Patents

Literature

215results about How to "Good split effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

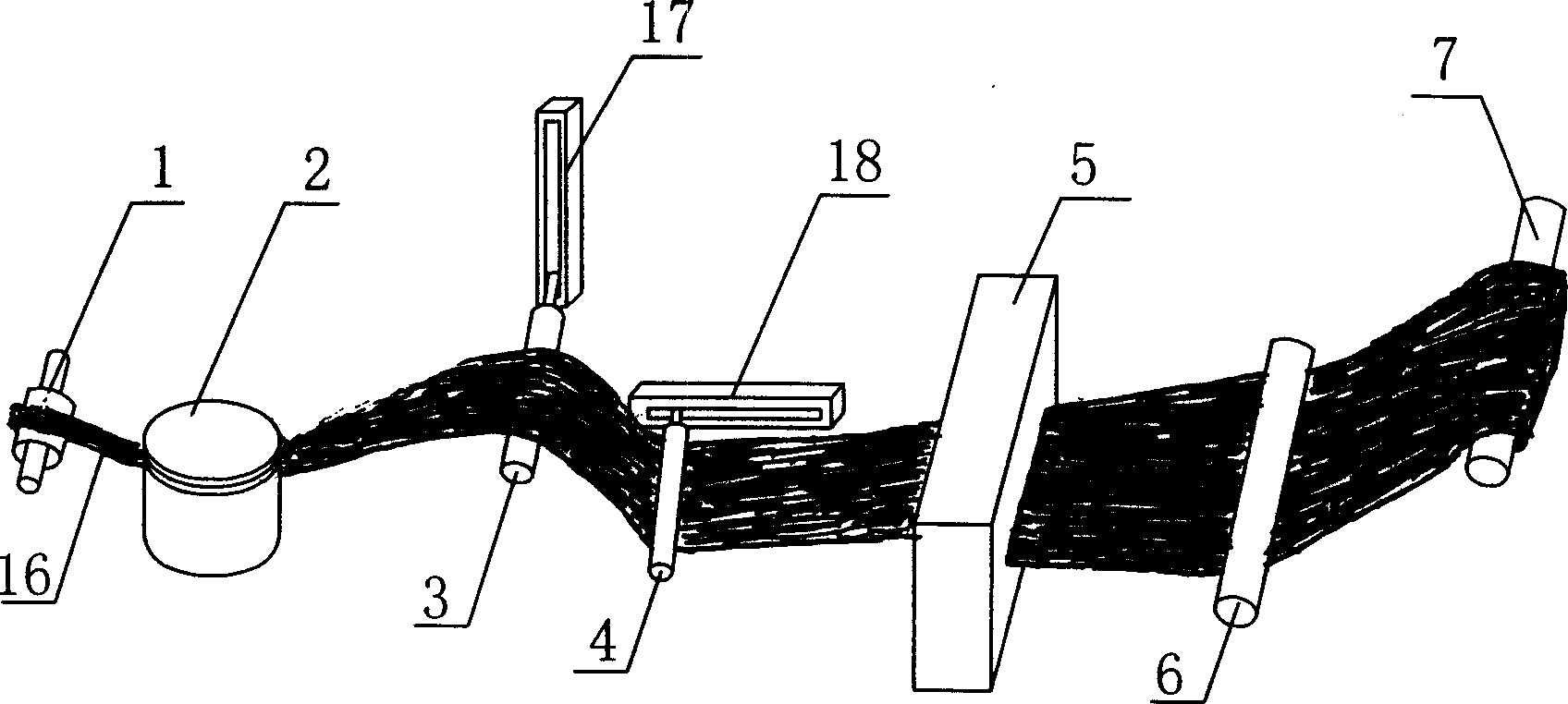

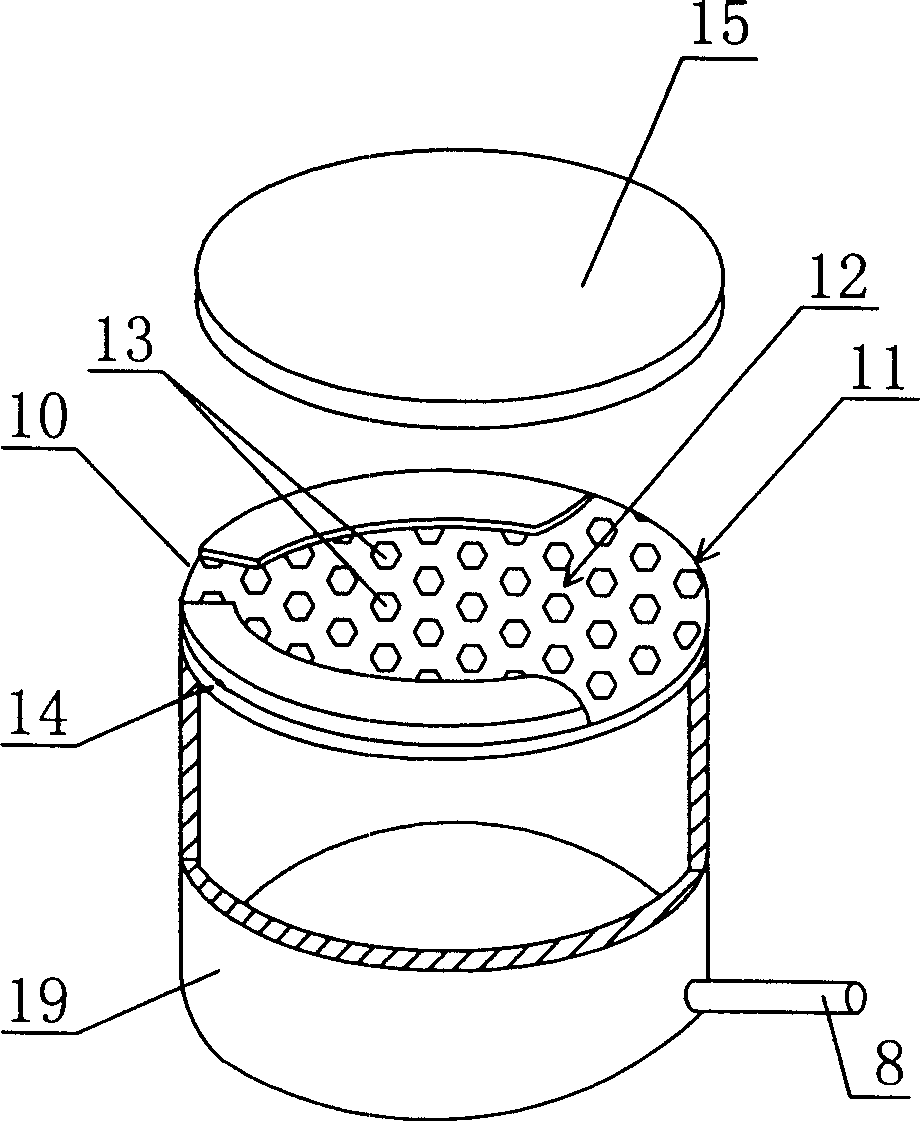

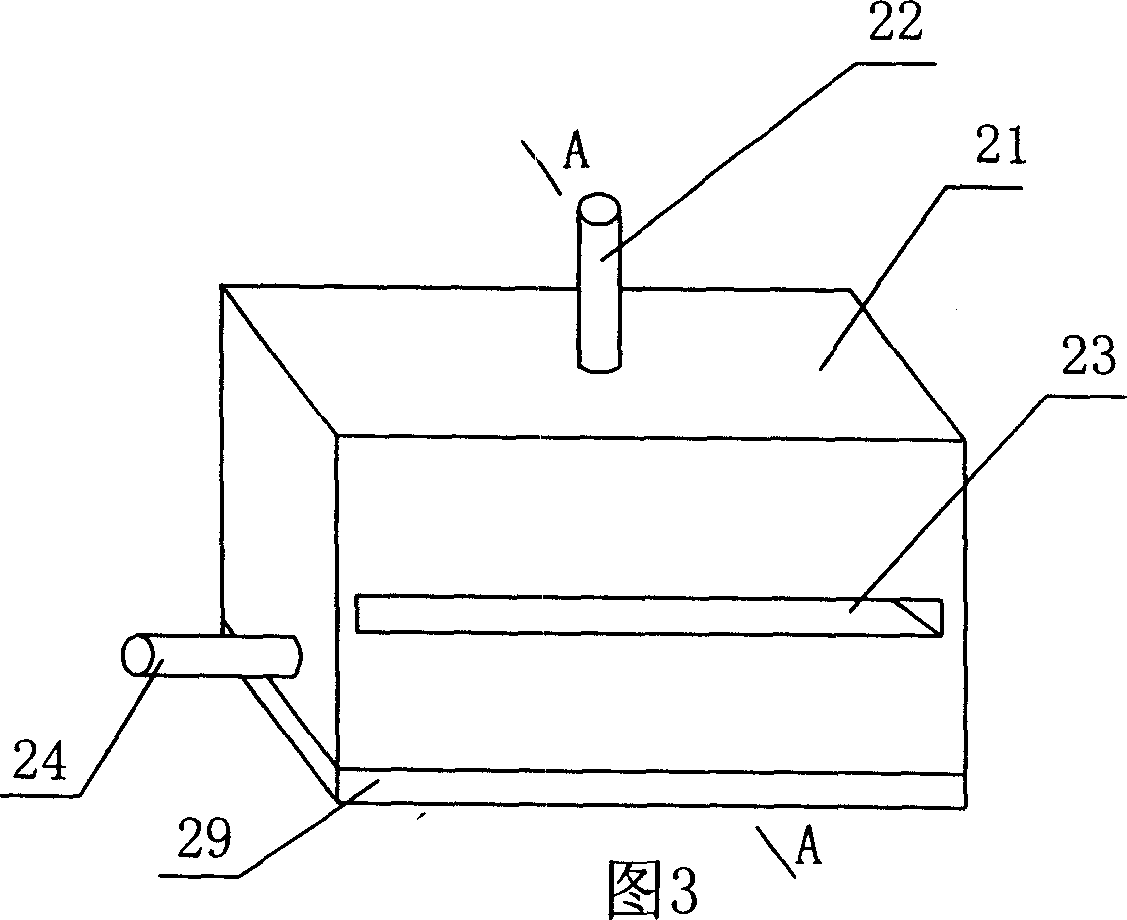

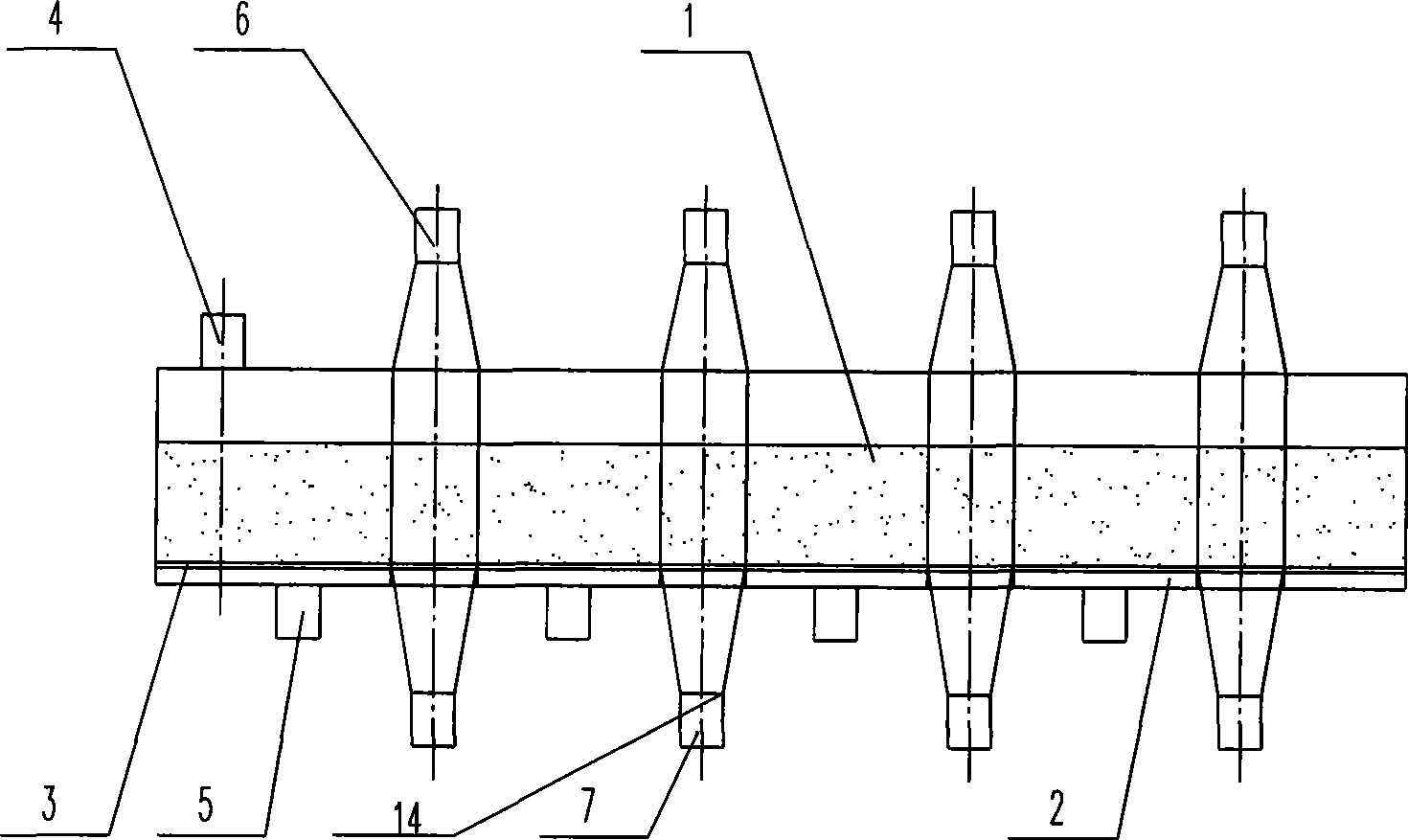

Continuous tow dispersing device

InactiveCN1811025AAvoid damageEvenly distributedFilament handlingFibre rougheningEngineeringMechanical engineering

The continuous tow dispersing device includes unwinding roller, winding roller and tightening roller, as well as air separator and carding unit set successively between the unwinding roller and the winding roller. The air separator has a hollow barrel, and a tow separating cavity in the upper port of the hollow barrel with a tow separating plate with ventilating holes in the bottom and a closing cover plate in the top. The carding unit has a box; inside the box, there are horizontal upper plate with at least two parallel air slots, lower plate with air holes and carding groove between the upper plate and the lower plate; and on the box, there is mechanical vibrator. The device has simple structure, no need of outer power, tow dispersing action completed with air pressure, good tow dispersing effect, low tow damage and other advantages.

Owner:HUNAN UNIV

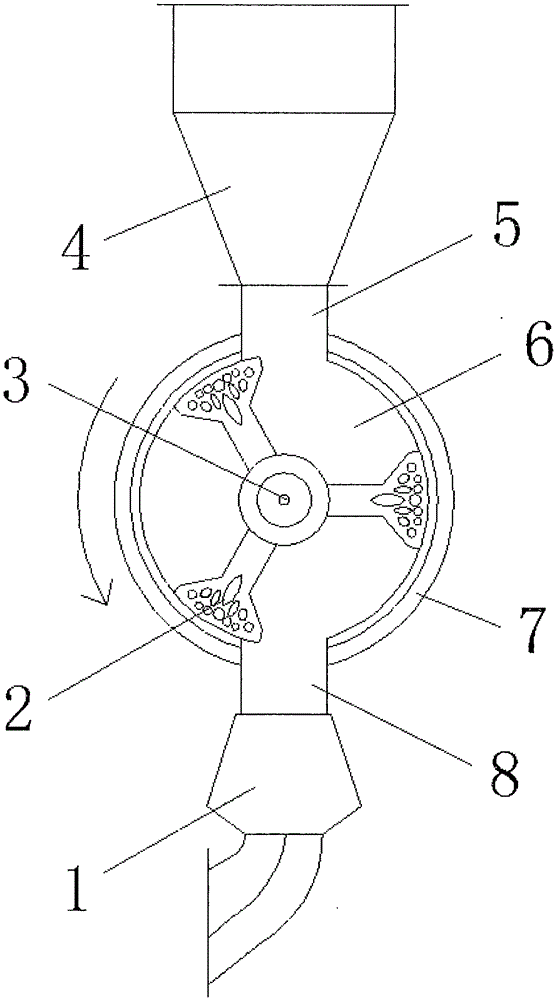

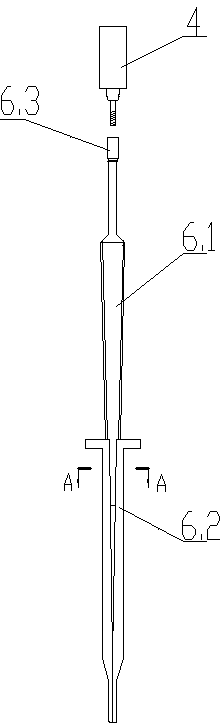

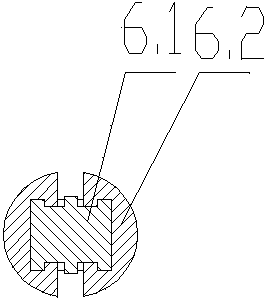

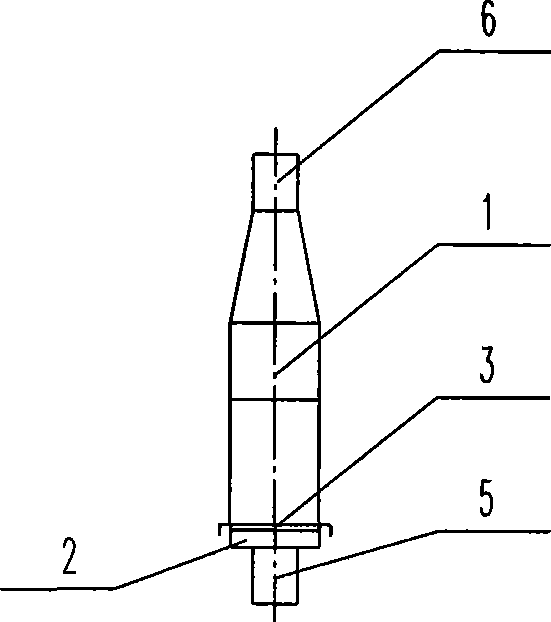

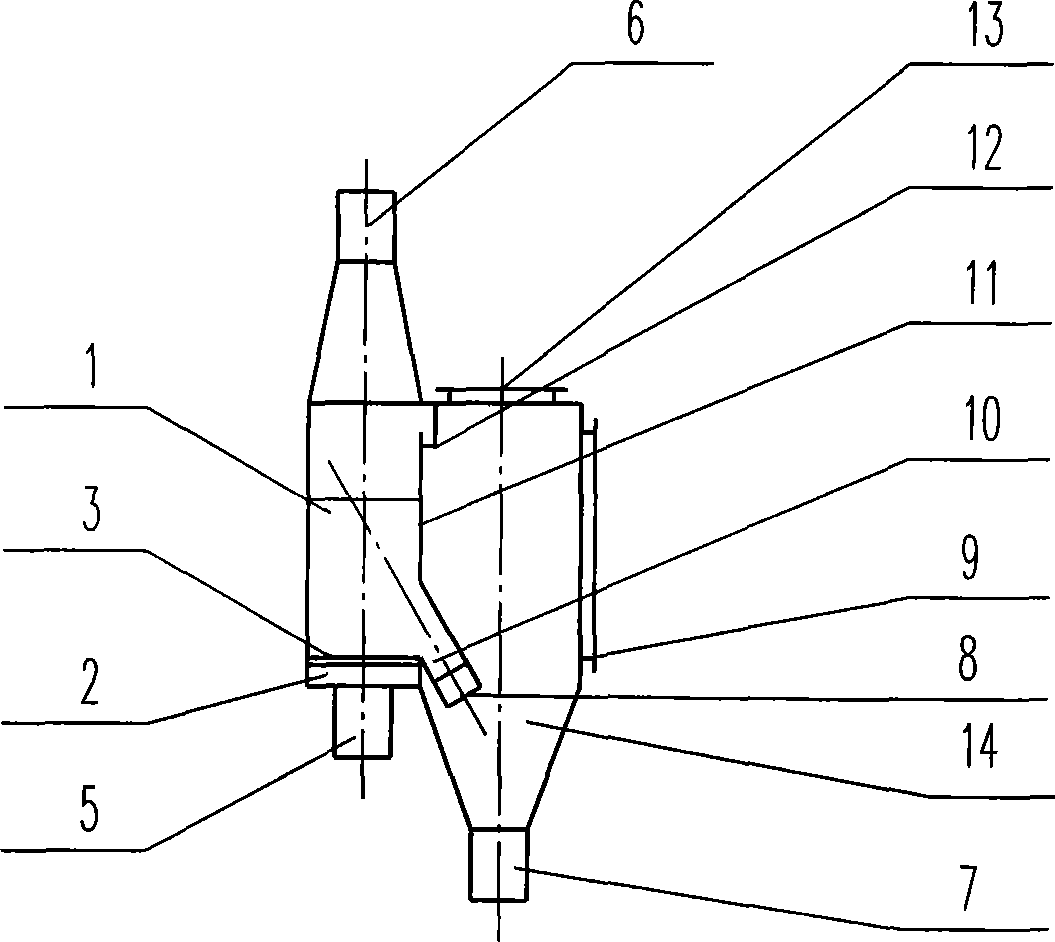

Constant-volume feeding device

The invention discloses a constant-volume feeding device which comprises a discharge hopper, a constant-volume distributor, a feeding hopper and a distribution cylinder. A feeding pipe is connected with the upper end of the distributor cylinder, the feeding hopper is welded to the top of the feeding pipe, a discharge pipe is connected with the lower end of the distributor cylinder, the discharge hopper is welded to the bottom of the discharge pipe, the constant-volume distributor is installed in the distributor cylinder and comprises a positioning ring, distributor hammer heads and distributor baffles, the positioning ring is welded to a rotary shaft, the distributor baffles are welded to the outer side face of the positioning ring at equal intervals, and the distributor hammer heads are welded to the ends of the distributor baffles respectively. The constant-volume feeding device is simple in structure and convenient to use, constant-volume feeding of materials can be effectively achieved, the distribution effect is good, distribution is accurate, normal production and machining are not affected, continuous constant-volume feeding operation can be achieved, manual distribution is not needed, and a lot of manpower and material resources are saved.

