Parametric modeling design method for fabricated building

A parametric modeling and design method technology, applied in computer-aided design, calculation, electrical digital data processing, etc., can solve the problems of heavy collision detection workload, unfavorable unification of drawing standards, and repeated workload, etc., to eliminate The effect of designers’ negligence, eliminating manual size adjustment, and saving design costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In order to improve work efficiency and unify drafting standard, method of the present invention comprises the steps:

[0032] The first step is to extract parameters.

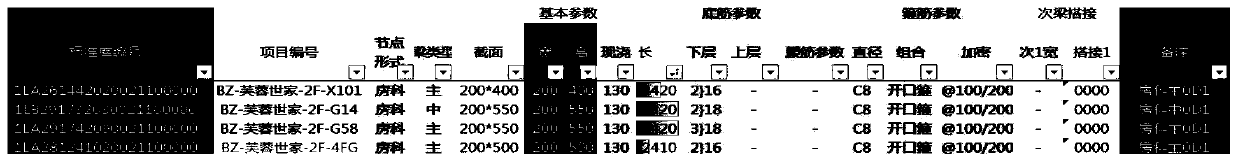

[0033] Specifically, the parameters of each component obtained by splitting are extracted from the structural construction drawing of CAD. The extracted parameters are used to put into a database, for example, the database is recorded in the form of Microsoft Office Access or excel. It can be a separate database record for standard parts of each family, such as composite beam database, composite slab database, staircase database, prefabricated column database, prefabricated slab database, prefabricated beam database. Take the composite beam as an example, its parameters include: section parameters: 250*650. Length parameter: 6795. Stirrup parameters: Φ8@100 / 200. Bottom bar parameters: 2Φ25. Rib parameters: G4Φ12. Lap parameters of primary and secondary beams: width of secondary beam, center line o...

Embodiment 2

[0050] Corresponding to the purpose of the present invention is to provide a new parametric modeling and design method for prefabricated buildings, the present invention provides the following specific design steps.

[0051] Before developing the method described in the present invention, the inventors believed that: for prefabricated buildings, the design depth needs to reach a whole new level, just like the production of automobiles or airplanes, for industrial workers, they only need to work according to the drawings That is, it does not matter where the produced components are used. Since it is like producing automobiles and airplanes, the inventor tried to use Unigraphics NX software (that is, UG software, which is a comprehensive software for automobile design, manufacturing, and simulation) to solve its prefabricated building design, production, Many practical problems encountered by management. For example, 1. There is no material preparation list in the process drawi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com