MOF@SiO2 core-shell microsphere HPLC chiral column for enantiomeric resolution

A technology of enantiomers and chiral columns, applied in the field of chiral separation of high performance liquid chromatography, can solve the problems of low column efficiency of chiral MOFs columns, difficulty in obtaining stationary phase particles, and affecting the separation performance of chromatographic columns. Achieve excellent separation performance, low cost of column production, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Preparation of MOF@SiO 2 Core-shell microsphere HPLC chiral column (column A), the specific method is:

[0022] (1) Chiral [Co 2 (D-cam) 2 (TMDPy)]@SiO 2 Synthesis of core-shell composites: 100 mL of deionized water was added to a round bottom flask, and 0.7205 g of Co(CH 3 COO) 2 4H 2 O and 1.0693 g aminopropylated SiO 2 The microspheres were stirred at room temperature for 30 min, filtered, and washed 3 times with deionized water. Add the filter residue to a round-bottomed flask, and add 100 mL of deionized water, 0.5854 g of D-camphoric acid, 0.5750 g of 1,3-di(4-pyridyl)propane, 0.3295 g of anhydrous potassium carbonate, and then reflux at 110°C React for 6 days and cool to room temperature. filter, the resulting [Co 2 (D-cam) 2 (TMDPy)]@SiO 2 The microspheres were washed 6 times with deionized water and absolute ethanol respectively, used as the stationary phase, and dried for later use. (See figure 2 )

[0023] (2) Filling of chiral column: Weigh...

Embodiment 2

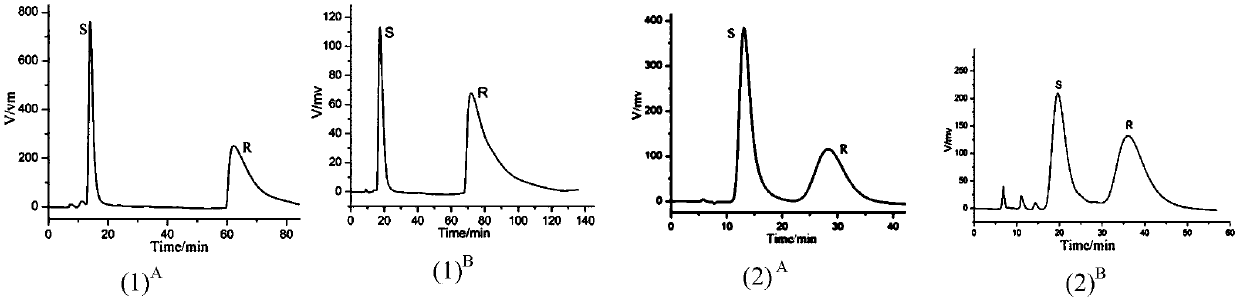

[0036] A good HPLC chiral column usually has good reproducibility and stability. In order to examine the reproducibility and stability of column A, using n-hexane / isopropanol (9:1, V / V) as the mobile phase, trans-1,2-diphenyloxirane was continuously injected for 5 Second-rate. Depend on Figure 4 It can be seen that the chiral MOF@SiO 2 The resolution effect of the column on trans-1,2-diphenyloxirane remained basically unchanged, and the relative standard deviation (RSD) of its retention time (n=5) and peak area were 0.47% and 1.38%, respectively, It shows that the chiral MOF@SiO of the present invention 2 The column has good stability and reproducibility.

[0037] Figure 5 are racemic compounds respectively in MOF@SiO 2 Schematic diagram of the comparison of split results on column and MOF column, by Figure 5 It can be seen that pure MOF[Co 2 (D-cam) 2 (TMDPy)] crystals are irregular in shape and particles are not uniform, and the column efficiency obtained by pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com