Owner:刘云海

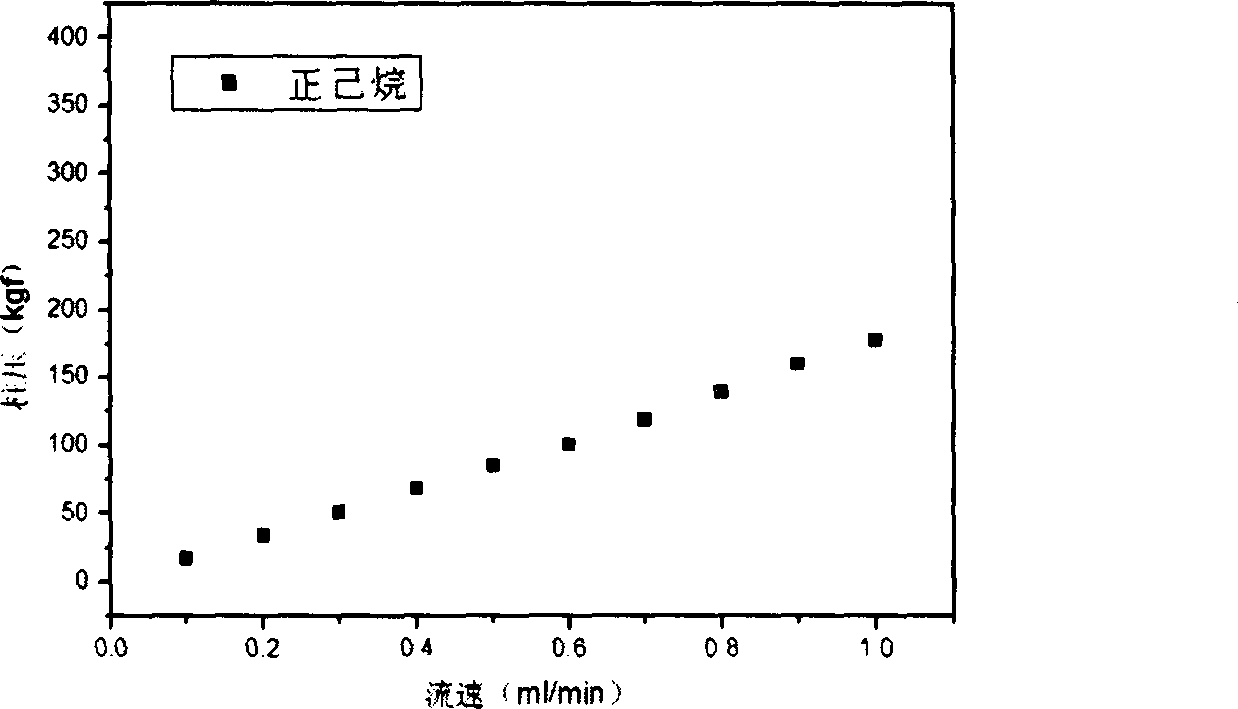

Splitter for rock boring

ActiveCN104074518AImprove efficiencyStrong ability to splitDisloding machinesControl systemEngineering

The invention discloses a splitter for rock boring, which comprises a chassis, a large arm, a small arm and a control system, and is characterized by further comprising a propelling beam, a hydraulic rock drill, a propelling oil cylinder, a splitting machine and a switching mechanism, wherein the propelling beam is connected with one end of the small arm through an angle adjusting device; both the hydraulic rock drill and the propelling oil cylinder are arranged on the propelling beam; the propelling oil cylinder drives the hydraulic rock drill to slide on the propelling beam; the switching mechanism is connected to one side edge of the propelling beam; the splitting machine is arranged on the switching mechanism. The splitter is high in efficiency and high in splitting effect.

Owner:HENR TECH GUANGXI CO LTD

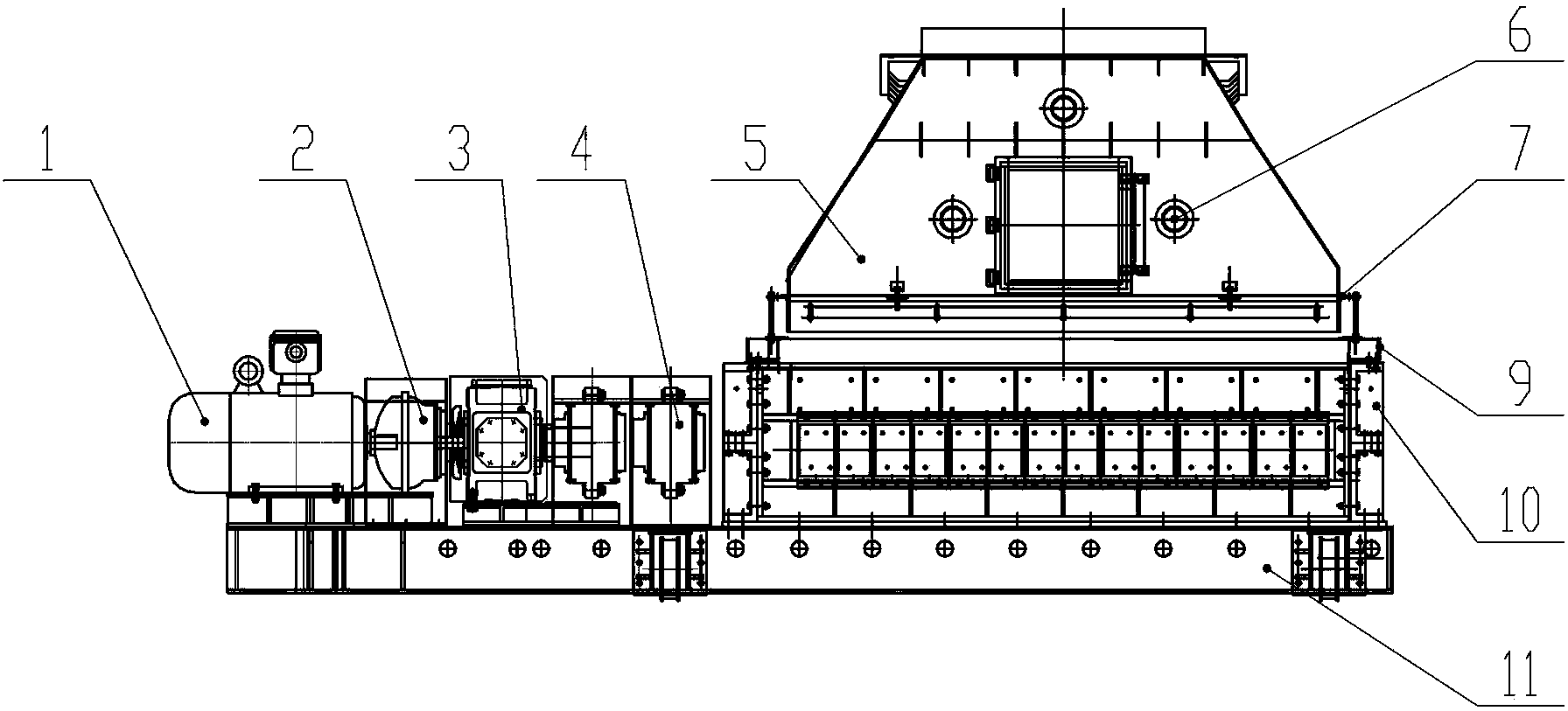

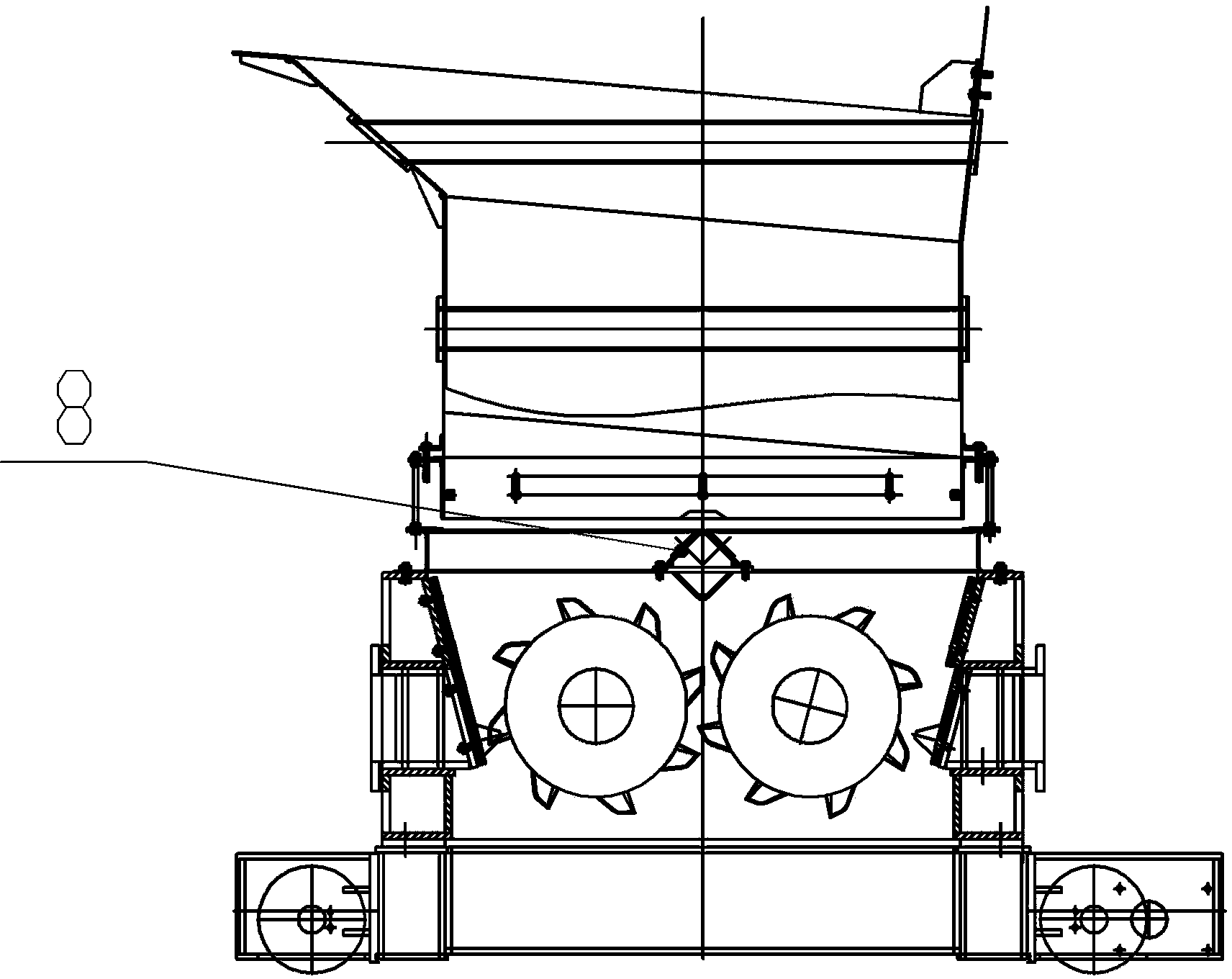

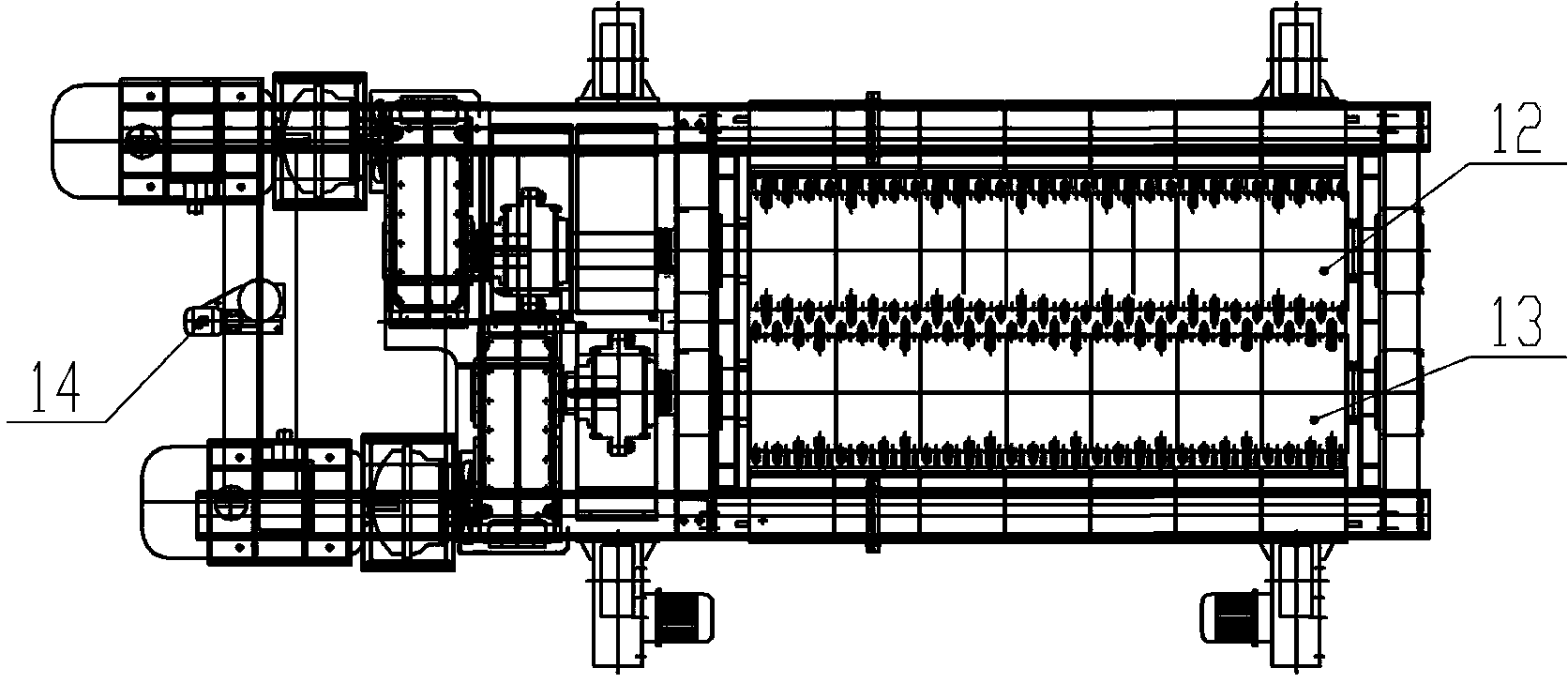

Large efficient screening-type double-toothed roll crusher provided with distribution device

The invention discloses a large efficient screening-type double-toothed roll crusher provided with a distribution device. The double-toothed roll crusher comprises a crushing device and the distribution device. The crushing device comprises a crushing drive motor, a fluid coupling, a reducer, a double-drum gear coupling, a crushing box, a base support, a left toothed roll, a right toothed roll and a lubricating grease pump, wherein the crushing drive motor, the fluid coupling, the reducer and the double-drum gear coupling form two sets of crushing drive units; and the two sets of crushing drive units are connected wit the left toothed roll and the right toothed roll inside the crushing box respectively. The distribution device comprises a distribution chute, an adjustable distribution stick, a movable connecting bracket, a distribution seat and a fixed connecting bracket, wherein the fixed connecting bracket and the distribution seat are fixed on the crushing box of the crushing device, the distribution chute is fixed at a discharge port of a material output belt machine head, and the distribution chute is connected with the crushing box through the movable and fixed connecting brackets. According to the large efficient screening-type double-toothed roll crusher, the problems of capital investment, equipment movement and the like of crushing equipment combined by a plurality of devices are solved fundamentally, the labor intensity of daily equipment maintenance is reduced, and the mining of surface mine materials is accelerated.

Owner:HENAN ZHENYUAN TECH

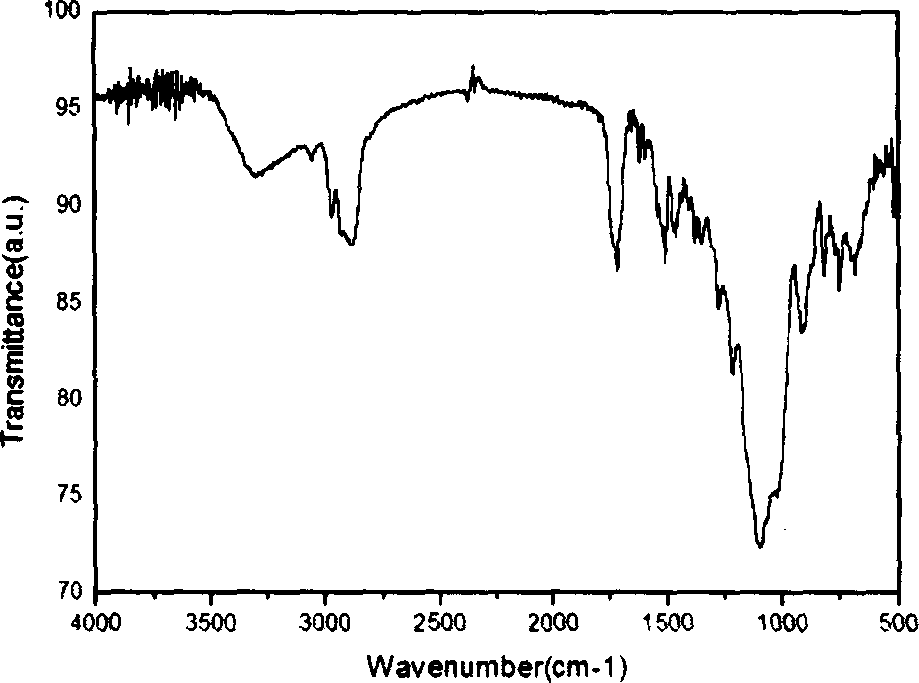

Method for preparing molecular engram CS/TEOS hybridized film by separation of phenylalanine isomer

InactiveCN1843598AIncreased swelling resistanceGood split effectSemi-permeable membranesHigh densitySilicic acid

The invention discloses a method for preparing molecule print chitose / silicic acid carbethoxy hybridized film used to separate phenylalanine isomer of water solution. Said method comprises: adding chitose into acetate water solution whose content is 2%; mixing and filtering insoluble part with filter cloth to attain chitose solution; mixing and adding silicic acid carbethoxy into chitose solution; fully mixing, than adding L-phenylalanine water solution to be mixed for 12 hours; defoaming and filling casting liquid on the horizontally arranged clear organic glass plate horizontally to be extended and form transparent film; thermal treating the film and washing. The invention has the advantages that: the method is simple; attained molecule print chitose / silicic acid carbethoxy film has high density without significant phase separation, and it has better mechanical strength, and better separation function on phenylalanine isomer.

Owner:TIANJIN UNIV

Hot roller drafting type corterra pre-oriented filament drafting and wingding device

InactiveCN102586910ASimple structureCompact structureArtificial thread manufacturing machinesFilament manufactureEconomic benefitsProcess requirements

The invention discloses a hot roller drafting type corterra pre-oriented filament drafting and wingding device, comprising a heating drafting part which is installed in front of an installation faceplate and comprises two spinning hot roller groups i.e. a first spinning hot roller group GR1 for carrying out pre-oriented drafting and low-temperature heating on corterra filament tows and a second spinning hot roller group GR2 for carrying out low-power drafting and drafting stress eliminating on the heated corterra filament tows, wherein the first spinning hot roller group GR1 and the second spinning hot roller group GR2 are sequentially arranged along the circularly-moving direction of the tows; each spinning hot roller group is provided with a hot roller and a separator roller; and the hot rollers are perpendicular to the installation faceplate. The device disclosed by the invention has the advantages that the process requirements for the heating pre-oriented drafting of the corterra filament tows are satisfied; the construction cost of hot roller drafting type corterra pre-oriented filament drafting and wingding device is reduced to the minimum; the consumption is reduced; the multi-end spinning with 24 ends / spinning positons can be realized; the economic benefit is increased; and the equipment production capacity is capable of meeting the market demands.

