Hot roller drafting type corterra pre-oriented filament drafting and wingding device

A winding device and pre-orientation technology, applied in the direction of filament generation, artificial filament heat treatment, stretch spinning, etc. Problems such as large retraction rate of oriented filaments and properties of structurally hardened filaments can achieve the effects of improving the splitting effect, facilitating spinning position and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

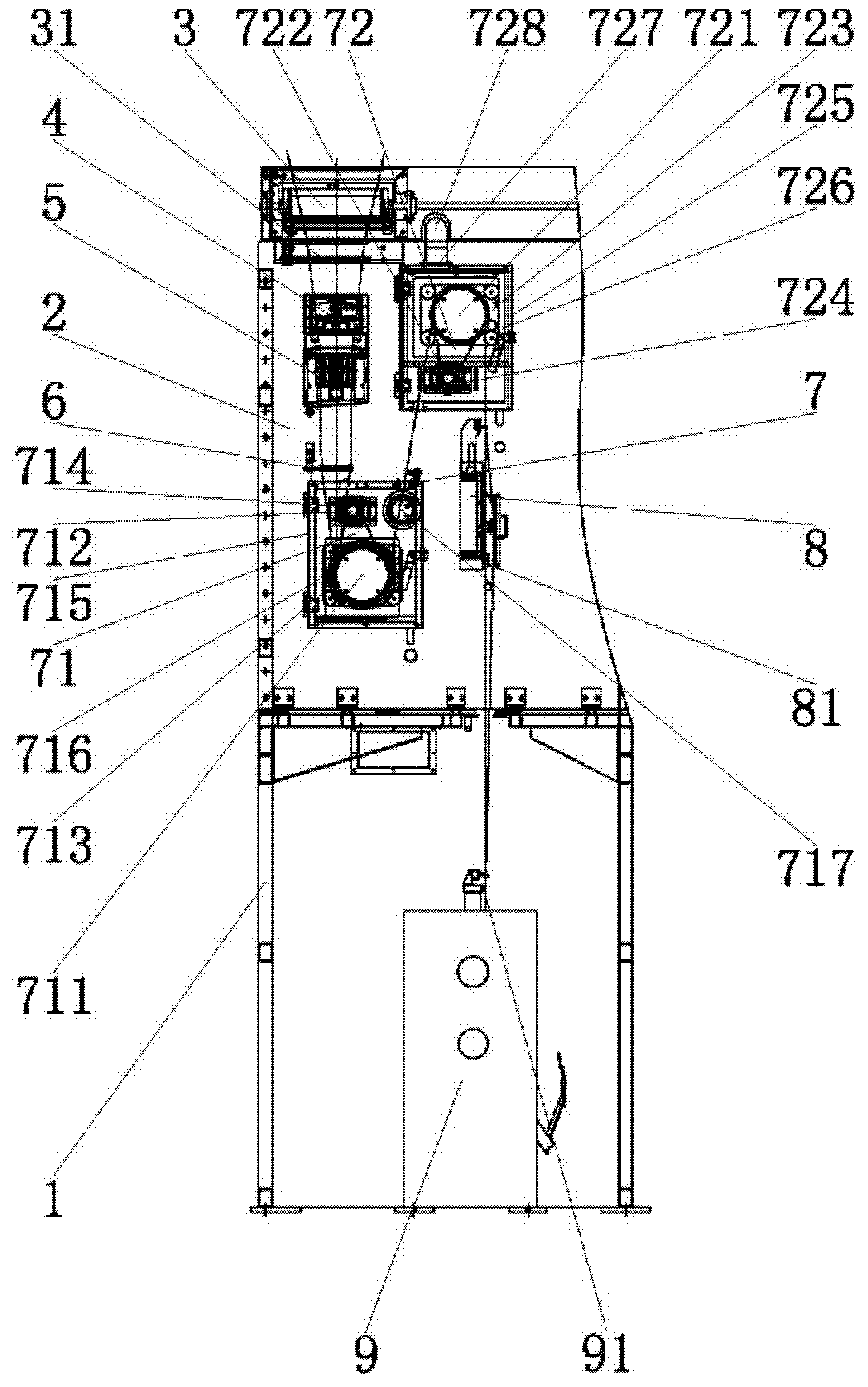

