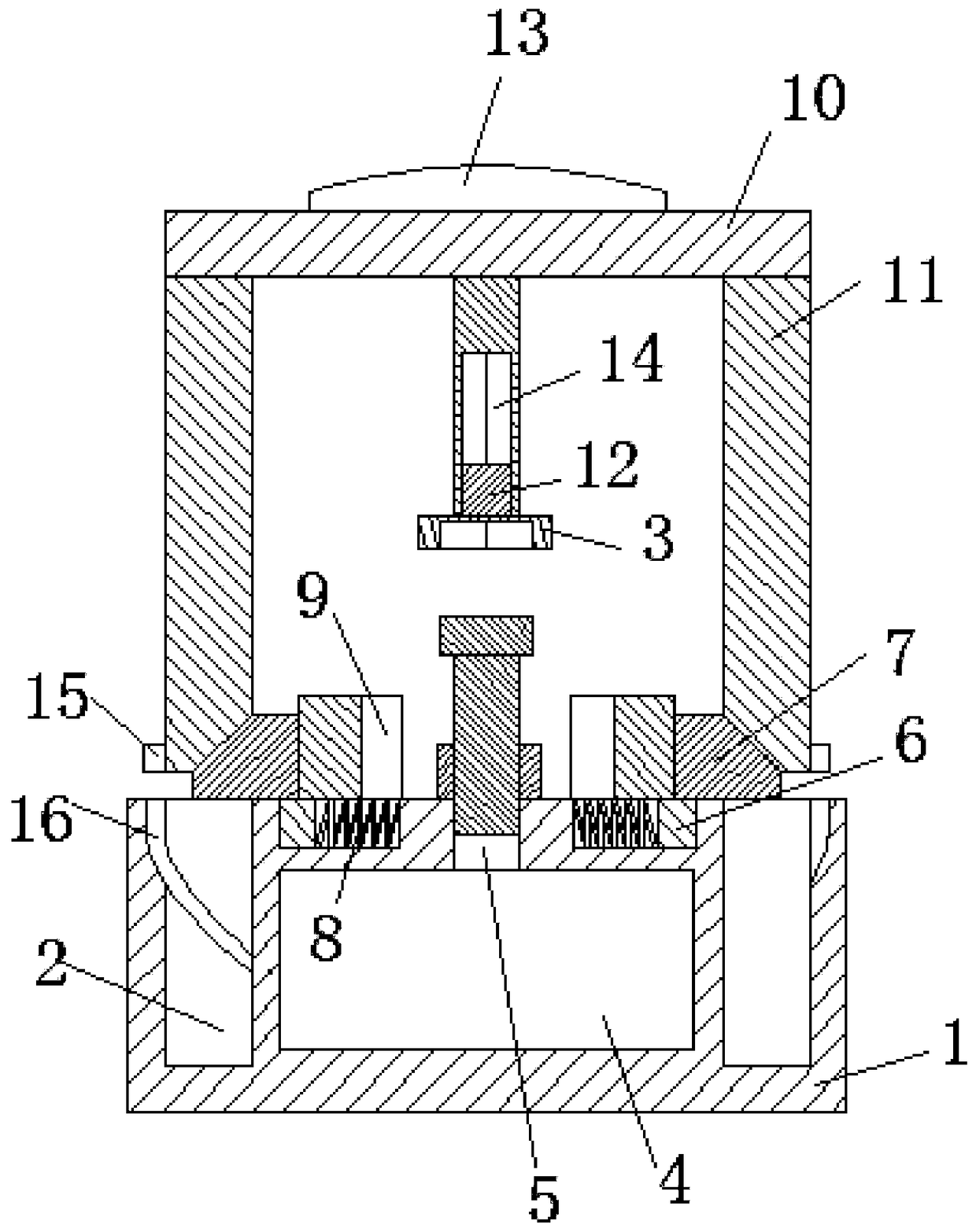

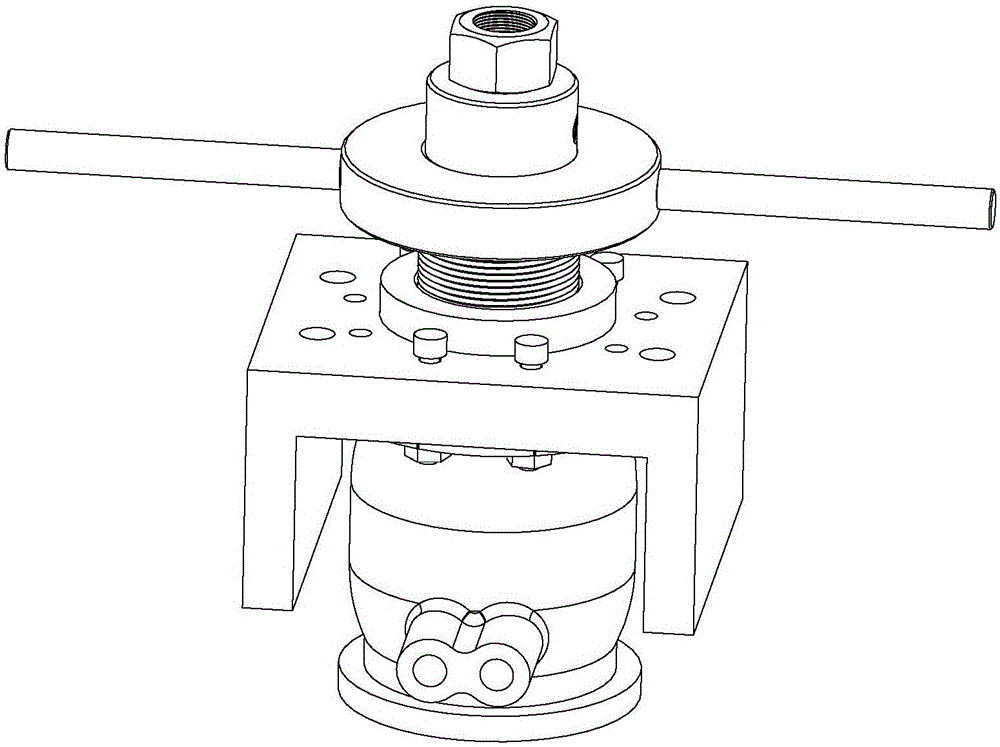

Discarded bolt and nut splitting device for building, and using method

The invention discloses a discarded bolt and nut splitting device for a building, and a using method. The splitting device comprises a base, a rotary drum, a dismounting and mounting head and a clamping mechanism, and the base is provided with a socket used for placing the bottom of a bolt; the rotary drum is rotatably installed on the base, and can be moved relative to the base up and down; the dismounting and mounting head is directly or indirectly connected to the rotary drum fixedly, and provided with a plug fit with the head shape of the bolt; and the clamping mechanism is installed on the base, and can do reverse or forward motion along with the up-and-down movement of the rotary drum, so that a nut is loosened or clamped. The disassembly device is rational in structure and ingeniousin layout, and through accurate position cooperation and connection relationship among components, the bolt and the nut can be split efficiently.

