Continuous tow dispersing device

A technology of dispersing device and continuous fiber, applied in fiber processing, fiber combing, transportation and packaging, etc., can solve the problems of high requirement of mechanical synergy, broken wire surface, many mechanical parts, etc., to achieve uniform distribution and distribution. The effect of fast wire speed and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

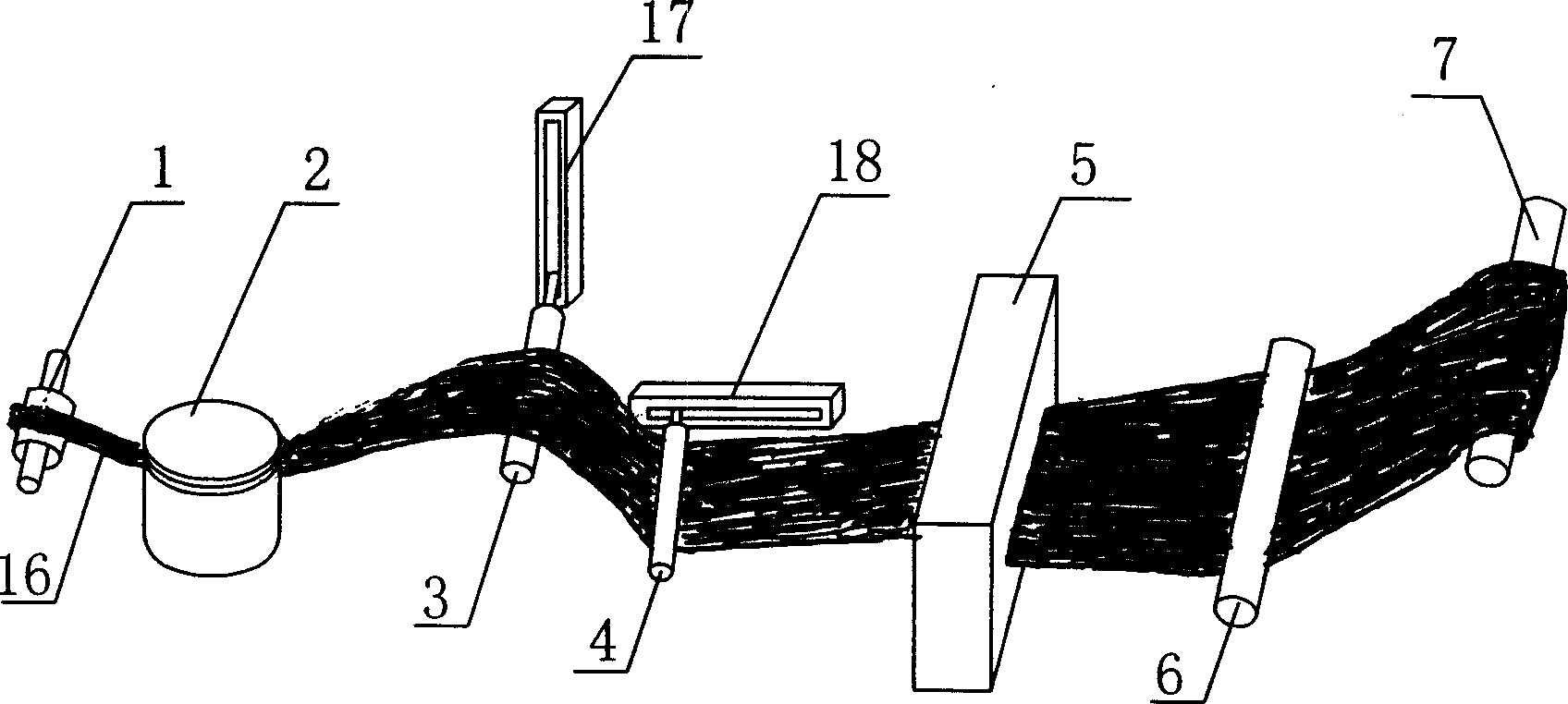

[0025] See figure 1 , The device splits the 14K carbon fiber bundle 16, and the fiber width is dispersed from 6mm to about 180-220mm; the carbon fiber bundle surface density before splitting is 0.5mg / cm 2 , The areal density of single ribbon after splitting is 20μg / cm 2 , The threading speed is 0.6m / min.

