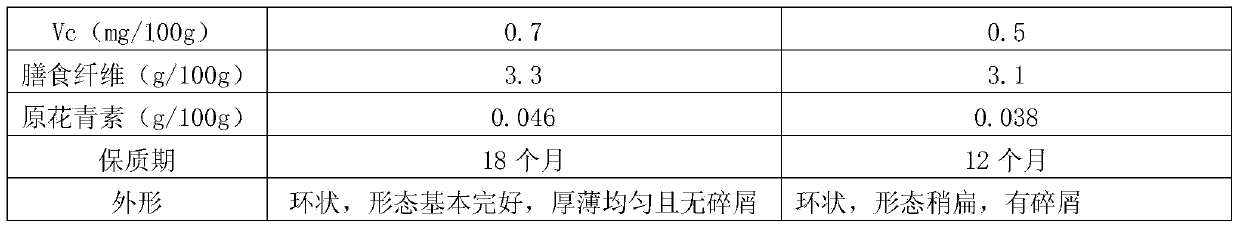

Patents

Literature

53results about How to "Fixed shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

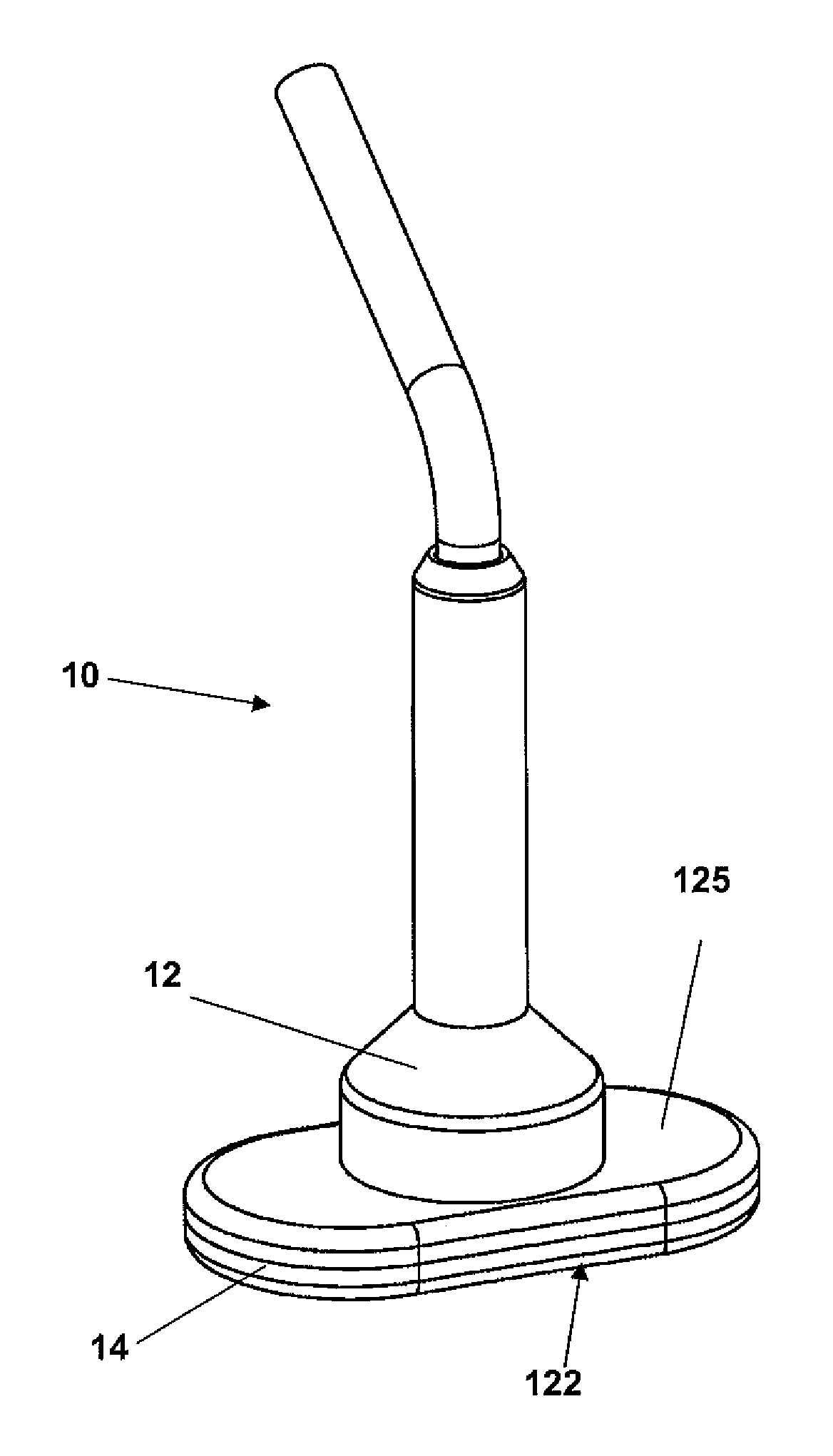

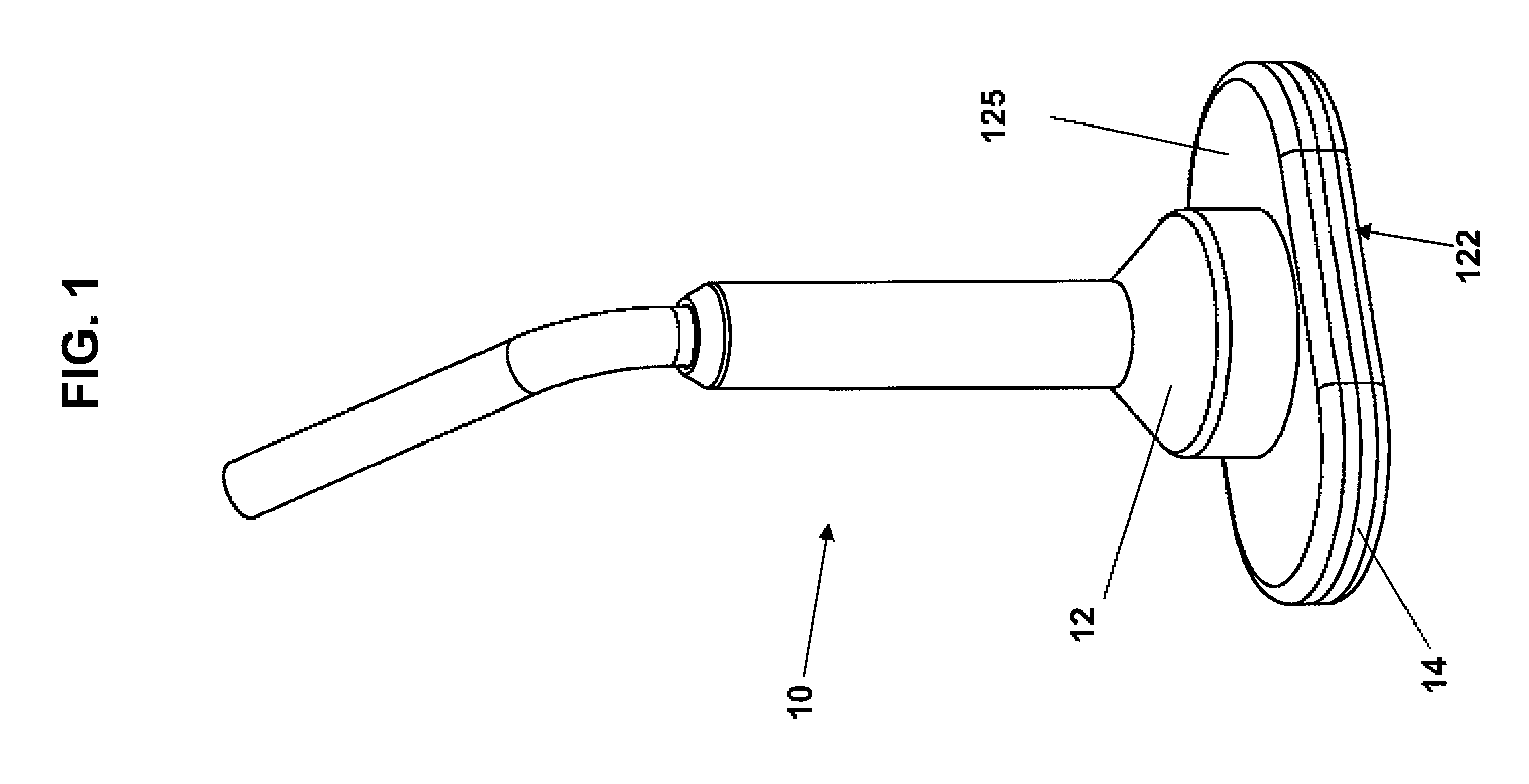

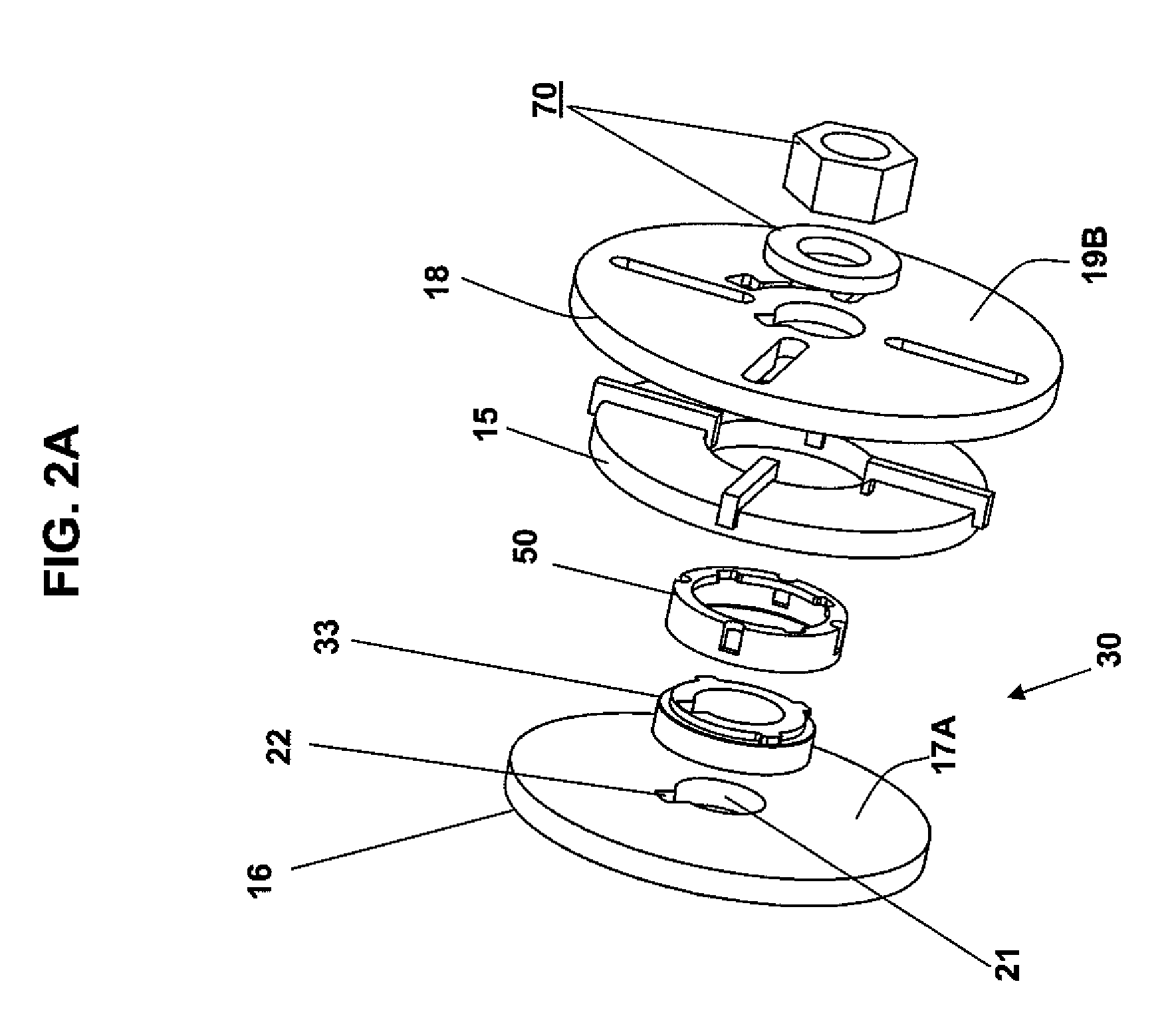