Owner:温州瑞智门窗有限公司

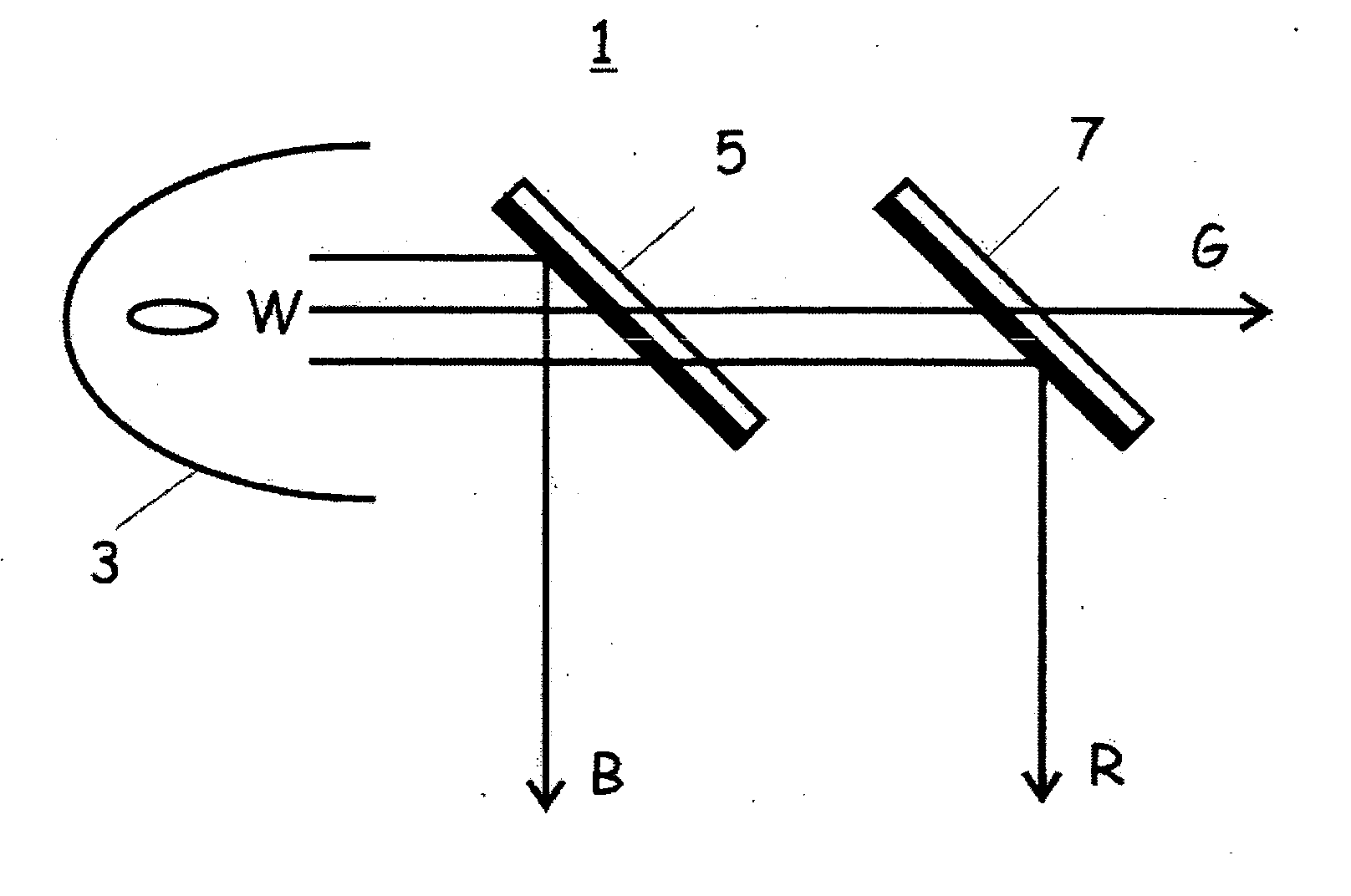

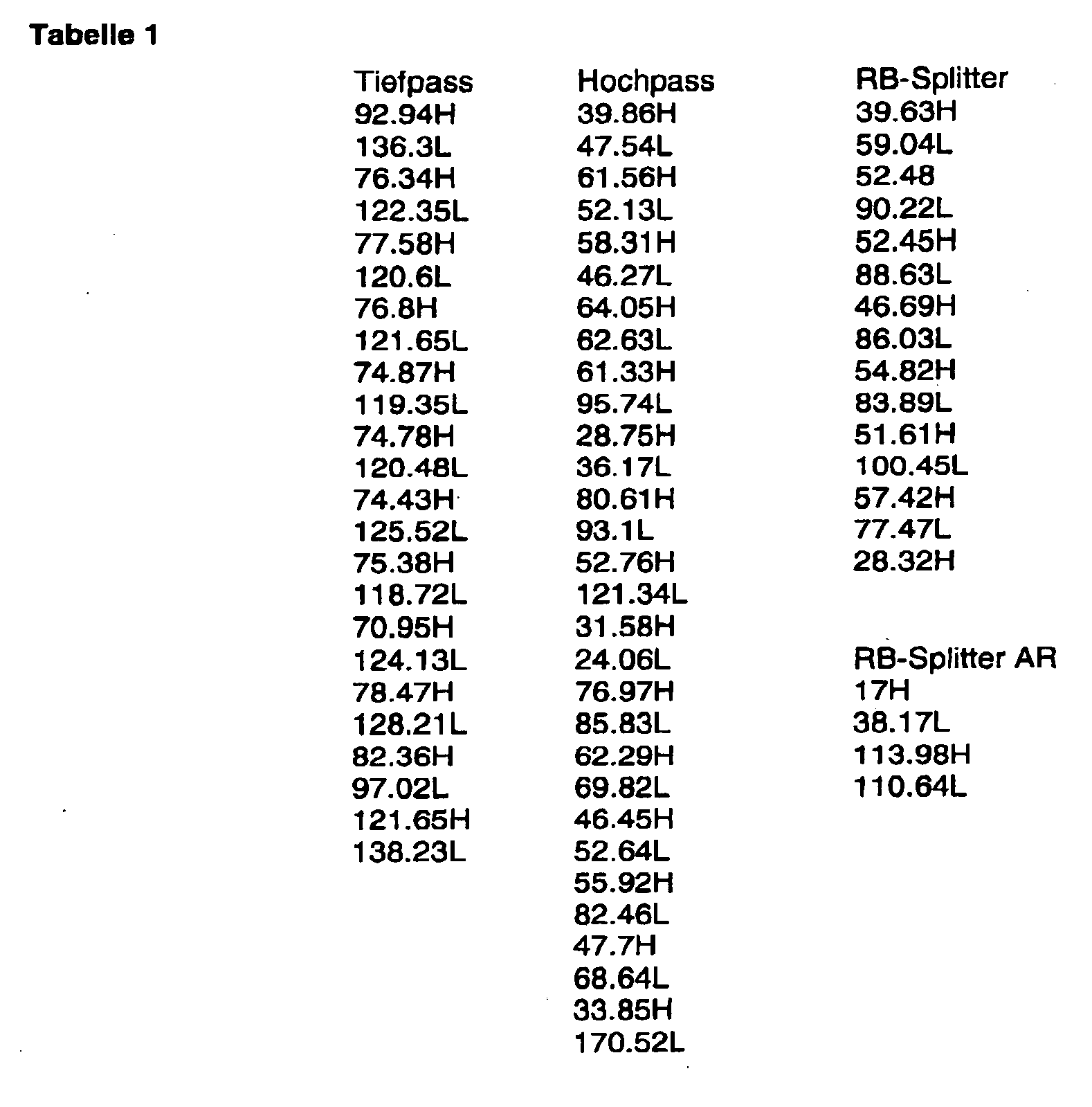

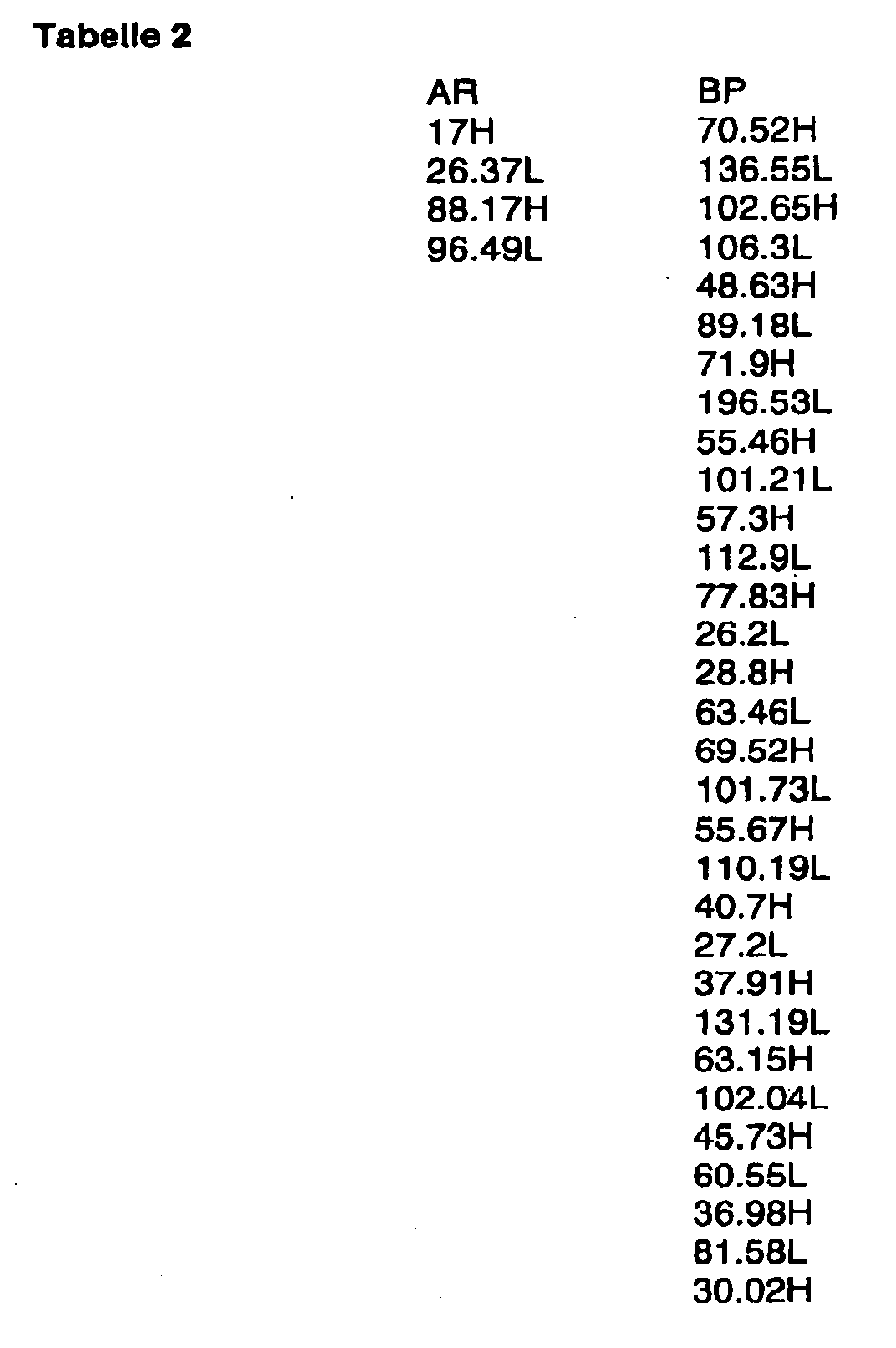

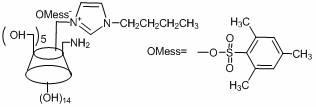

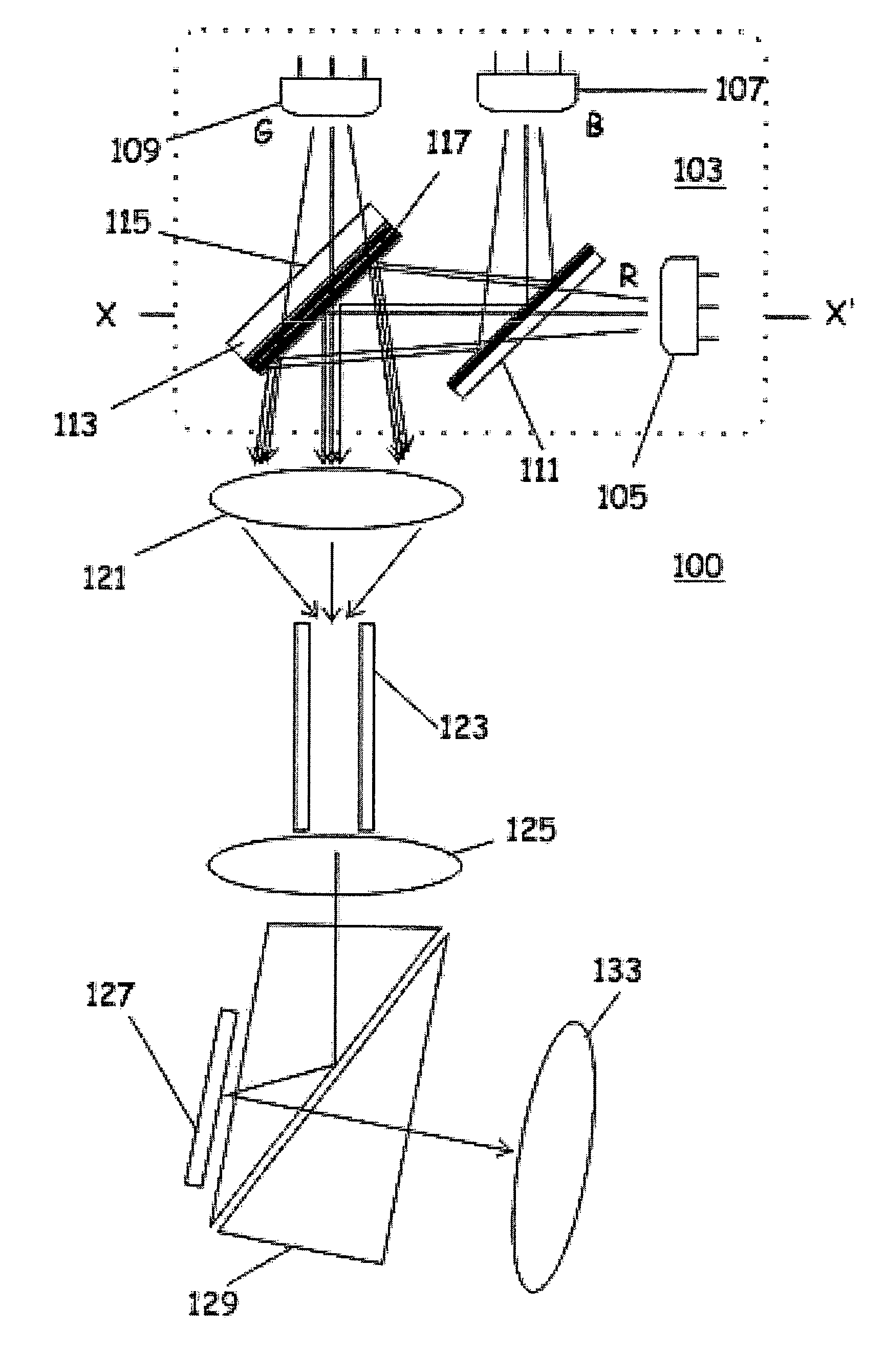

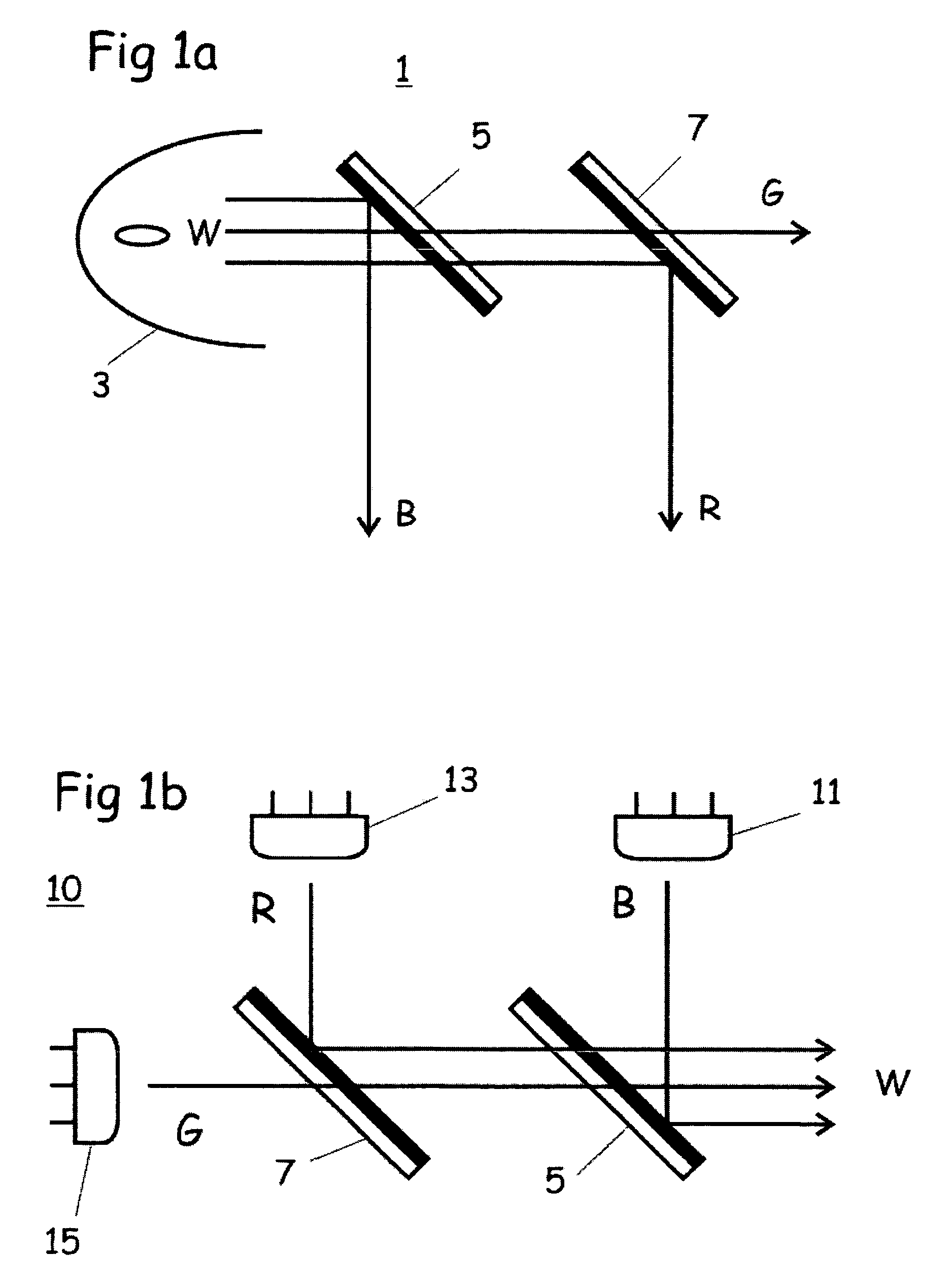

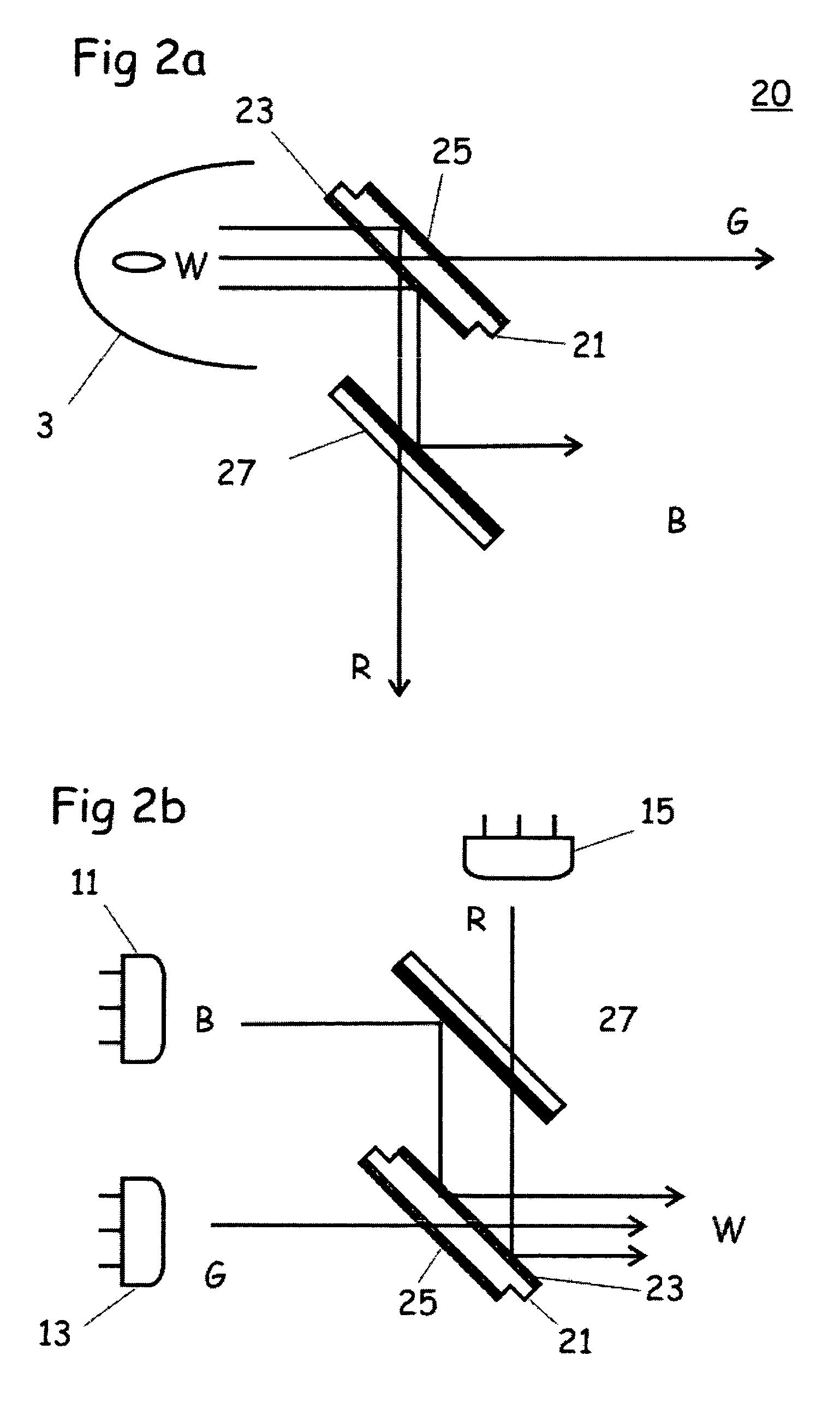

Device for combination of light of different wavelengths

ActiveUS20060256445A1Produced cost-effectivelyEffective combinationOptical elementsLight beamLength wave

The present invention relates to a method for combining or for splitting the beam paths of substantially nonpolarized light of at least three different wavelength intervals. The splitting or the combining of the beam path of light of those wavelength intervals located between the other wavelength intervals takes place when the beam paths of the light of the two other wavelength intervals are already or still combined. The present invention also relates to an illumination unit comprising a white light source and utilizing this method by means of interference filters for splitting the white light into red, blue and green light beams. The invention also relates to an illumination unit comprising a red, green and blue light source and utilizing these methods by means of interference filters for the combination of the beam paths of the light sources.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

