Modified cellulose acetate membrane for chiral resolution, preparation method and application thereof

A cellulose acetate membrane, chiral separation technology, applied in organic chemical methods, chemical instruments and methods, membrane technology, etc., can solve the problems of high toxicity of linking agents, cumbersome preparation process and high cost of splitting objects, and achieve separation The effect is excellent, the effect of overcoming the single split object and improving the separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation method of the modified cellulose acetate membrane of the β-cyclodextrin surface modification of the present embodiment comprises the following steps:

[0048] 1) First, the cellulose acetate membrane is activated and pretreated, and the commercial cellulose acetate membrane is immersed in an aqueous solution (100mL) of 0.3wt.% NaOH (0.3g, 7.5mmol), and the commercial cellulose acetate membrane The pore size is 0.45 μm, heated in a water bath at 30°C for 40 minutes to hydrolyze the acetyl groups on the membrane. Then the membrane was taken out and washed 6 times with deionized water until the washing solution reached neutrality.

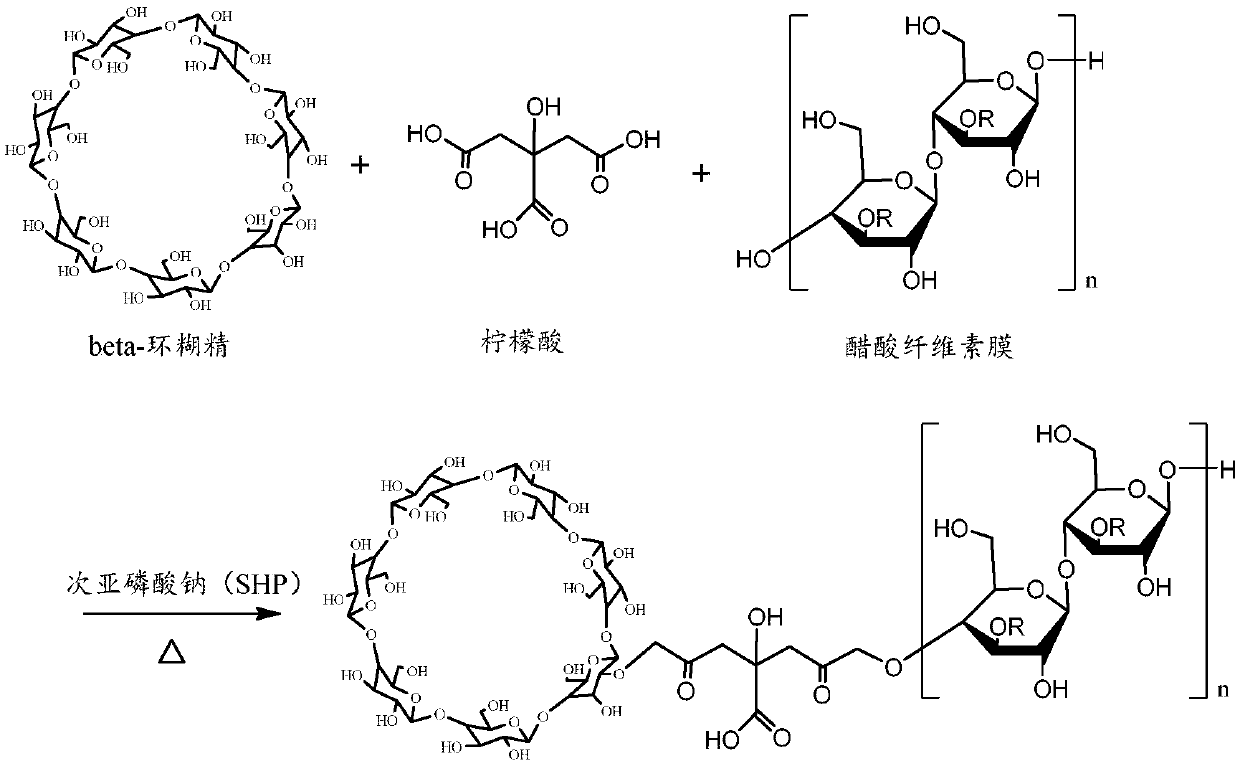

[0049] 2) β-cyclodextrin modified cellulose acetate membrane: preparation containing 3% w / w β-cyclodextrin (β-CD, 3g, 2.64mmol), 3% w / w citric acid (CA 3g, 14.27mmol), 0.3% w / w sodium hypophosphite (SHP 0.3g, 2.83mmol) in 100mL aqueous solution was placed in a beaker, heated at 60°C and stirred for 8min to dissolve β-CD and obt...

Embodiment 2

[0064] The preparation method of the modified cellulose acetate membrane of the β-cyclodextrin surface modification of the present embodiment comprises the following steps:

[0065] 1) First, the cellulose acetate membrane is activated and pretreated, and the commercial cellulose acetate membrane is immersed in an aqueous solution (100mL) of 0.2wt.% NaOH (0.3g, 7.5mmol), and the commercial cellulose acetate membrane The pore size is 0.22 μm, and heated in a water bath at 25°C for 50 minutes to hydrolyze the acetyl groups on the membrane. Then the membrane was taken out and washed 6 times with deionized water until the washing solution reached neutrality.

[0066] 2) β-cyclodextrin modified cellulose acetate membrane: prepare 2% w / w β-cyclodextrin, 2% w / w citric acid, 0.2% w / w sodium hypophosphite (SHP 0.3g, 2.83mmol) Put 100mL of aqueous solution in a beaker, heat at 70°C, and stir for 5 minutes to dissolve β-CD and obtain a uniform aqueous solution. Put the pretreated cellu...

Embodiment 3

[0071] The preparation method of the modified cellulose acetate membrane of the β-cyclodextrin surface modification of the present embodiment comprises the following steps:

[0072] 1) First, the cellulose acetate membrane is activated and pretreated, and the commercial cellulose acetate membrane is immersed in an aqueous solution (100mL) of 0.4wt.% NaOH (0.3g, 7.5mmol), and the commercial cellulose acetate membrane The pore size is 0.45 μm, and heated in a water bath at 35°C for 30 minutes to hydrolyze the acetyl groups on the membrane. Then the membrane was taken out and washed 6 times with deionized water until the washing solution reached neutrality.

[0073] 2) β-cyclodextrin modified cellulose acetate membrane: prepare 100mL aqueous solution containing 4% w / w β-cyclodextrin, 4% w / w citric acid, 0.5% w / w sodium hypophosphite in a beaker, at 50 Heat at ℃ and stir for 10 minutes to dissolve β-CD and obtain a uniform aqueous solution. Put the pretreated cellulose acetate f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com