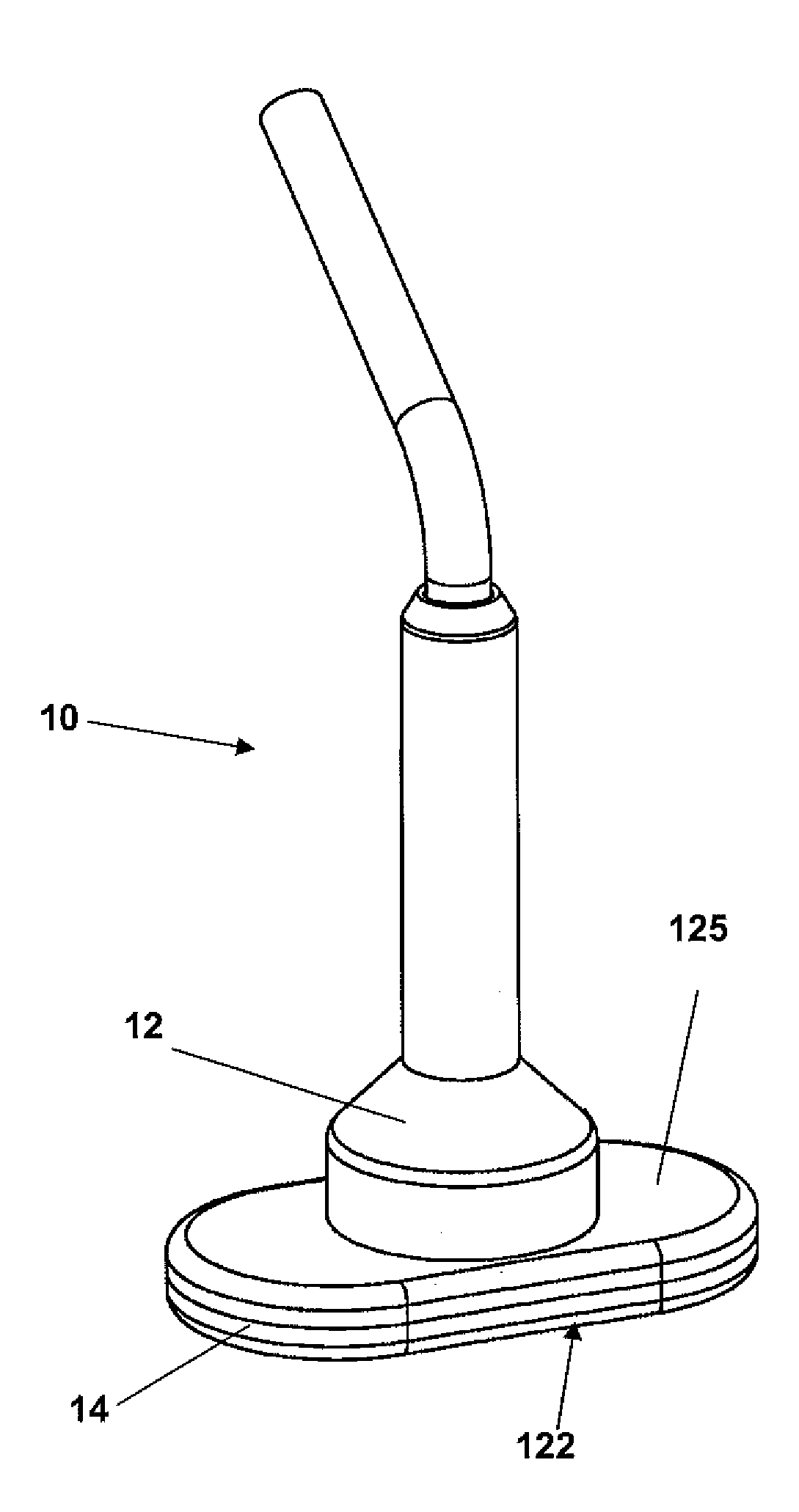

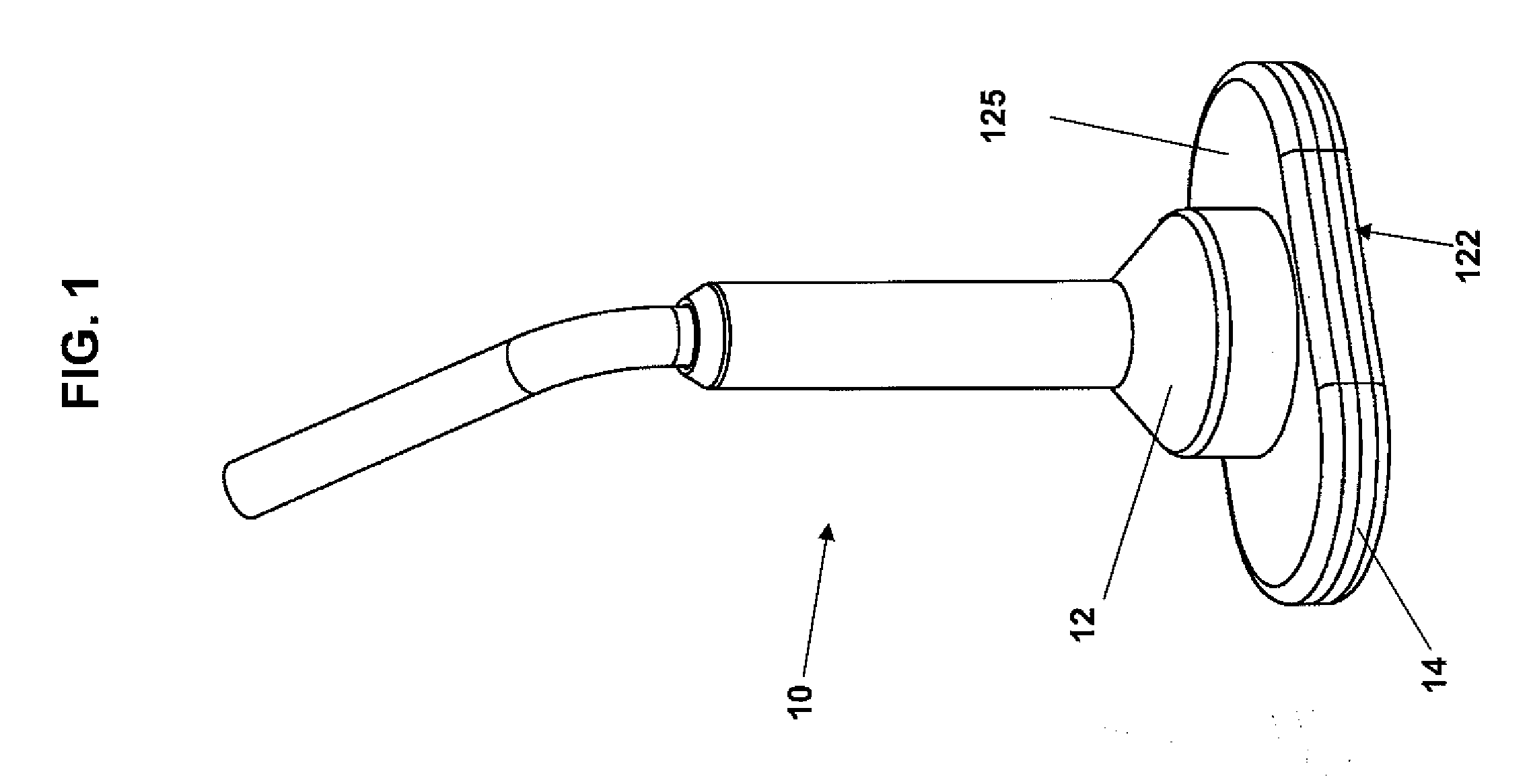

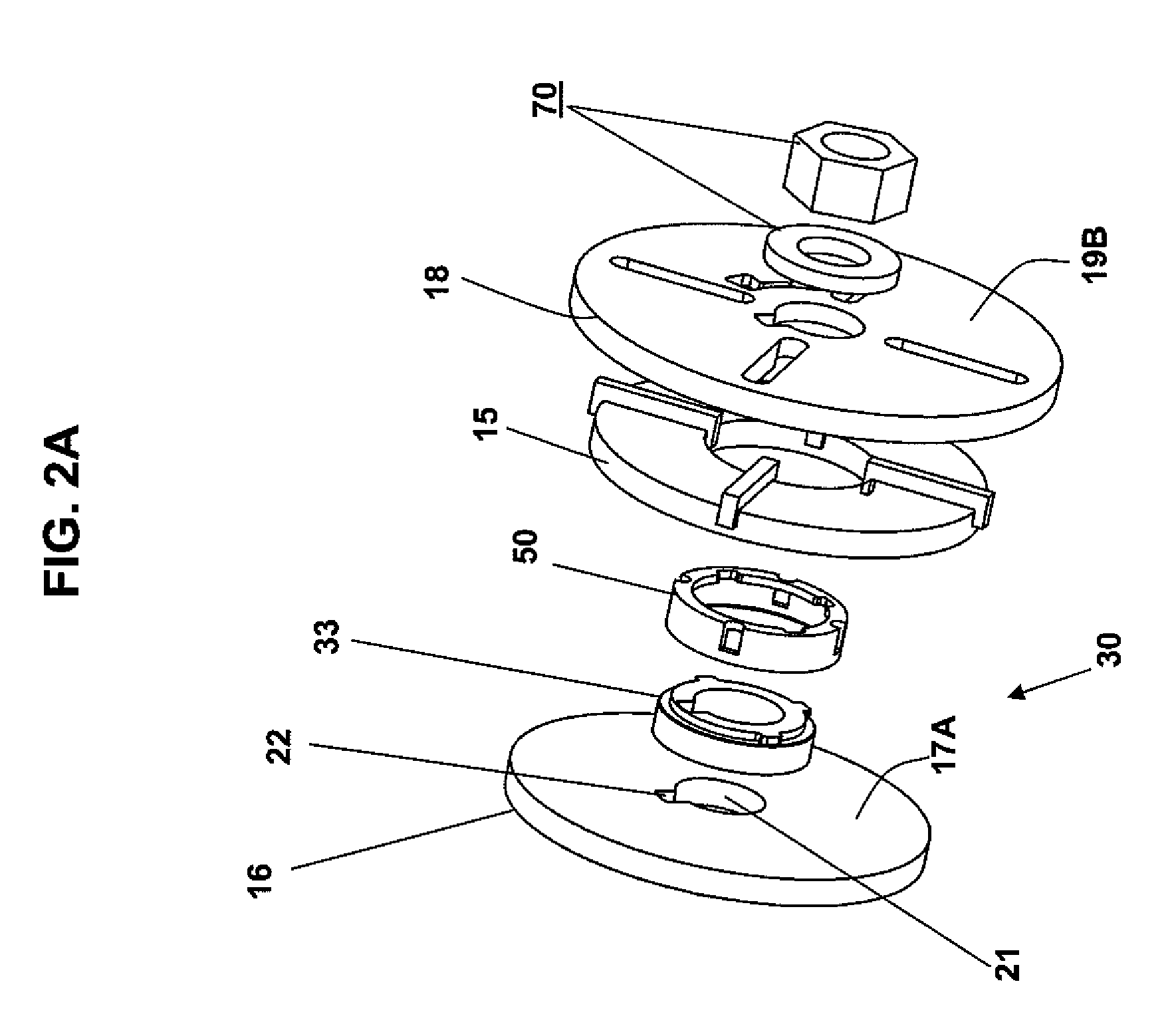