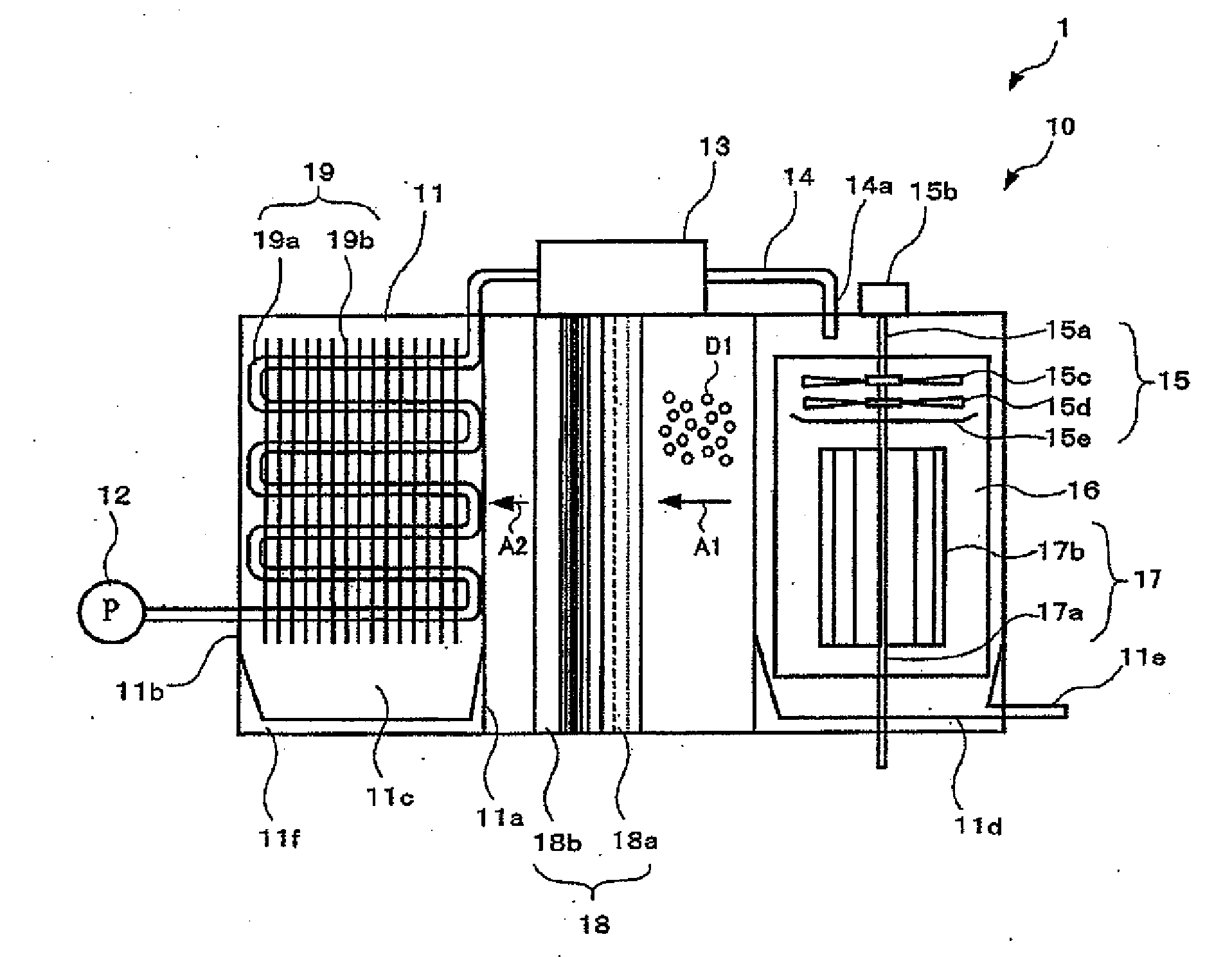

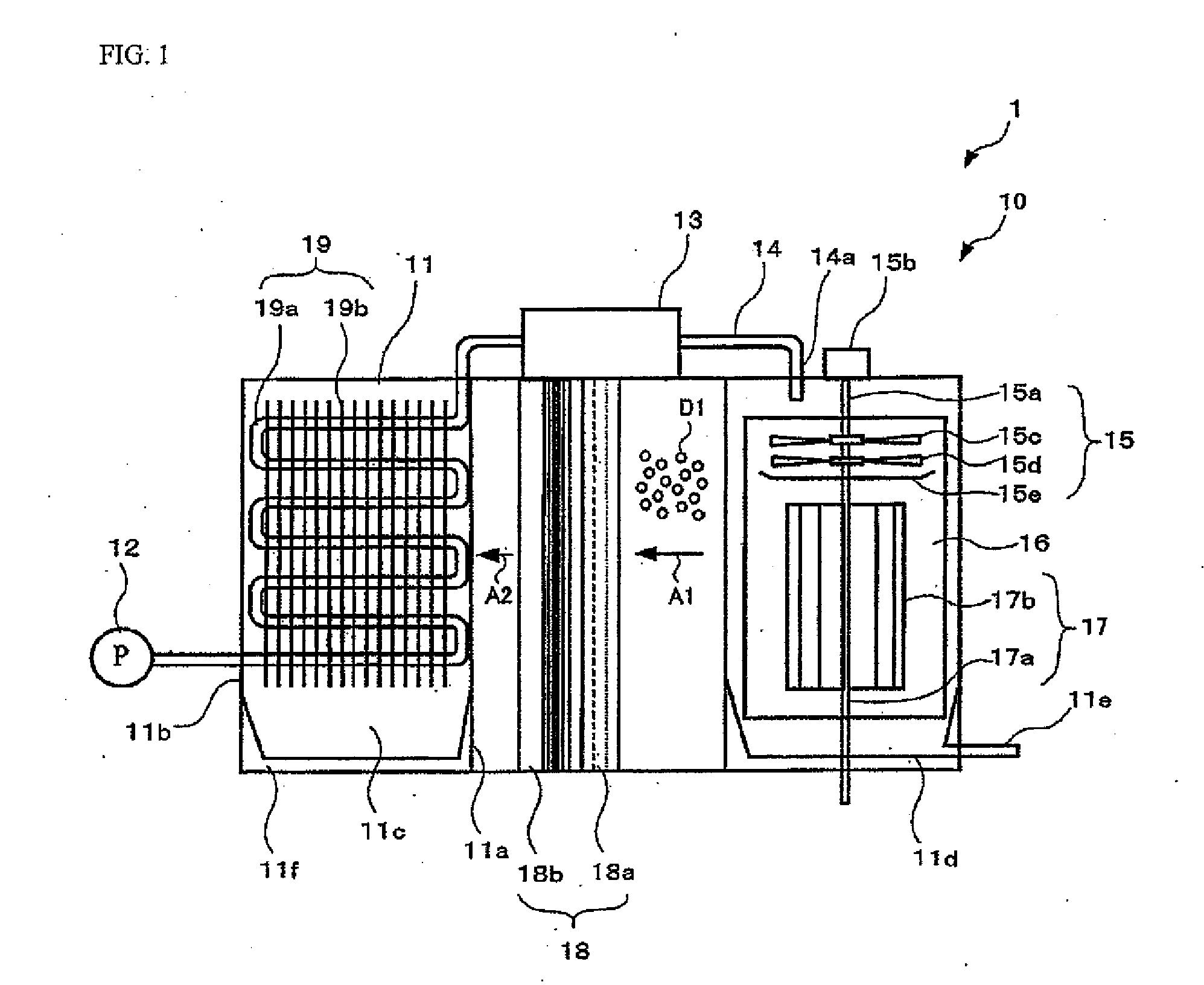

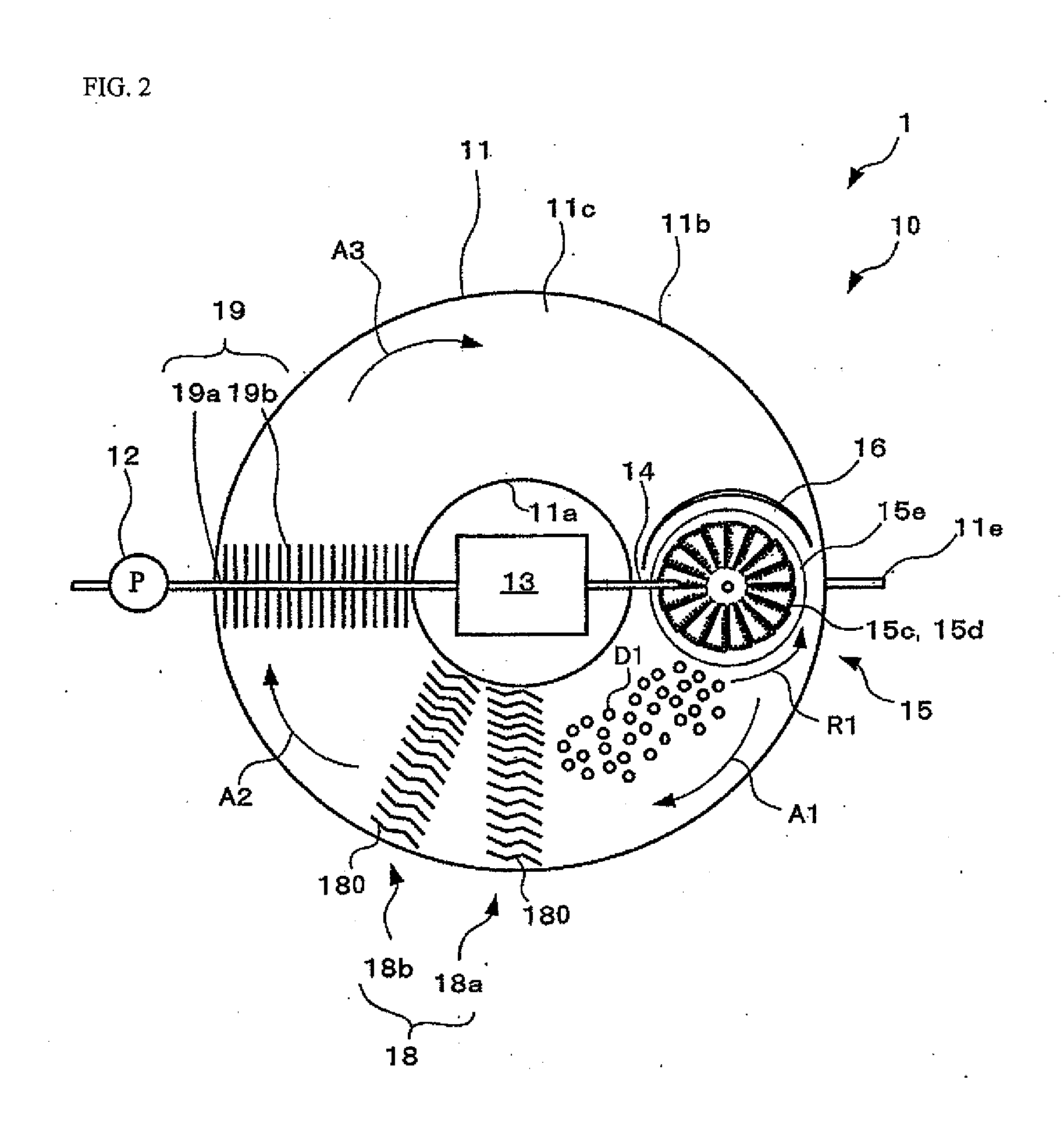

Water Purifying Apparatus

InactiveUS20120175237A1Improve deformationImprove efficiencySeawater treatmentVapor condensationWater vaporPurified water

Provided is a water purifying apparatus capable of efficiently producing purified water from raw water. The water purifying apparatus comprises: a casing (11) having a circulation path; a splitter device (15) disposed within the casing (11) and adapted to split raw water into droplets and create a carrier airflow (A1) capable of circulating along the circulation path and carrying water vapor evaporated from the droplets (D1); and a condenser (19) disposed within the casing (11) at a position downstream of the splitter device (15) in a direction of the carrier airflow and adapted to condense the water vapor to create purified water. The splitter device (15) comprises a rotary shaft (15a) extending in an up-down direction of the casing (11), and a blade (152A to 152Q) radially attached to the rotary shaft (15a) and having irregularities (152p, 152q, 152r, 152s, 152t).

Owner:CIP SOFTWARE

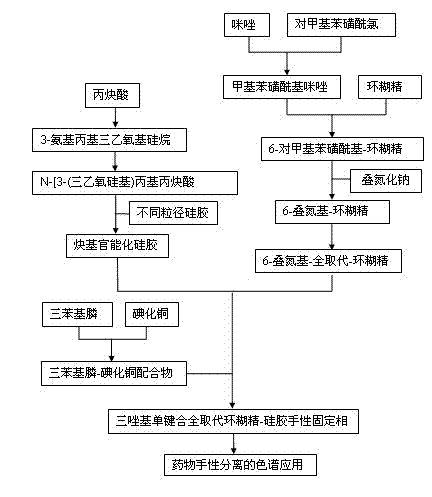

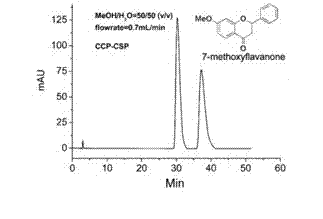

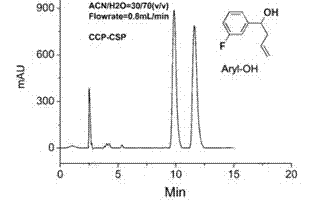

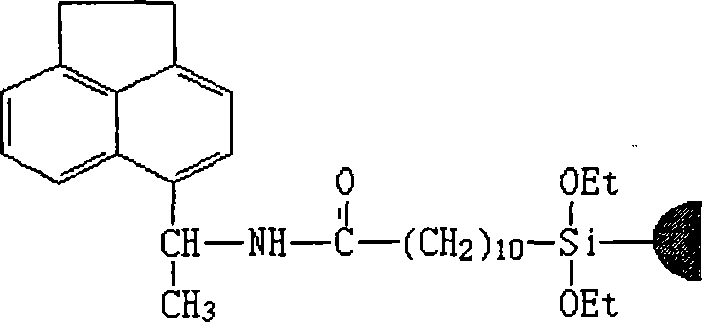

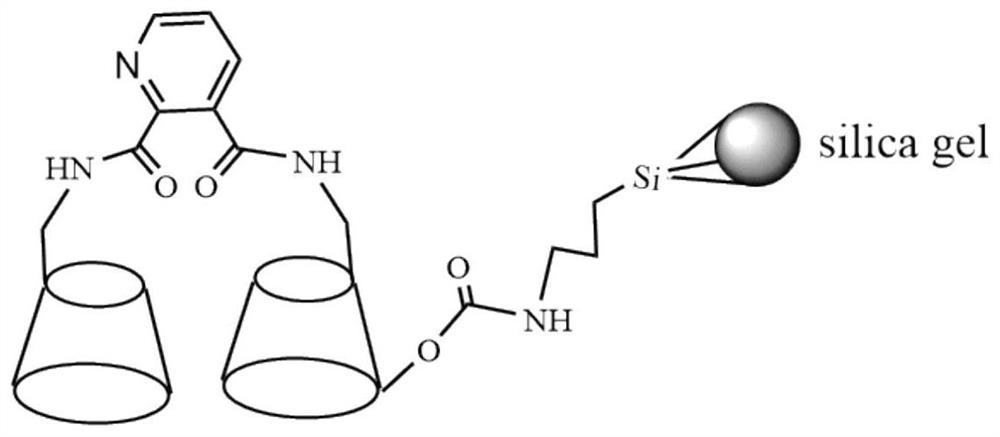

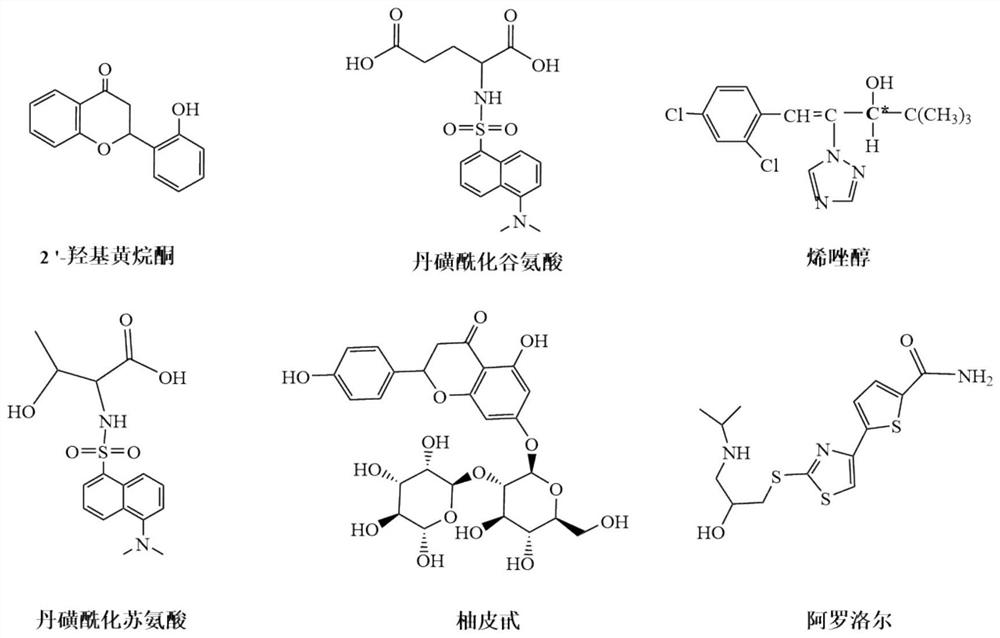

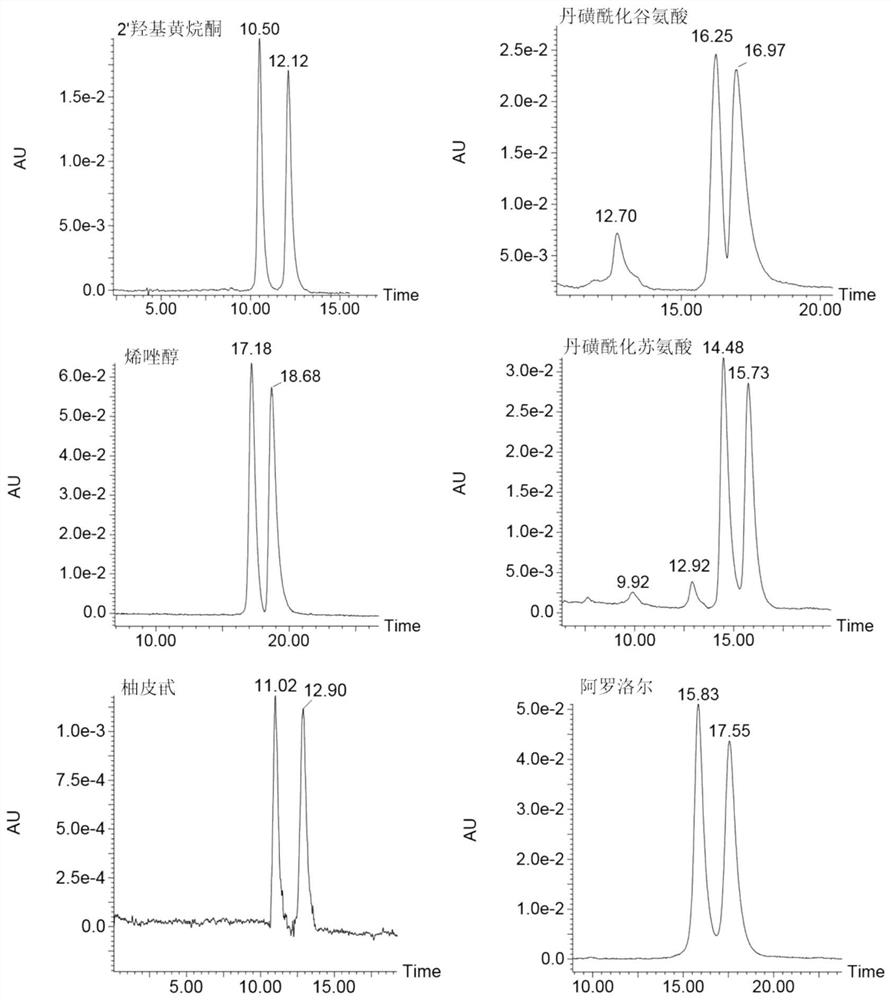

Triazole singly-bonded fully-substituted cyclodextrin silica gel chiral fixed phase and preparation method thereof

InactiveCN102389782AGood acid and alkali stabilityClick reaction implementationOther chemical processesOptically-active compound separationPtru catalystCyclodextrin

The invention discloses a click reaction based preparation method and use of a triazole singly-bonded fully-substituted cyclodextrin silica gel chiral fixed phase. In the method, the triazole singly-bonded fully-substituted cyclodextrin silica gel chiral fixed phase with high chemical stability is prepared by the selective azidation of the position 6 of cyclodextrin and full substitution and alkynylation of silica gel, by using a newly developed catalyst and by a click reaction, and the structural design of cyclodextrin is enriched. The triazole singly-bonded fully-substituted cyclodextrin silica gel chiral fixed phase demonstrates high chiral resolution capacity for amino acid and acidic and neutral racemate medicines and is expected to be used in field of medicine chiral resolution of various chromatographic techniques as a chiral fixed phase.

