Automatic slitting equipment for pipes

A pipe and automatic technology, applied in metal processing and other directions, can solve the problems of low degree of automation and processing efficiency, pipe damage, simple structure, etc., and achieve the effect of improving processing efficiency, reducing scrap rate and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

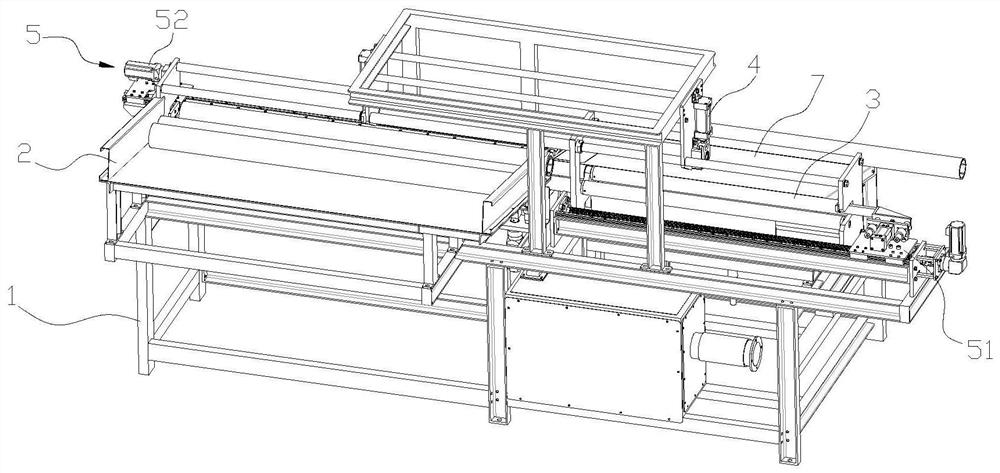

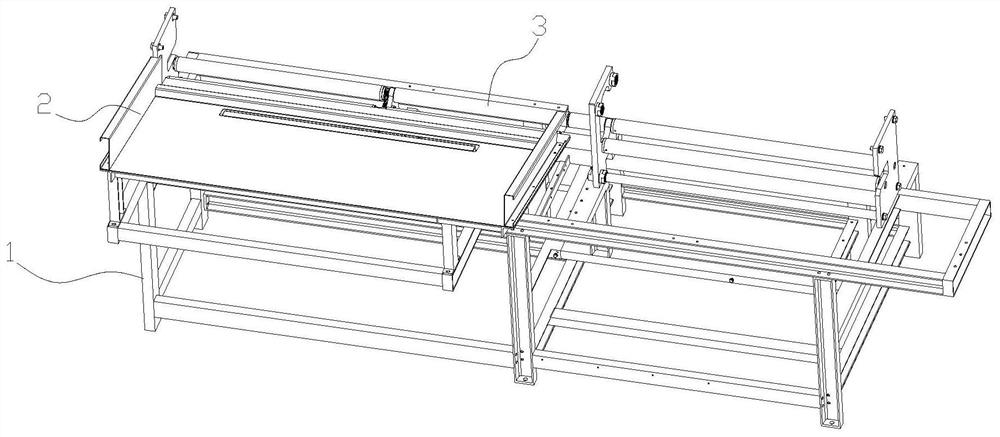

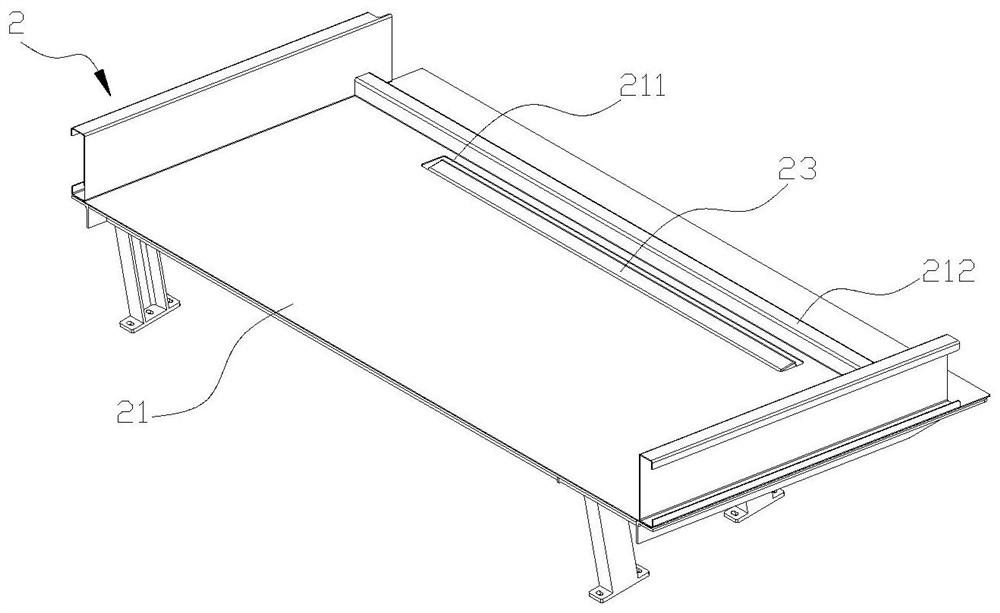

[0071] Such as figure 1 As shown, an automatic pipe cutting device according to the present invention includes a control system, a frame 1 , a feeding mechanism 2 and a backup roller mechanism 3 arranged on the frame 1 . A pinch roller mechanism 4, a feeding mechanism 5, a material cutting mechanism 6 and a blanking mechanism 7.

[0072] see figure 1 , frame 1 is welded by steel plates, extending from left to right (with figure 1 The direction shown is an example), and the overall shape is approximately cuboid.

[0073] The backup roller mechanism 3 is arranged in the middle of the frame 1 and extends along the length direction of the frame 1, that is, the axial direction of the backup roller mechanism 3 is from left to right. The supporting roller mechanism 3 is used to support and drive the pipe to rotate synchronously. When the supporting roller mechanism 3 supports the pipe, its outer peripheral surface contacts with the outer peripheral surface of the pipe, and drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com