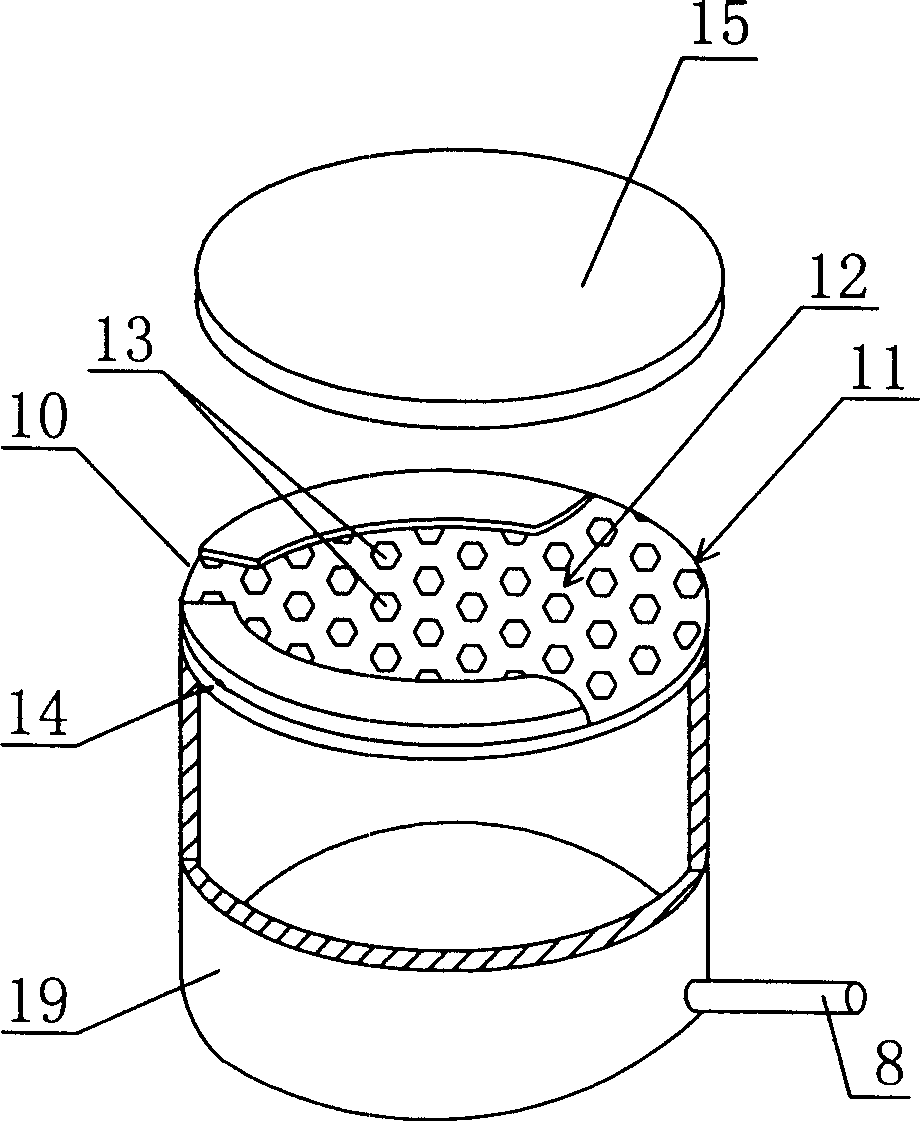

[0026] See figure 2 , The width of the inlet 10 of the wire dividing cavity 12 of the air separator 2 is 5-10mm, the width of the outlet 11 is 120mm, and the diameter of the air hole 13 on the wire dividing plate 14 is 2-6mm (the pores of different diameters can be arranged from a gradient), The porosity (the ratio of the area of the top surface of the dividing plate to the area of the vent holes on the top surface) is about 40%, and the air inlet 8 sends 0.6-0.9Mpa air to disperse the 6mm wide carbon fiber bundle to 80-100mm tow.