Owner:NANJING XINLUOMEI NEW MATERIALS

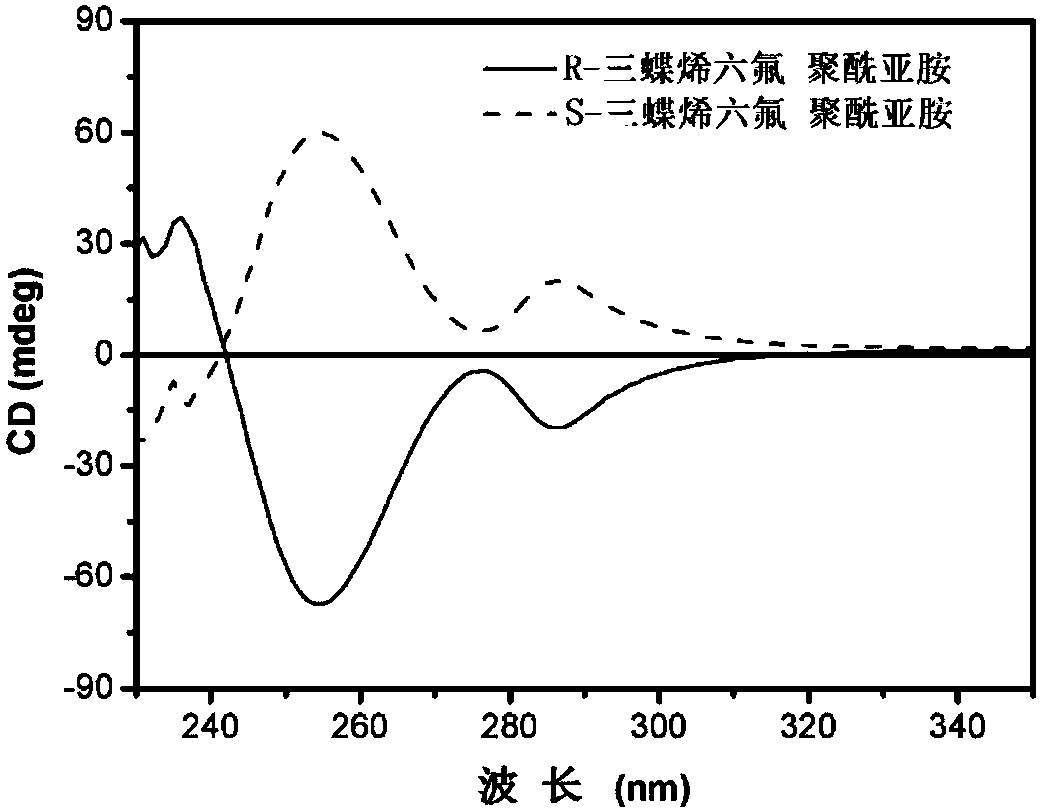

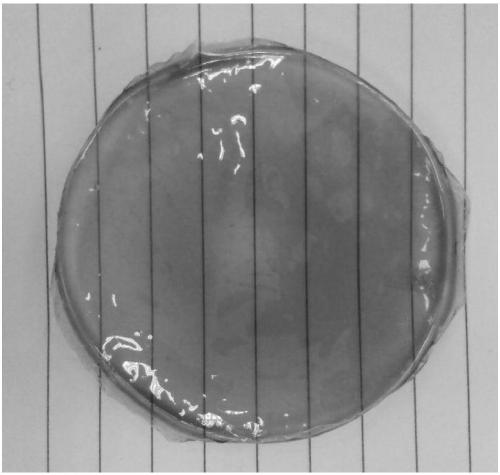

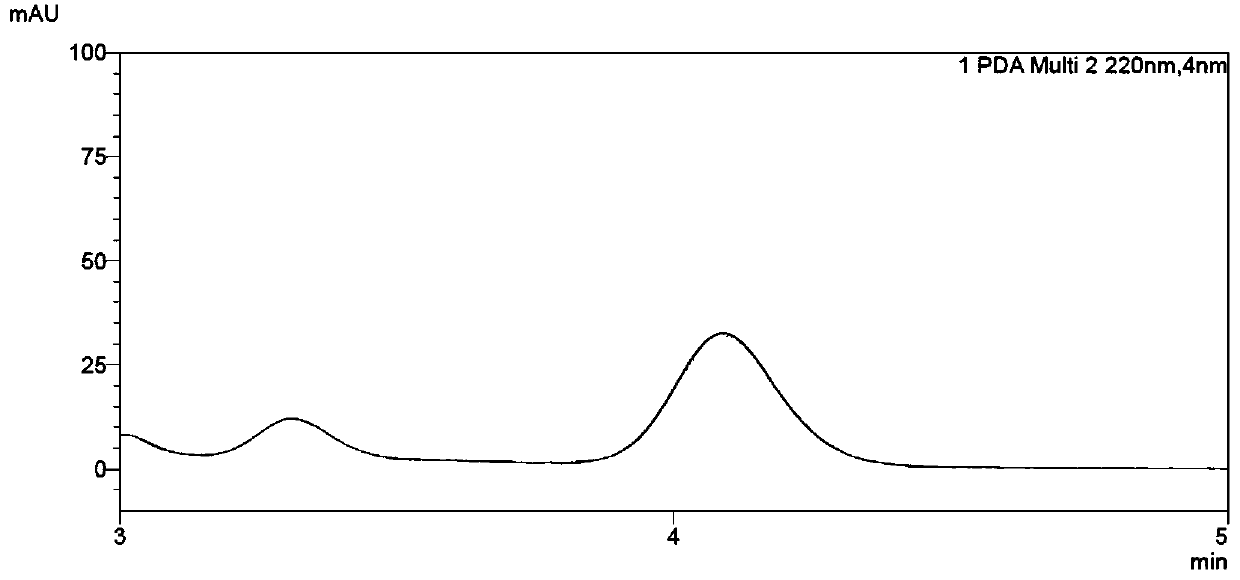

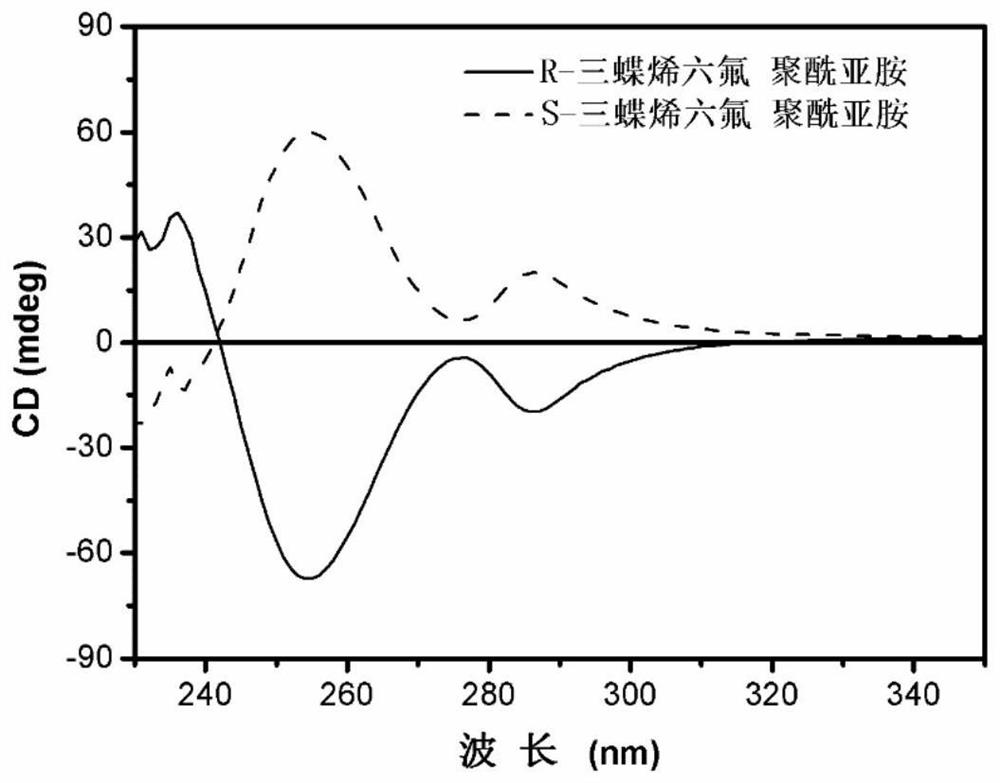

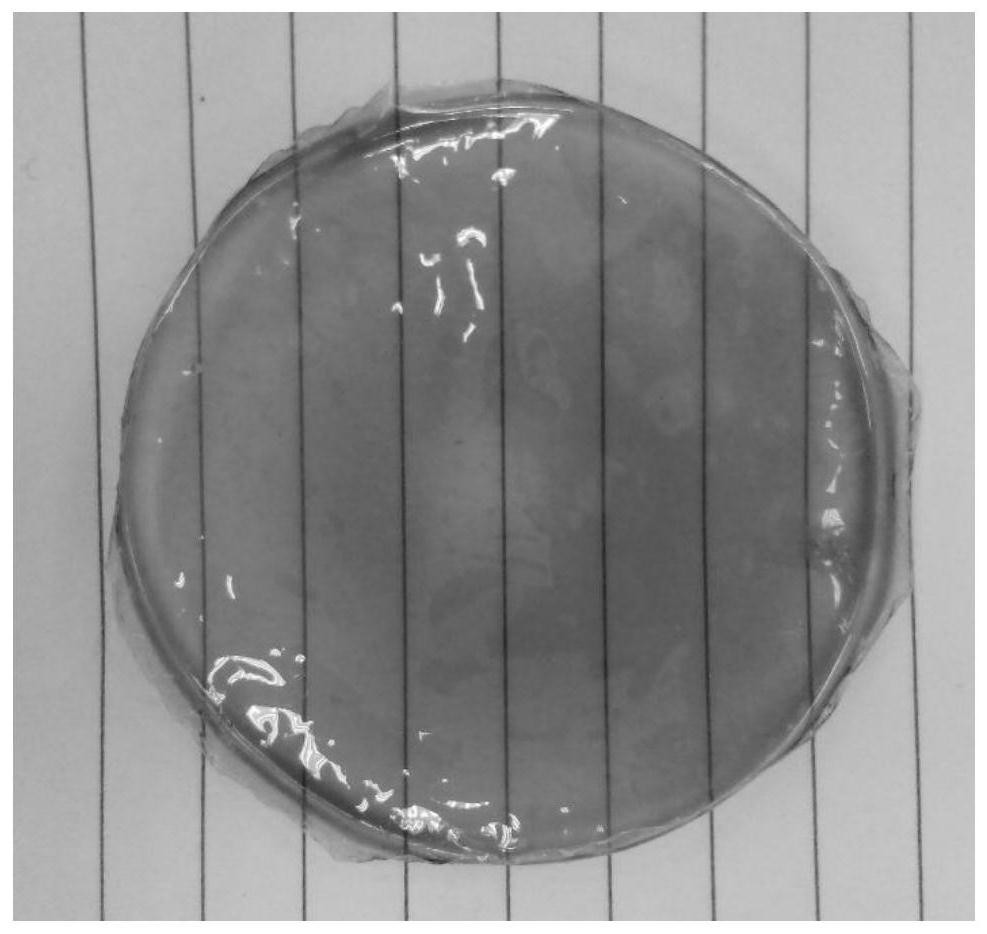

Chiral triptycene polyimide film, preparation method thereof and application of chiral trisphene polyimide film in chiral molecular separation

ActiveCN109575328AImprove thermal stabilityHigh molecular weightSemi-permeable membranesMembranesSolventChiral resolution

The invention belongs to the technical field of polymer film separation, and discloses preparation and application of two chiral triptycene polyimide films. The preparation comprises the steps of (1)carrying out polymerization reaction on a dianhydride monomer compound and optical pure 2,6-diaminotriptycene to obtain two chiral triptycene polyimide; (2) preparing a chiral film by a solvent evaporation method; and (3) separating racemation micromolecules by the chiral film through a racemation film experiment. The preparation has the advantages of low material cost, simple film making method,outstanding chiral separation effect and the like, and has large application prospect in the aspect of chiral resolution and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

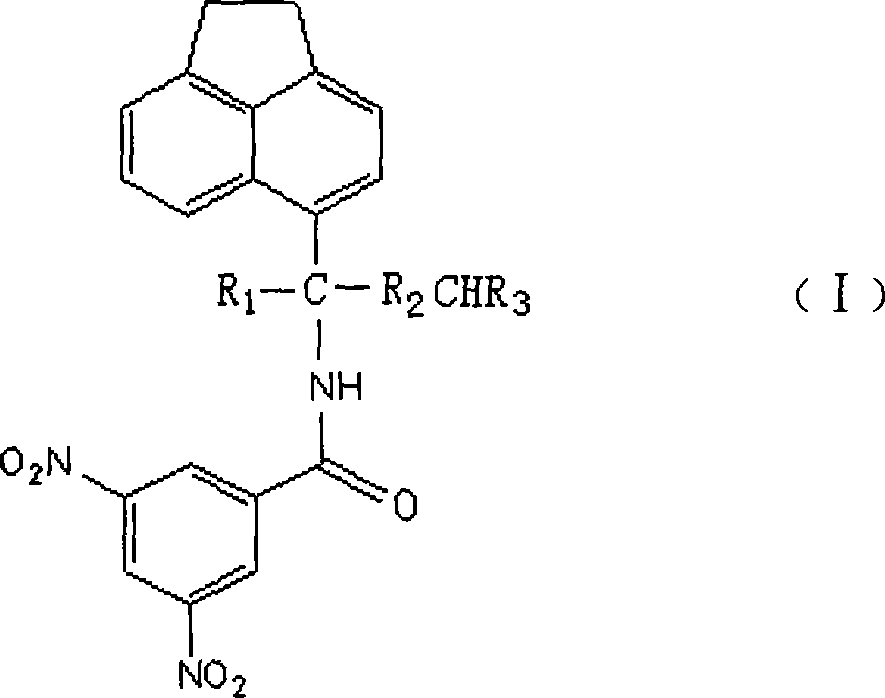

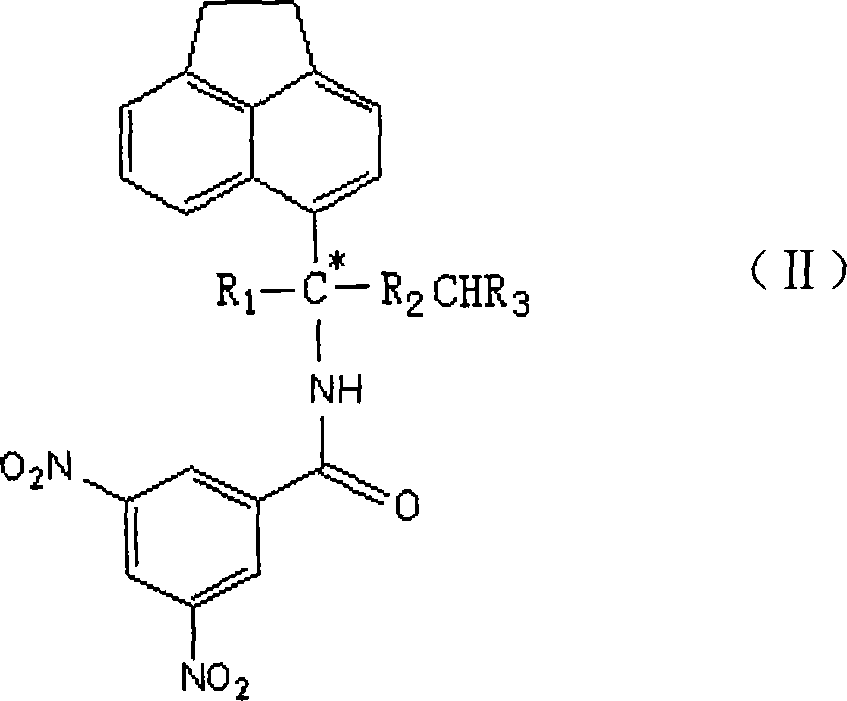

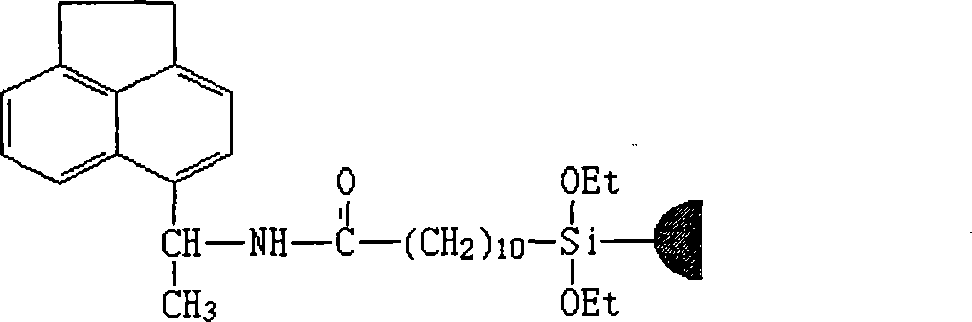

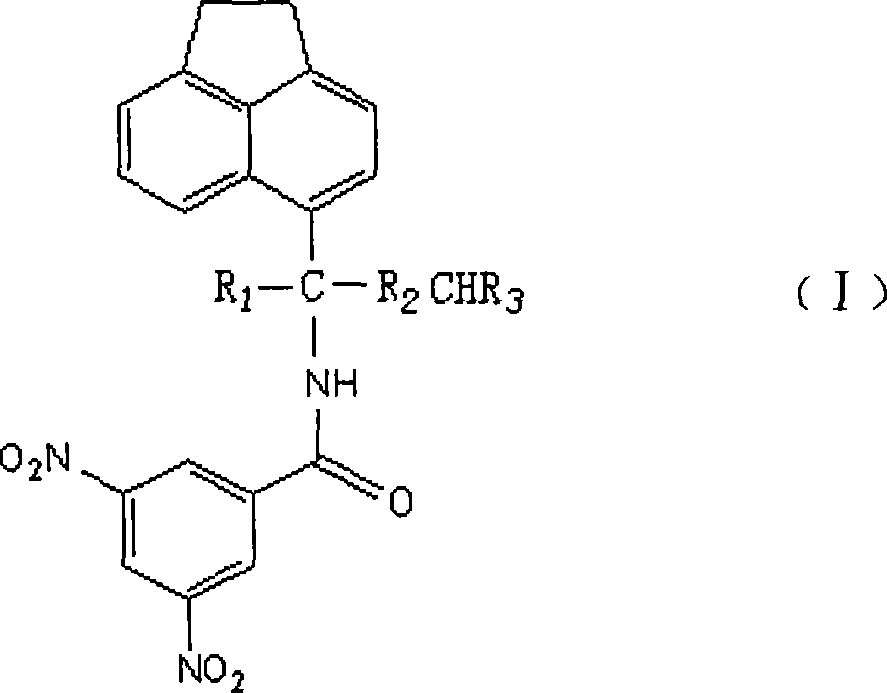

2-nitro-benzoyl-imino-acenaphthylene derivative compound and use thereof

InactiveCN101024621ALow costShort synthetic stepsOther chemical processesOptically-active compound separationAcenaphthyleneKetone

The invention relates to a dinitrobenzene formacyl imdo group acenaphthene derivatization compound that has the structure of general expression (I). And R1 represents hydrogen, C1-C3 is alkyl, R2 is alkylidene group, alkenyl, and R3 expresses one-hydrogen or two-hydrogen. After taking acylation reaction of arene, alpha-H replacing reaction of ketone, and reduction amination of ketone carbonyl, and acylation reaction of amine acyl halide, the product would be gained. The invention also relates to the single antipode of the compound, including chiral reagent or chiral additive. It could be used as chiral reagent in film method and chiral stationary phase or chiral mobile phase.

Owner:SICHUAN UNIV

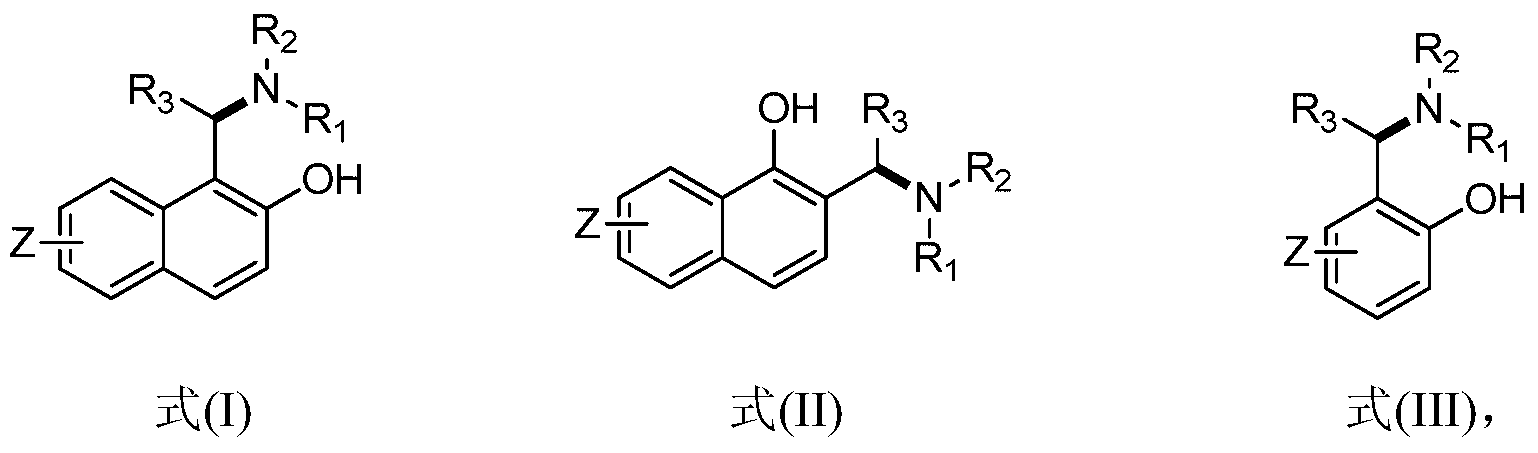

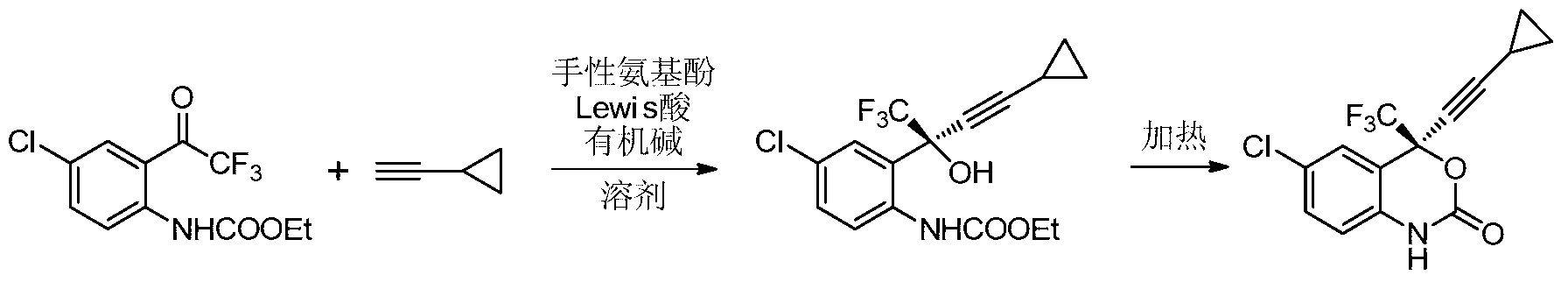

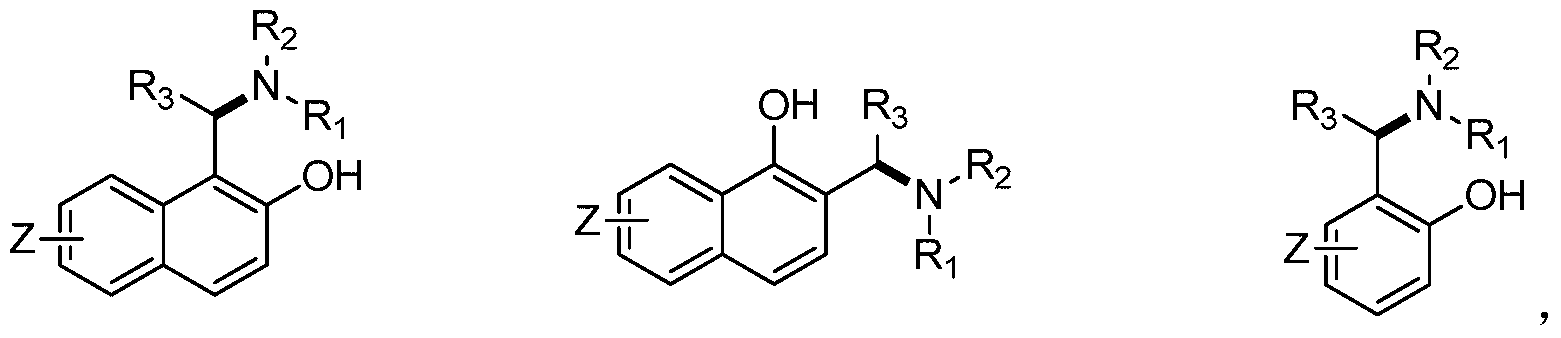

Application of chiral aminophenol ligand to asymmetric synthesis of efavirenz

ActiveCN104016936AEasy to synthesizeEfficient splitOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsKetoneEnantio selectivity

