Pressurizing glue jointer applied to preparing large section integrated material

A glulam, large-section technology, used in veneer presses, plywood presses, wood processing appliances, etc., can solve the problem of uneven distribution of glue strength, difficulty in applying uniform pressure, and difficulty in ensuring the geometric and dimensional accuracy of finished glulam, etc. problems, to avoid bonding, ensure the bonding strength, and facilitate the discharge of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technology will be further described below in conjunction with the accompanying drawings and implementation methods.

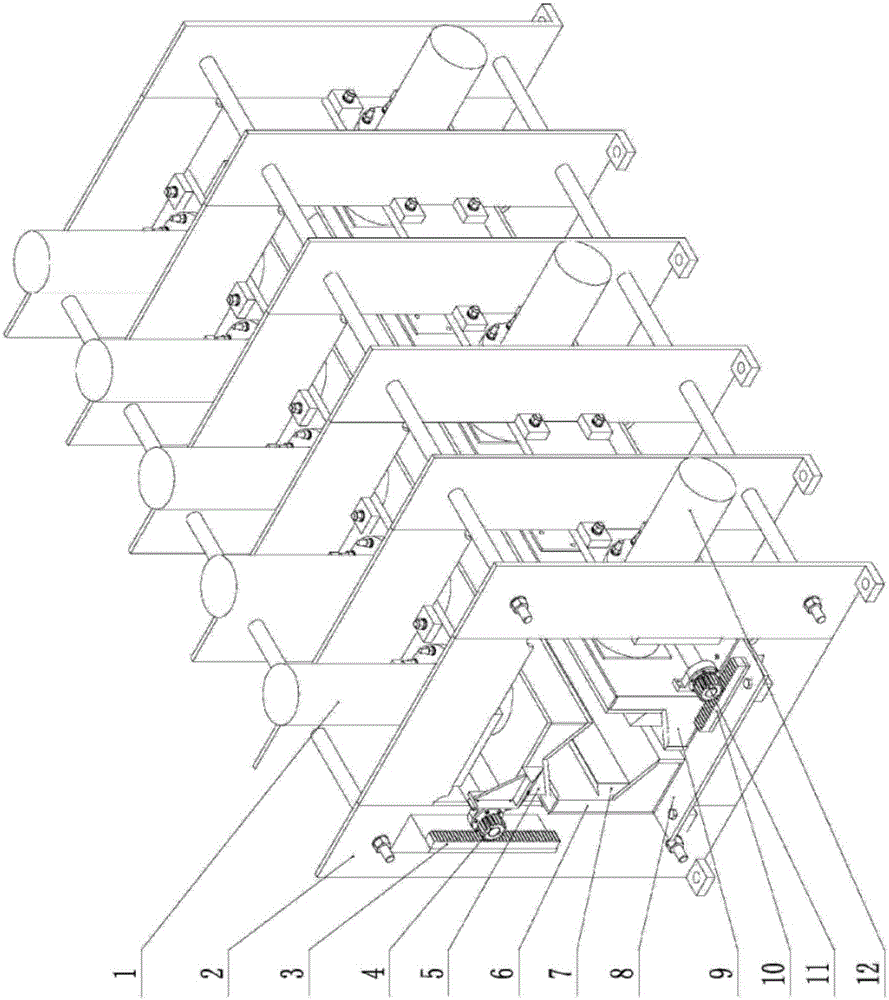

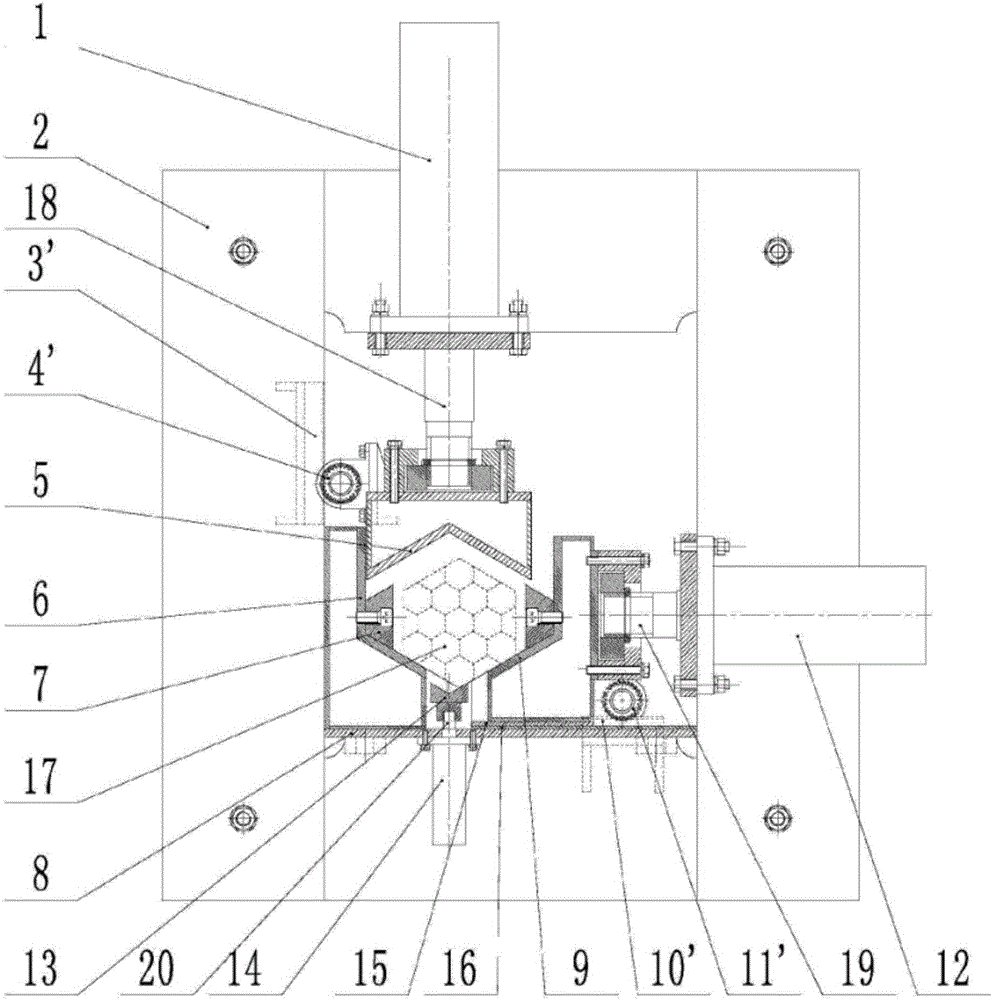

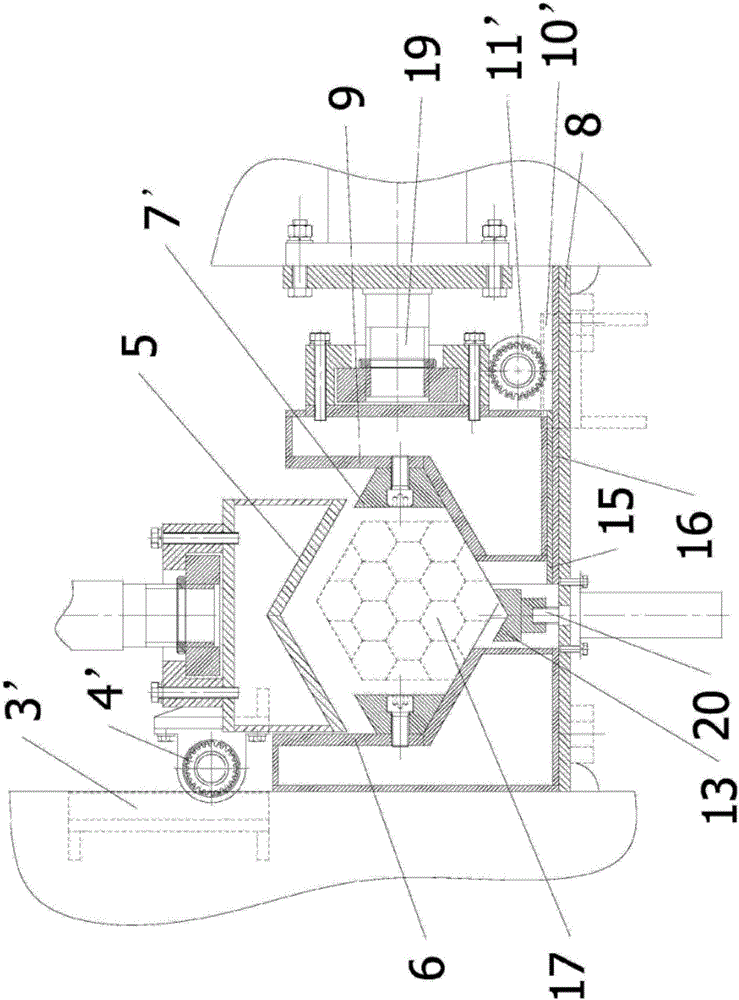

[0027] Such as Figure 1-9 As shown, the present invention provides a specific embodiment of a pressure gluing machine applied to the preparation of large-section laminated materials. Such as Figure 1~2 As shown, the pressurized glue machine mainly includes vertical pressurized cylinder group 1, rectangular press frame 2, vertical synchronous rack 3', 3, vertical synchronous gear assembly 4', 4, V-shaped upper platen 5, L-shaped Horizontal fixed platen 6, first cylinder pad 7', second cylinder pad 7, press bottom plate 8, L-shaped horizontal pressure plate 9, horizontal synchronous rack 10', 10, horizontal synchronous gear assembly 11' , 11. Horizontal pressure cylinder group 12, hexagonal prism degumming top block 13, degumming top block oil cylinder 14, horizontal guide rail slider 15, horizontal guide rail 16, large section hexagonal prism wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com