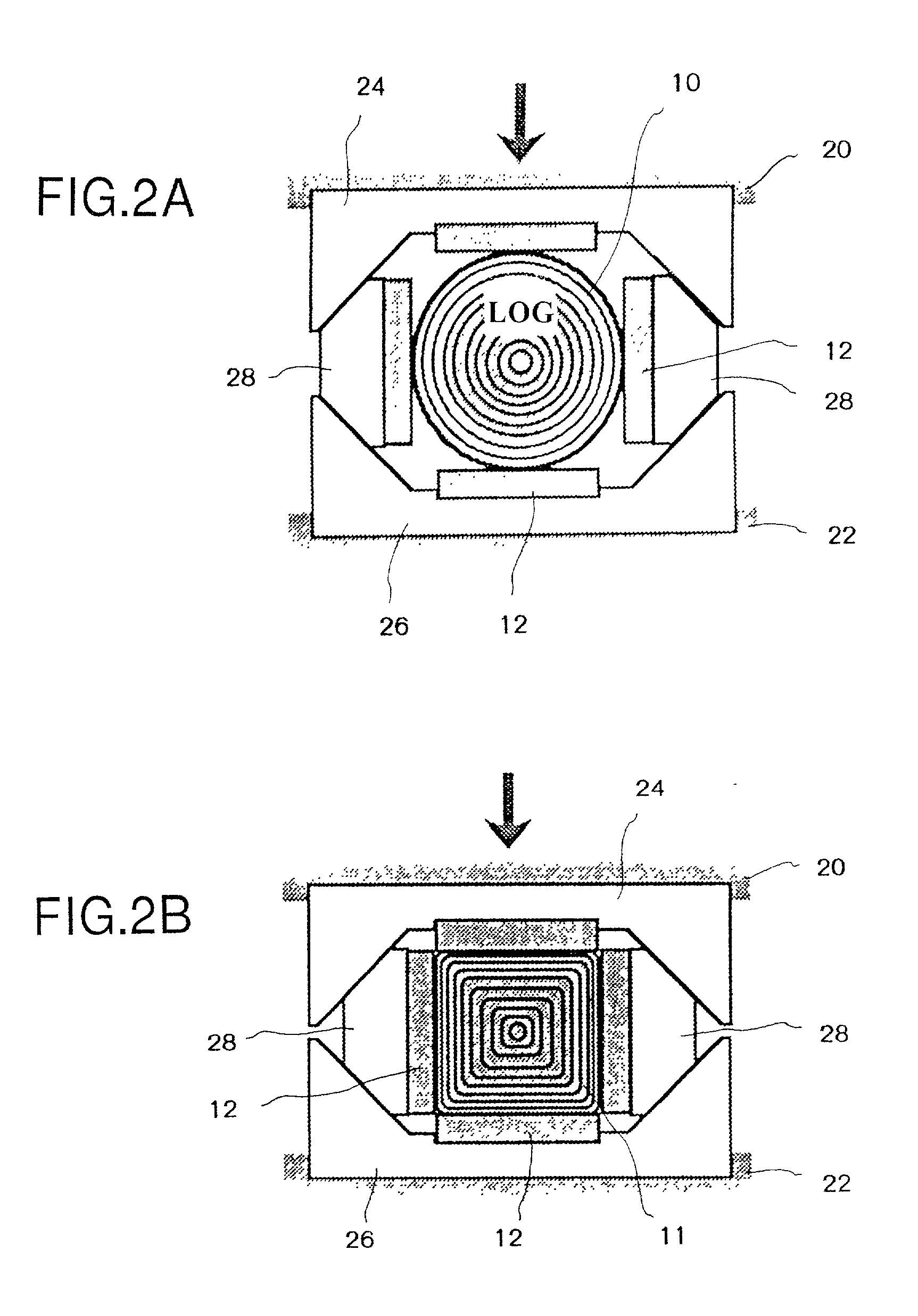

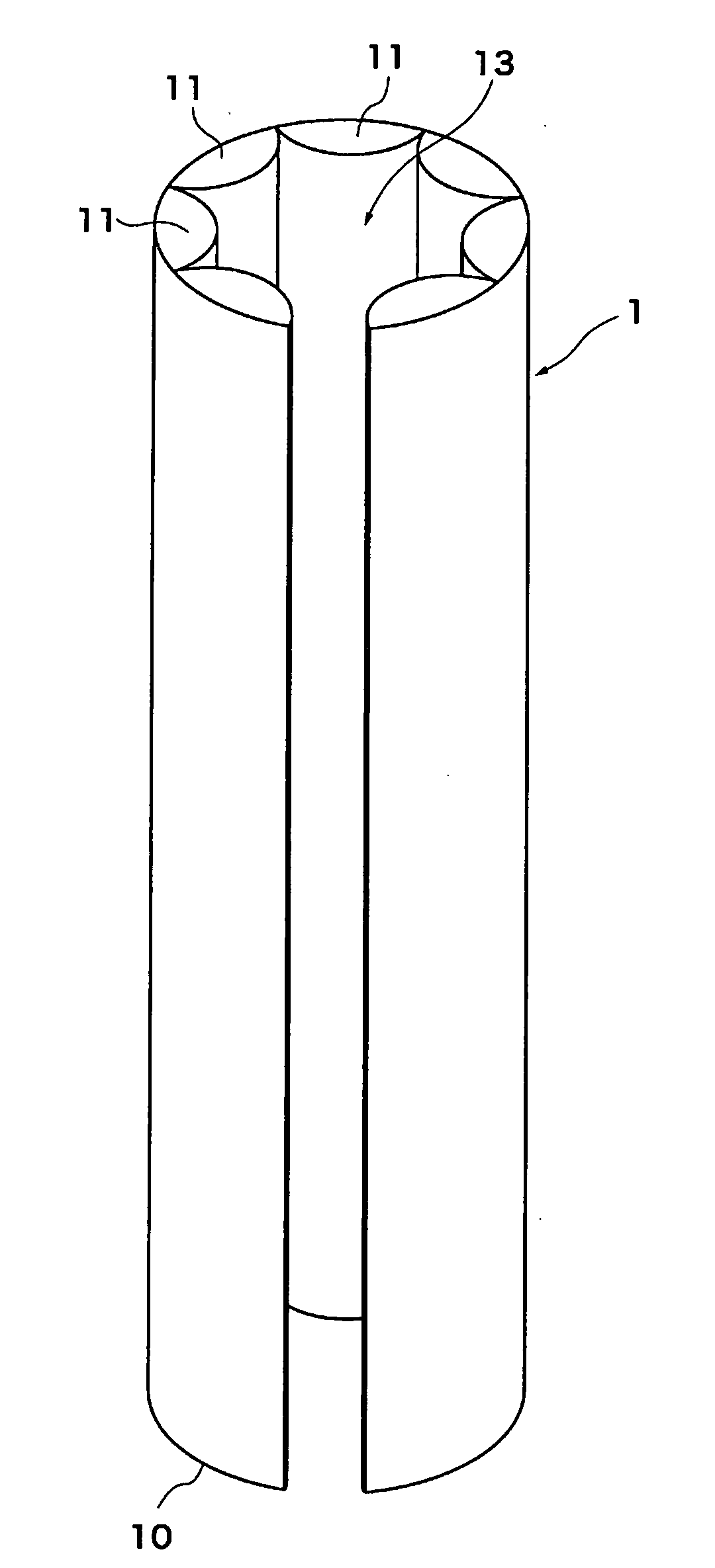

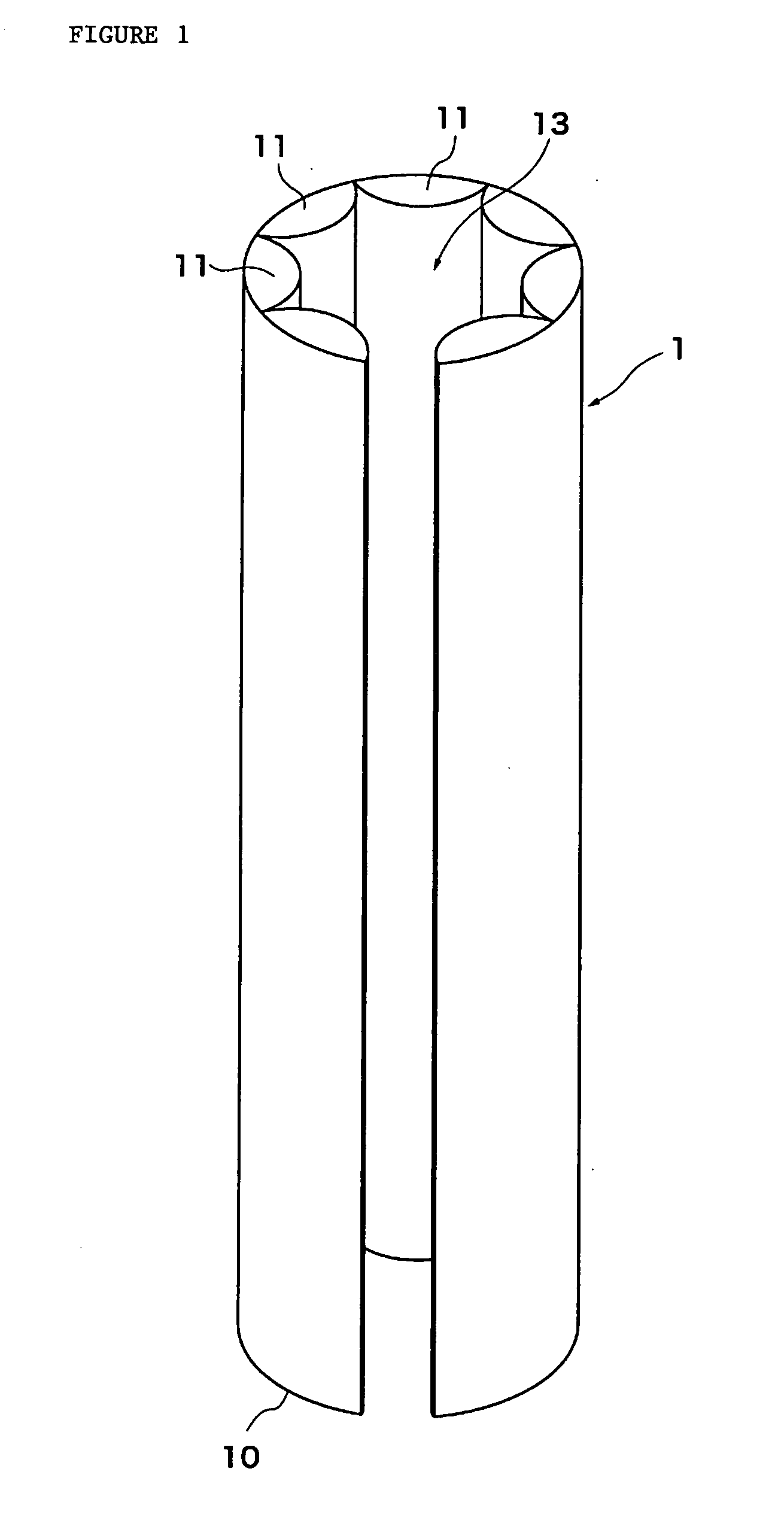