The invention relates to an application of a chiral aminophenol ligand to asymmetric synthesis of efavirenz. A chiral aminophenol ligand compound is used for inducing asymmetric synthesis of (S)-6-chloro-4-cyclopropylethynyl-4-trifluoromethyl-1,4-dihydro-2H-1,3-benzoxazine-2-ketone (Efavirenz). The ligand is cheap, easily available, safe and recoverable, is used in asymmetric synthesis of efavirenz, and has the advantages of high yield, good enantioselectivity, simplicity and convenience in operation, capability of realizing industrialized production and good product quality.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

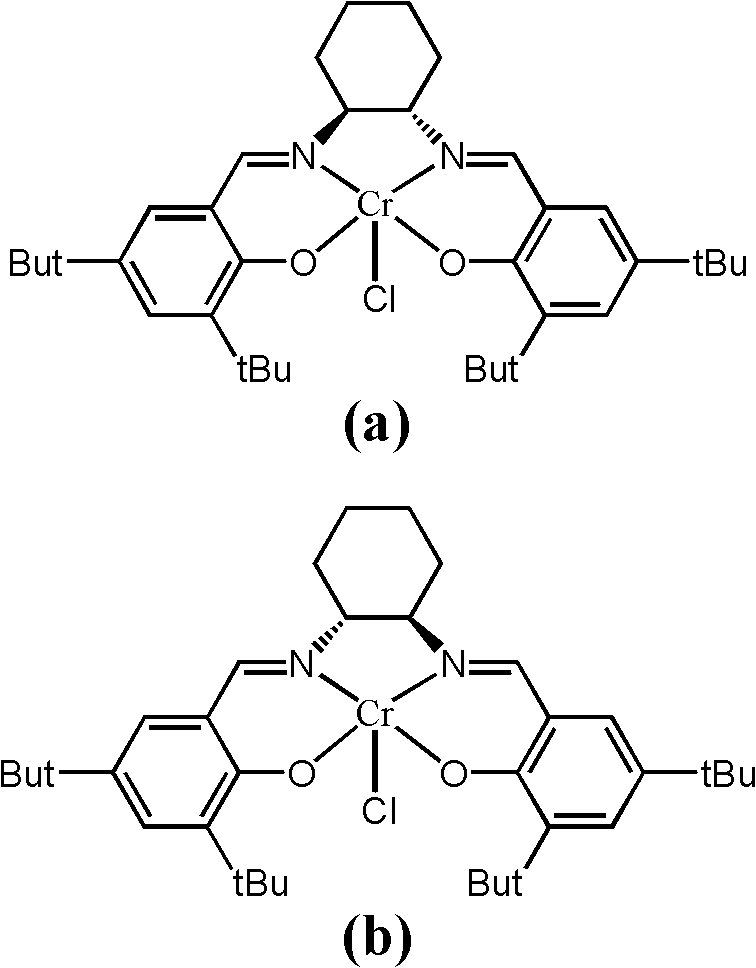

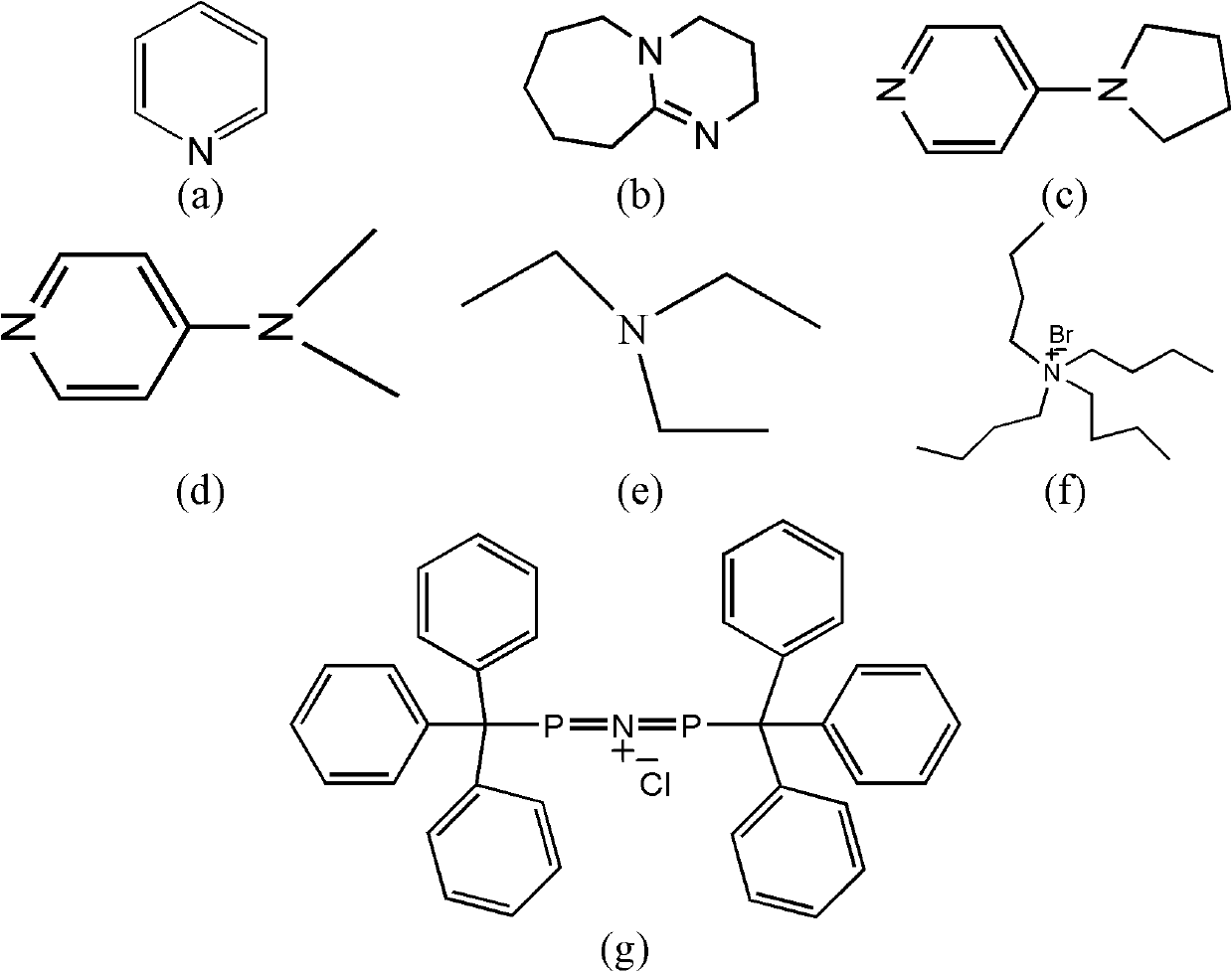

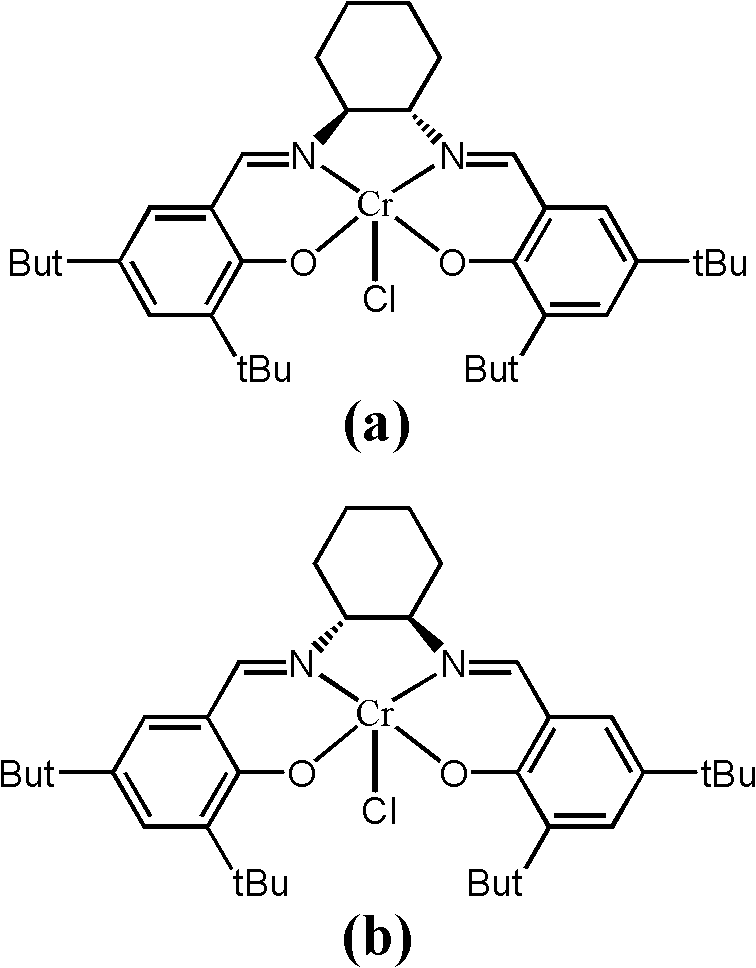

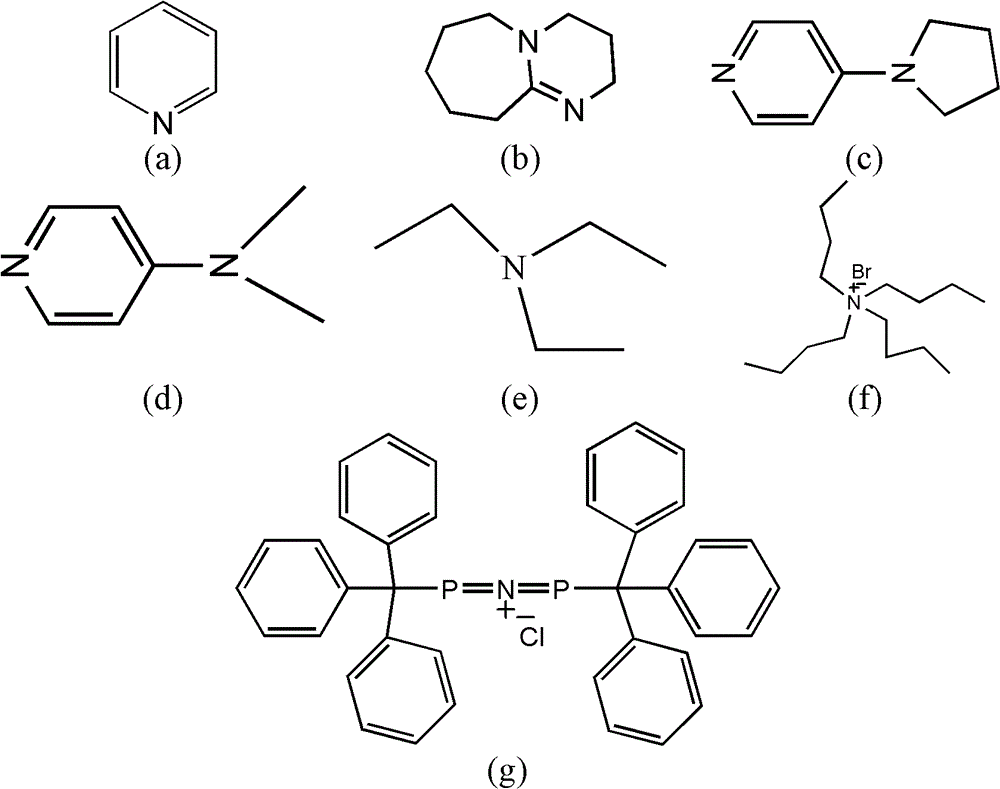

Catalyst for splitting racemic epoxyalkane and application thereof

InactiveCN103301882AReduce dosageReduce wasteGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsQuaternary ammonium cationNitrogen

The invention relates to a catalyst for splitting racemic epoxyalkane. The catalyst is composed of nitrogen-containing organic alkali or quaternary ammonium salt, and Cr (Salen) [(R,R) / (S,S)-N,N'-Bis(3,5-di-tert-butylsalicylidene)-1,2-cyclohexanediamino chromium (III) chloride], the mole ratio of the organic alkali or quaternary ammonium salt to the Cr (Salen) is 0.1-10; in the process of carrying out asymmetric ring-opening splitting of the racemic epoxyalkane, the splitting conversion rate of the catalyst to epoxyalkane can be greater than 49%, and the ee value of a split product 1-azido-2-trialkyl siloxane can be over 90%. The catalyst mainly solves the problem that previous catalytic racemic epoxyalkane is low in asymmetric ring-opening reaction activity, large in application amount of the catalyst and low in enantioselectivity, realizes the efficient splitting of racemic epoxyalkane, and can obtain high-purity chiral epoxyalkane and trialkyl siloxane.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