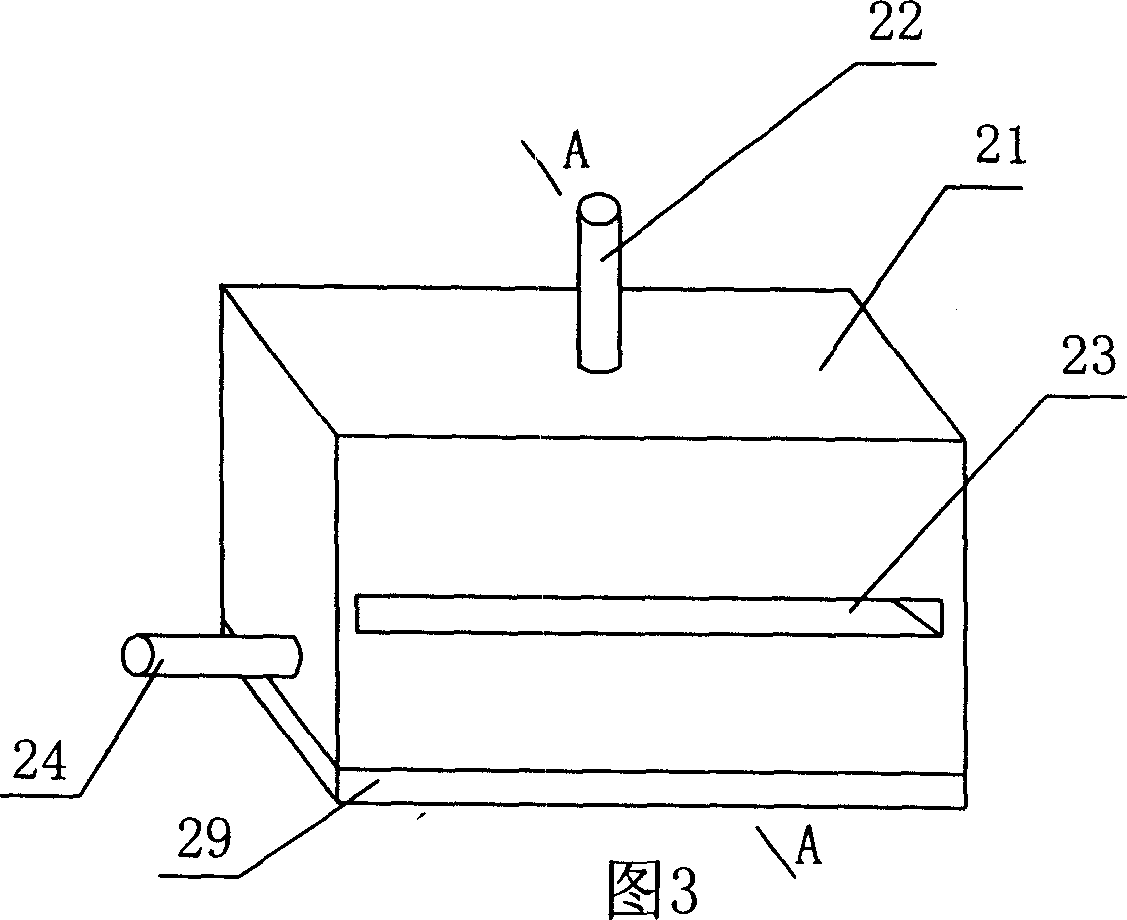

[0027] Referring to Figures 3 to 5, the comber 5 is fed with dry air at 40°C-60°C from the air inlet 2, with an air inlet pressure of 0.1-0.4M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com