A high-speed woodworker power principle axis

A technology of electric spindles and spindles, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of not being able to ensure the dustproof requirements of electric spindles, and achieve the goals of dust prevention, improved service life, and expanded application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

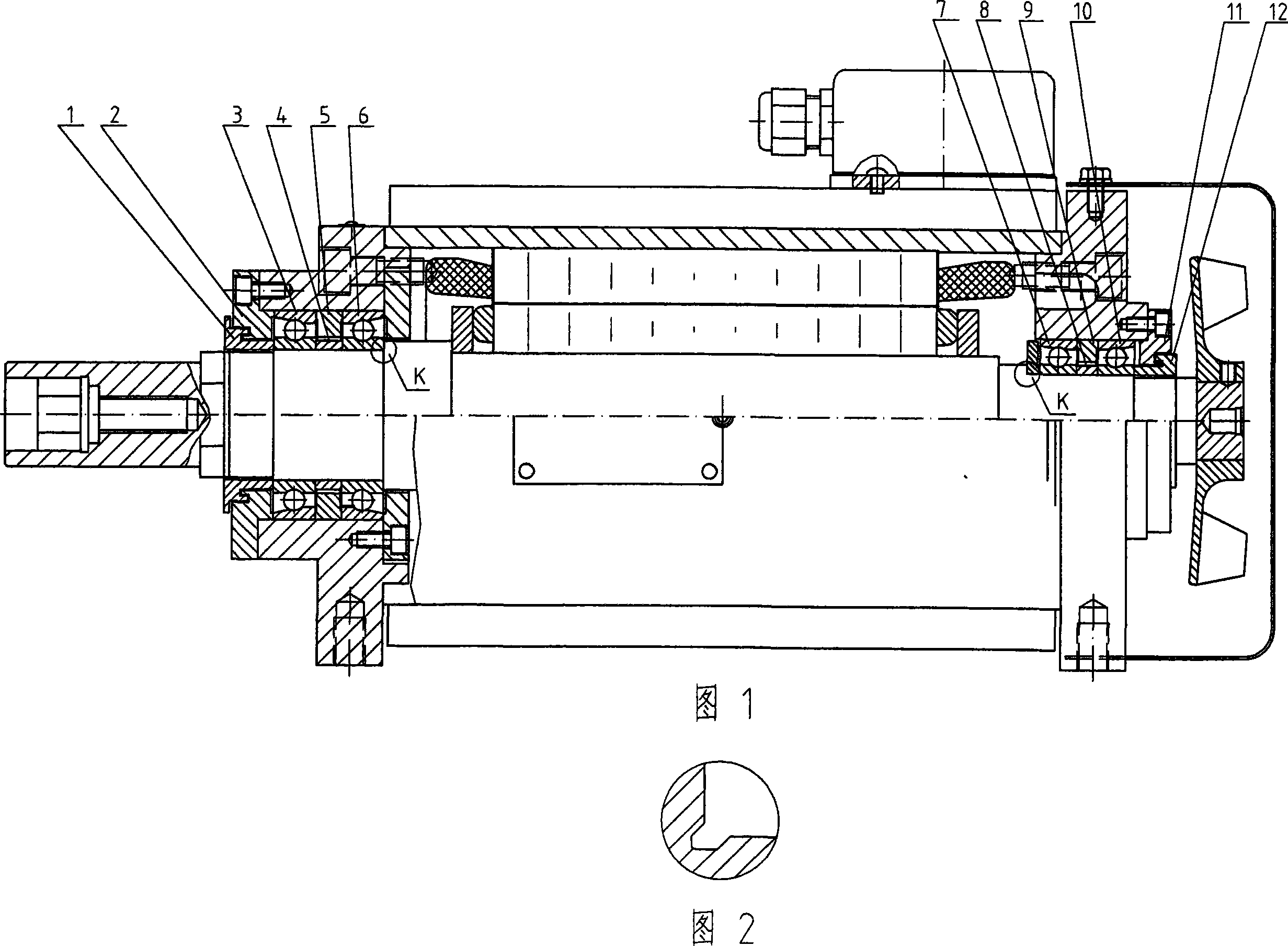

[0011] It can be seen from Figure 1 that the high-speed woodworking electric spindle includes a spindle, a stator and a rotor. Two front angular contact ball bearings 3, 6 are provided at the front shaft extension of the spindle, and an inner partition is provided in the middle of the two front angular contact ball bearings 3, 6 Ring 4 and outer spacer ring 5, the rear shaft extension end of the main shaft is provided with two rear angular contact ball bearings 7, 10, and an inner spacer ring 8 and an outer spacer ring 9 are arranged between the two rear angular contact ball bearings 7, 10. In order to meet the high-speed requirements of high-speed woodworking electric spindles and the high precision of the spindle shaft extension, high-precision angular contact ball bearings are used in the bearing structure design. The high-precision angular contact ball bearings have high precision and high limit speed, which can meet the requirements of high-speed woodworking electrical The sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com