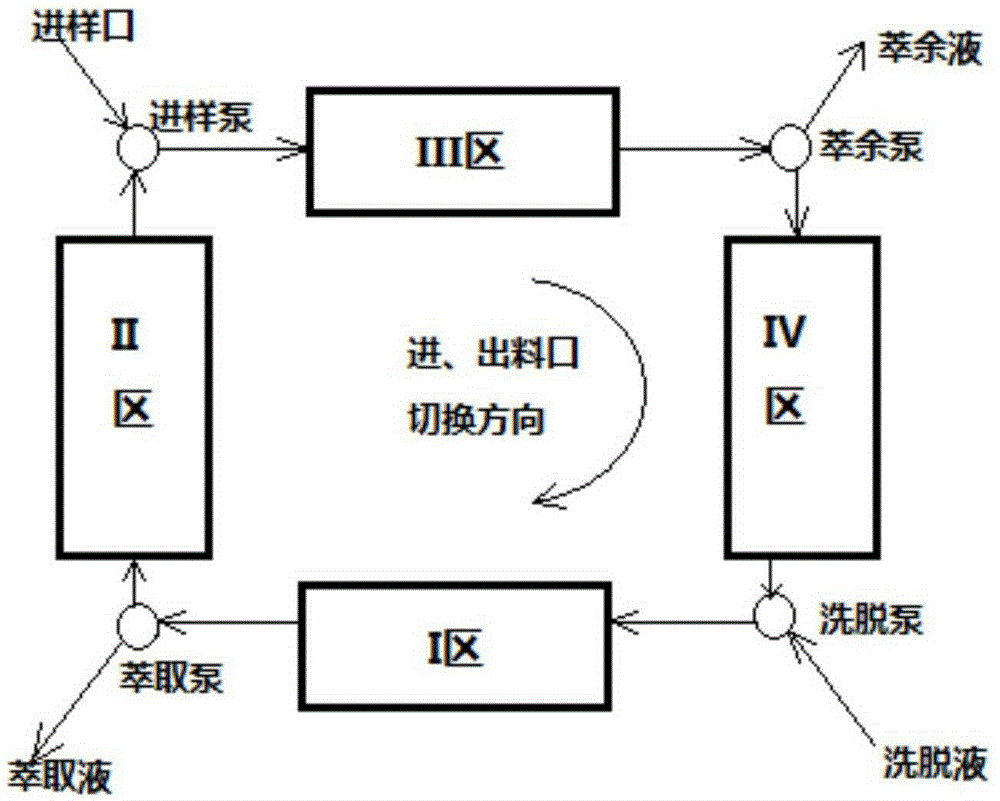

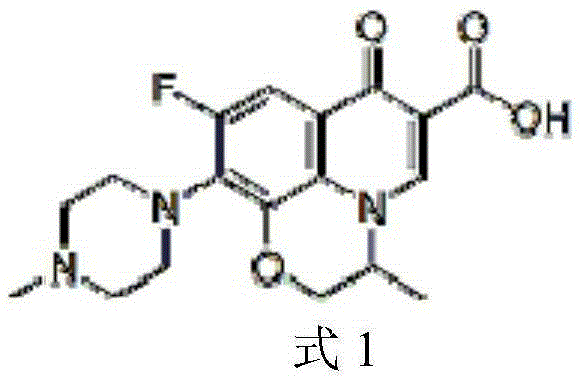

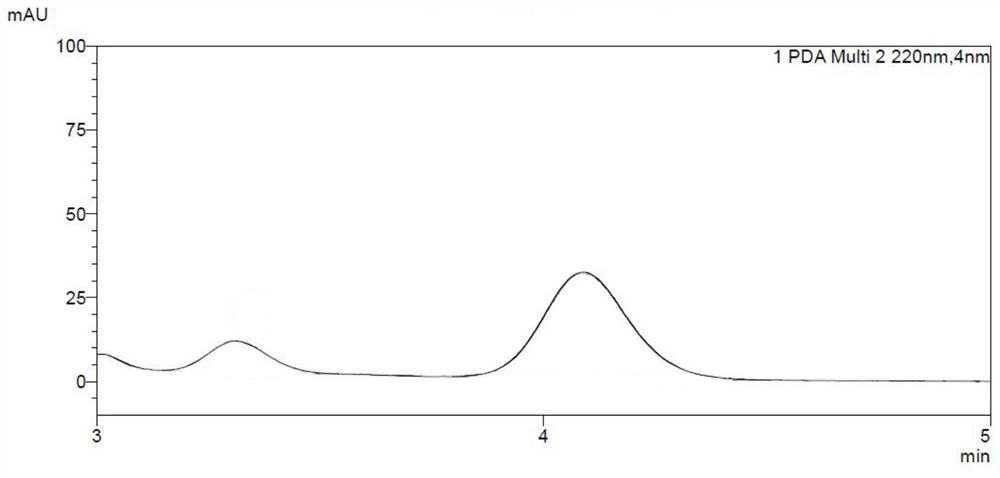

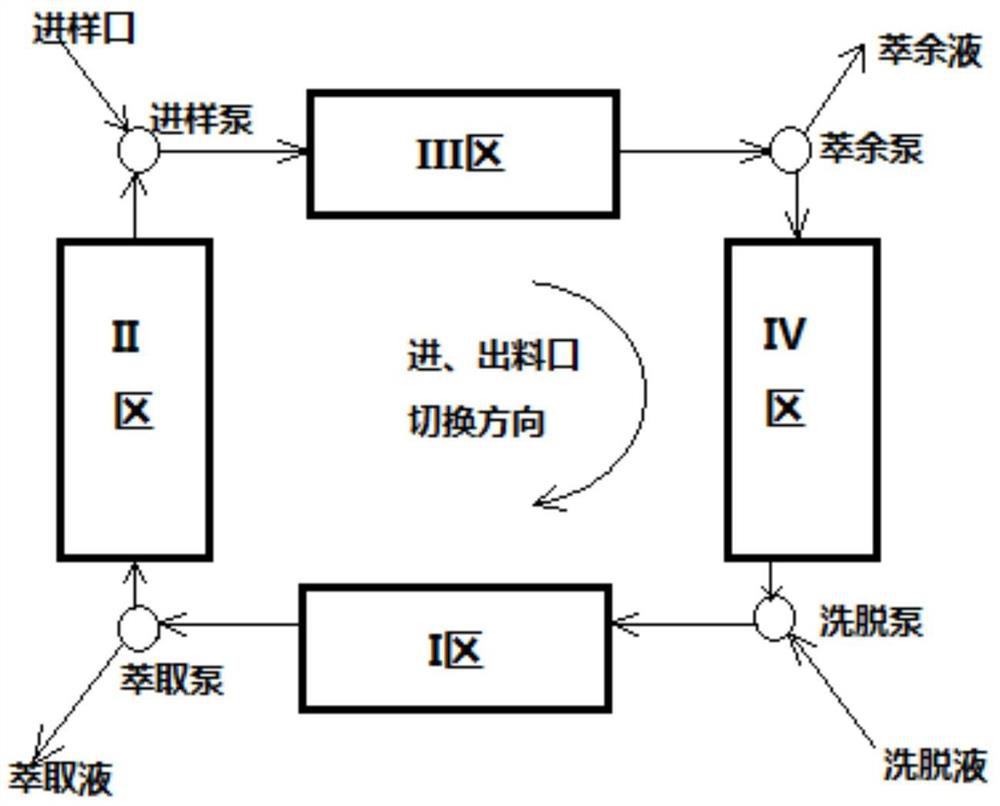

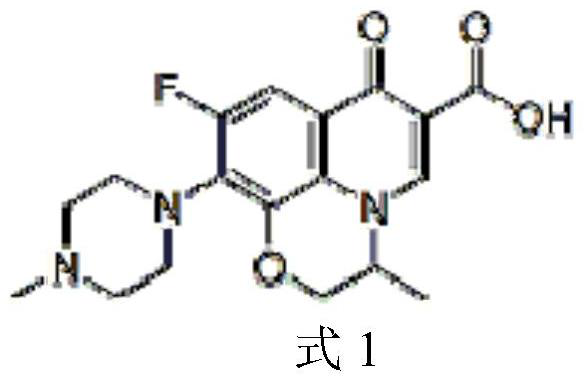

Method for separating ofloxacin enantiomer

ActiveCN106749322AEfficient splitHigh purityOptically-active compound separationOrganic racemisationCelluloseCarbamate

The invention discloses a method for separating an ofloxacin enantiomer. The method for separating the ofloxacin enantiomer comprises the steps: (1) dissolving an ofloxacin sample to obtain an ofloxacin solution; and (2) separating the ofloxacin enantiomer in the ofloxacin solution by using a simulated moving bed chromatography system, wherein chromatographic conditions are that the chromatographic column is a Chiralcel OD-H chiral column; the fixed phase is silica gel, the surface of which is coated with cellulose-tri[3, 5-xylyl carbamate]; and the mobile phase is a mixed solution containing ethanol, n-hexane and phosphoric acid. The method for separating the ofloxacin enantiomer has the advantages of simple process and stable and reliable product and can be used for industrial mass production.

Owner:WATERSTONE PHARMA WUHAN

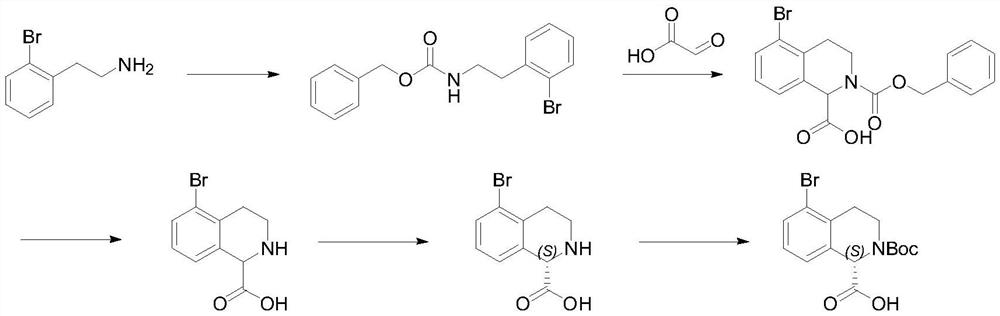

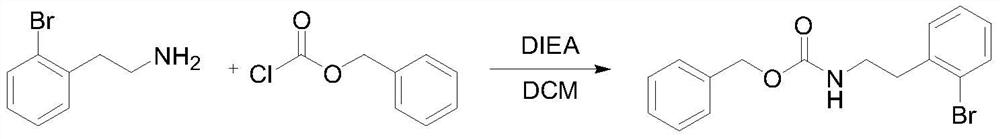

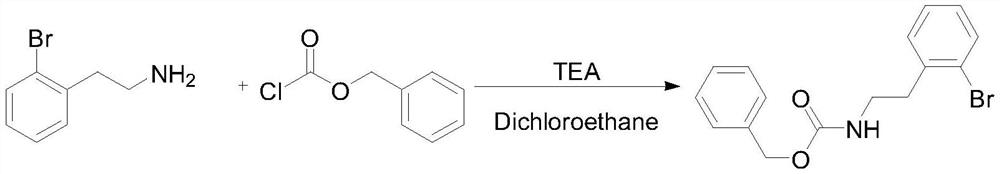

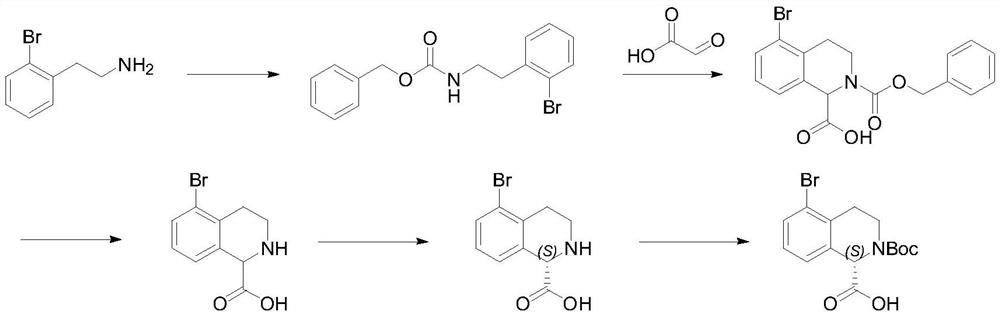

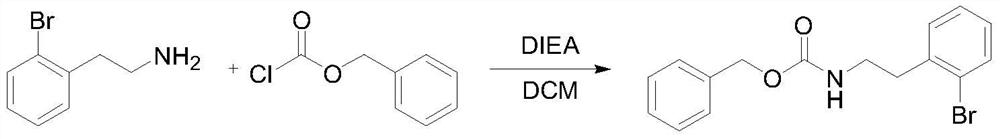

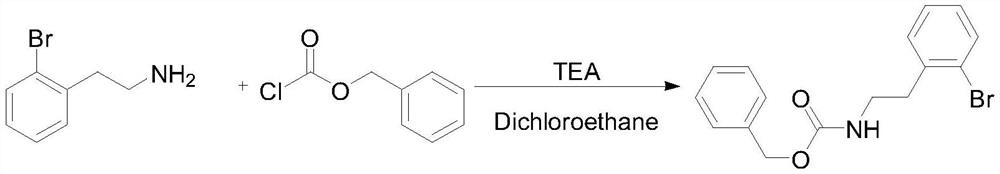

Preparation method of (S)-5-bromo-1, 2, 3, 4-tetrahydro-N-Boc-isoquinoline-1-carboxylic acid

ActiveCN112724084AThe synthetic route is reasonable and effectiveRaw materials are easy to getOrganic chemistry methodsQuinolineFormic acid

The invention discloses a preparation method for synthesizing (S)-5-bromo-1, 2, 3, 4-tetrahydro-N-Boc-isoquinoline-1-carboxylic acid, and belongs to the technical field of medical intermediates. The method comprises the following steps: reacting o-bromophenylethylamine serving as a raw material with benzyl chloroformate in an alkaline environment to obtain benzyl o-bromophenylethylamine formate; then carrying out cyclization reaction with glyoxylic acid under the catalysis of acid; then carrying out palladium-carbon catalytic hydrogenation to remove protection, so as to obtain 5-bromo-1, 2, 3, 4-tetrahydroisoquinoline-1-carboxylic acid; finally, obtaining the (S)-5-bromo-1, 2, 3, 4-tetrahydro-N-Boc-isoquinoline-1-carboxylic acid through induced resolution and Boc protection. The method is simple, convenient and stable in process operation, high in yield, environmentally friendly, cheap and easily available in raw materials and beneficial to industrial production.

Owner:CHEMVON BIOTECH CO LTD

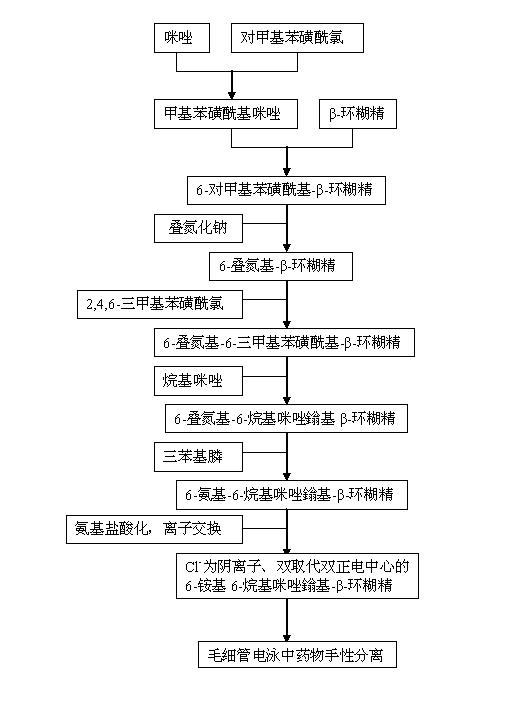

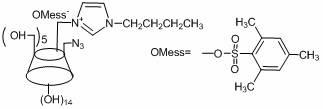

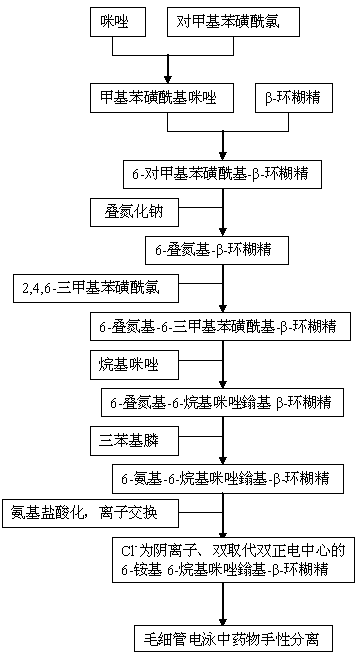

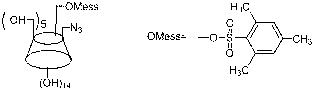

Double-substituted 6-alkyl imidazolium-6-ammonium-beta-cyclodextrin with double positive electricity centers and preparation method thereof

ActiveCN102225974AGood split effectEfficient splitOptically-active compound separationOrganic racemisationSolubilitySulfonyl chloride

The invention discloses double-substituted 6-alkyl imidazolium-6-ammonium-beta-cyclodextrin with double positive electricity centers and a preparation method thereof. The structural formula of double-substituted 6-imidazolidinylnio-6-ammonium-beta-cyclodextrin is as shown in the specification. The preparation method comprises the following steps: adding imidazole in 4-methyl-benzene sulfonyl chloride and then reacting with beta-cyclodextrin so as to obtain 6-p-methyl-benzene-sulfonyl-beta-cyclodextrin (Ts-CD) the 6-hydroxyl of which is substituted; reacting Ts-CD with sodium azide so as to obtain 6-azido-beta-cyclodextrin, namely, N3-CD; reacting N3-CD with 2,4,6-trimethyl benzene sulfonyl chloride so as to obtain 6-azido-6-(2,4,6-trimethyl benzene sulfonyl)-beta-cyclodextrin, namely, N3-Mess-CD; reacting N3-Mess-CD with alkyl imidazole so as to obtain double-substituted 6-azido-6-alkyl imidazolium-beta-cyclodextrin, and reducing azido to amino with triphenylphosphine so as to obtain double-substituted 6-amino-6-alkyl imidazolium-beta-cyclodextrin; and carrying out amino hydrochlorination and ion exchange so as to obtain double-substituted 6-alkyl imidazolium-6-ammonium-beta-cyclodextrin with the double positive electricity centers. The obtained cyclodextrin has good water solubility and effective chiral resolution capacity.

Owner:NANJING UNIV OF SCI & TECH

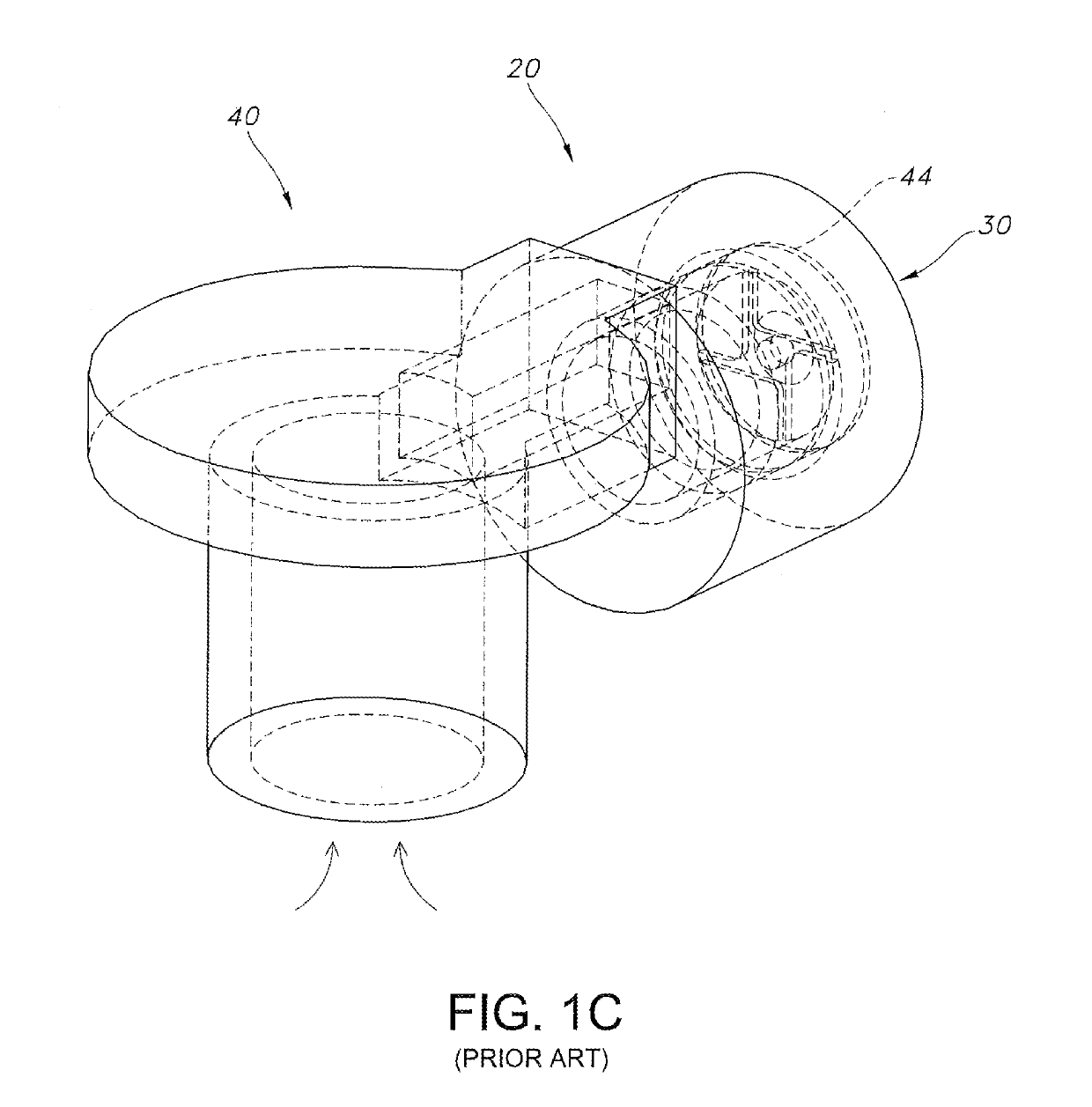

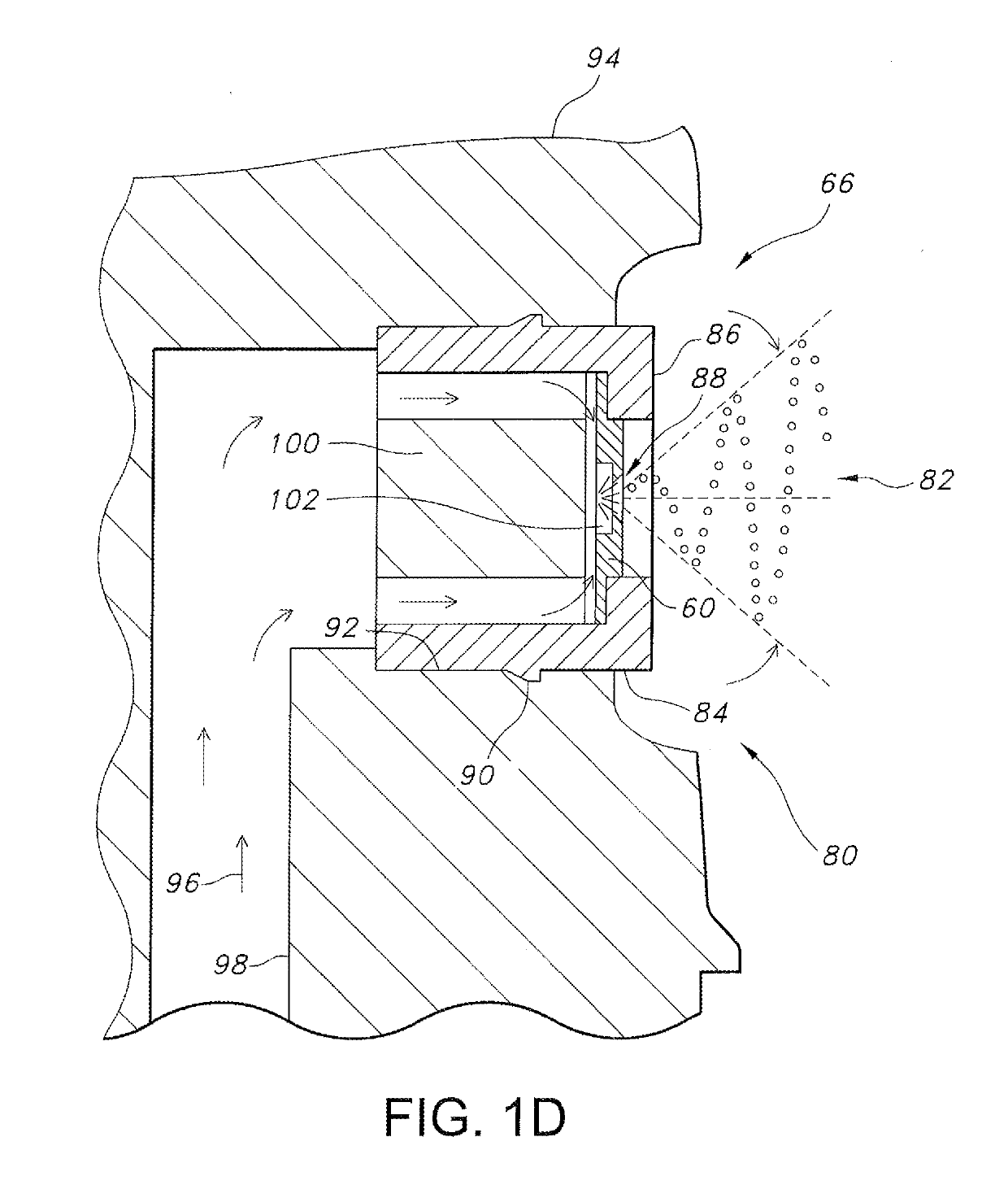

Flag mushroom cup nozzle assembly and method

An alignable conformal, cup-shaped flag-mushroom fluidic nozzle assembly is engineered to generate a flat fan or sheet oscillating spray of viscous fluid product 316. The nozzle assembly includes a cylindrical flag mushroom fluidic cup member 180 having a substantially closed distal end wall with a centrally located snout defined therein. The flag mushroom cup assembly effectively splits the operating features of the fluidic circuit between a lower or proximal portion formed in the housing's sealing post member and an upper, or distal portion formed in cup member 180 which, in cooperation with the sealing post's distal surface, defines an interaction chamber 192 fed by impinging jets each comprising a continuous distribution of streamlines that impinge at selected angles to define arcs providing a lesser degree of impingement at a centered axial plane within the exit orifice 194 and a greater degree of impingement at the edges of exit orifice 194.