Owner:BEIJING CHONGLEE MACHINERY ENG

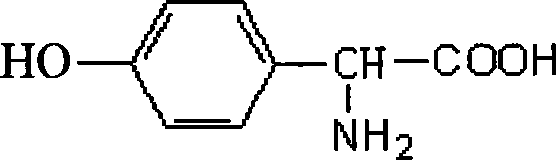

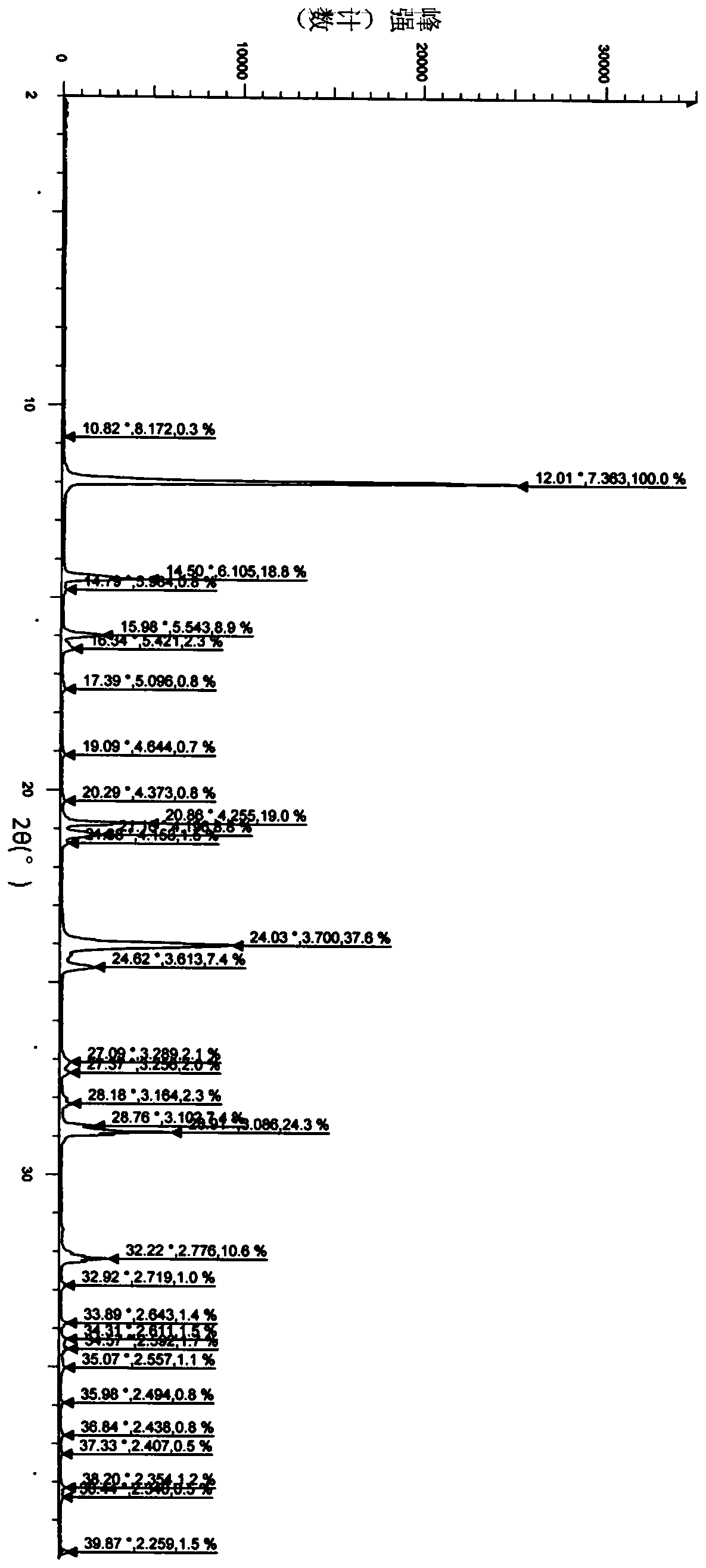

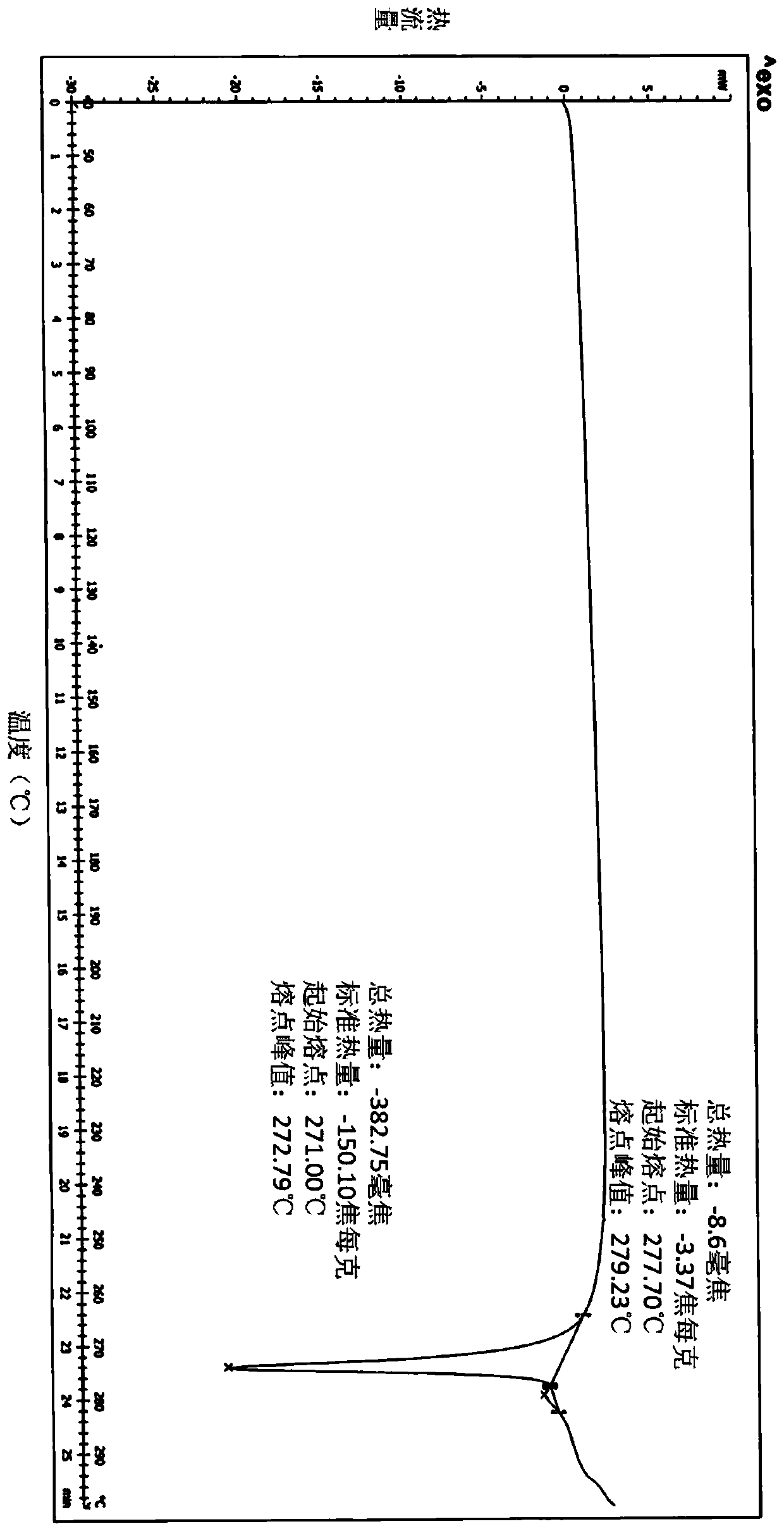

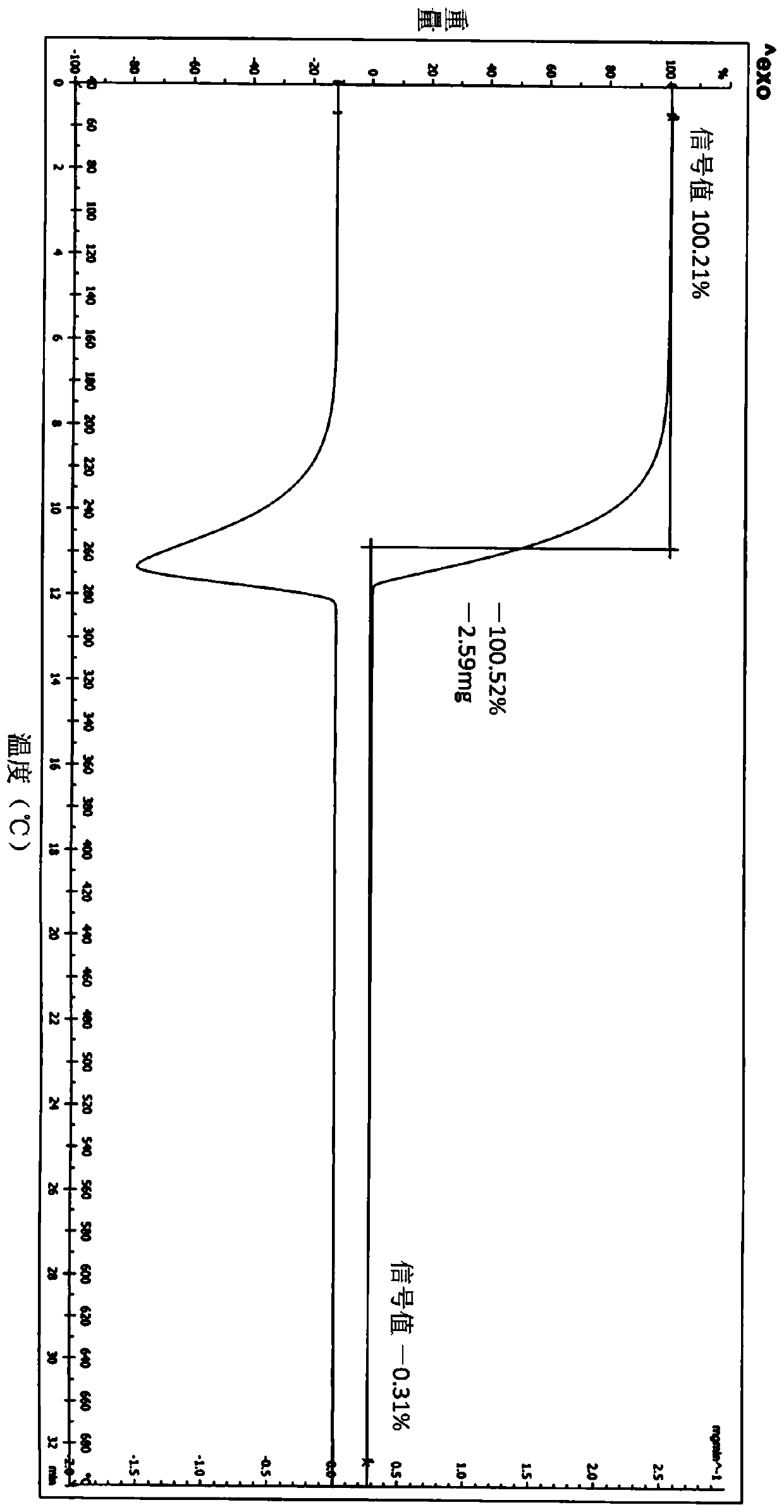

Method of preparing D-p-hydroxyphenylglycine

ActiveCN101239926AGood split effectLow costOrganic compound preparationAmino-carboxyl compound preparationRoom temperatureP-hydroxyphenylglycine

The invention provides a preparing method of D-p-hydroxyphenylglycine, which comprises adding DL-p-hydroxyphenylglycine and resolving agent beta-naphthalenesulfonic acid in water to prepare solution, rising temperature and reacting under agitating, adding induction seeds, adjusting the specific totation of the solution, performing heat-preservation reaction, cooling, sufficiently crystallizing, reducing pressure, filtering and drying, thereby obatining solid D-p-hydroxyphenylglycine beta-naphthalenesulfonic acid complex salts or L-p-hydroxyphenylglycine beta naphthalenesulfonic acid complex salts; dissolving D-p-hydroxyphenylglycine beta-naphthalenesulfonic acid complex salts in water to prepare aqueous solution, rising temperature, adding active carbon to perform decoloring treatment, adjusting the PH value by alkali liquid, cooling the sollution to room temperature, filtering, washing, and drying, thereby obatining D-p-hydroxyphenylglycine. The D-p-hydroxyphenylglycine produced by the method of the invention has good quality, short reaction time and low cost.

Owner:INNER MONGOLIA CHANGSHENG PHARMA

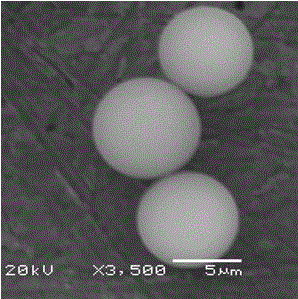

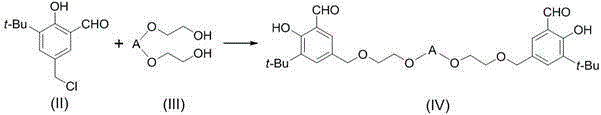

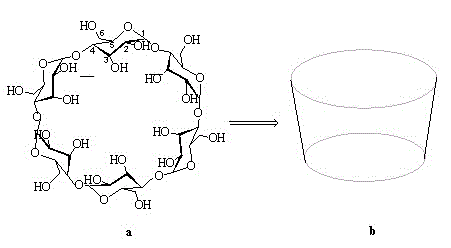

Preparation method of organic-inorganic hybrid cyclodextrin chiral stationary phase

InactiveCN104689808AHigh mechanical strengthGood split effectOther chemical processesSynthesis methodsSolvent

The invention discloses a preparation method of an organic-inorganic hybrid cyclodextrin chiral stationary phase. According to the method, a surfactant is taken as a template, a silicon-based-beta-cyclodextrin derivative and a silanization reagent are subjected to a hydro-thermal synthesis method to obtain the spherical organic-inorganic hybrid cyclodextrin chiral stationary phase, average aperture of silicon ball is 2.5 nanometers, and particle size is 5-8 micrometers. The preparation method has the advantages of mild reaction condition, simple preparation process and adjustable load capacity of the cyclodextrin derivative. The organic-inorganic hybrid cyclodextrin chiral mesoporous silicon ball stationary phase is not restricted by usage of a mobile phase polar solvent during a usage process, resolution efficiency is high, and chiral resolution capability is good.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

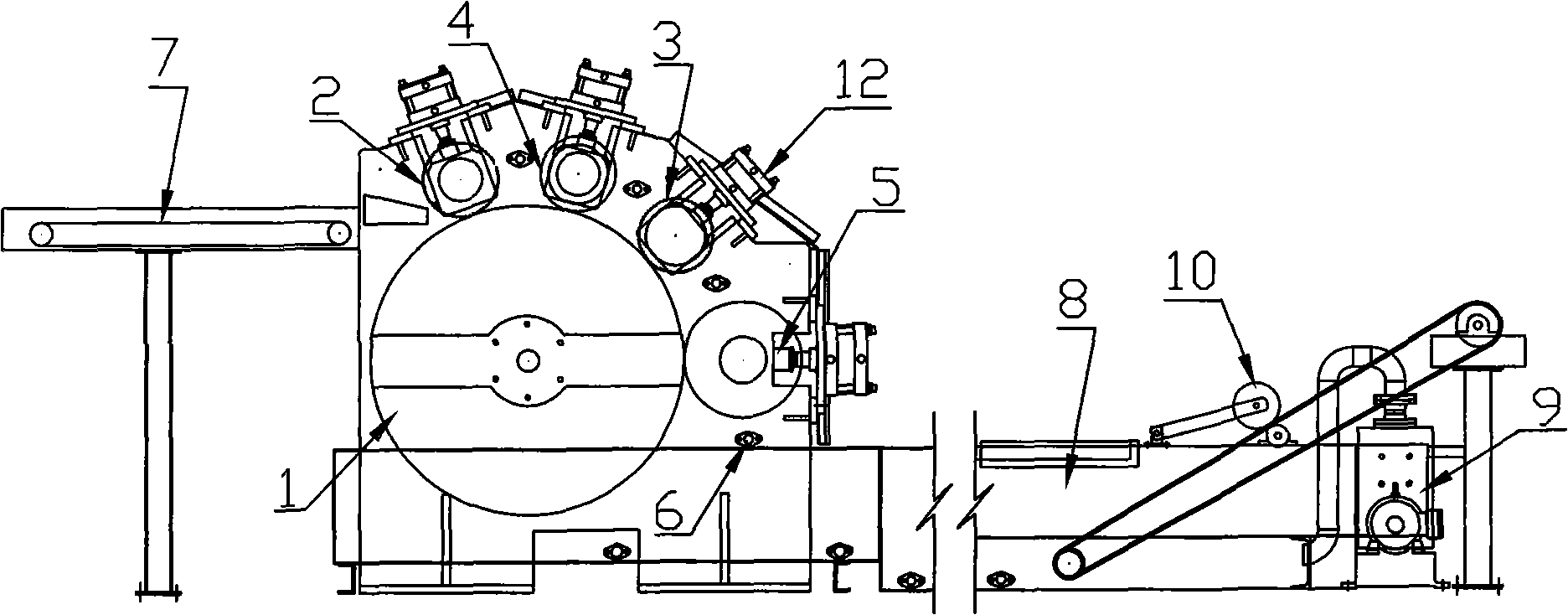

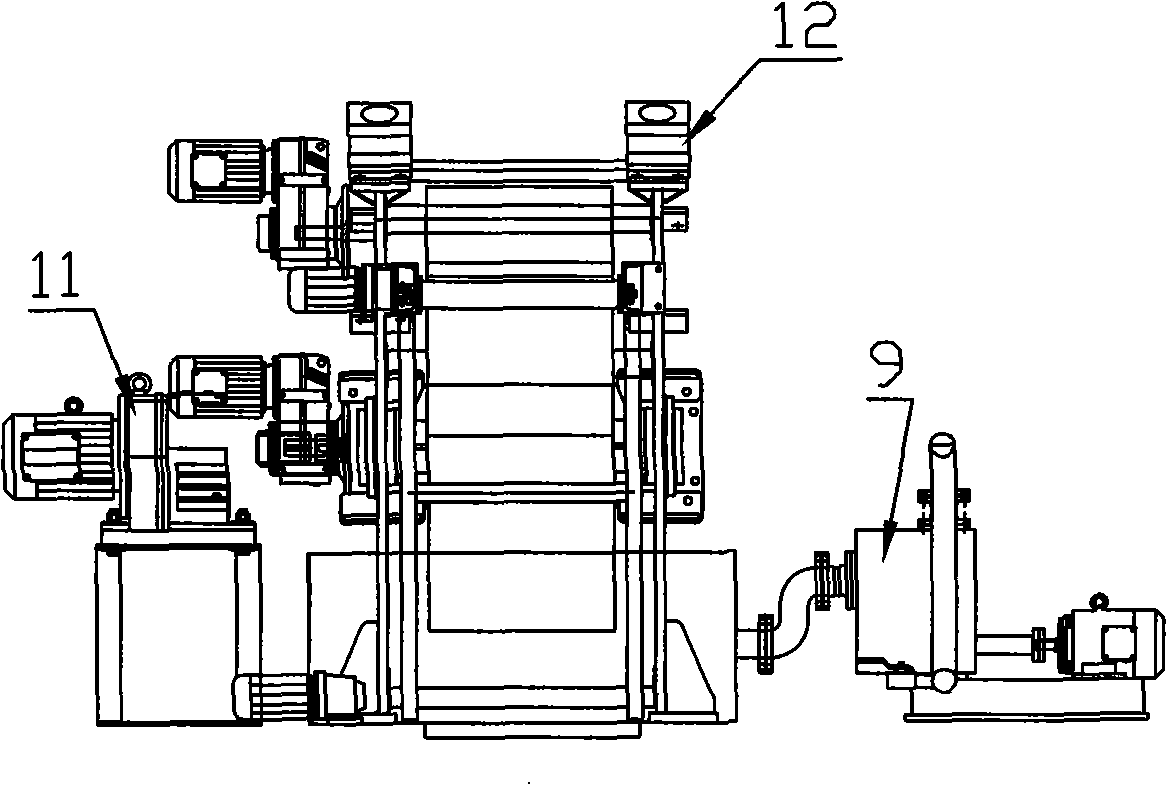

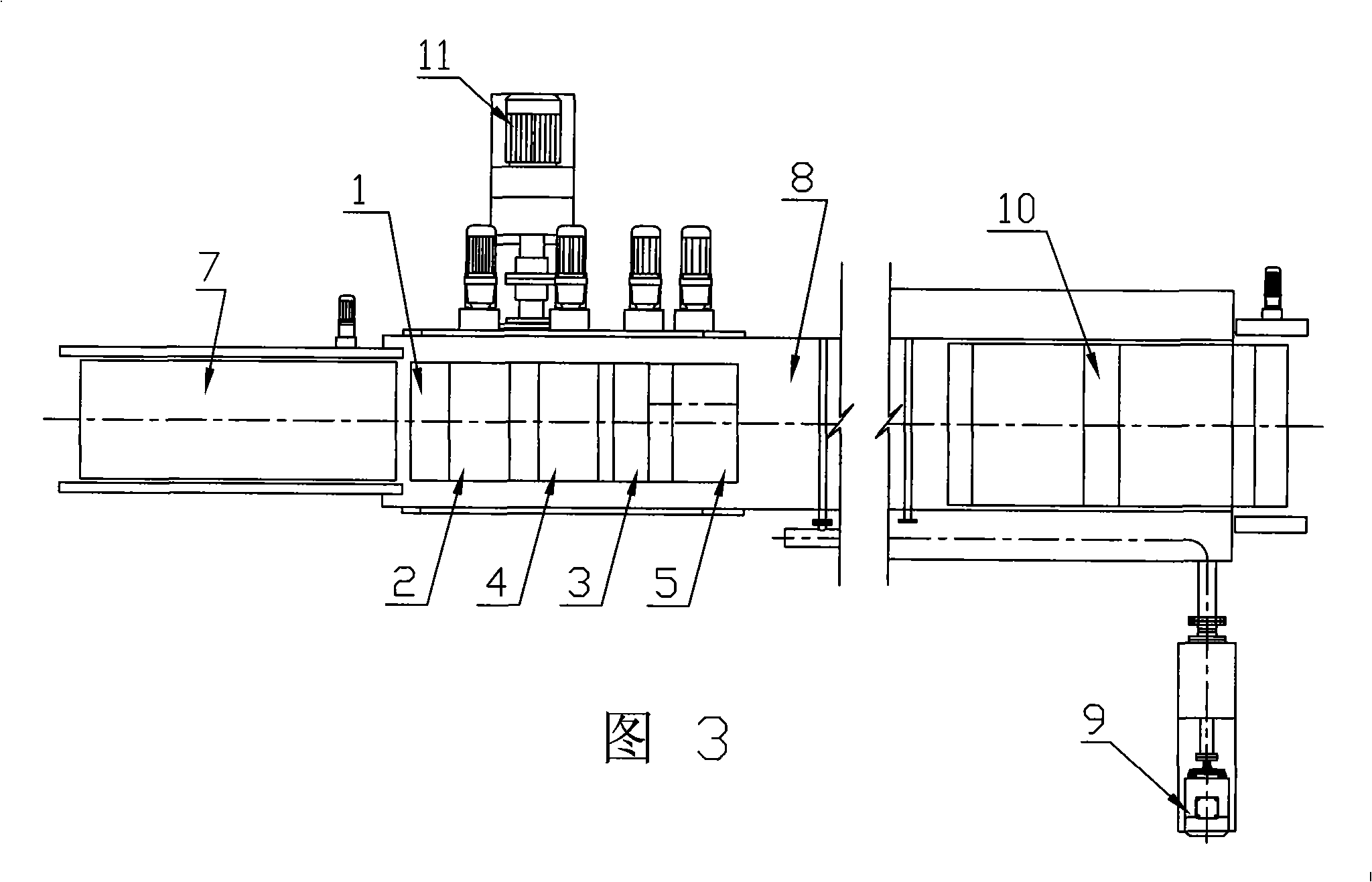

Multi-wheel scutching integrated machine of degumming and rinshing

InactiveCN101270499AHigh degree of automationSimple and fast operationMechanical fibre separationEngineeringHigh pressure water

The invention relates to a multi-gear train integral machine of scotching, degumming and washing which includes a ramie feed unit, a bone-cutting skin-scraping unit and a bone-cracking ramie-extruding unit; wherein, the bone-cutting skin-scraping unit mainly consists of a big round roll (1) and two rollers (2) and (3); the bone-cracking ramie-extruding unit mainly consists of a first small round roll (4) and a second small round roll(5). The big round roll is fixed on a frame through a bearing seat; the two rollers and the small round rolls are respectively mounted on the dump rails of each own through a sealing seat, arranged around the big round roll (1), respectively provided with a high pressure water scraper (6) which sprays water curtain along the tangent direction and opposite to the speed direction of the ramie, and the two ends of the shafts of the two rollers and the small round rolls are all provided with a pressurizing air cylinder (12). The machine finishes from ramie stalks to semi-fine dry ramie for one time and has the advantages of high automatization degree, safe use, good fiber separating effect, good ramie output, saving water, being beneficial to popularization, etc. The method can be used for processing fresh ramie so as to obtain semi-fine dry ramie.

Owner:WUHAN TEXTILE UNIV

Method for preparing R-ketamine and pharmaceutically acceptable salt thereof

ActiveCN110218157AEasy to operateGood split effectOrganic active ingredientsNervous disorderMedicineRaw material

The invention relates to a method for preparing R-ketamine and a pharmaceutically acceptable salt thereof. More specifically, the present invention relates to a method for resolving a ketamine racemate to obtain R-ketamine, wherein a resolving agent adopted is D-DTTA, the method includes steps of resolution, purification, dissociating, and the like, and obtained R-ketamine hydrochloride is low incontent of related substances, and is suitable for use as a pharmaceutical raw material. The method is simple in operation, good in resolution effect and high in yield, and is suitable for industrialproduction.