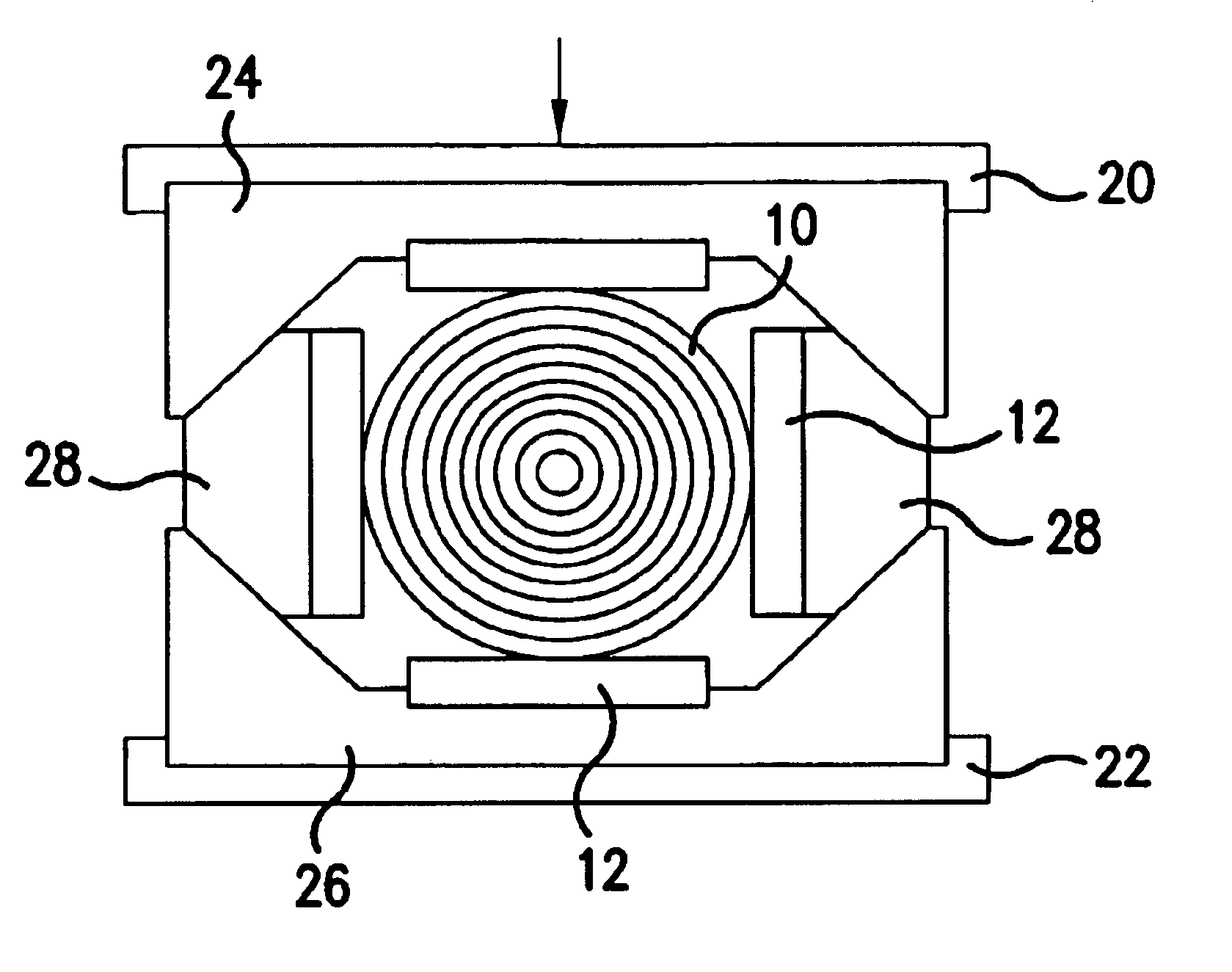

Transcranial magnetic stimulation induction coil device and method of manufacture

ActiveUS7998053B2Fixed shapeFix size fixElectrotherapyTransformers/inductances casingsConductor CoilMagnetic brain stimulation