Owner:DLHBOWLES INC

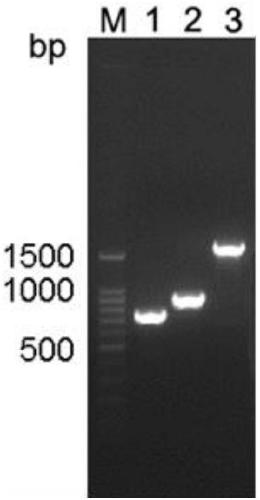

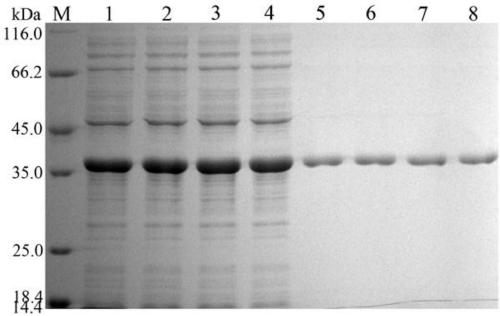

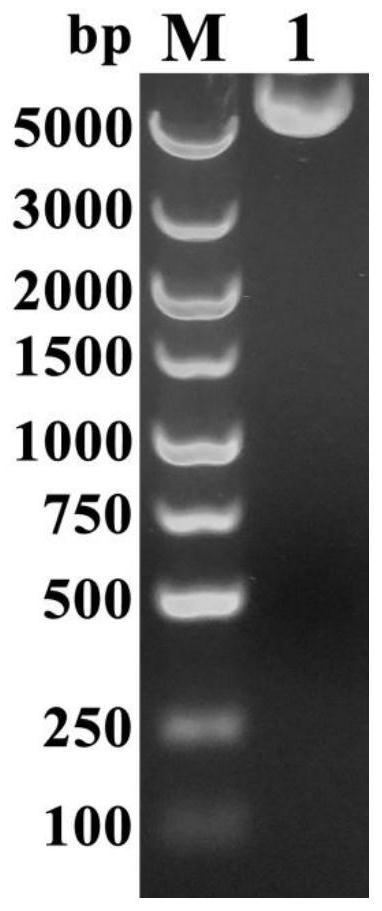

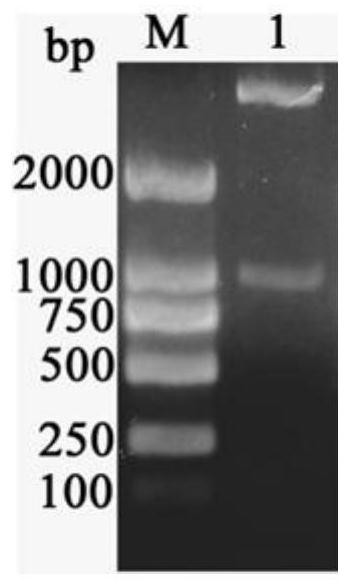

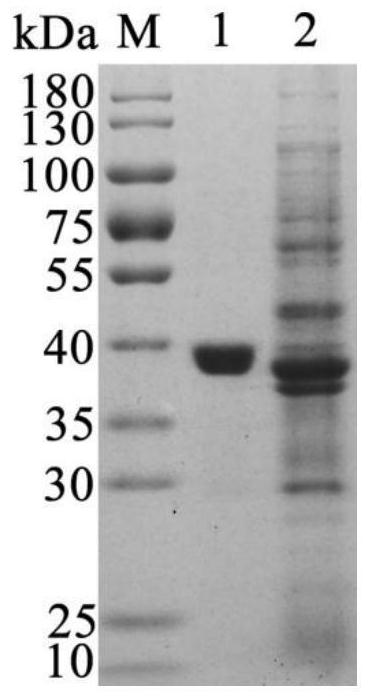

Malate dehydrogenase mutant gene and construction method and application thereof

InactiveCN109306355AHigh activityEfficient splitOxidoreductasesFermentationEscherichia coliWild type

The invention discloses a malate dehydrogenase mutant gene and a construction method and application thereof, and belongs to the technical field of biological genetic engineering. The malate dehydrogenase mutant gene is characterized in that streptomyces coelicolor malate dehydrogenase is taken as a template, a gene sequence capable of expressing the malate dehydrogenase is constructed through genetic engineering measures such as primer design, stepwise PCR (polymerase chain reaction), fusion PCR, transformed bacteria resistance screening and nucleotide sequencing, and the constructed malate dehydrogenase is transferred into DE3 strains of escherichia coli to be expressed; the activity of the expressed malate dehydrogenase is two times or above that of malate dehydrogenase under wild-typesample expression, and more efficient resolution and purification enzymes are provided for production of D-malic acid.

Owner:ANHUI NORMAL UNIV

Device for combination of light of different wavelengths

ActiveUS7420740B2Produced cost-effectivelyEffective combinationOptical elementsLight beamGreen-light

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

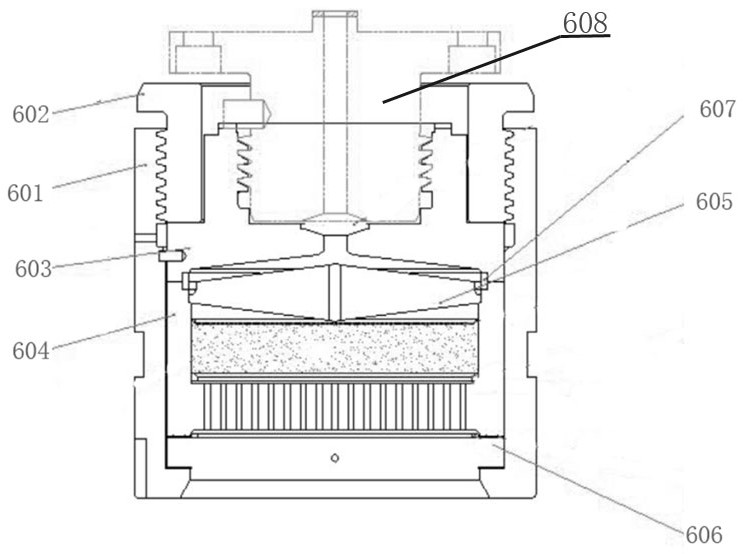

Polymer fiber spinning component disassembly system and disassembly method

ActiveCN111604351BImprove insulation effectImprove sealingSolid waste disposalMetal working apparatusAssembly disassemblyEngineering

The invention belongs to the technical field of melt spinning. A dismantling system for polymer fiber spinning components, which is used to realize the dismantling of spinning components, specifically including a heat preservation trolley, a press, a force wrench, an ejector, a holder, an inner core decomposition device and a separation knife, The heat preservation trolley is used for storage and heat preservation of the spinning assembly; the press is used to apply pressure to the deflector of the spinning assembly, and the pressure head of the press fits the deflector accordingly; the force wrench includes the working end and the force application arm, the working end is matched with the lock nut; the ejector device is used to separate the inner core of the assembly in the spinning assembly from the ejection housing; the clamper is used for clamping and transferring of the spinning assembly; the inner core disassembly device is used for The aluminum ring on the sand box is extruded and deformed; the separating knife is used for component separation and cleaning of residual materials. Also disclosed is a method for dismantling polymer fiber spinning components. The structural design is reasonable, which can greatly improve the disassembly efficiency, and burn the disassembled parts, which improves the cleaning efficiency, reduces the difficulty of operation, and makes each process proceed in an orderly manner.

Owner:SHEN MA INDUSTRY CO LTD

Double-substituted 6-alkyl imidazolium-6-ammonium-beta-cyclodextrin with double positive electricity centers and preparation method thereof

ActiveCN102225974BGood split effectEfficient splitOptically-active compound separationOrganic racemisationSolubilitySulfonyl chloride

The invention discloses double-substituted 6-alkyl imidazolium-6-ammonium-beta-cyclodextrin with double positive electricity centers and a preparation method thereof. The structural formula of double-substituted 6-imidazolidinylnio-6-ammonium-beta-cyclodextrin is as shown in the specification. The preparation method comprises the following steps: adding imidazole in 4-methyl-benzene sulfonyl chloride and then reacting with beta-cyclodextrin so as to obtain 6-p-methyl-benzene-sulfonyl-beta-cyclodextrin (Ts-CD) the 6-hydroxyl of which is substituted; reacting Ts-CD with sodium azide so as to obtain 6-azido-beta-cyclodextrin, namely, N3-CD; reacting N3-CD with 2,4,6-trimethyl benzene sulfonyl chloride so as to obtain 6-azido-6-(2,4,6-trimethyl benzene sulfonyl)-beta-cyclodextrin, namely, N3-Mess-CD; reacting N3-Mess-CD with alkyl imidazole so as to obtain double-substituted 6-azido-6-alkyl imidazolium-beta-cyclodextrin, and reducing azido to amino with triphenylphosphine so as to obtain double-substituted 6-amino-6-alkyl imidazolium-beta-cyclodextrin; and carrying out amino hydrochlorination and ion exchange so as to obtain double-substituted 6-alkyl imidazolium-6-ammonium-beta-cyclodextrin with the double positive electricity centers. The obtained cyclodextrin has good water solubility and effective chiral resolution capacity.

Owner:NANJING UNIV OF SCI & TECH

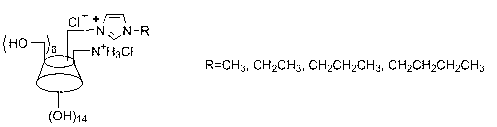

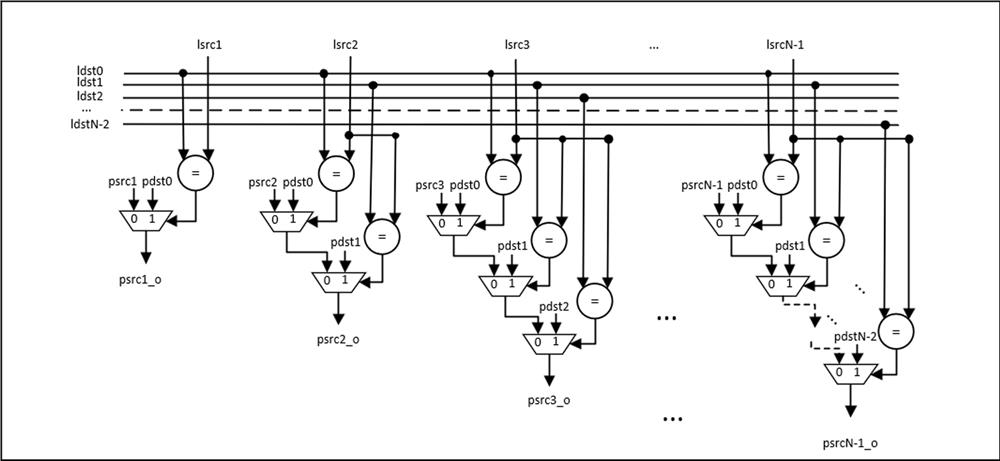

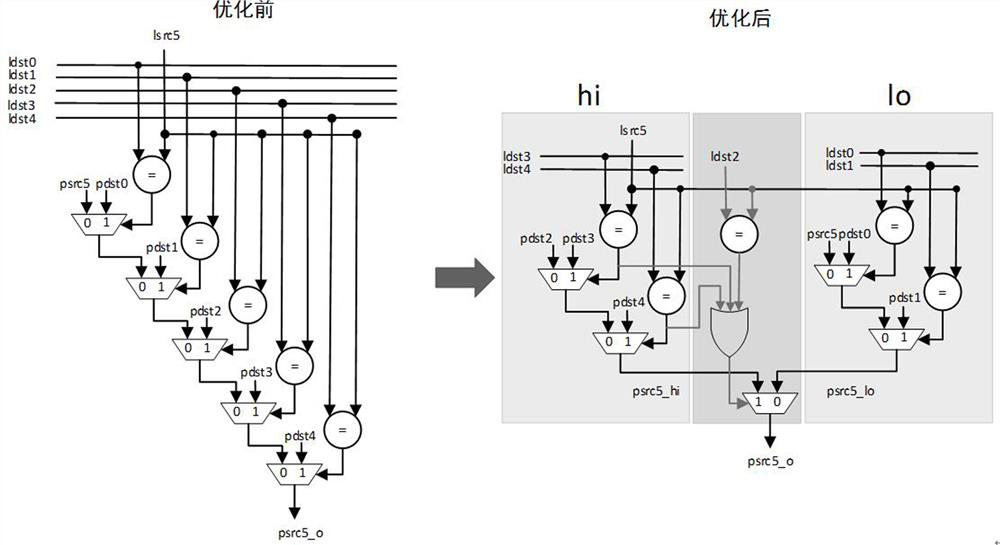

Register renaming method and system for processor

ActiveCN114116009BEfficient splitReduce critical path delayConcurrent instruction executionComputer architectureEngineering

The invention discloses a register renaming method for a processor. The method comprises: splitting logical purpose registers corresponding to multiple input pipeline instructions to generate at least two inspection groups; performing correlation check on the inspection groups respectively A final physical source register is determined; and a critical path for register renaming of the superscalar processor is determined according to the final physical source register. Therefore, the critical path of the register renaming dependency check processing circuit can be optimized, the time delay of the critical path can be reduced, and the frequency of the superscalar processor can be increased.

Owner:GUANGDONG COMM & NETWORKS INST

2-nitro-benzoyl-imino-acenaphthylene derivative compound and use thereof

InactiveCN101024621BLow costShort synthetic stepsOther chemical processesOptically-active compound separationAcenaphthyleneHydrogen

Owner:SICHUAN UNIV

Pyridinedicarboxamido bridged bis-β-cyclodextrin stationary phase and its preparation method and application

ActiveCN113797905BExcellent chromatographic performanceChromatographic performance is stableOther chemical processesSolid sorbent liquid separationStationary phaseFluid phase

Owner:NANCHANG UNIV

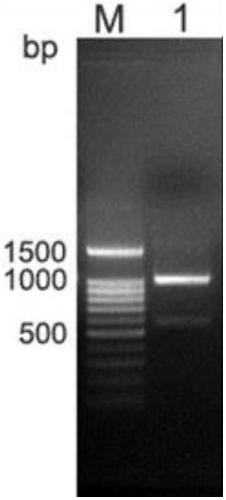

Construction method, encoded protein and application of a thermostable malate dehydrogenase gene

ActiveCN110577961BHigh activityEfficient splitOxidoreductasesFermentationWild typeAcyl CoA dehydrogenase

The invention discloses a method for constructing a heat-stable malate dehydrogenase gene, an encoded protein and its application. The malate dehydrogenase gene of the present invention uses the original expression plasmid gene sequence as a template and adopts designed mutation primers to carry out rapid Amplify the mutant plasmid by point mutation PCR, screen the resistance of transformed bacteria, construct a gene sequence capable of expressing malate dehydrogenase, and transfer the constructed mutant malate dehydrogenase gene to Escherichia coli DE3 strain for expression. The expressed malate dehydrogenase has the characteristics of higher thermal stability and higher activity than the malate dehydrogenase expressed in the wild type of the sample, and provides a more efficient resolution and purification enzyme for the production of D-malic acid.

Owner:SHANDONG YANGCHENG BIOLOGY TECH CO LTD

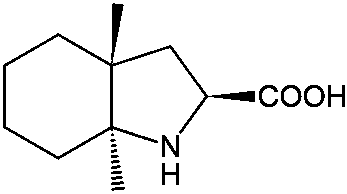

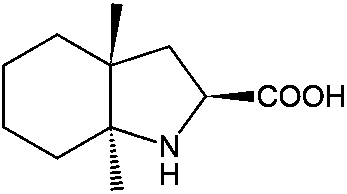

Resolution method for racemate of trandolapril intermediate

InactiveCN110452950ASplit method securityThe splitting method is environmentally friendlyFermentationPichia pastorisRoom temperature

The invention discloses a resolution method for a racemate of a trandolapril intermediate. The trandolapril intermediate is shown by a structural formula I and subjected to a catalytic reaction undera weak alkaline environment by utilizing pichia pastoris lipase. It is found through research that the pichia pastoris lipase can resolve the racemate of the trandolapril intermediate under a room-temperature condition and an alkaline condition to obtain the intermediate suitable for producing trandolapril, and the resolution method is safe, environmentally friendly and free of toxins and pollution.

