Constant support and hanger

A support hanger and pull rod technology, applied in the field of support hangers, can solve the problems of inconvenient use and inability to adjust the length, and achieve the effects of improving convenience, improving safety, and avoiding concentrated stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention will be further described,

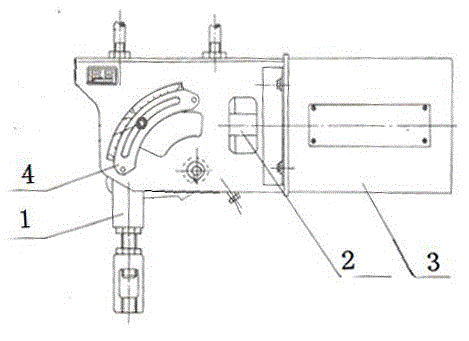

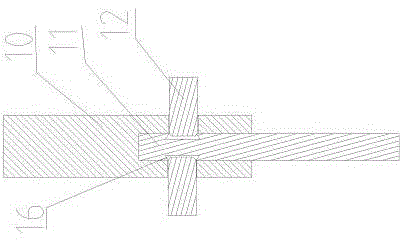

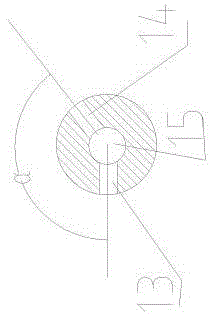

[0016] As shown in the figure, in order to solve the above-mentioned technical problems, the present invention provides a constant force suspension, which includes a housing 3, a pull rod assembly 2, a locking device 4 and a load assembly 1, and the pull rod assembly 2 is arranged laterally on the housing 3, one end of the tie rod assembly 2 is connected to the load assembly 1, and the tie rod assembly 2 is vertically arranged with the load assembly. The load assembly 1 includes an upper pull rod 10 and a lower pull rod 11. Longitudinal counterbore 15 is provided, internal thread is provided in described longitudinal counterbore 15, and external thread is provided on the outer circumference of described pull-down rod 11, and described upper and lower pull-down rod 10,11 are integrally connected by thread, and described longitudinal counterbore The hole wall of 15 is radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com