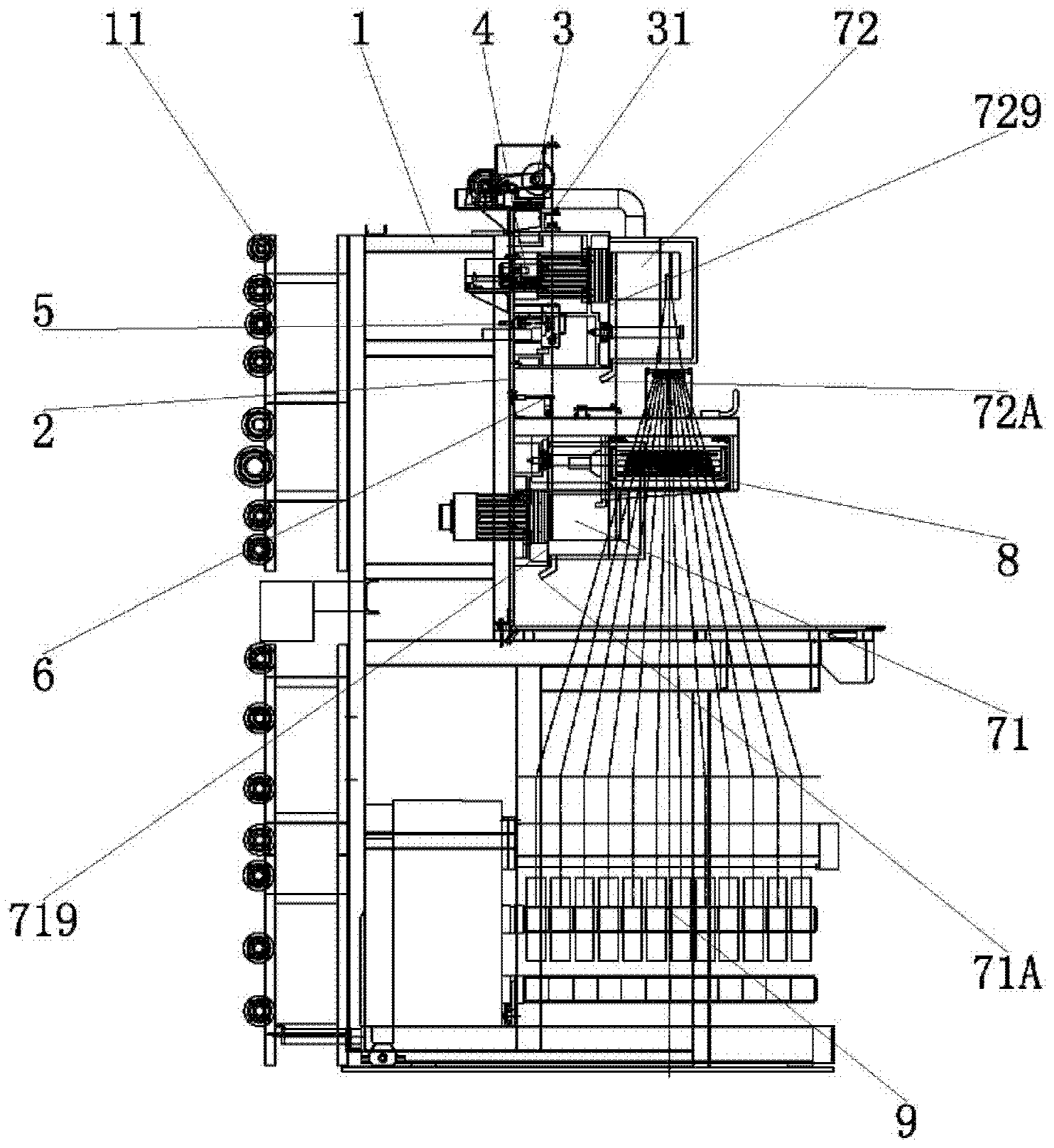

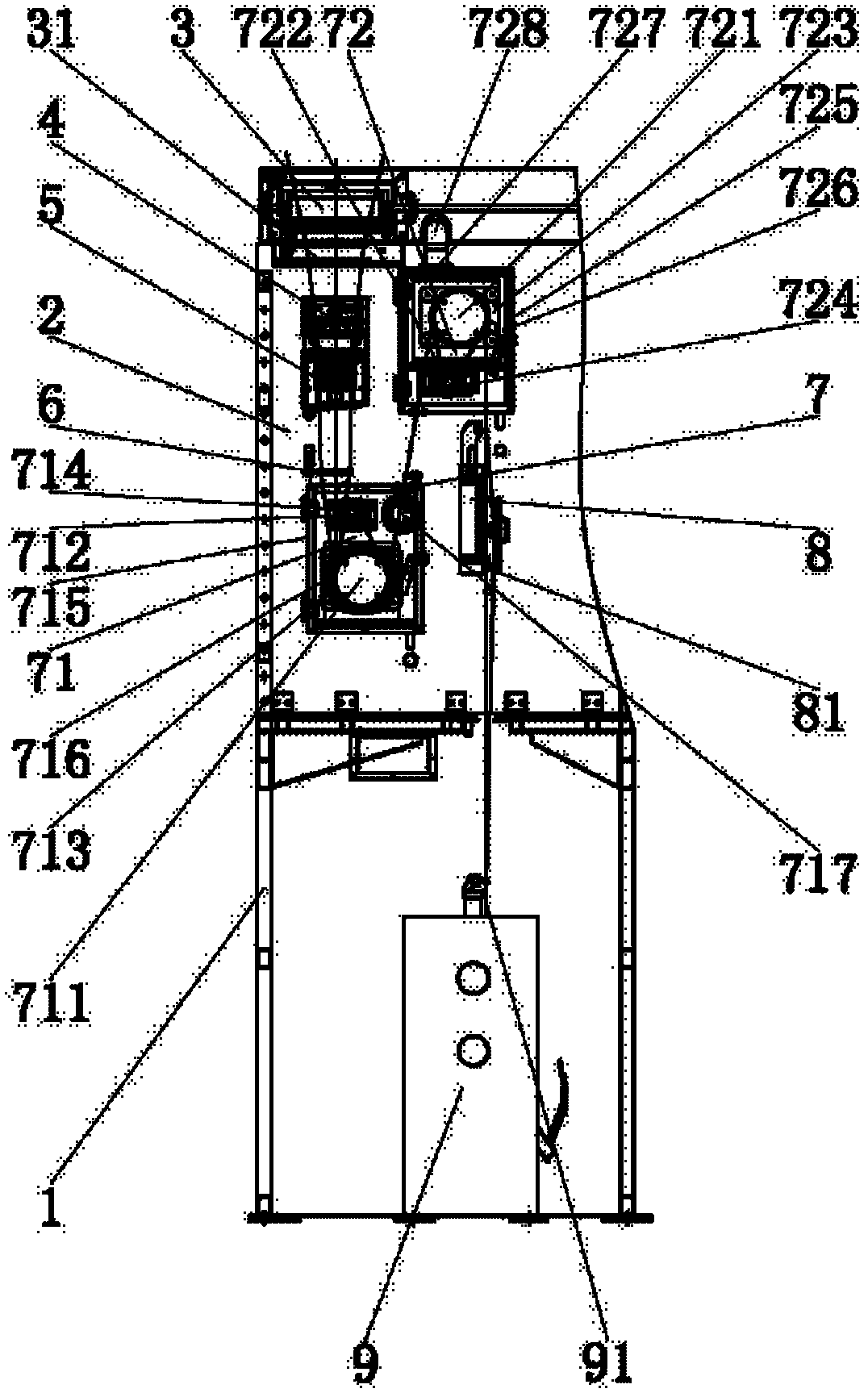

[0026] figure 1 It is a schematic diagram of the front view structure of a spinning position of the hot roller drafting type High-Tron pre-oriented filament drafting and winding device of the present invention, as figure 1 As shown in the drawing, a hot roll drafting type high telon pre-oriented filament drafting and winding device includes a vertical frame 1, and the upper part of the front of the frame 1 is provided with a mounting panel 2. In order to install various components reasonably, The installation panel 2 is designed with a plurality of through holes for parts to pass through; the left side of the top of the frame is provided with an oiling part 3 (the oiling part 3 is provided with one for each spinning position, and can be connected together for transmission. Also every spinning position can be driven independently, the usual design is 6 to 8 spinning positions as a group, arranged side by side.), the tow output port 31 of the oiling part 3 is positioned at the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com