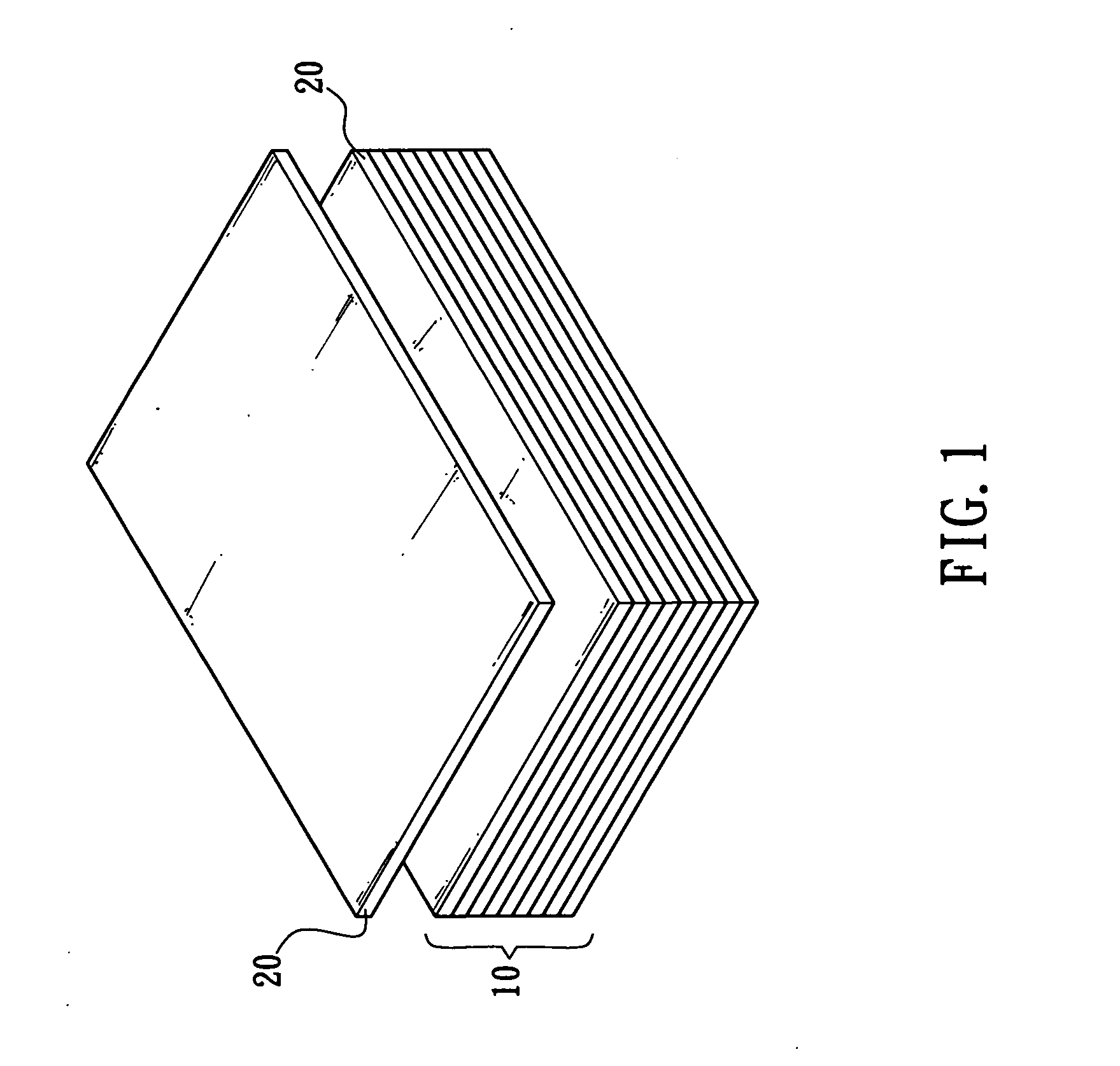

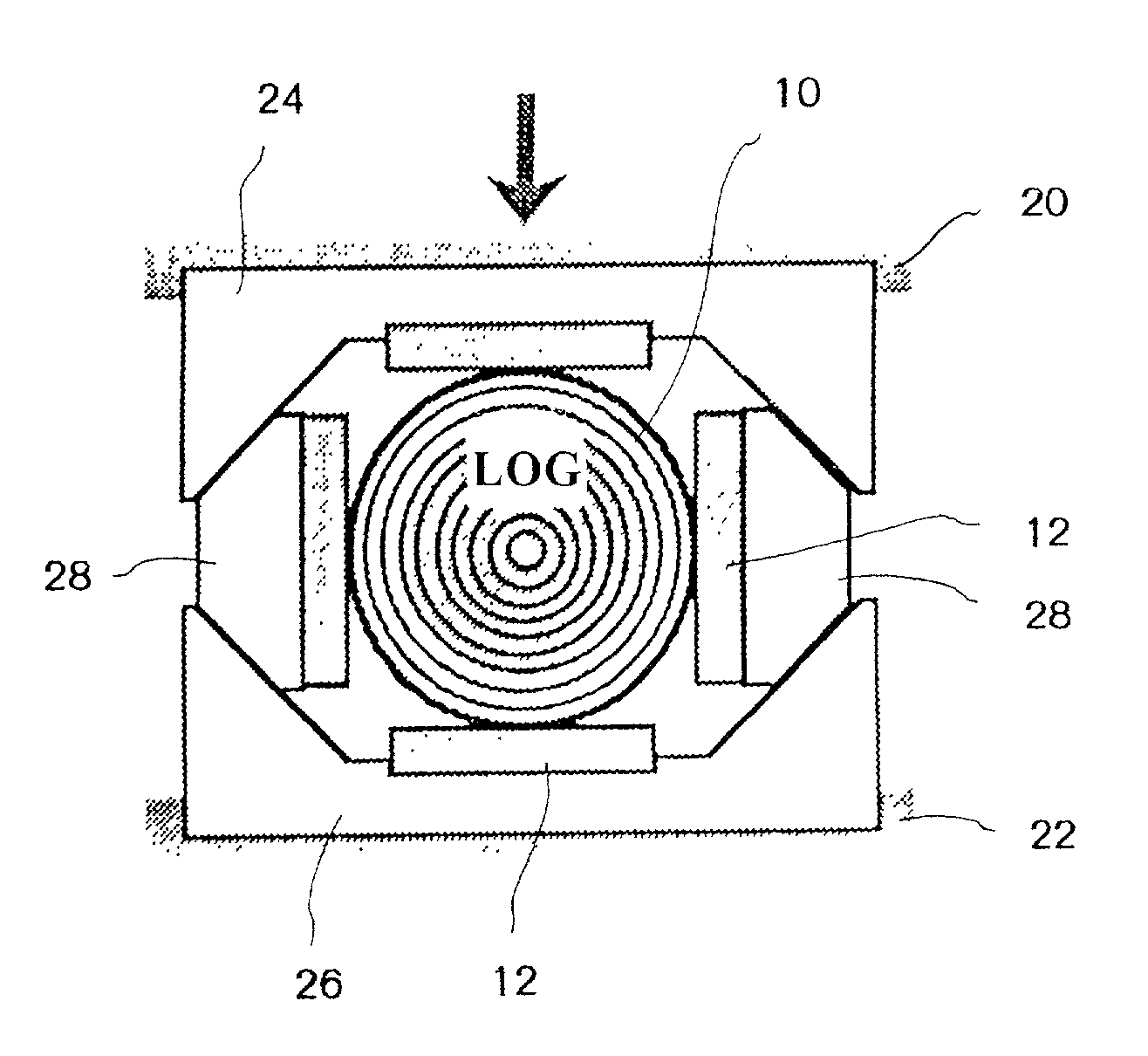