Owner:JIANGSU HENGRUI MEDICINE CO LTD

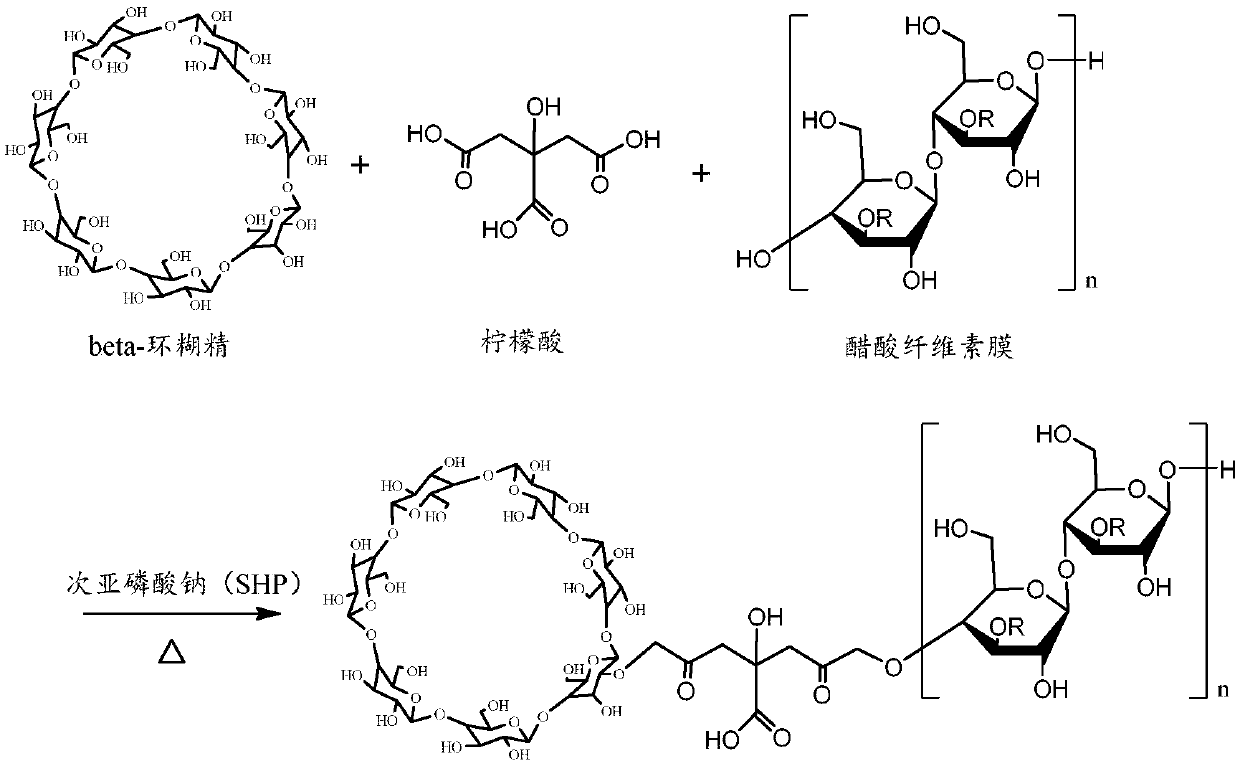

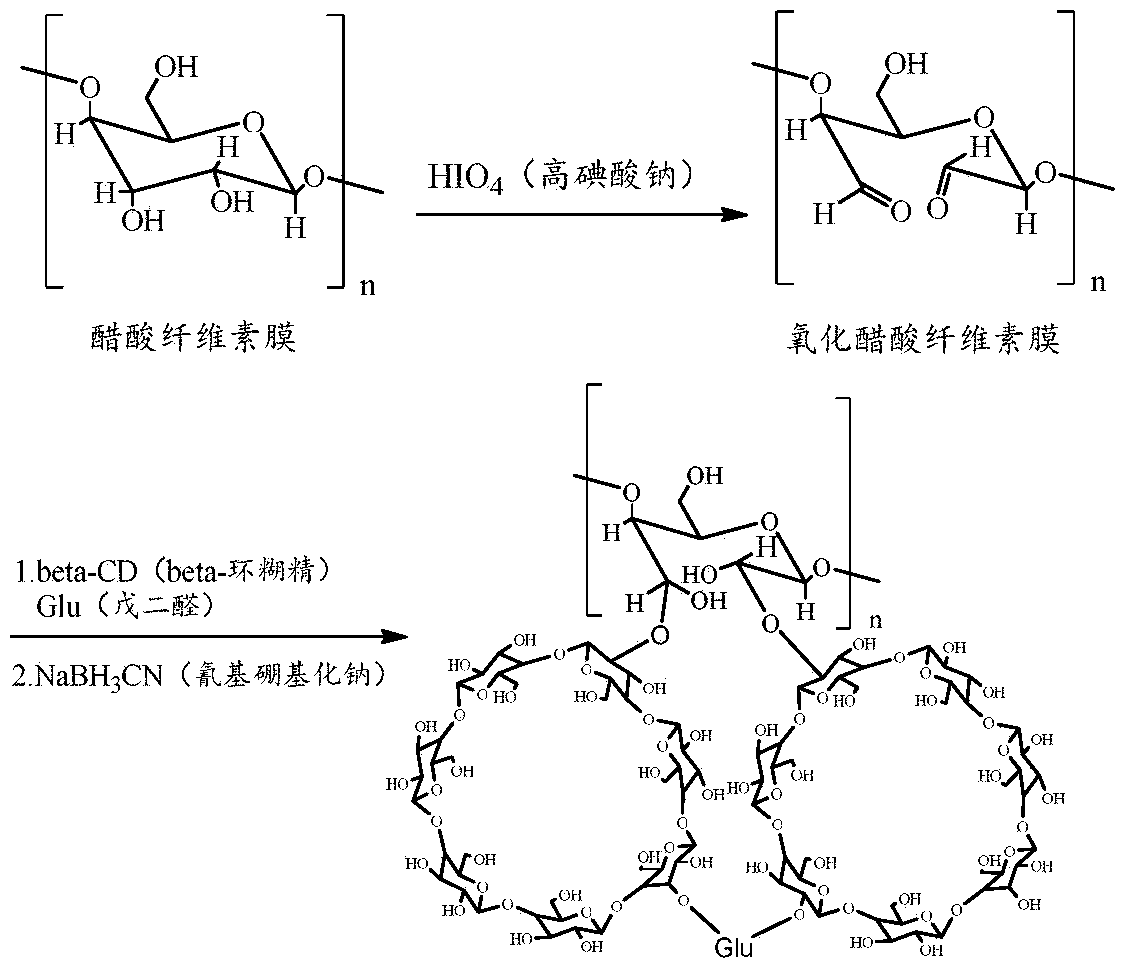

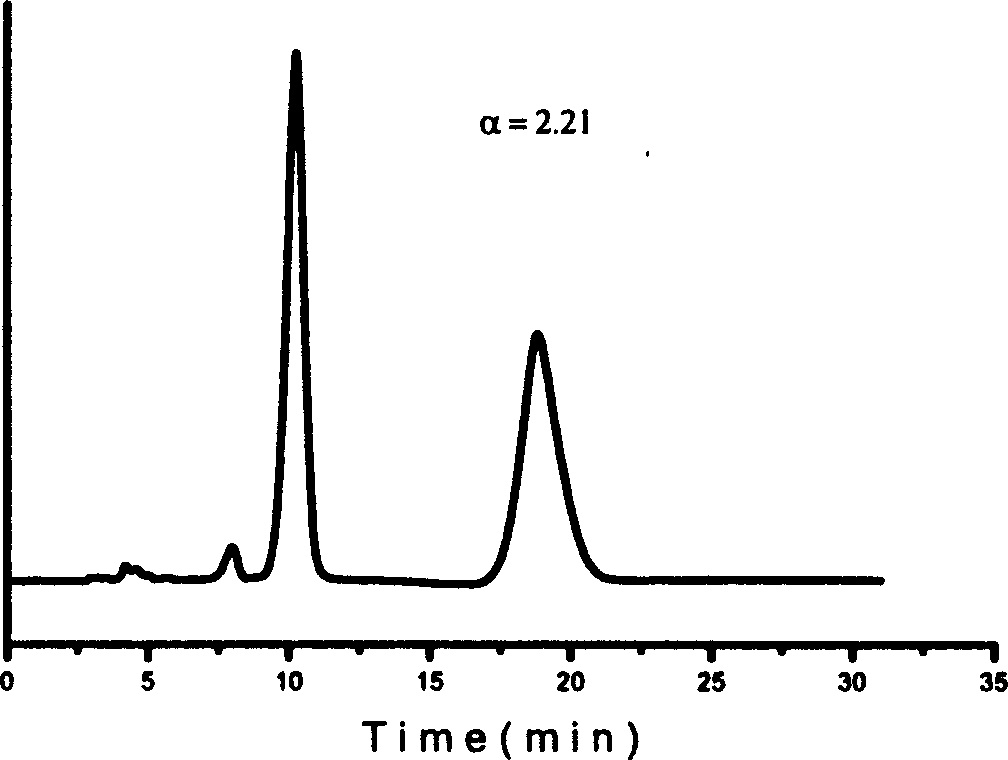

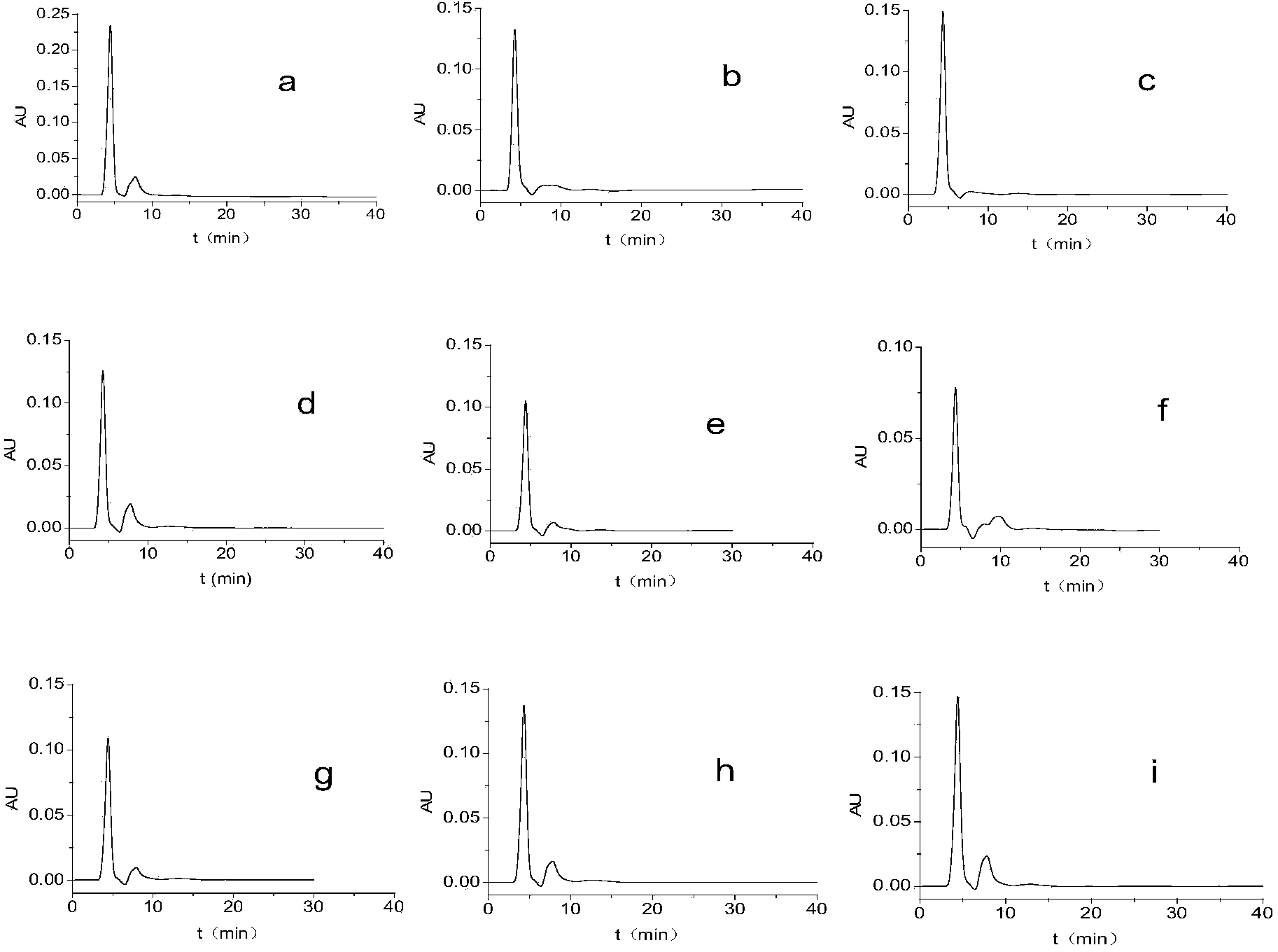

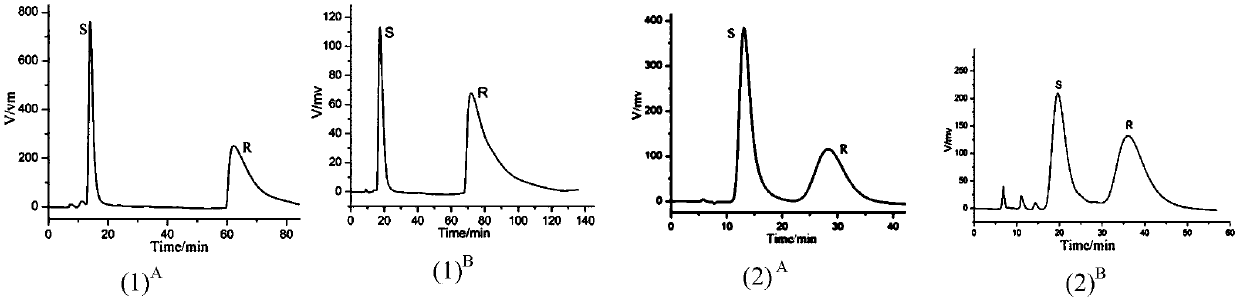

Modified cellulose acetate membrane for chiral resolution, preparation method and application thereof

ActiveCN108671773ALow input costEasy to separateSemi-permeable membranesOrganic chemistry methodsConcentration ratioTryptophan

The invention discloses a modified cellulose acetate membrane for chiral resolution, a preparation method and application thereof, and belongs to the technical field of chiral resolution. The modifiedcellulose acetate membrane is prepared by taking a cellulose acetate membrane as a basilemma, beta-cyclodextrin or hydroxypropyl-beta-cyclodextrin as a chiral selector, and citric acid as a couplingagent. In a preparation process of the chiral cellulose acetate membrane, sodium hypophosphite is used as a catalyst, and the mass ratio of the beta-cyclodextrin, citric acid to sodium hypophosphite is (2 to 4) to (2 to 4) to (0.2 to 0.5). Racemic tryptophan and mandelic acid are used as resolution targets, the concentration of D-enantiomer and L-enantiomer in a filtrate and the concentration ratio of the two are monitored by high performance liquid chromatography, the prepared chiral membrane realizes that the number of layers required for tryptophan complete resolution is greatly reduced, and not only the resolution effect of tryptophan is excellent, but also the resolution effect of the enantiomer of mandelic acid is good, complete resolution can be performed, and a problem that an chiral membrane at the prior art has single resolution targets is overcome.

Owner:CHINA PHARM UNIV

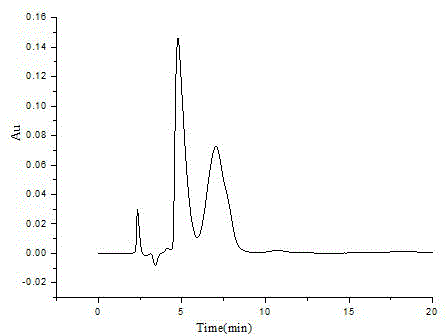

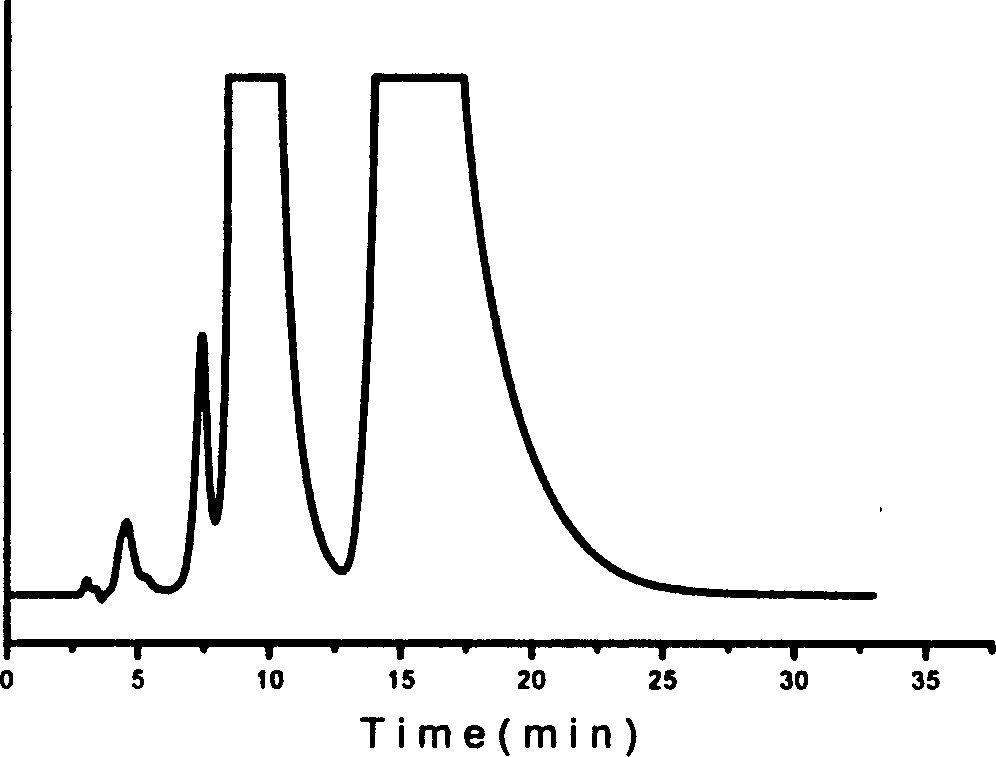

Method for splitting antipode of 3-butylbenzene phthalein

InactiveCN1539835ASimple and fast operationHigh yieldOrganic chemistryFormateChiral stationary phase

A process for splitting 3-n-butylphenyl phthaleine antipode features that the phenylamino formate or benzoate of polyose compound is used as chiral fixed phase, and the liquid-phase chromatography is directly used for said splitting. Its advantages are high speed and effect, high stability and long service life.

Owner:萍乡分水科技有限公司

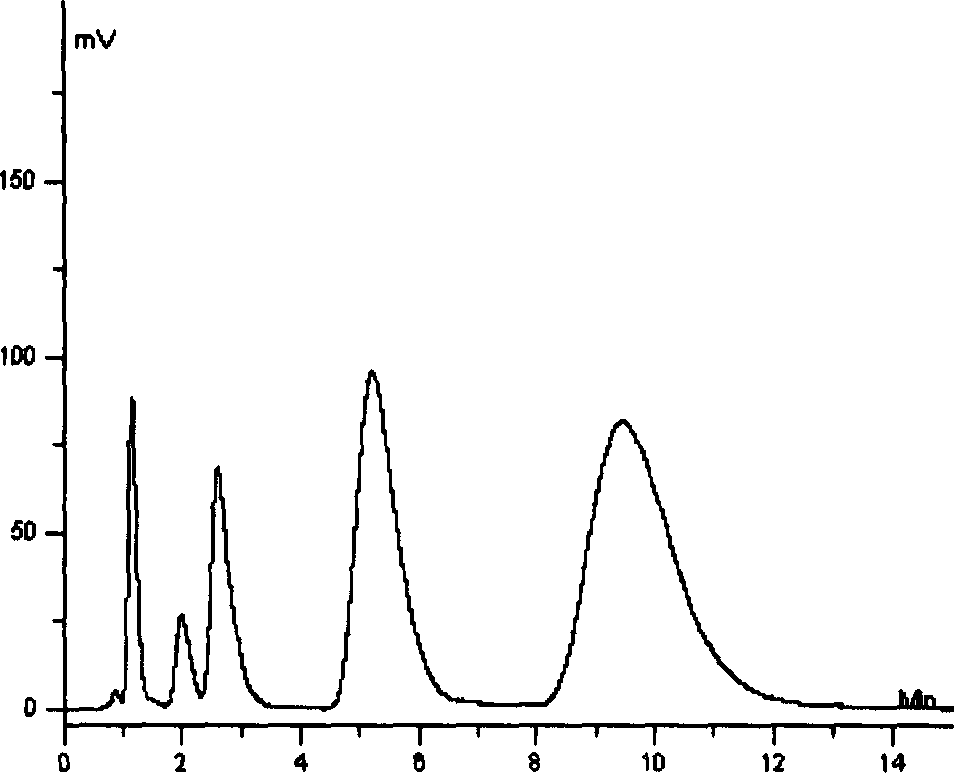

Novel hybrid mesoporous silica gel chromatographic stationary phase and preparation method thereof

InactiveCN103272573AGood split effectEvenly distributedOther chemical processesStationary phaseMesoporous silica

The invention discloses a novel hybrid mesoporous silica gel chromatographic stationary phase and a preparation method thereof. Under the condition of a dual-template agent, an R-(+)-1,1'-binaphthyl -2,2'-diphenol group is introduced into the surface of hybrid mesoporous silica gel and firstly applied to the chromatographic stationary phase. After column-filling operation is carried out, five kinds of binaphthyl compounds are separated successfully; and the chromatographic peak is good in shape and can be separated rapidly. The method is simple in preparation process in which a cationic surfactant and a triblock copolymer are taken as the dual-template agent, the hybrid mesoporous silica gel chromatographic stationary phase is prepared by the copolycondensation of a binaphthol derivate silicon source with 1,2-bis-triethoxysilyl ethane (BTSE) under an acidic condition. The hybrid mesoporous silica gel chromatographic stationary phase has a neat spherical shape and is homogeneous in particle diameter distribution (3 to 10 microns) as well as uniform and adjustable in particle diameter. Thus, the chromatographic stationary phase disclosed by the invention can be applied widely.

