Novel hybrid mesoporous silica gel chromatographic stationary phase and preparation method thereof

A technology of hybrid mesoporous silica gel and chromatographic stationary phase, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of spherical shape, rareness, constraints, etc., and achieve the effect of good separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

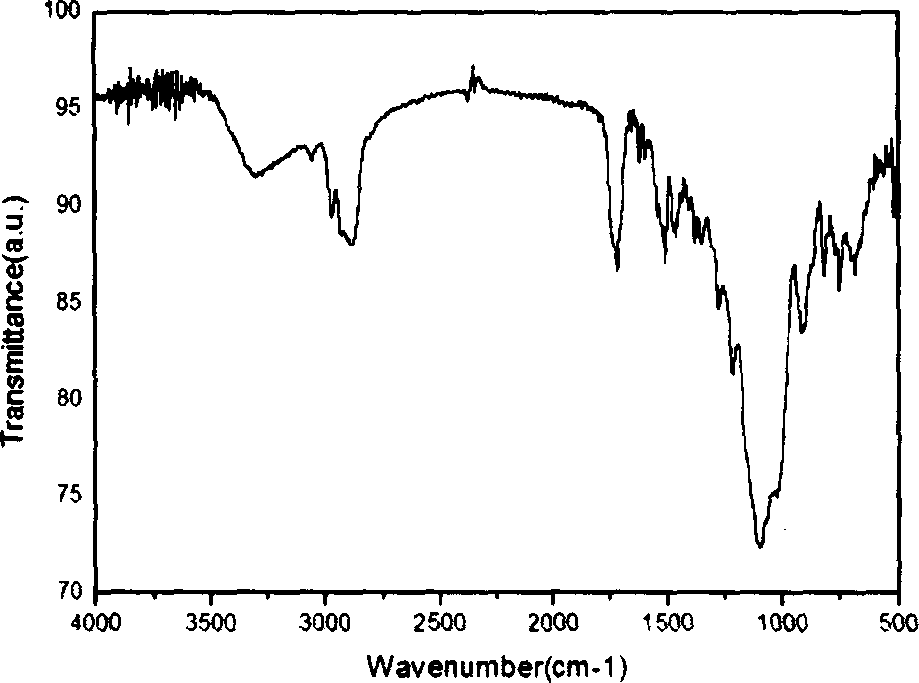

Embodiment 1

[0016] Add 0.858g (3mmol) of R-(+)-1,1'-binaphthyl-2,2'-diphenol to 60ml of dried methylene chloride, add 0.304g (3mmol) of triethylamine, and Under stirring, slowly add 0.742g (3mmol) isocyanatopropyltriethoxysilane (ICPTES) dropwise. After the dropwise addition, continue to stir at room temperature for 2h, evaporate the solvent and triethylamine in the reaction system to obtain colorless 0.96 g of transparent viscous product R-2-(3-triethoxysilyl)-propylcarbamoyloxy-2'-hydroxyl-1,1'-binaphthyl (M-binol).