Owner:JIANGSU YONGDA PHARMA

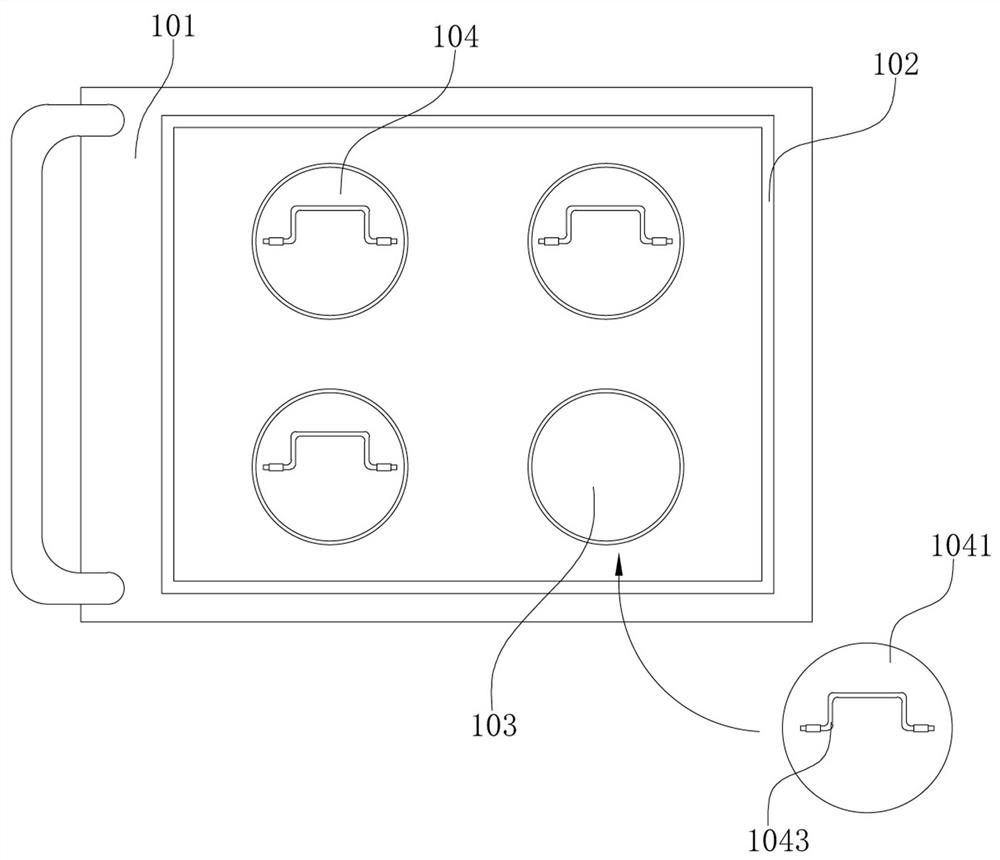

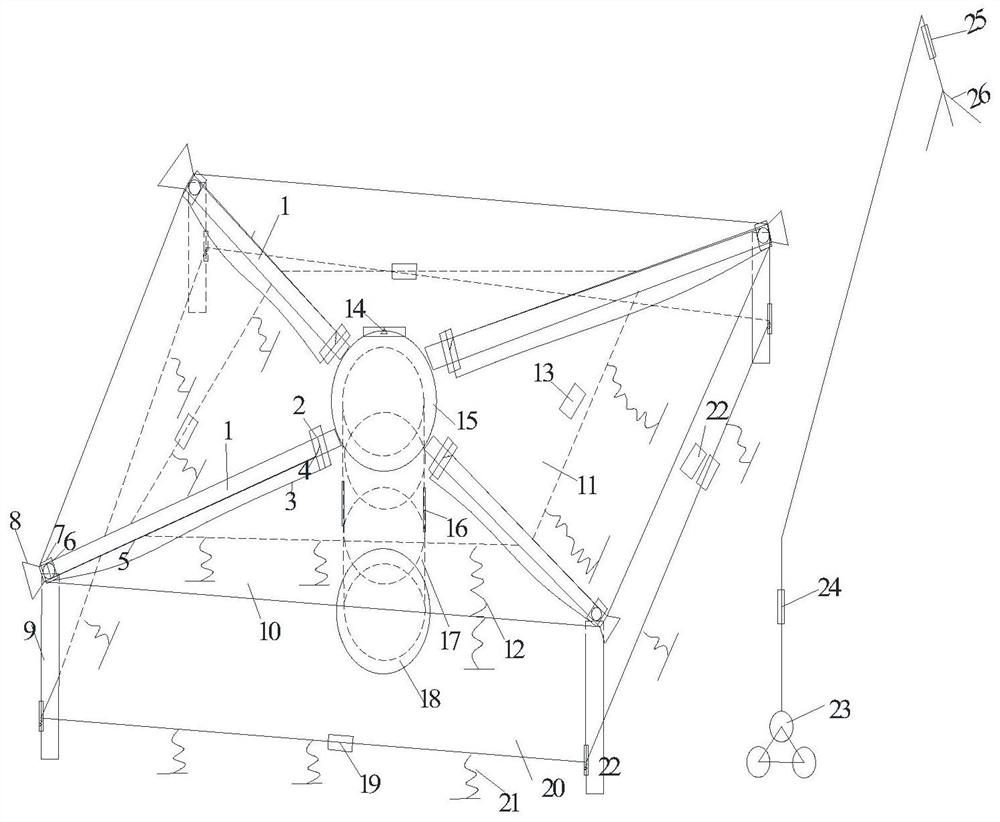

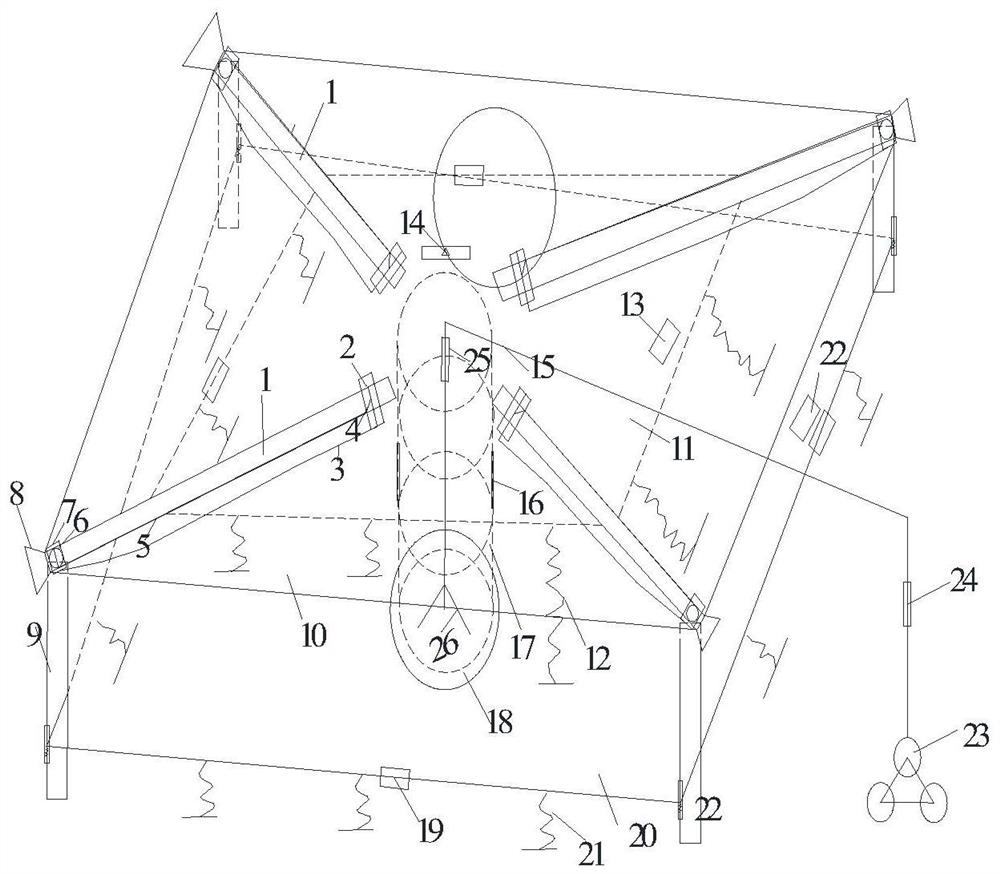

Accurate matching and efficient splitting experimental device for early strength of activated fly ash-doped cement test piece

InactiveCN112881136AEarly Strength Precise Proportion PreciseLow early strengthPreparing sample for investigationMicro nanoPipe

The invention discloses an accurate matching and efficient splitting experimental device for early strength of an activated fly ash-doped cement test piece. The matching precision of the fly ash and the micro-nano material is an important factor influencing the early strength of a micro-nano material activated fly ash-doped cement test piece, and weighing for manufacturing a standard test piece is carried out manually and gradually; due to multiple sensitive factors of the early strength, the standard test piece is mostly taken out from a matching cylindrical pipe and is disassembled from the bottom or the top end by means of external force, and the test result is influenced, so that the accurate matching and efficient splitting experimental device for early strength of the test piece is needed. Different components such as micro-nano materials, coal ash and water are distributed to the middle-layer vibration platform through 4-6 sets of precise metering filling pipes arranged on the upper-layer platform, are uniformly stirred through a stirring system and then are lowered to the lower-layer early strength matching cylindrical pipe on the basis of full vibration of the vibration platform; by means of layered stirring and compaction of an intelligent stirring system and full vibration of a lower-layer vibration platform, after 6-8 hours, the early strength matching cylindrical pipe is placed in a strength testing device to be laterally split, and then accurate early strength matching and efficient splitting can be completed.

Owner:ANHUI UNIV OF SCI & TECH

Catalyst for splitting racemic epoxyalkane and application thereof

InactiveCN103301882BReduce dosageReduce wasteGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsNitrogenChloride

The invention relates to a catalyst for splitting racemic epoxyalkane. The catalyst is composed of nitrogen-containing organic alkali or quaternary ammonium salt, and Cr (Salen) [(R,R) / (S,S)-N,N'-Bis(3,5-di-tert-butylsalicylidene)-1,2-cyclohexanediamino chromium (III) chloride], the mole ratio of the organic alkali or quaternary ammonium salt to the Cr (Salen) is 0.1-10; in the process of carrying out asymmetric ring-opening splitting of the racemic epoxyalkane, the splitting conversion rate of the catalyst to epoxyalkane can be greater than 49%, and the ee value of a split product 1-azido-2-trialkyl siloxane can be over 90%. The catalyst mainly solves the problem that previous catalytic racemic epoxyalkane is low in asymmetric ring-opening reaction activity, large in application amount of the catalyst and low in enantioselectivity, realizes the efficient splitting of racemic epoxyalkane, and can obtain high-purity chiral epoxyalkane and trialkyl siloxane.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

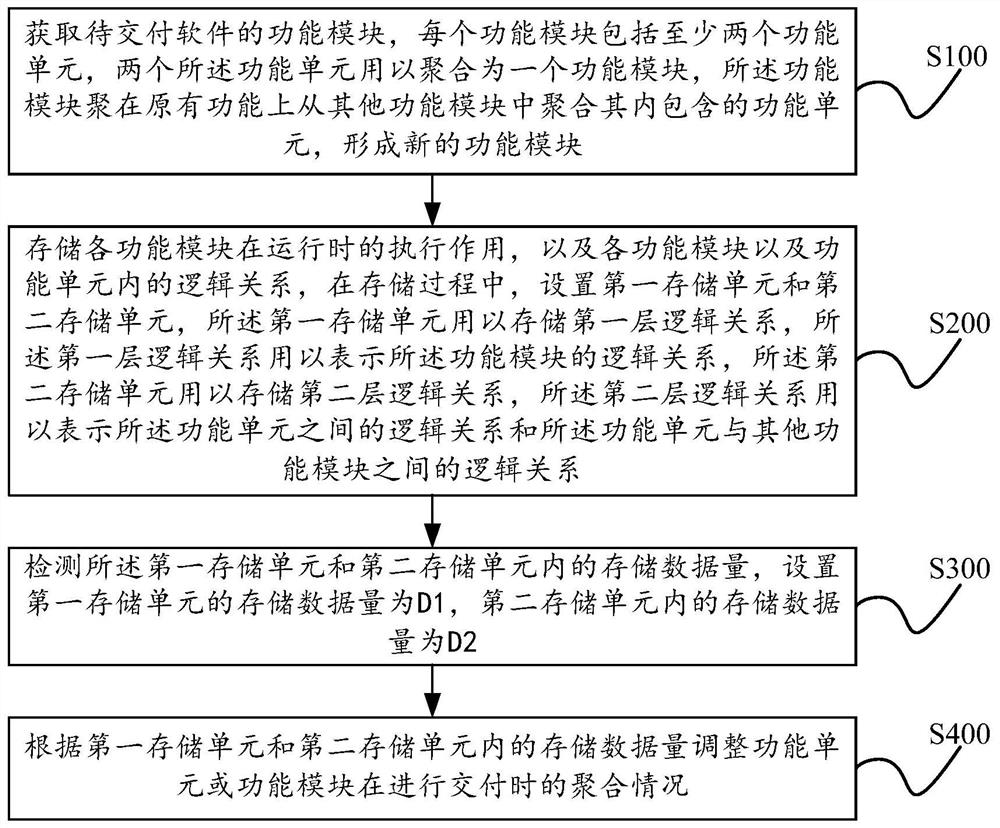

Low-code delivery method based on software development

ActiveCN114398021ALess quantityImprove delivery efficiencyMemory adressing/allocation/relocationModel driven codeSoftware developmentEmbedded system

The invention relates to a low-code delivery method based on software development, which comprises the following steps: obtaining functional modules of software to be delivered, each functional module comprising at least two functional units, the two functional units being used for aggregating into one functional module, functional units contained in the functional modules are polymerized from other functional modules on the basis of original functions; the storage module is provided with a first storage unit and a second storage unit, the first storage unit is used for storing a first-layer logic relation, and the second storage unit is used for storing a second-layer logic relation; detecting the storage data volume in the first storage unit and the second storage unit; and adjusting the aggregation condition of the functional unit or the functional module during delivery according to the data volume stored in the first storage unit and the second storage unit. According to the method, the functional units and functional module division of the to-be-delivered software are reasonably adjusted, so that the delivery code quantity is greatly reduced during delivery, the delivery efficiency is improved, and the delivery time limit and the delivery period are shortened.

Owner:北京大唐神州科技有限公司

Chiral triptycene polyimide film and its preparation method and application of chiral molecular separation

ActiveCN109575328BImprove thermal stabilityHigh molecular weightSemi-permeable membranesMembranesSolvent evaporationThin membrane

The invention belongs to the technical field of polymer film separation, and discloses preparation and application of two chiral triptycene polyimide films. The preparation comprises the steps of (1)carrying out polymerization reaction on a dianhydride monomer compound and optical pure 2,6-diaminotriptycene to obtain two chiral triptycene polyimide; (2) preparing a chiral film by a solvent evaporation method; and (3) separating racemation micromolecules by the chiral film through a racemation film experiment. The preparation has the advantages of low material cost, simple film making method,outstanding chiral separation effect and the like, and has large application prospect in the aspect of chiral resolution and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for separating ofloxacin enantiomers

ActiveCN106749322BEfficient splitHigh purityOptically-active compound separationOrganic racemisationCelluloseO-Phosphoric Acid

The invention discloses a method for separating an ofloxacin enantiomer. The method for separating the ofloxacin enantiomer comprises the steps: (1) dissolving an ofloxacin sample to obtain an ofloxacin solution; and (2) separating the ofloxacin enantiomer in the ofloxacin solution by using a simulated moving bed chromatography system, wherein chromatographic conditions are that the chromatographic column is a Chiralcel OD-H chiral column; the fixed phase is silica gel, the surface of which is coated with cellulose-tri[3, 5-xylyl carbamate]; and the mobile phase is a mixed solution containing ethanol, n-hexane and phosphoric acid. The method for separating the ofloxacin enantiomer has the advantages of simple process and stable and reliable product and can be used for industrial mass production.

Owner:WATERSTONE PHARMA WUHAN

A kind of preparation method of (s)-5-bromo-1,2,3,4-tetrahydro-n-boc-isoquinoline-1-carboxylic acid

ActiveCN112724084BAppropriate split effectEfficient splitOrganic chemistry methodsBenzyl chloroformateFormate

The invention discloses a preparation method for synthesizing (S)-5-bromo-1,2,3,4-tetrahydro-N-Boc-isoquinoline-1-carboxylic acid, belonging to the technical field of pharmaceutical intermediates. Using o-bromophenethylamine as a raw material to react with benzyl chloroformate in an alkaline environment to obtain benzyl o-bromophenethylamine formate, followed by cyclization reaction with glyoxylic acid under acid catalysis, followed by palladium carbon catalytic hydrogenation Deprotection gives 5-bromo-1,2,3,4-tetrahydroisoquinoline-1-carboxylic acid, and finally obtains (S)-5-bromo-1,2,3, 4‑Tetrahydro‑N‑Boc‑isoquinoline‑1‑carboxylic acid. The process of the invention is simple and stable in operation, high in yield, friendly to the environment, cheap and easy to obtain raw materials, and is beneficial to industrialized production.

Owner:CHEMVON BIOTECH CO LTD

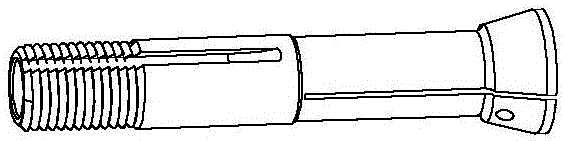

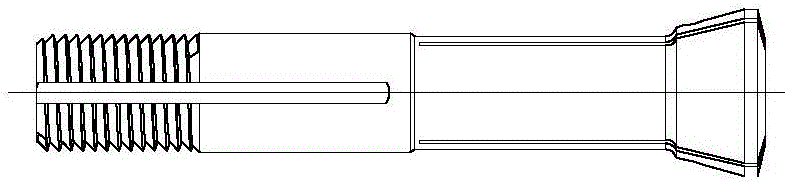

Shaft pulling device used for pulling airplane anti-icing valve guide shaft and shaft pulling method

ActiveCN106625393AQuick releaseEasy to useWeight reductionMetal-working hand toolsEngineeringValve guide

The invention discloses a shaft pulling device used for pulling an airplane anti-icing valve guide shaft. The shaft pulling device comprises a taper pipe barrel (3), a lock nozzle (1), a lock nozzle square-head nut (6), a positioning base (2), two long wrench handles (5), two short wrench handles (5), two L-shaped fastening and positioning blocks (7) and a rotating nut (4). The two L-shaped fastening and positioning blocks (7) are oppositely and symmetrically fixed to the two ends of a waist plate of the positioning base (2) through bases via connecting pieces; the lock nozzle (1) penetrates in the taper pipe barrel (3); the lock nozzle square-head nut (6) is screwed on an outer thread at one end of the lock nozzle (1); and the above parts penetrate a middle large through hole of the waist plate of the positioning base (2) together after being assembled. The positioning base (2) is fixed to a valve shell provided with the airplane anti-icing valve guide shaft.

Owner:GUANGZHOU AIRCRAFT MAINTENANCE ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com