Owner:CHINA PHARM UNIV

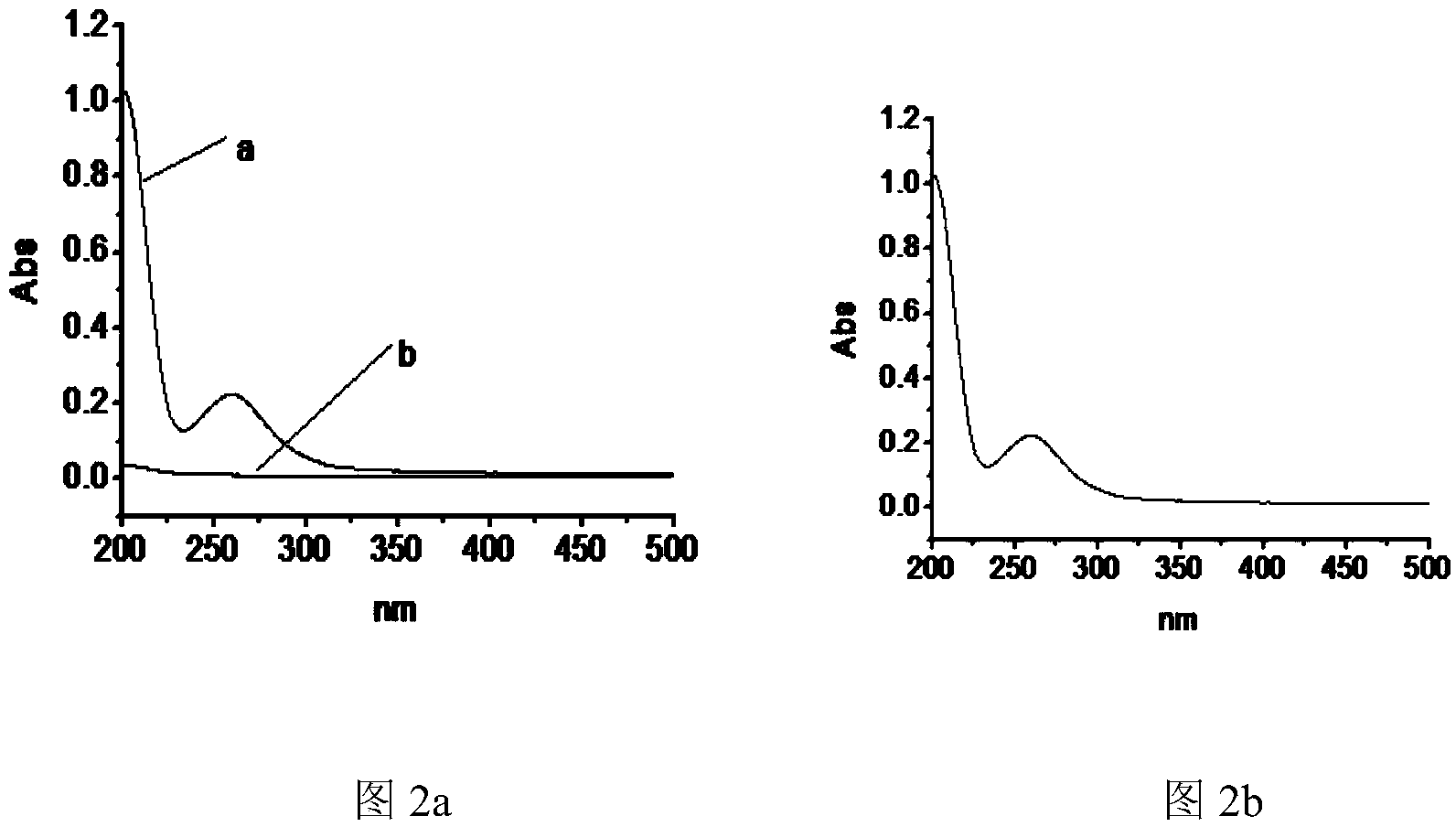

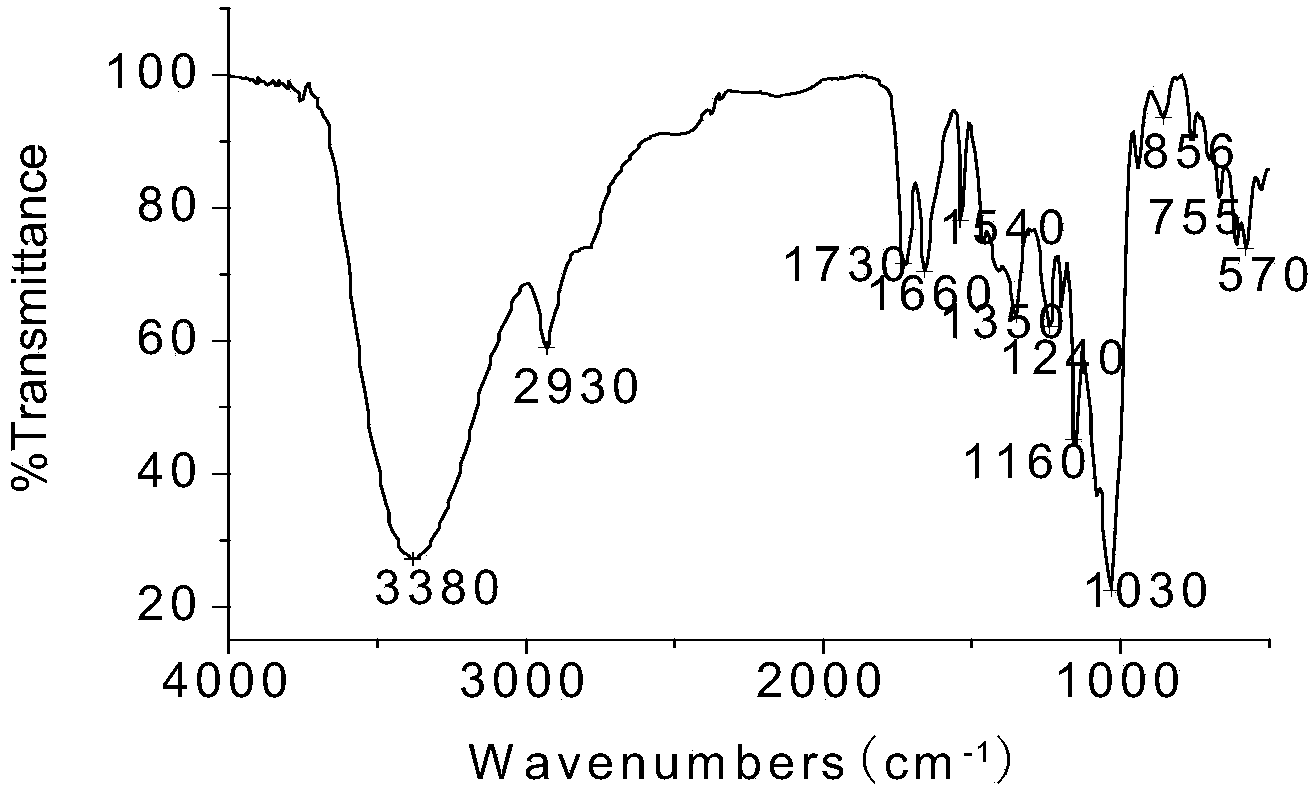

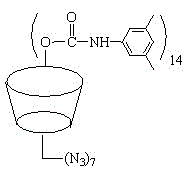

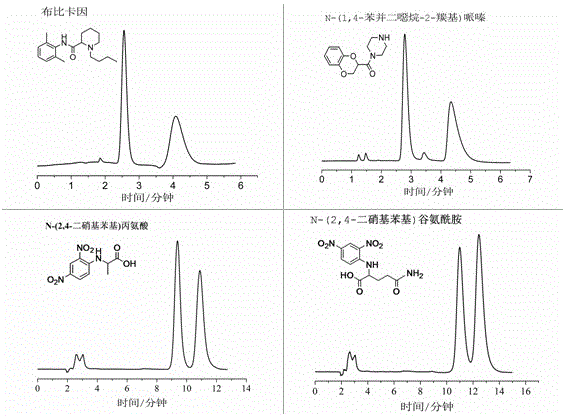

Bis-(6-oxo-m-nitrobenzaldehyde sulfonyl)-beta-cyclodextrin as well as preparation method and application thereof

ActiveCN103965376AGood split effectMaterial analysis by electric/magnetic meansElectrophoretic processesOfloxacinCetirizine

The invention relates to the technical field of preparation and application of a chiral selector, and particularly discloses a bis-(6-oxo-m-nitrobenzaldehyde sulfonyl)-beta-cyclodextrin (beta-CD-N2) as well as a preparation method and an application of the beta-CD-N2 serving as the chiral selector in high-performance capillary electrophoresis, namely the application of the beta-CD-N2 in preparation of a chiral electrophoresis monolithic column for separating chiral materials. The preparation method is characterized in that firstly a synthesis method of the beta-CD-N2 is confirmed, the derivative is characterized by using means such as ultraviolet, infrared, photoelectron spectroscopy, nuclear magnetic resonance, mass spectrometry and elemental analysis, after comprehensive analysis, the molecular formula of the derivative is identified as C54H76O43N2S2, and the derivative is identified as a target derivative and is not reported before. The beta-CD-N2 is used for preparing a chiral HPCE (high-performance capillary electrophoresis) monolithic column and separating the chiral materials such as cetirizine, mexiletine, propafenone, ofloxacin and bupivacaine and can realize baseline separation, and accordingly, a novel method for quantitative determination of HPCE of a multi-chiral material single enantiomer can be established.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Nutrition-enhanced chewy rice noodles and preparation method thereof

InactiveCN107361290ANutrient enhancers, a wide varietyOvercome single nutritionFood ingredient functionsSodium CaseinateDigestion

The invention discloses nutrition-enhanced chewy rice noodles and a preparation method thereof. The nutrition-enhanced chewy rice noodles comprise the following raw materials: rice flour, sweet potato flour, egg meal, gluten flour, papaya powder, strawberry powder, lotus root starch, kudzuvine root powder, ginger powder, honeysuckle flower powder, liquorice root powder, xylitol, lactitol, sodium caseinate, sodium stearoyl lactylate, sorbitan monooleate, an enzyme preparation, a nutrition enhancer, diammonium phosphate, and sodium alginate. The nutrition-enhanced chewy rice noodles and the preparation method thereof disclosed by the invention are characterized in that the preparation processes are simple; and the prepared nutrition-enhanced chewy rice noodles have the advantages of rich nutrition, easy absorption and digestion, and good health-care effects; moreover, the rice noodles are fine in flexibility, chewy, long-lasting in flavor and good in taste after being cooked, and thus, appetite of people can be easily stimulated.

Owner:安徽省富邦天成食品有限公司

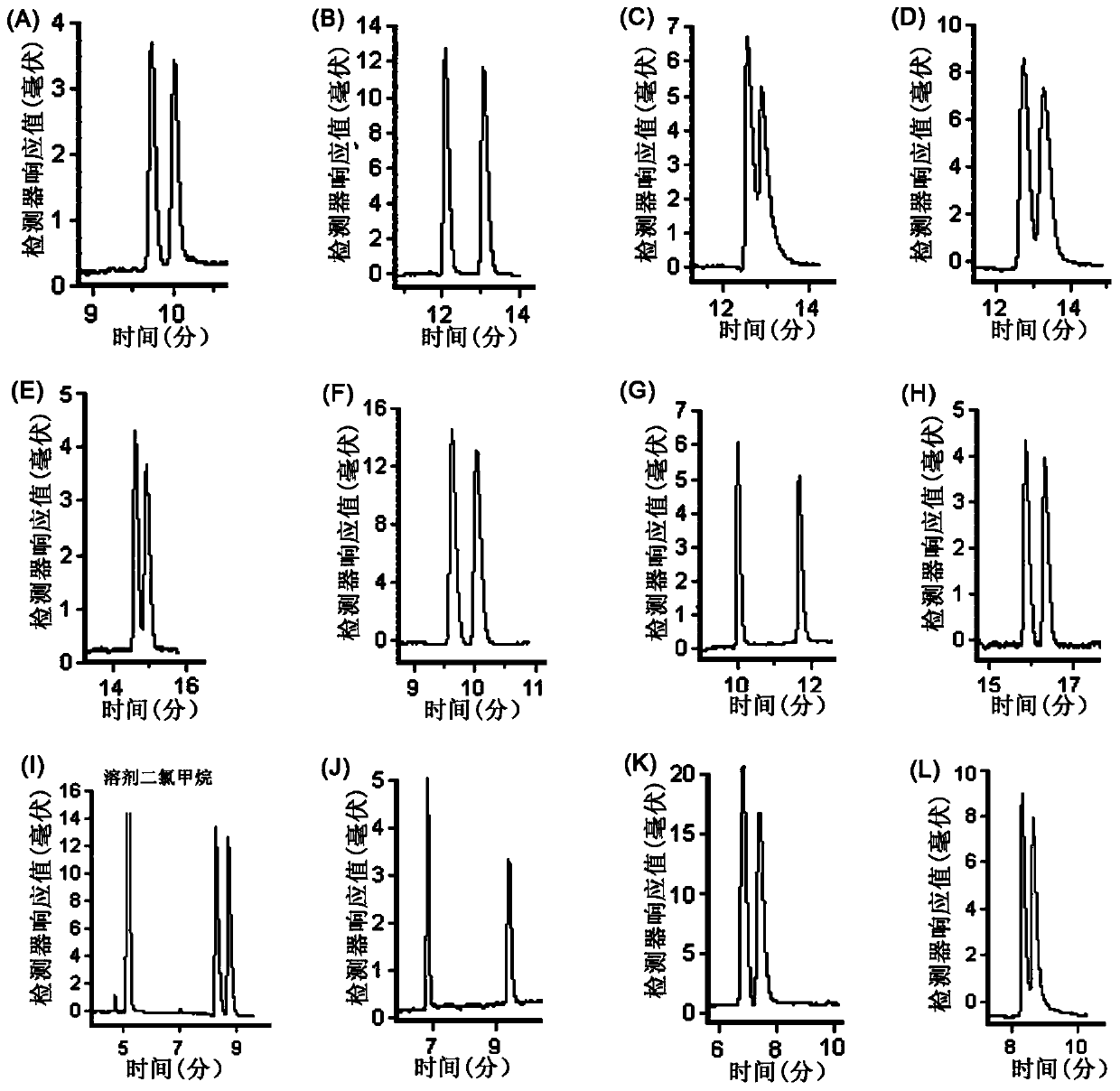

Capillary gas chromatography chiral column based on chiral organic molecular cage material

ActiveCN111013193AGood split effectObvious split advantageComponent separationSolid sorbent liquid separationEpoxyCapillary gas chromatography

The invention discloses a capillary gas chromatography chiral column based on a chiral organic molecular cage material, which is prepared by the following steps: firstly, synthesizing the chiral organic molecular cage material, dissolving the chiral organic molecular cage material in a volatile organic solvent to prepare a solution, mixing the solution with a polysiloxane solution to obtain a stationary phase, and preparing the capillary gas chromatography chiral column by adopting a static column preparation method. The prepared chromatographic column shows excellent chiral resolution performance on a plurality of chiral compounds including alcohol, dihydric alcohol, halogenated hydrocarbon, epoxy compounds, esters, lactones, ketones, ethers, organic acids and the like. The chromatographic column disclosed by the invention is applied to gas chromatography resolution of the chiral compounds, has the remarkable characteristics of simple preparation method, cheap raw materials, good stability, reusability, excellent chiral resolution performance and the like, and has a very good application prospect.

Owner:YUNNAN NORMAL UNIV

Preparation method of ethyl (R)-4-cyano-3-hydroxybutyrate

InactiveCN105132488AHigh recovery rateImprove operational stabilityFermentationCyanideEthyl Chloride

The invention discloses a preparation method of ethyl (R)-4-cyano-3-hydroxybutyrate. According to the preparation method, ethyl (S)-4-chloro-3-hydroxybutyrate is taken as a substrate, immobilized halohydrin dehalogenase is taken as a catalyst, the substrate and the catalyst react with cyanide salt under the condition of pH value in a range from 6.5 to 8.0, and ethyl (R)-4-chloro-3-hydroxybutyrate is obtained; a preparation method of immobilized halohydrin dehalogenase comprises steps as follows: adsorbent resin is added to a halohydrin dehalogenase solution, the halohydrin dehalogenase is adsorbed on the adsorbent resin and crosslinked by a difunctional crosslinking agent, finally, the adsorbent resin is separated from the halohydrin dehalogenase solution and washed, and the immobilized halohydrin dehalogenase is obtained. The enzyme recovery rate of the immobilized halohydrin dehalogenase is high, the operation stability is high, reduction of production cost is facilitated, when the immobilized halohydrin dehalogenase is used for preparing ethyl (R)-4-cyano-3-hydroxybutyrate, the process is simple, the resolution effect is excellent, e.e. value can be up to 99%, particularly, the postprocessing is simpler, and the yield can be higher than 91%.

Owner:JIANGSU UNIV OF TECH

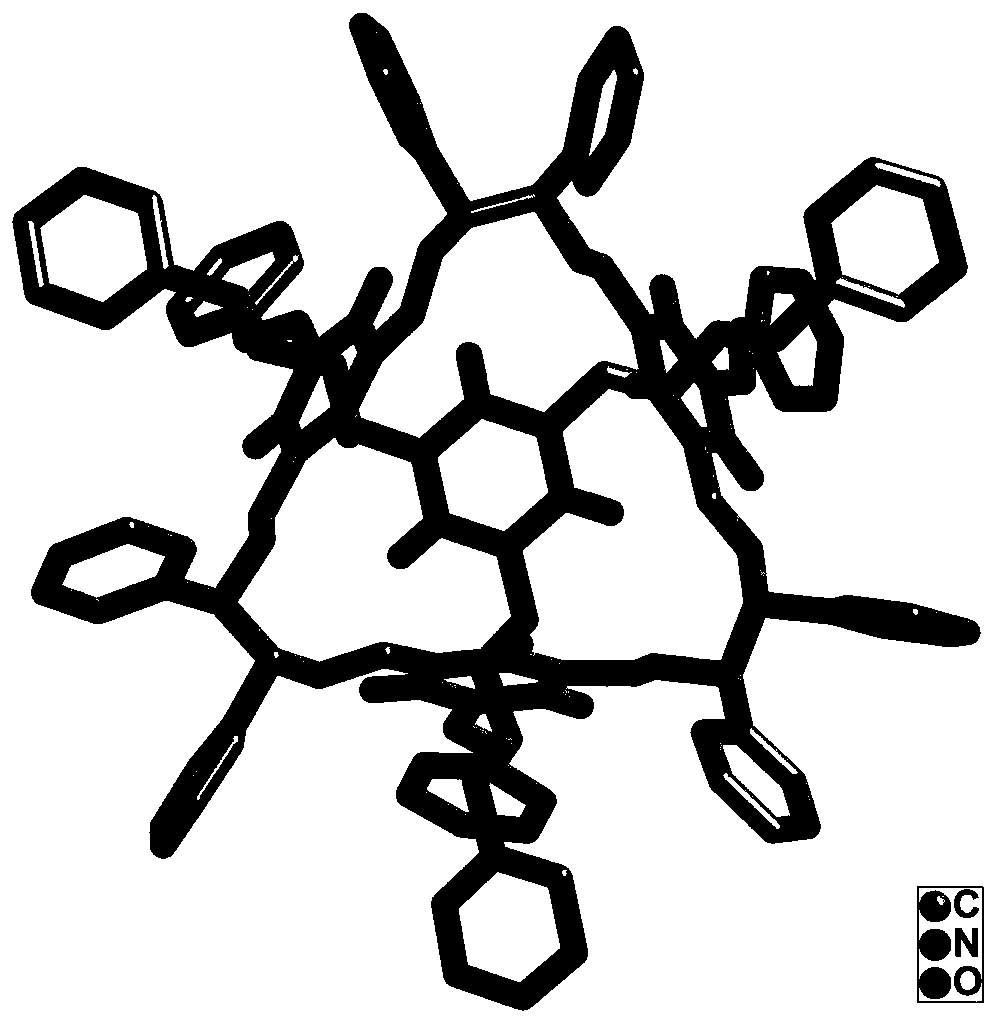

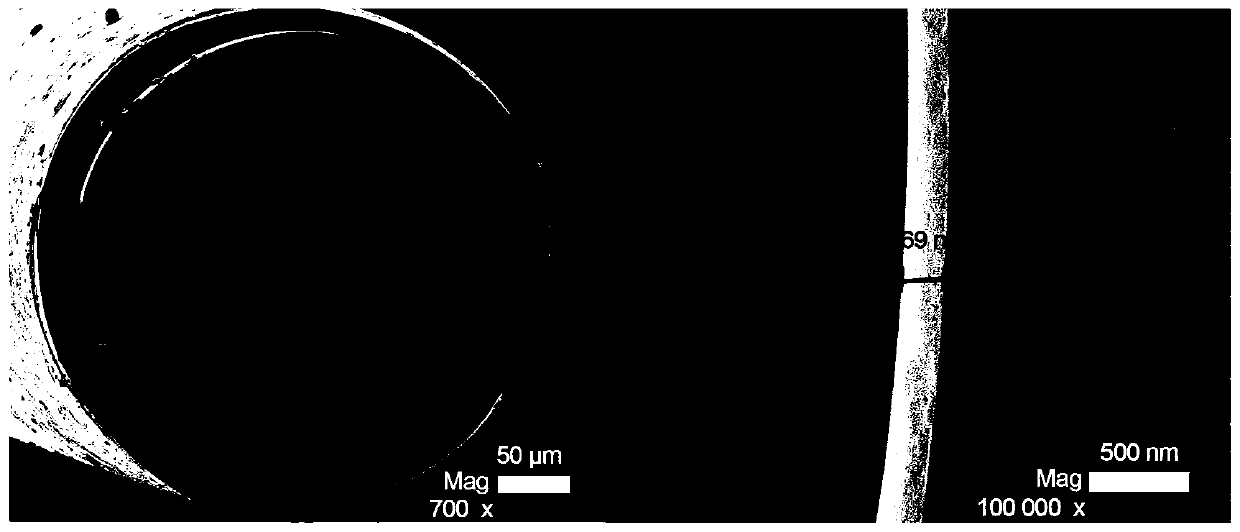

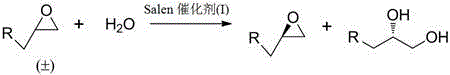

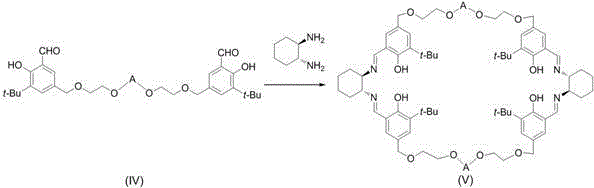

Trivalent cobalt Salen catalyst, synthesis method as well as application of trivalent cobalt Salen catalyst to resolution of terminal epoxides

ActiveCN104801343AGood split effectReduce usageOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsEpoxideOxide

The invention belongs to the technical field of organic chemistry, and particularly provides a trivalent cobalt Salen catalyst, a synthesis method of the trivalent cobalt Salen catalyst as well as an application of the trivalent cobalt Salen catalyst to resolution of terminal epoxides. The trivalent cobalt Salen catalyst is prepared from raw materials which are cheap and easy to obtain through simple reactions, is a binuclear macrocyclic catalyst, is used for catalyzing hydrolytic kinetic resolution of the terminal epoxides and is used at the temperature of 15-30 DEG C, the usage amount of the catalyst is 0.008-0.02 mol% of that of a racemization epoxide, the reaction yield can be higher than 48%, and the ee (enantiomeric excess) value of the resolution product is higher than 99%. The catalyst is mild in reaction condition, low in consumption, high in resolution efficiency and capable of being applied to hydrolytic kinetic resolution of the various terminal epoxides and has the high industrial application value.

Owner:FUDAN UNIV

MOF@SiO2 core-shell microsphere HPLC chiral column for enantiomeric resolution

ActiveCN109647002AExcellent splitting performanceHigh resolutionOther chemical processesSolid sorbent liquid separationPure crystalChemistry

The invention discloses an MOF@SiO2 core-shell microsphere HPLC chiral column for enantiomeric resolution. A method of in-situ growth is used, aminopropyl silica gel is used as a core, and chiral MOFscontrollably grow on the surface of the core as a shell to synthesize a core-shell composite material, and the MOF@SiO2 core-shell microsphere is used as a high performance liquid chromatography stationary phase for chiral separation. Compared with a pure MOF chiral column, the MOF@SiO2 core-shell microsphere HPLC chiral column of the invention can resolve multiple enantiomers, and the chromatographic column has many advantages of higher resolution, higher column efficiency and faster separation speed, which is of great significance to improve the problems of high background pressure and lowcolumn efficiency of a pure crystal column caused by uneven crystal particles.