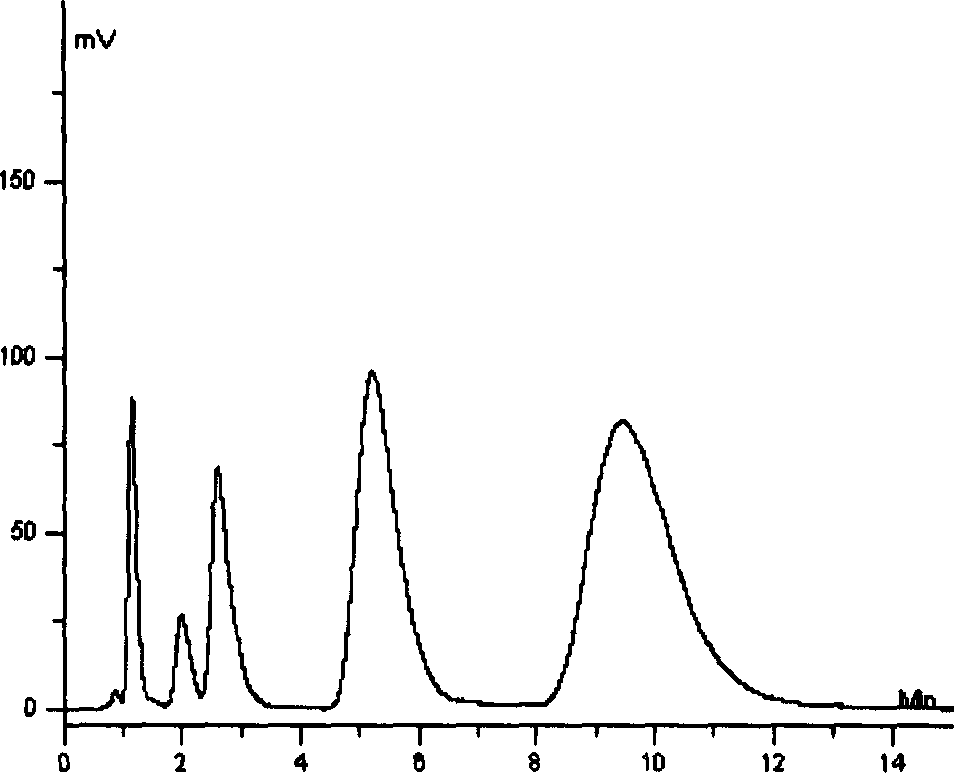

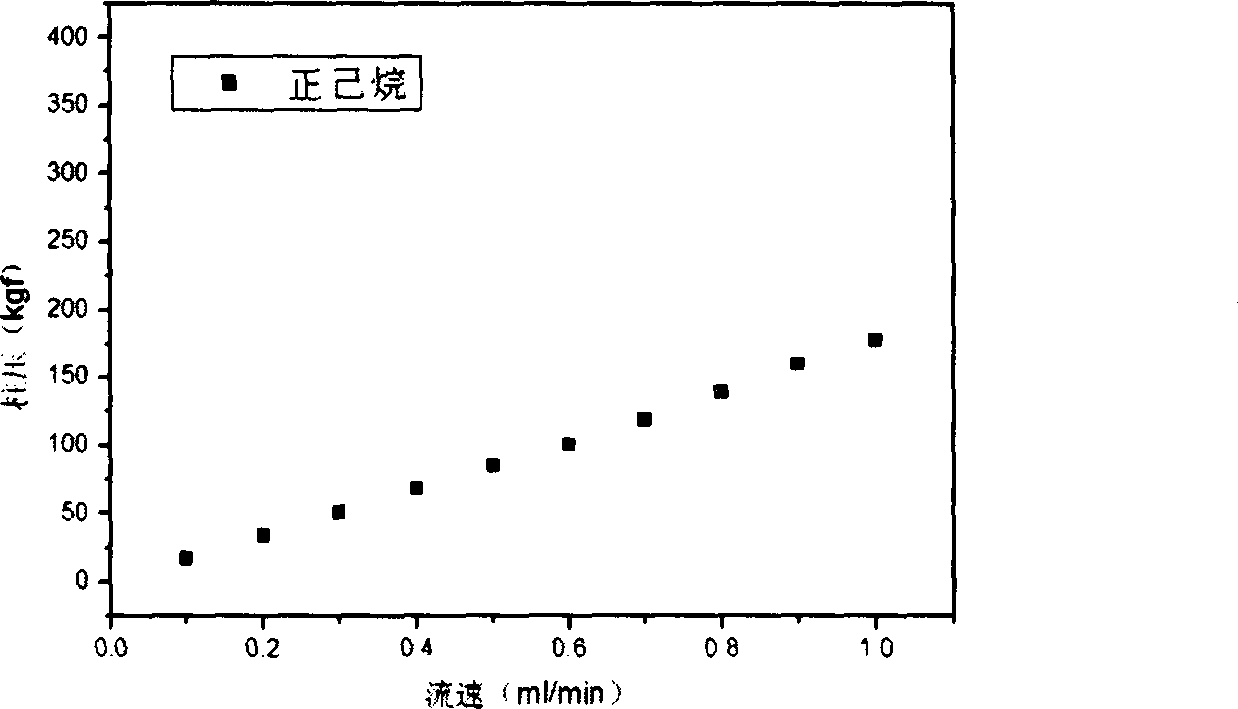

Embodiment 2

[0018] Add 0.12g cetyltrimethylammonium bromide (CTAB), 0.696g triblock copolymer (P123) to a mixed solvent consisting of 8.7ml 2mol / L hydrochloric acid solution, 7.14ml ethanol and 58.0ml deionized water , stirred until completely dissolved, mixed 0.48g of homemade silicon source M-binol and 777ul 1,2-bistriethoxysilylethane (BTSE) evenly, then slowly added to the above mixed solution under vigorous stirring, at room temperature After stirring for 30 minutes, transfer it to a stainless steel polytetrafluoroethylene reactor, and let it stand at 100°C for 16 hours. Filter with suction, wash with deionized water until neutral, and dry under vacuum at 60°C overnight.

Embodiment 3

[0020] Add 0.12g cetyltrimethylammonium bromide (CTAB), 0.696g triblock copolymer (P123) to a mixed solvent consisting of 7.2ml 2mol / L hydrochloric acid solution, 7.14ml ethanol and 58.0ml deionized water , stirred until completely dissolved, mixed 0.48g of homemade silicon source M-binol and 777ul 1,2-bistriethoxysilylethane (BTSE) evenly, then slowly added to the above mixed solution under vigorous stirring, at room temperature After stirring for 30 minutes, transfer it to a stainless steel polytetrafluoroethylene reactor, and let it stand at 100°C for 16 hours. Filter with suction, wash with deionized water until neutral, and dry under vacuum at 60°C overnight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com