Owner:YUNNAN NORMAL UNIV

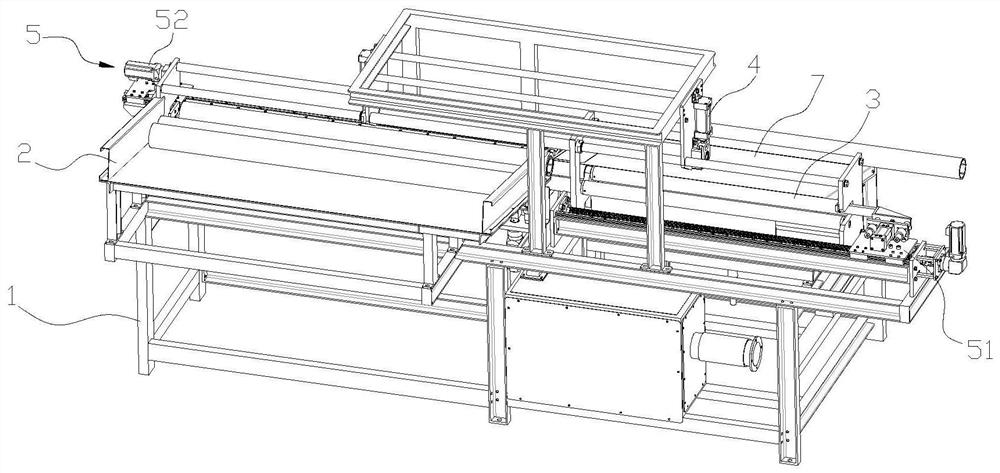

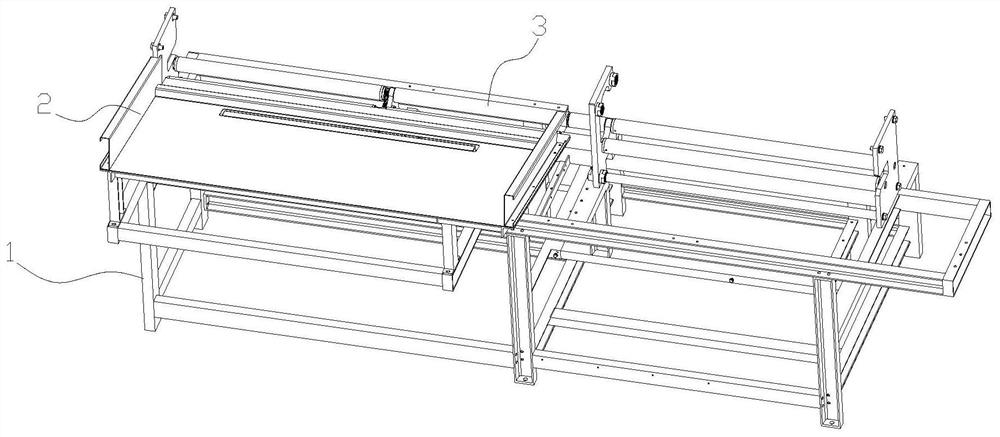

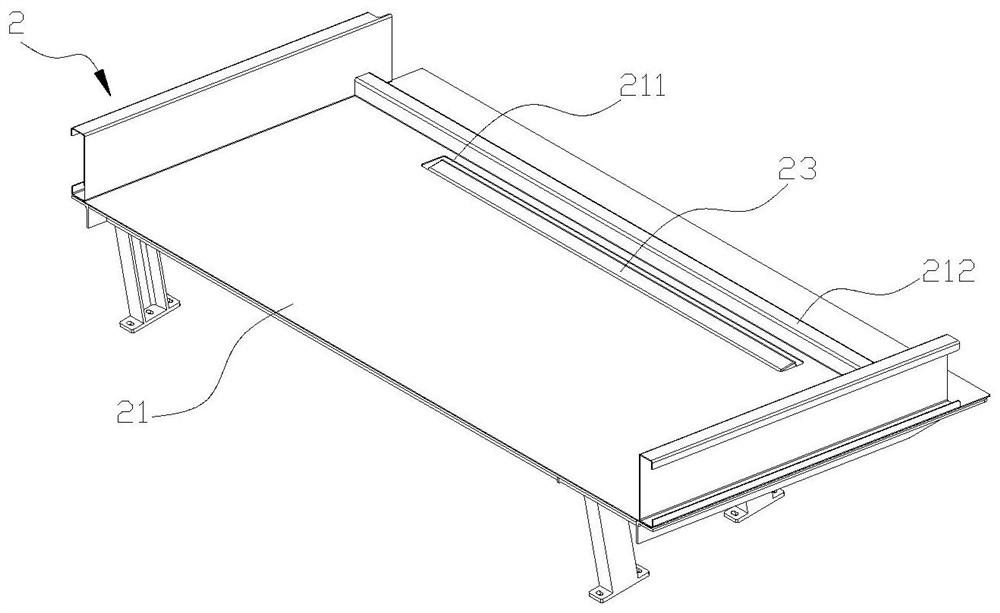

Automatic slitting equipment for pipes

InactiveCN112077912AAvoid concentrated stressReduce chippingMetal working apparatusControl systemControl engineering

The invention discloses automatic slitting equipment for pipes, and relates to the technical field of pipe processing. The automatic slitting equipment comprises a control system and a rack and further comprises a feeding mechanism, a bearing roller mechanism, a clamping roller mechanism, a conveying mechanism, a cutting mechanism and a discharging mechanism which are arranged on the rack; the bearing roller mechanism is used for bearing and driving pipes to synchronously rotate; the bearing roller mechanism is sequentially provided with a feeding station and a cutting station in the length direction of the bearing roller mechanism; the feeding mechanism is used for conveying the pipes to the feeding station; the conveying mechanism is used for conveying the pipes from the feeding stationto the cutting station; the clamping roller mechanism is used for being matched with the bearing roller mechanism to jointly clamp the pipes; the cutting mechanism is used for cutting off the pipes; the discharging mechanism is used for moving the cut-off pipes out of the cutting station; and a control system is used for controlling operation of all the mechanisms. The pipes are synchronously rotated during tool feeding of a tool, so that the pipes are stressed uniformly, the edge breakage probability is greatly reduced, the rejection rate is decreased, the processing efficiency is improved, and the automation degree is high.

Owner:GUANGZHOU ZHI JIAN GENERAL EQUIP MFG CO LTD

Preparation technology of chiral amino acid

ActiveCN102628076AEfficient removalIncrease acetylation contentFermentationAcetic anhydrideMethylamines

The invention discloses a preparation technology of chiral amino acid, comprising the following steps of: 1) performing acetylation between L-amino acid or DL-amino acid and acetic anhydride; 2) distilling the reactant obtained from the step 1), and cooling for crystallization; 3) mixing acetylated L-amino acid or acetylated DL-amino acid obtained from the step 2), toluene and a methylamine aqueous solution, an ethylamine aqueous solution or a caustic soda flake aqueous solution until the temperature reaches 80-90 DEG C, maintaining for 1.5-2.5 hours, distilling at minus 0.001-minus 0.1 MPa at 50-95 DEG C for 4-6 hours, adding water, and adjusting pH to 7-8; and 4) carrying out resolution on the substance obtained from the step 3) and D-aminoacylase or L-aminoacylase. By the preparation technology provided by the invention, impurities in the method for resolution of chiral amino acid from aminoacylase can be effectively removed, acetylation content can be raised, and the resolution effect can be obviously improved in comparison with the prior art.

Owner:滨海瀚鸿生化有限公司

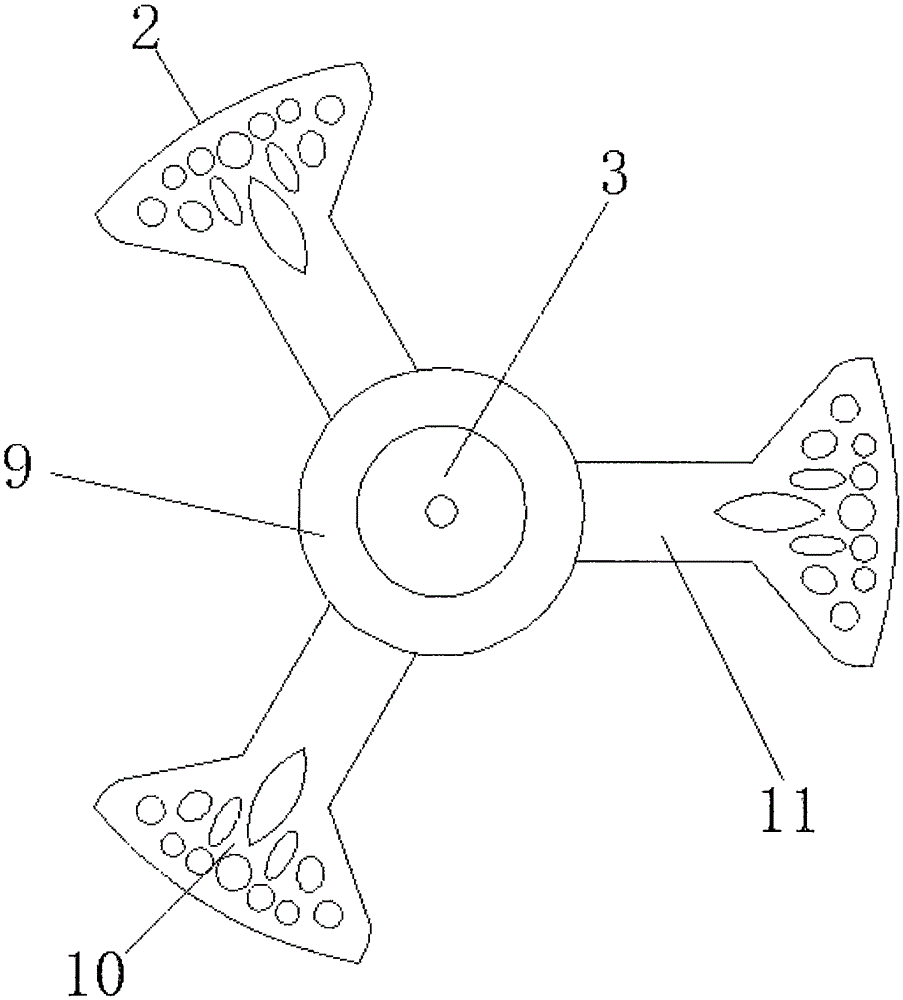

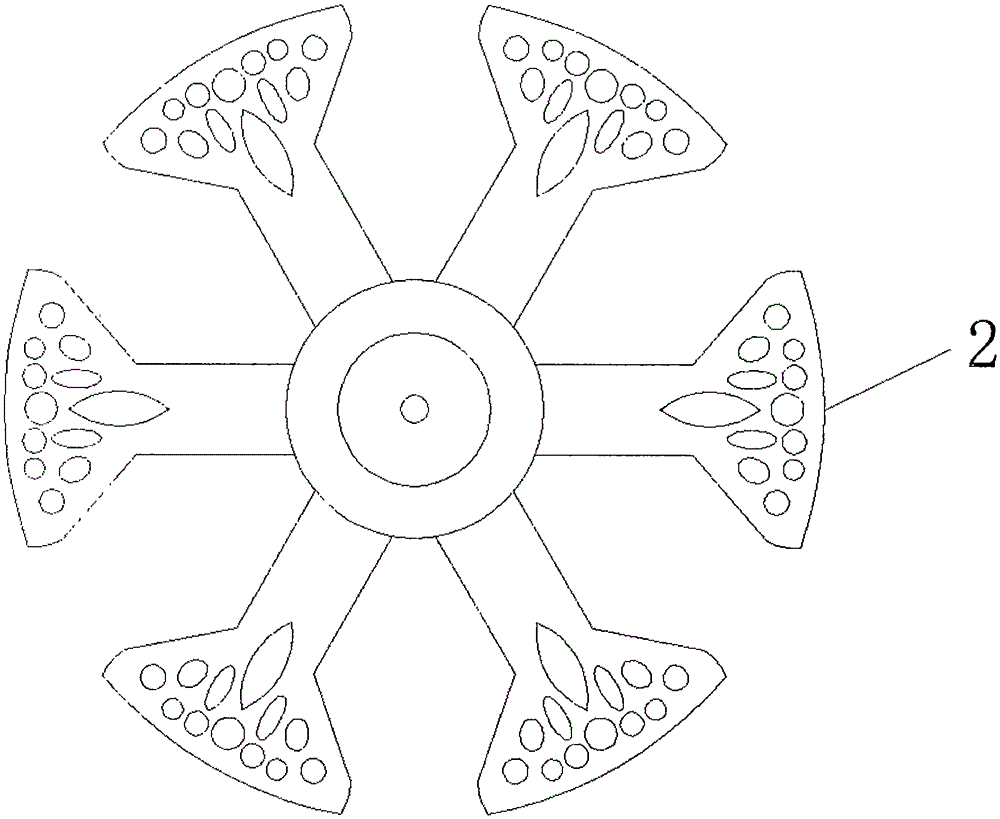

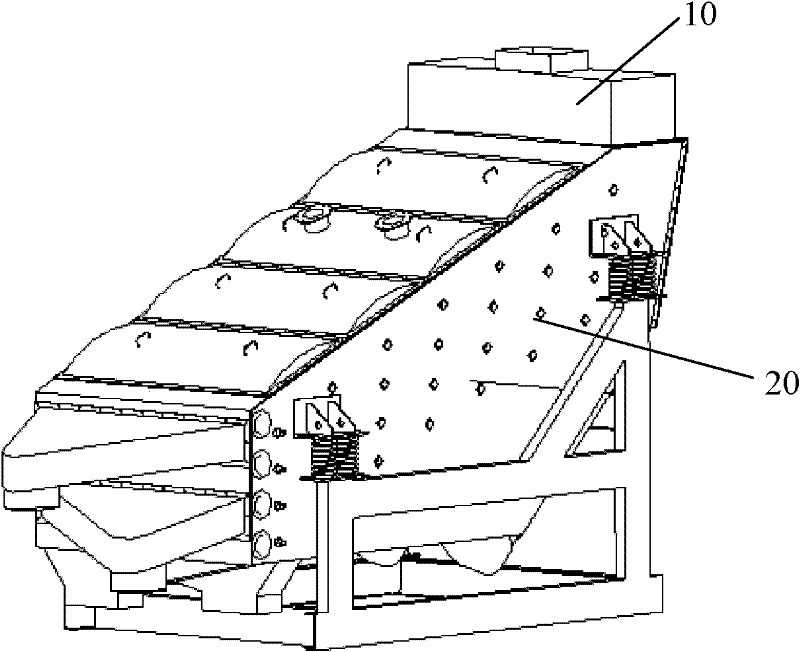

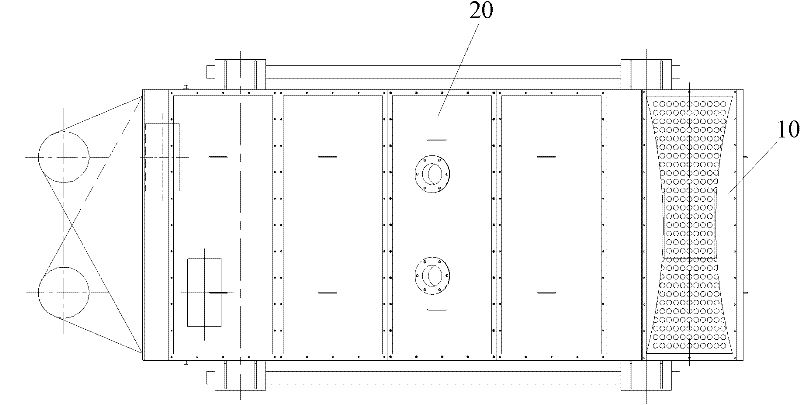

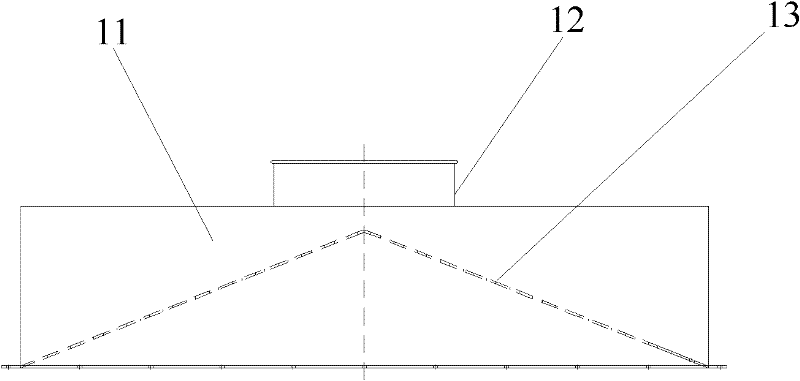

Material distribution screen, vibrating screening device including the material distribution screen, stirring equipment including the device

ActiveCN102284419AEasy to spreadUniform and fast material distribution effectSievingScreeningEngineeringMaterial Separation

The invention provides a material separation screen plate, a vibration screen device comprising the material separation screen plate, as well as stirring equipment comprising the device, and generally relates to the field of engineering equipment. A plurality of feed holes are formed on the material separation screen plate, and the material separation screen plate is of a middle-high peripheral-low structure, and is provided with opposite inner concave lateral sides in which projections in vertical direction are of inner concave shapes. The vibration screen device comprises a feed device and a vibration separation device, and the feed device is detachably arranged at the inlet on the top of the vibration separation device, wherein the feed device comprises a feed case and a separation screen plate, wherein a feed port is formed on the top of the feed case; and the separation screen plate is arranged inside the feed case, and a plurality of inlet holes are formed on the separation screen plate. The vibration screen device has a simple structure, is convenient to assemble and disassemble, and realizes that the separation effect is improved, so that a material can be uniformly distributed on a screen after entering from the feed port.

Owner:ZOOMLION HEAVY IND CO LTD

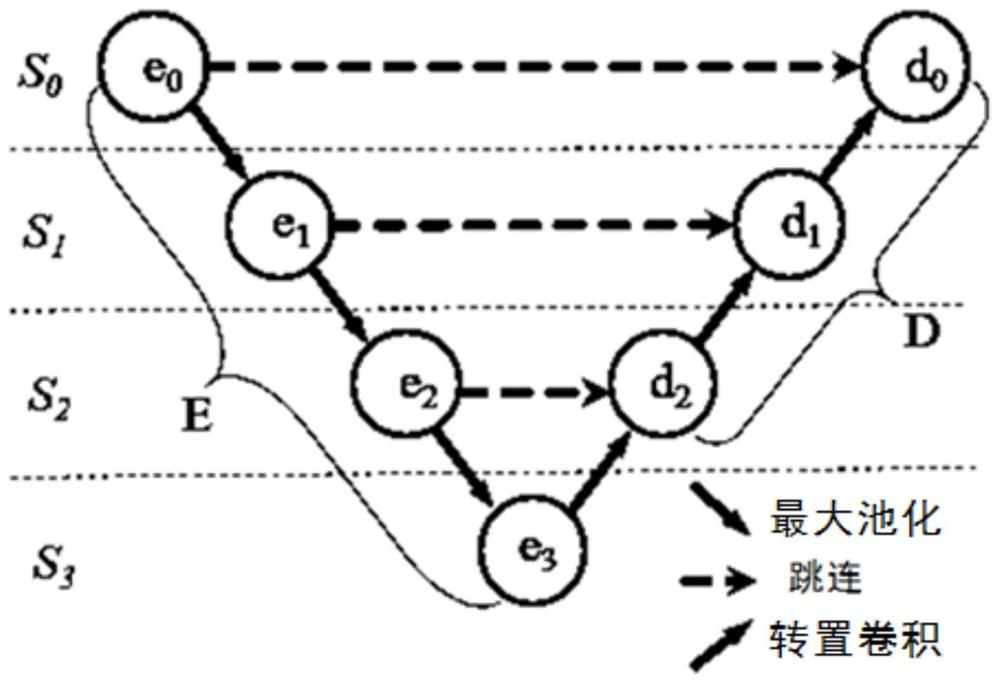

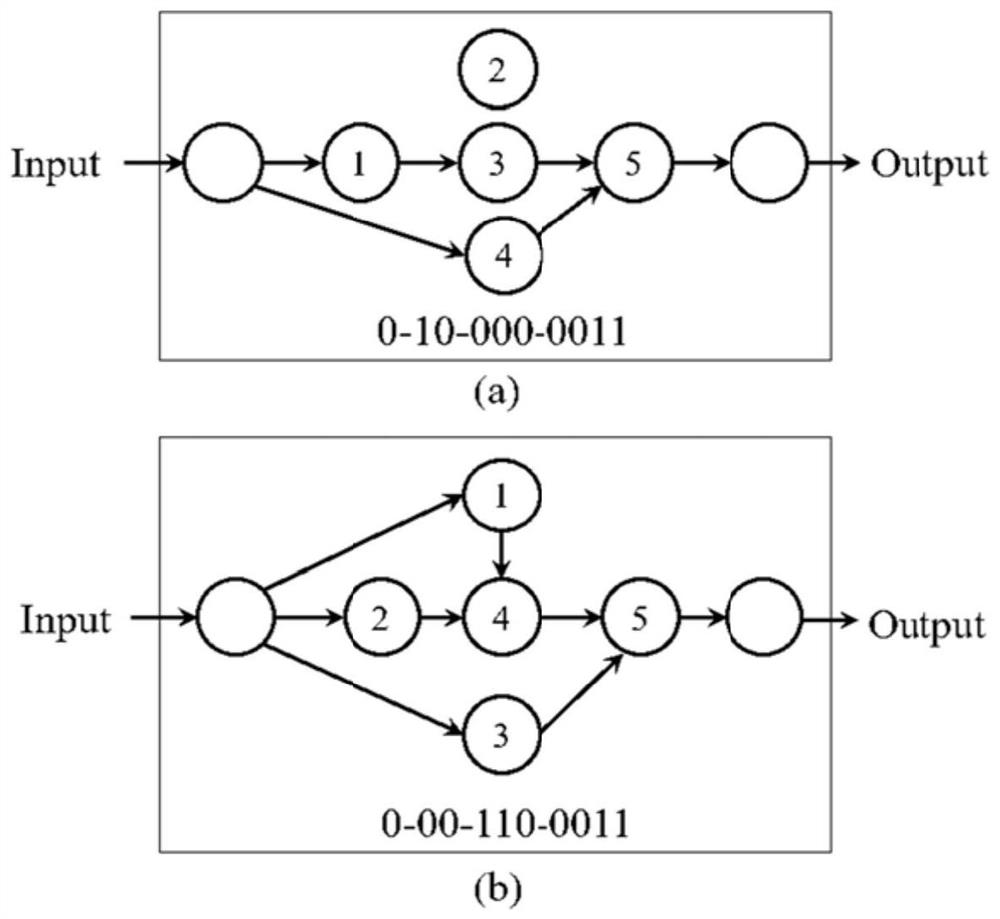

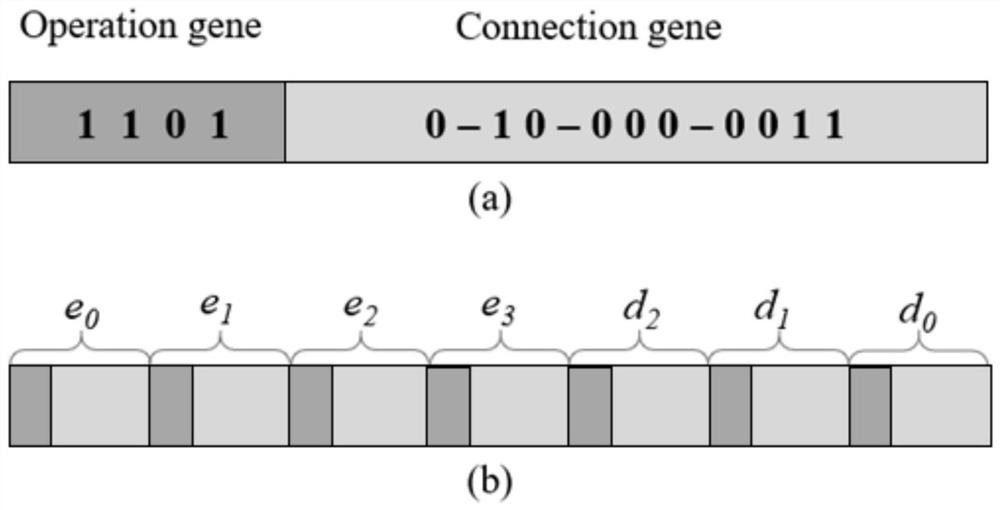

Road crack segmentation method based on genetic algorithm and U-shaped neural network

ActiveCN112257622AEasy to handleImprove search efficiencyInternal combustion piston enginesCharacter and pattern recognitionGenetics algorithmsNetwork model

The invention provides a road crack segmentation method based on a genetic algorithm and a U-shaped neural network. A genetic algorithm is used to search a full convolutional neural network architecture of a U-shaped coding and decoding structure, so as to achieve automatic design. The problems that a road crack segmentation neural network model which is manually designed is tedious in work and large in workload, the designed model is complex, and road crack segmentation is inaccurate under complex conditions are solved, and road cracks can be automatically and accurately segmented. A structure and operation which are better than those of manual design and lower in calculation complexity are found for the modules, high robustness is achieved for interference of complex road surface image cracks, disease non-uniformity and illumination imbalance, the characteristics of the road cracks can be extracted more accurately, and therefore the segmentation accuracy of the whole image is improved.

Owner:SHANTOU UNIV

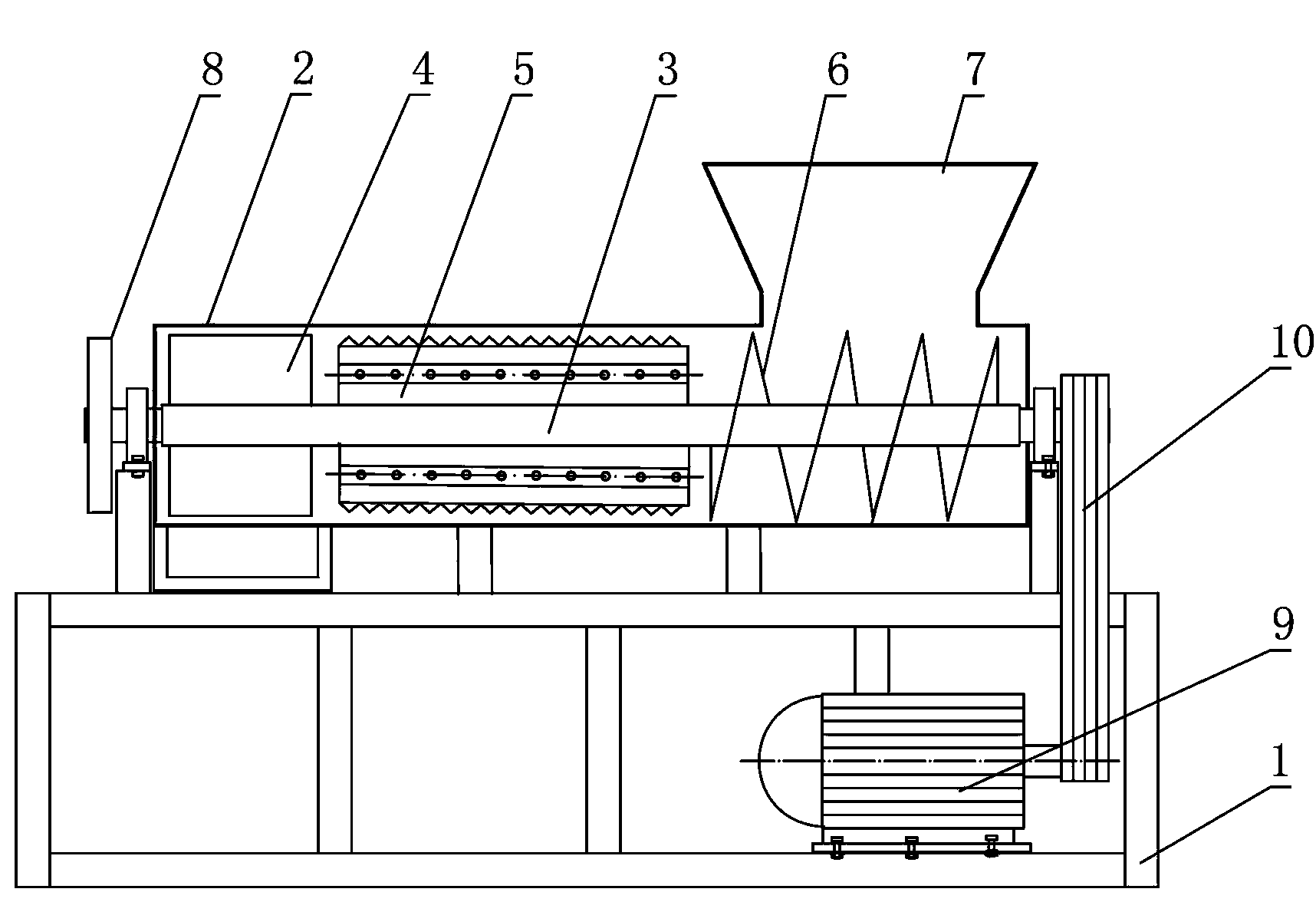

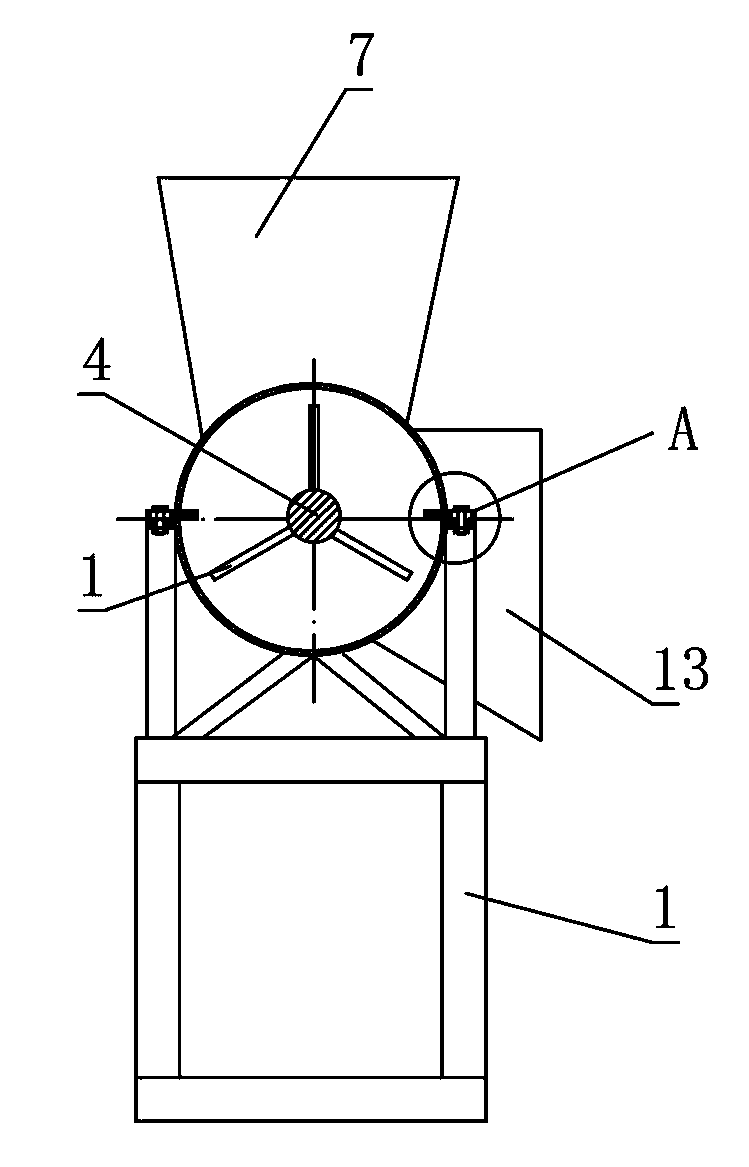

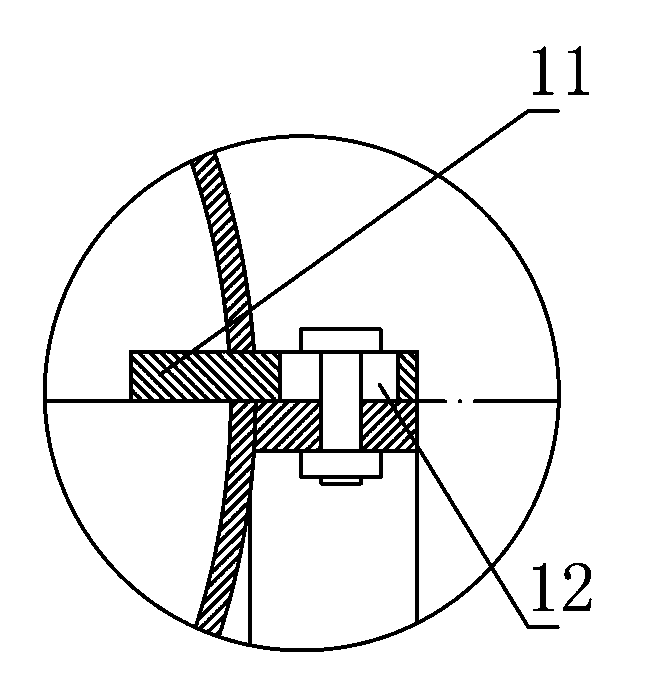

Straw devillicate machine

ActiveCN103510417AClearance adjustableReduce consumptionRaw material divisionEngineeringMechanical engineering

The invention discloses a straw devillicate machine. The machine mainly comprise a rack and a protective shell, wherein the protective shell is fixed to the rack, a rotary shaft is arranged in the protective shell, and a material poking plate, a movable cutter and a spiral conveying device are sequentially fixed on the rotary shaft from left to right; a material inlet is formed in the position, corresponding to the spiral conveying device, of the protective shell, a material outlet is formed in the position, corresponding to the material poking plate, of the protective shell, and a fixed cutter is arranged in the position, corresponding to the movable cutter, of the protective shell; the rotary shaft is driven through a motor. According to the machine, straw raw materials are transported to the position between the movable cutter and the fixed cutter through the spiral conveying device to be ground, and the straw raw materials are conveyed out by the material poking plate. The machine is simple in structure, convenient to maintain and low in price; due to the fact that gap between the movable cutter and the fixed cutter is adjustable, when the cutters are abraded, the cutters do not need to be replaced by only adjusting the gap between the two cutters; both the cross section of the cutting edge of the movable cutter and the cross section of the cutting edge of the fixed cutter are in the shape of sawteeth, the movable cutter and the fixed cutter are matched in a staggered mode, the contact area between the cutting edges is increased, work efficiency is improved, and meanwhile consumption of kinetic energy is reduced.

Owner:石河子市国力源环保制浆有限公司

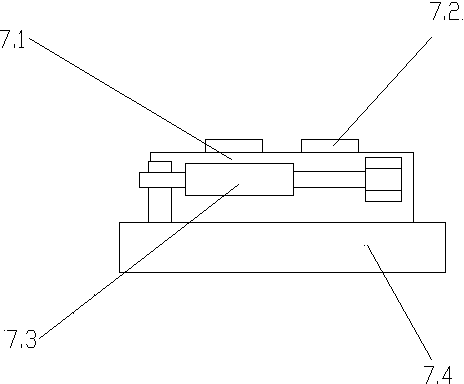

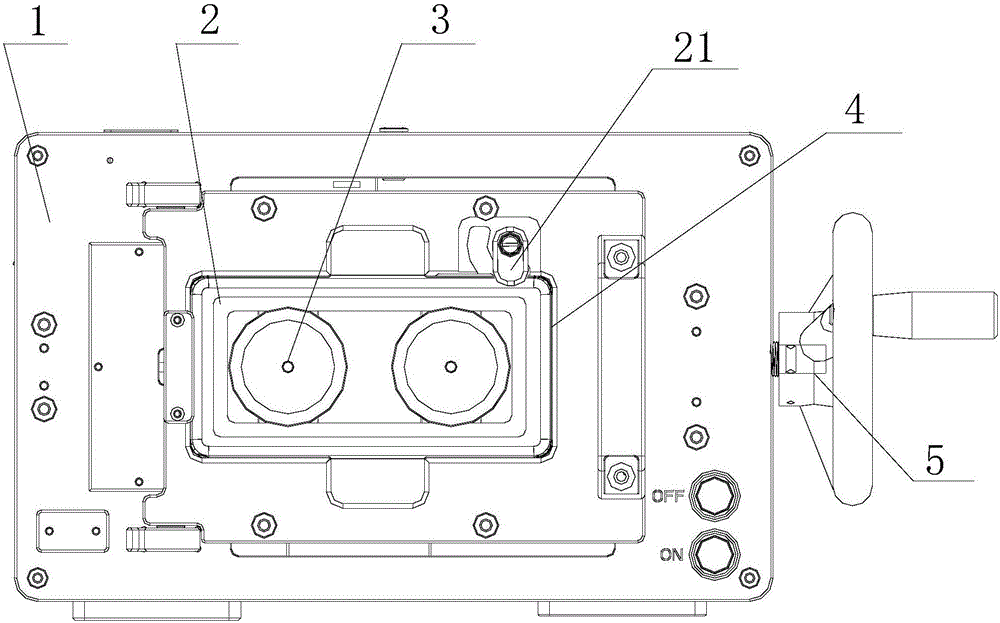

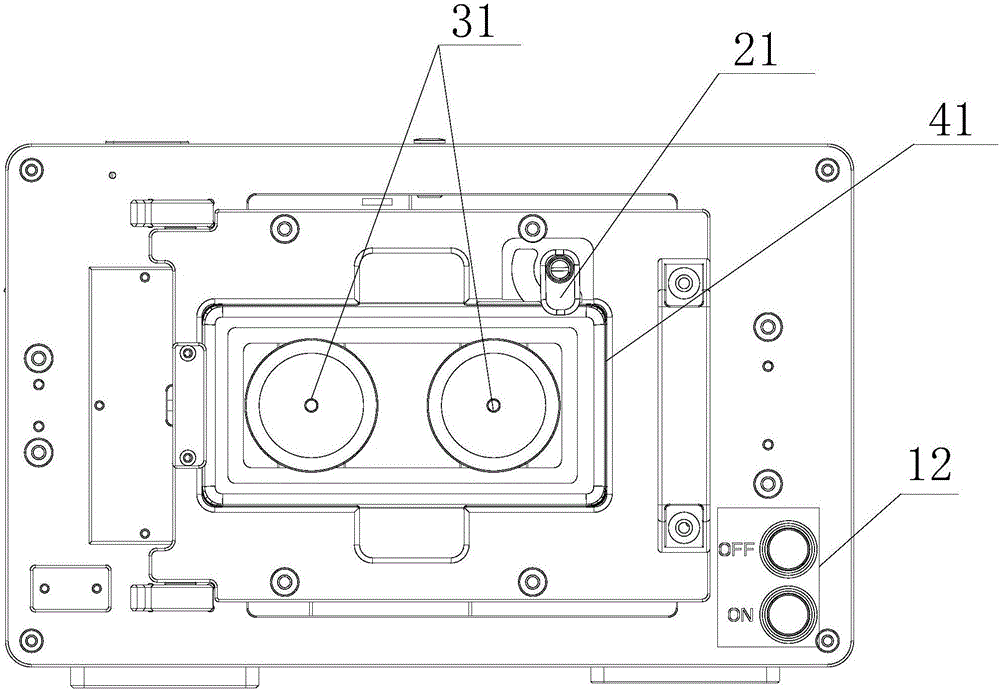

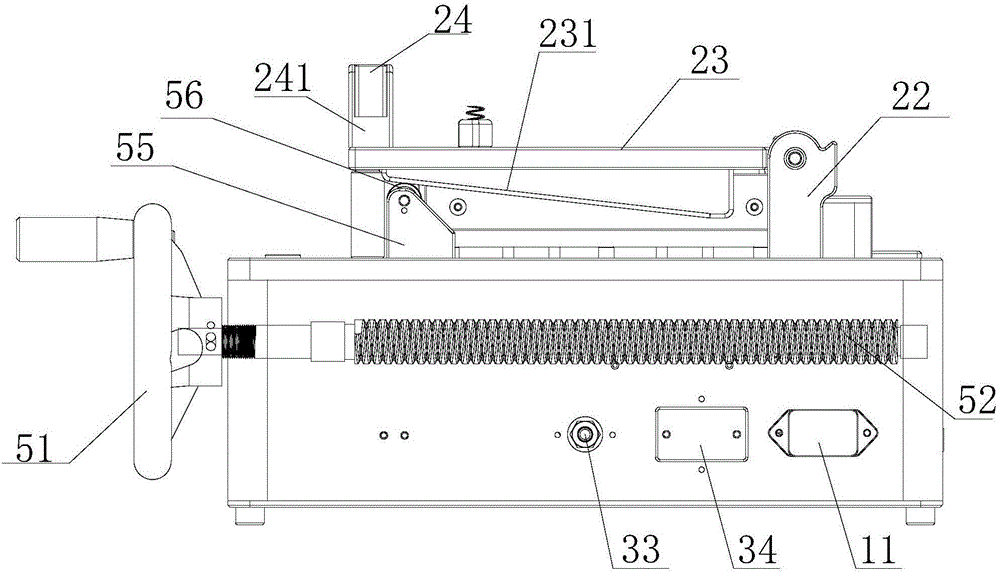

Display module dismounting tool and using method thereof

The invention relates to a display module dismounting tool and a using method thereof. The display module dismounting tool comprises a shell, and further comprises a heating device, a sucking device and a dismounting device which are partially or integrally arranged inside the shell, wherein a clamp device used for clamping a mobile phone front shell assembly and limiting the rotational range thereof is arranged at the upper part of the shell; the heating device is connected with the clamp device and is used for heating the mobile phone front shell assembly; the sucking device is indirectly connected with the clamp device and is used for sucking the mobile phone front shell assembly; the dismounting device is connected with the clamp device and is used for ejecting the clamp device so as to dismount the mobile phone front shell assembly. The display module dismounting tool clamps the mobile phone front shell assembly through the clamp device, heats the mobile phone front shell assembly through the heating device so as to conveniently dismount each part, sucks a touch screen and a display screen of a mobile phone front shell through the sucking device, and ejects the clamp device so as to dismount a middle frame of the mobile phone front shell from the touch screen and the display through the dismounting device. The display module dismounting tool has the advantages of strong universality, simplicity in operation, convenience in maintenance and cost reduction.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

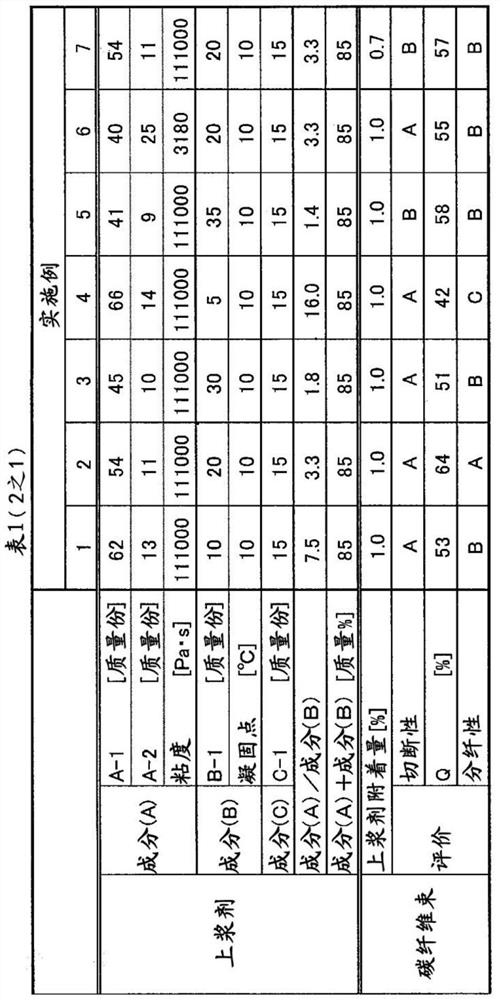

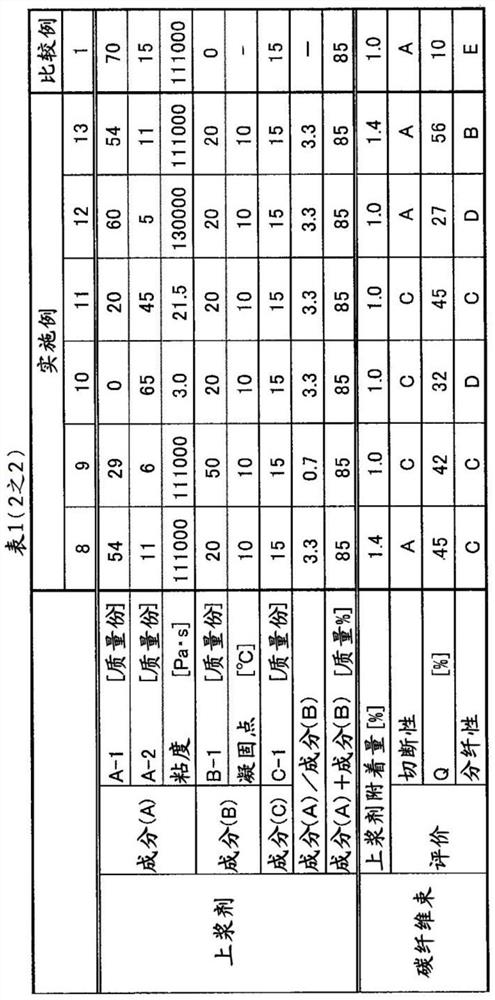

Sizing agent, reinforcing fiber bundle, fiber-reinforced resin forming material, and fiber-reinforced composite material

PendingCN112292488AImprove cutting effectGood split effectCarbon fibresCarbon preparation/purificationEpoxyPolymer science

Provided is a sizing agent containing component (A) and component (B), wherein the mass ratio A / B of component (A) relative to component (B) is 0.5-20, and the ratio of the total combined amount of component (A) and component (B) to the total amount of the sizing agent is at least 80 mass%. The component (A) is an epoxy resin having a viscosity at 30 DEG C of 1-180,000 Pa.s. The component (B) is an aliphatic ester compound having a freezing point of 50 DEG C or lower.

Owner:MITSUBISHI CHEM CORP

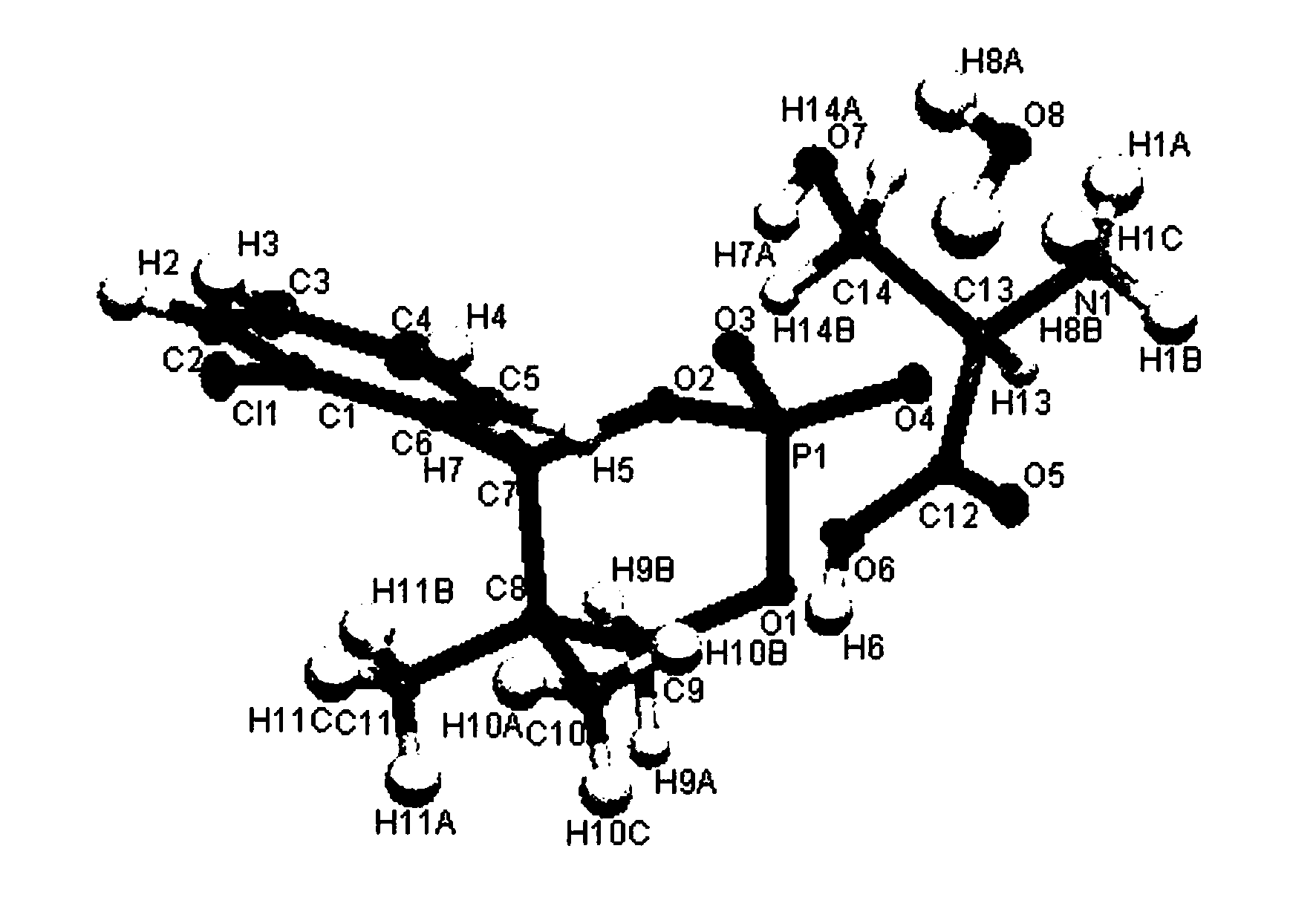

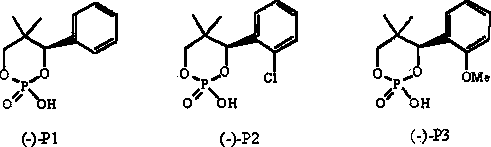

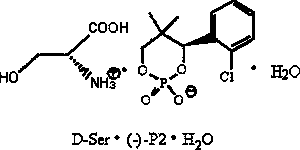

Preparation method according to D-serine through splitting method

ActiveCN103755582AGood split abilityReduce the amount of resolving agentOrganic compound preparationAmino-carboxyl compound preparationAqueous solutionPeptide serine serine

The invention discloses a preparation method according to D-serine through a splitting method. The preparation method takes levo-cyclic phosphoric acid as a splitting agent, adopts a half-quantity splitting method to split dl-serine, and comprises the following steps: heating and reflowing the dl-serine and half equivalent of the levo-cyclic phosphoric acid splitting agent in an inorganic proton acid alcohol and aqueous solution; reducing temperature and devitrifying; carrying out separating and dissociating to obtain the D-serine and L-serine respectivelt; recycling the L-serine after racemization. The preparation method is simple to operate; effective utilization rate of the chiral splitting agent is increased; dosage of the chiral splitting agent is decreased; the cost is relatively low; the yield is high; products are good in purity; the preparation method belongs to the field of racemoid splitting.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Beta-cyclodextrin derivative and preparation method thereof, and polyurea-bond cyclodextrin chiral stationary phase prepared from beta-cyclodextrin derivative

ActiveCN103910812AWide variety of sourcesMild reaction conditionsOther chemical processesBulk chemical productionSimulated moving bedCyclodextrin Derivatives

The invention discloses a beta-cyclodextrin derivative and a preparation method thereof and a polyurea-bond cyclodextrin chiral stationary phase prepared from the beta-cyclodextrin derivative. The beta-cyclodextrin derivative has a molecular formula of [((CH3)2C6H3NHCO)14C42H49O28)(N3)7] and has a structural formula as shown in a formula (I) which is described in the specification. The beta-cyclodextrin derivative is used as a chiral selector and undergoes a Staudinger reaction with ammoniated silica gel so as to obtain the novel poly-bonded cyclodextrin chiral stationary phase. The chiral stationary phase provided by the invention has good stability in a mobile phase with strong polarity and high water content, has good selectivity with regard to chiral compounds and can be applied in high performance liquid chromatography (HPLC), simulated moving bed chromatography (SMB), supercutical fluid chromatography (SFC), etc.

Owner:广州研创生物技术发展有限公司

Horizontal strip type fluidization distributor

ActiveCN101397681AImprove and ensure purification efficiencyGood split effectBulk conveyorsChemical/physical processesAluminium electrolysisAgricultural engineering

The invention discloses a powdered materiel distribution device, particularly relates to a distribution device of alumina powder in an aluminium electrolysis fume purification system. The structure of the level strip type fluidization distribution device is as follows: the distribution device comprises a materiel chamber, a gas chamber and a ventilating plate, wherein, the materiel chamber is horizontally arranged or nearly arranged in a horizontal manner and communicated with at least two distribution boxes that can discharge independently; and the materiel chamber is communicated with the distribution boxes by a distribution pipe and the distribution device. The distribution device effectively carries out multi-point distribution to the alumina powder by small elevation difference, has good distribution effect, improves and guarantees the purifying efficiency of aluminium electrolysis fume and has low equipment investment, simple structure and easy execution.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

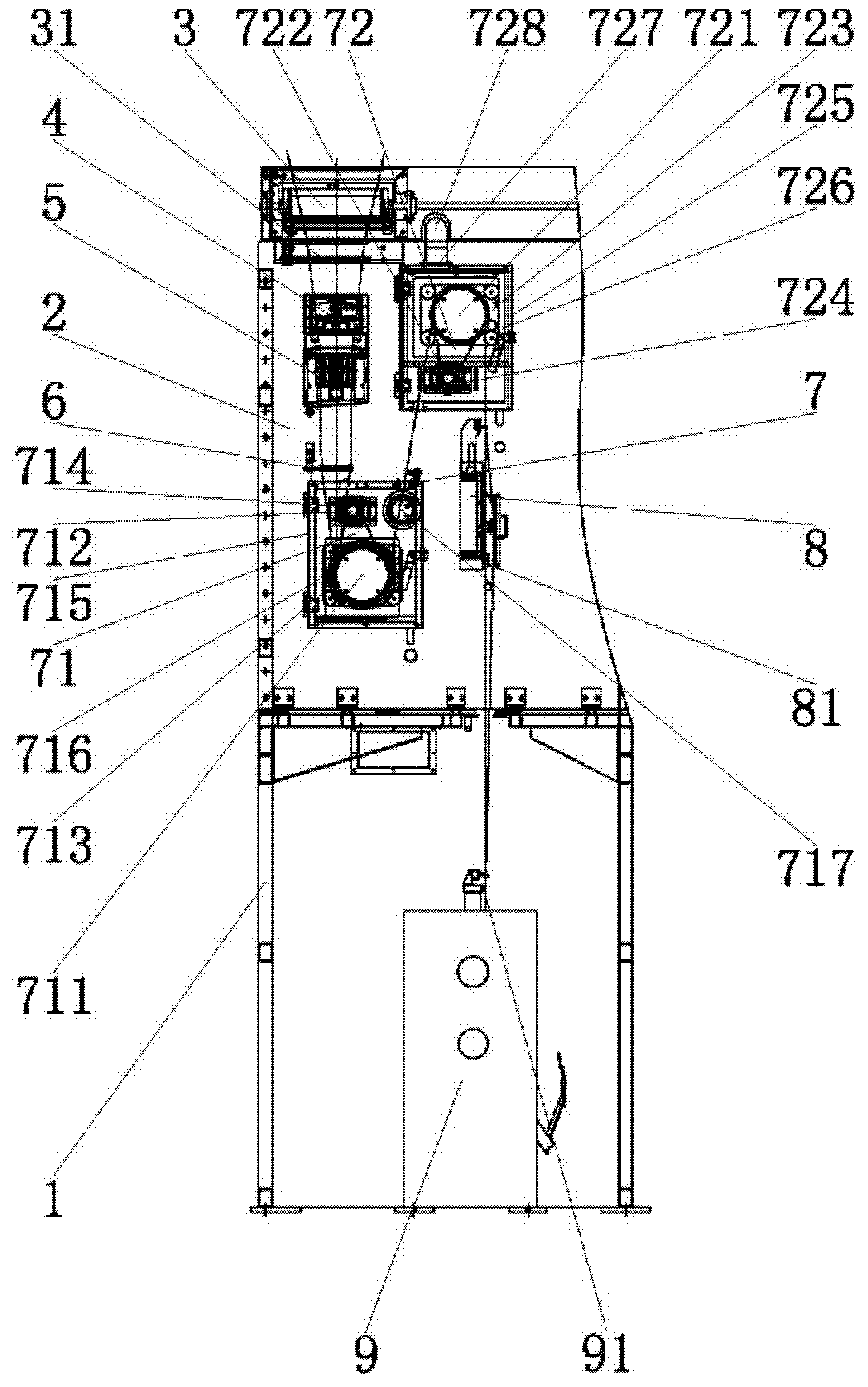

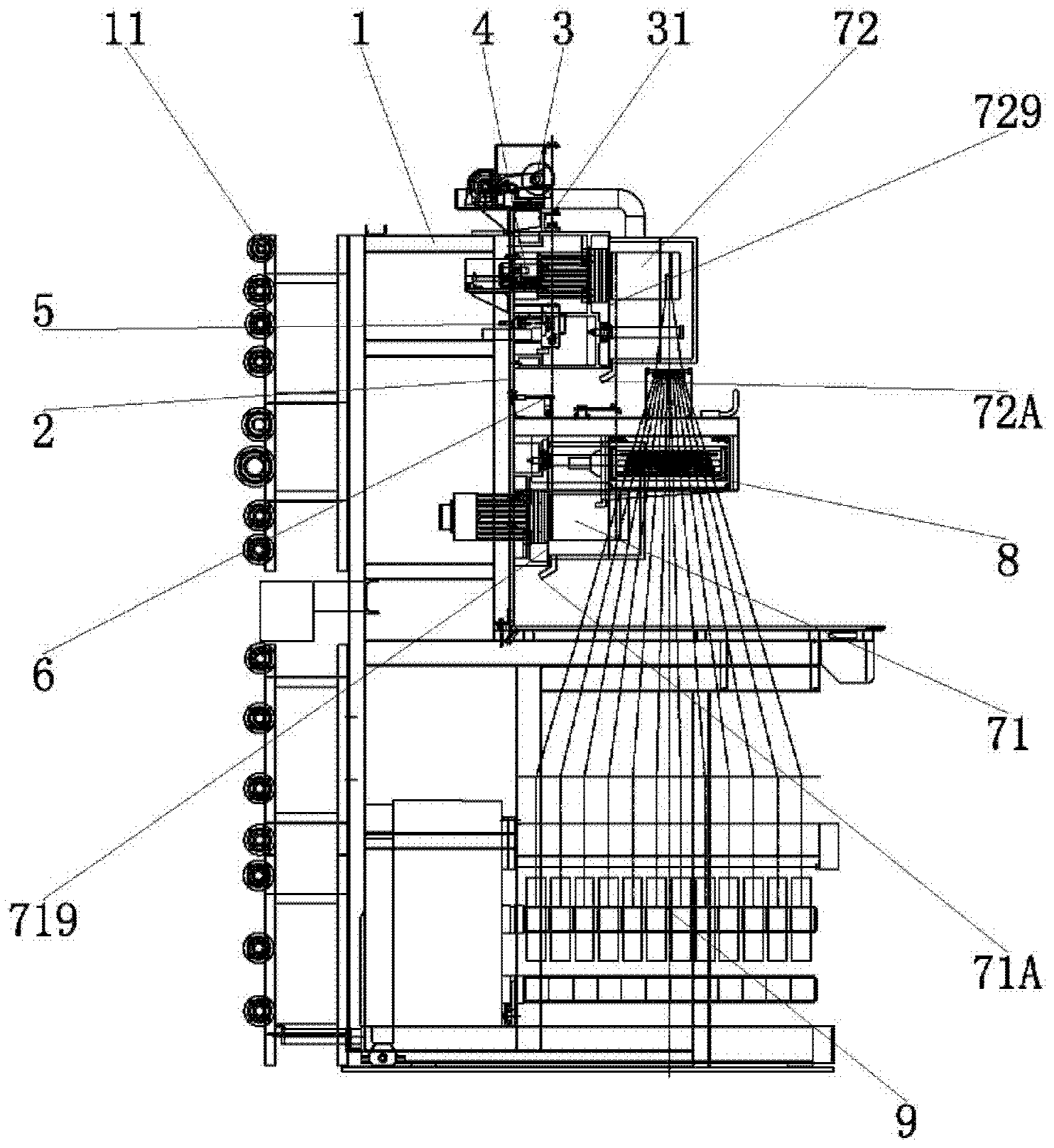

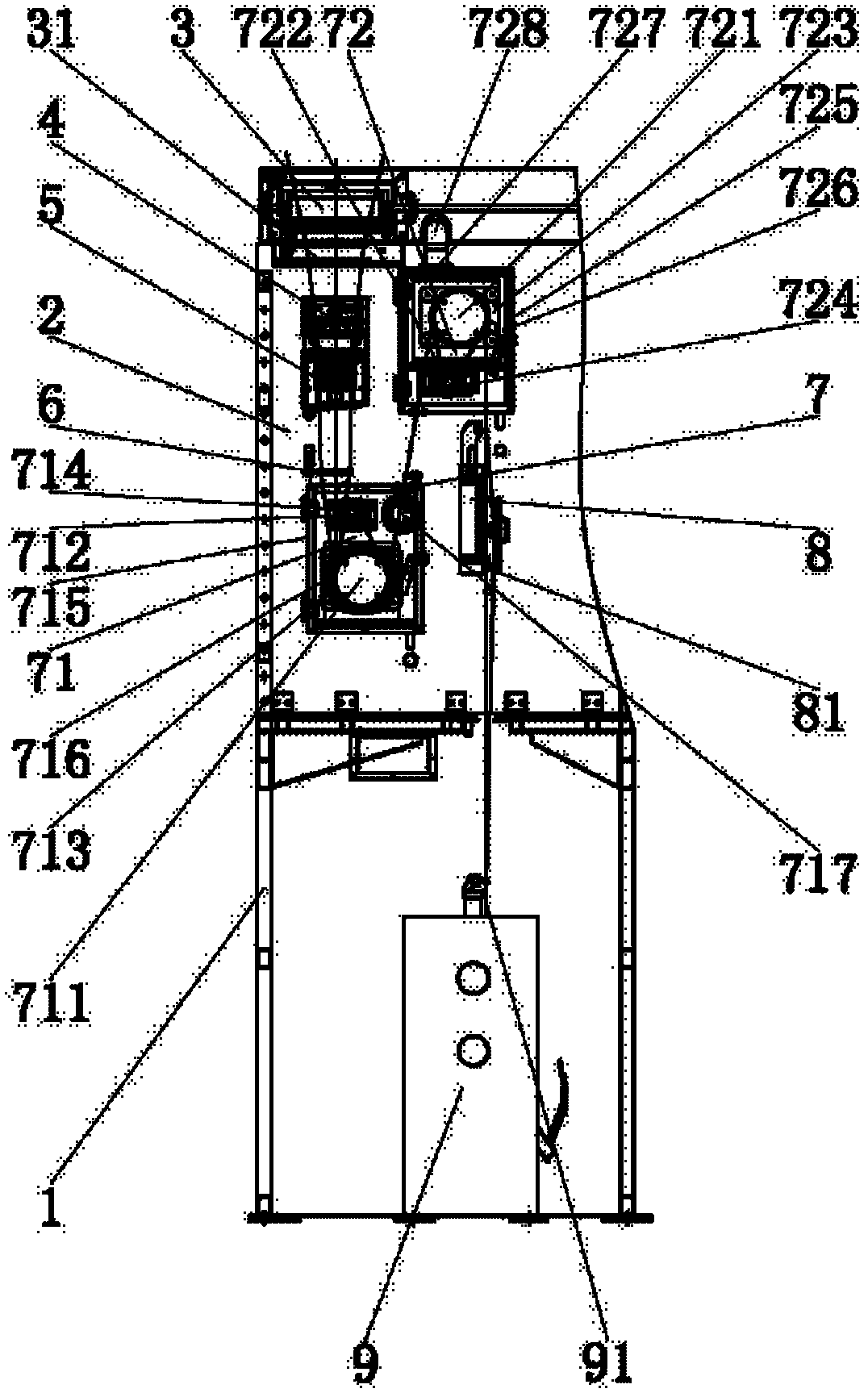

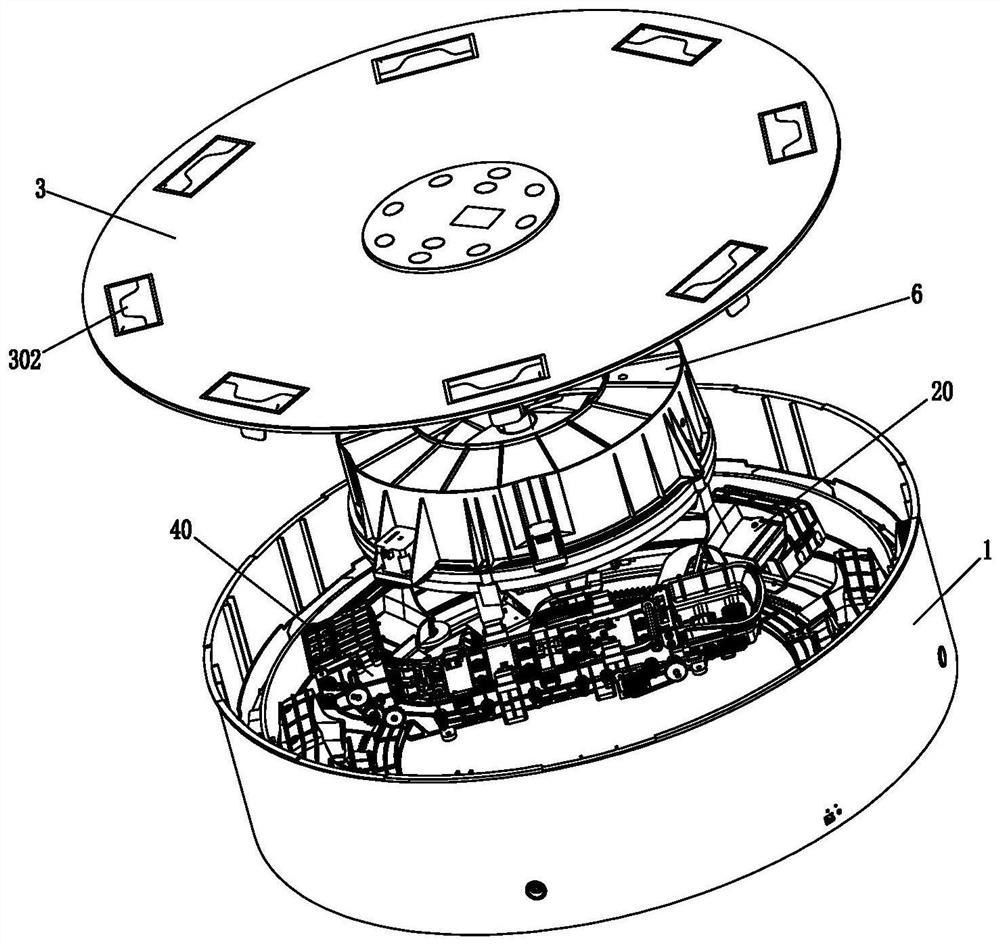

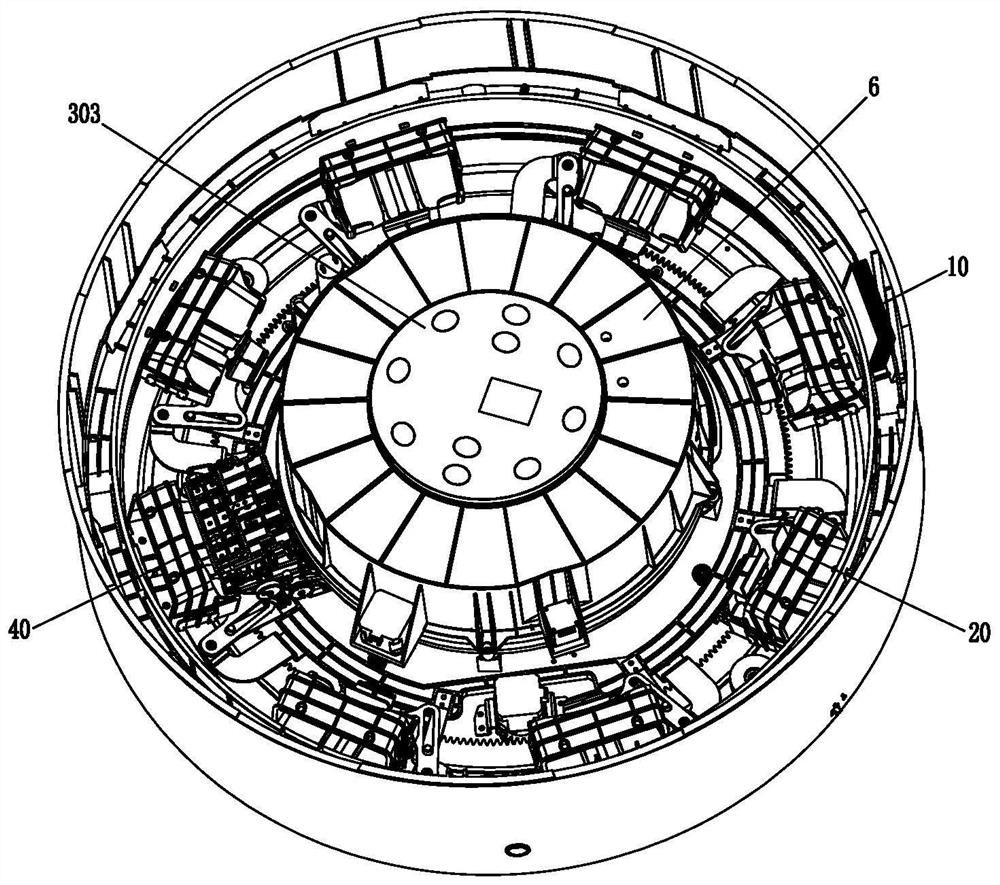

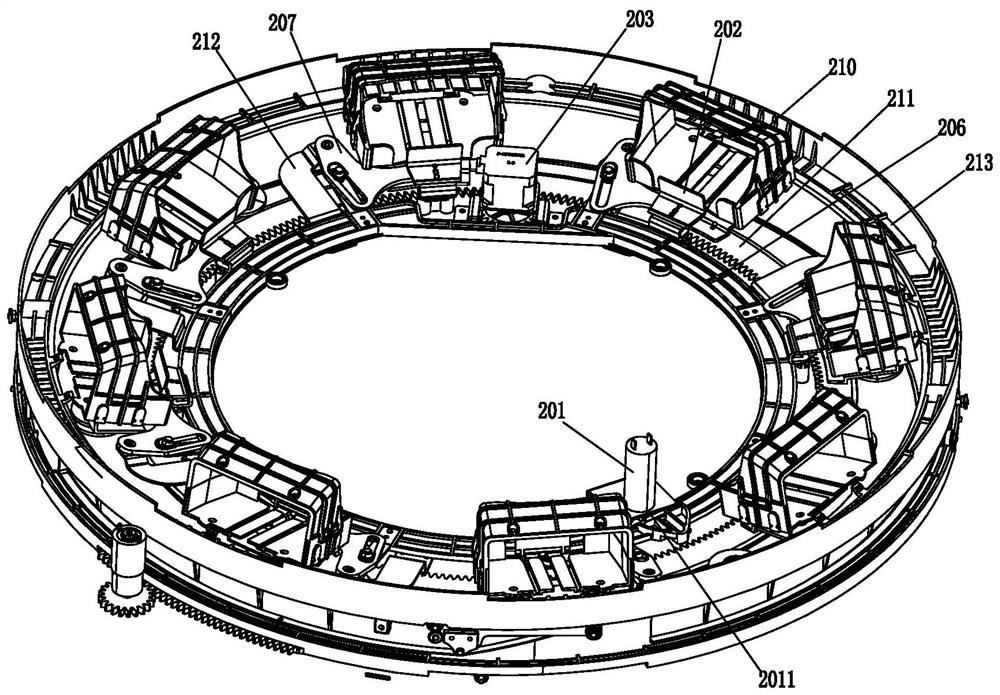

Poker machine, card dealing device and card distributing mechanism of poker machine, and poker card sorting method

The invention discloses a poker machine, a card dealing device and a card distributing mechanism of the poker machine, and a poker card sorting method. The card distributing mechanism comprises a card storage box, a card conveying wheel, a card distributing wheel and a card distributing pressing wheel. The card conveying wheel and the card distributing wheel are both driving wheels, and the card distributing pressing wheel is a driven wheel. The card distributing wheel is located outside a card outlet of the card storage box, and the card distributing pressing wheel is installed on a movable part. The movable part moves up and down on a fixed seat. The movable part and the fixed seat are connected through an elastic part to endow the card distributing pressing wheel with the tendency of pressing towards the card distributing wheel. The card distributing pressing wheel and the card distributing wheel are correspondingly arranged up and down, and a card inlet channel of the card dealing device is formed between the card distributing pressing wheel and the card distributing wheel. The card conveying wheel and the card distributing wheel are located on the inner side and the outer side of the card outlet side wall of the card storage box respectively. According to the scheme, the card distributing mechanism is separated from the card outlet side wall of the card storage box, the poker cards in the card storage box are prevented from floating or being placed overhead, the poker cards are promoted to quickly enter the card distributing device, the card distributing efficiency is improved, the structure is simple, the operation is reliable, and the failure rate is low.

Owner:ZHEJIANG CHAOSHENG ELECTROMECHANICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com