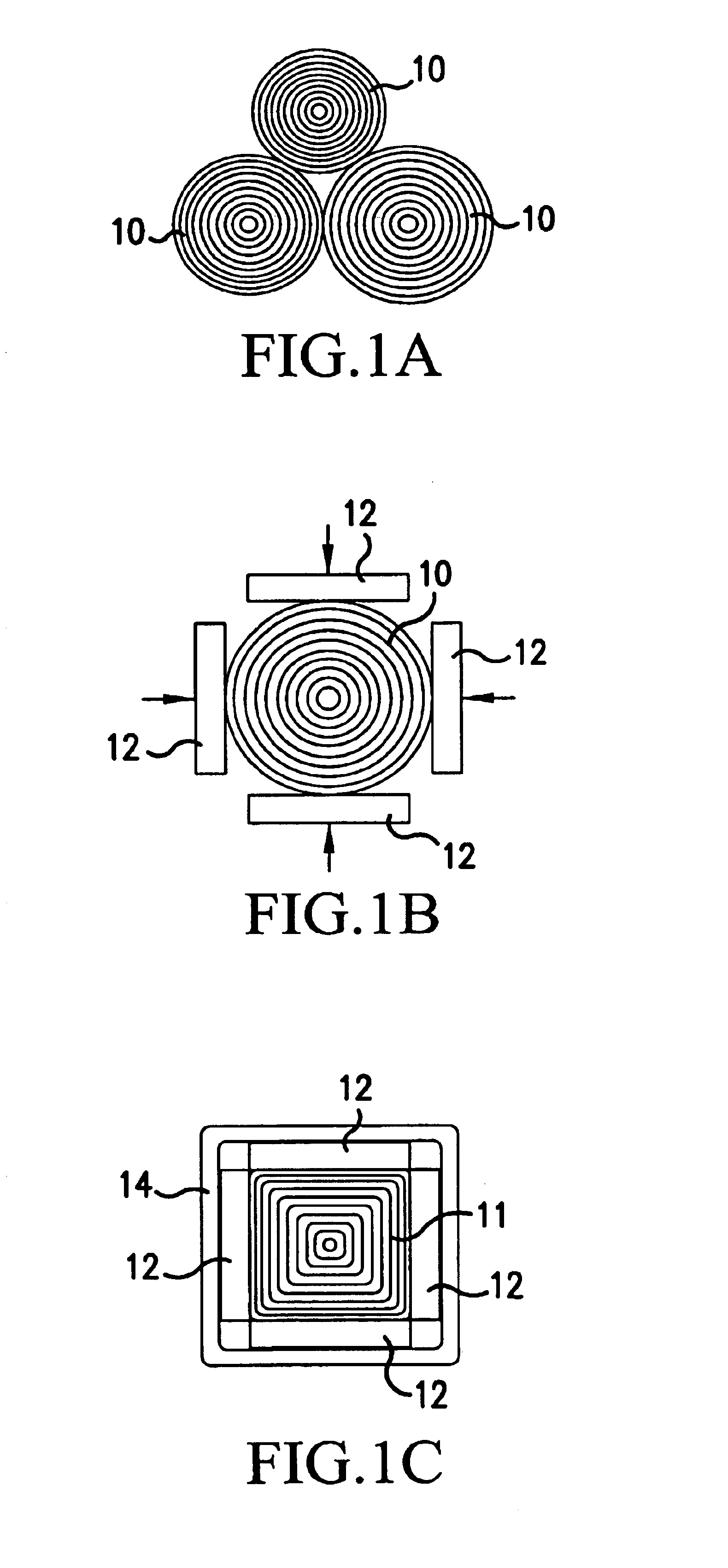

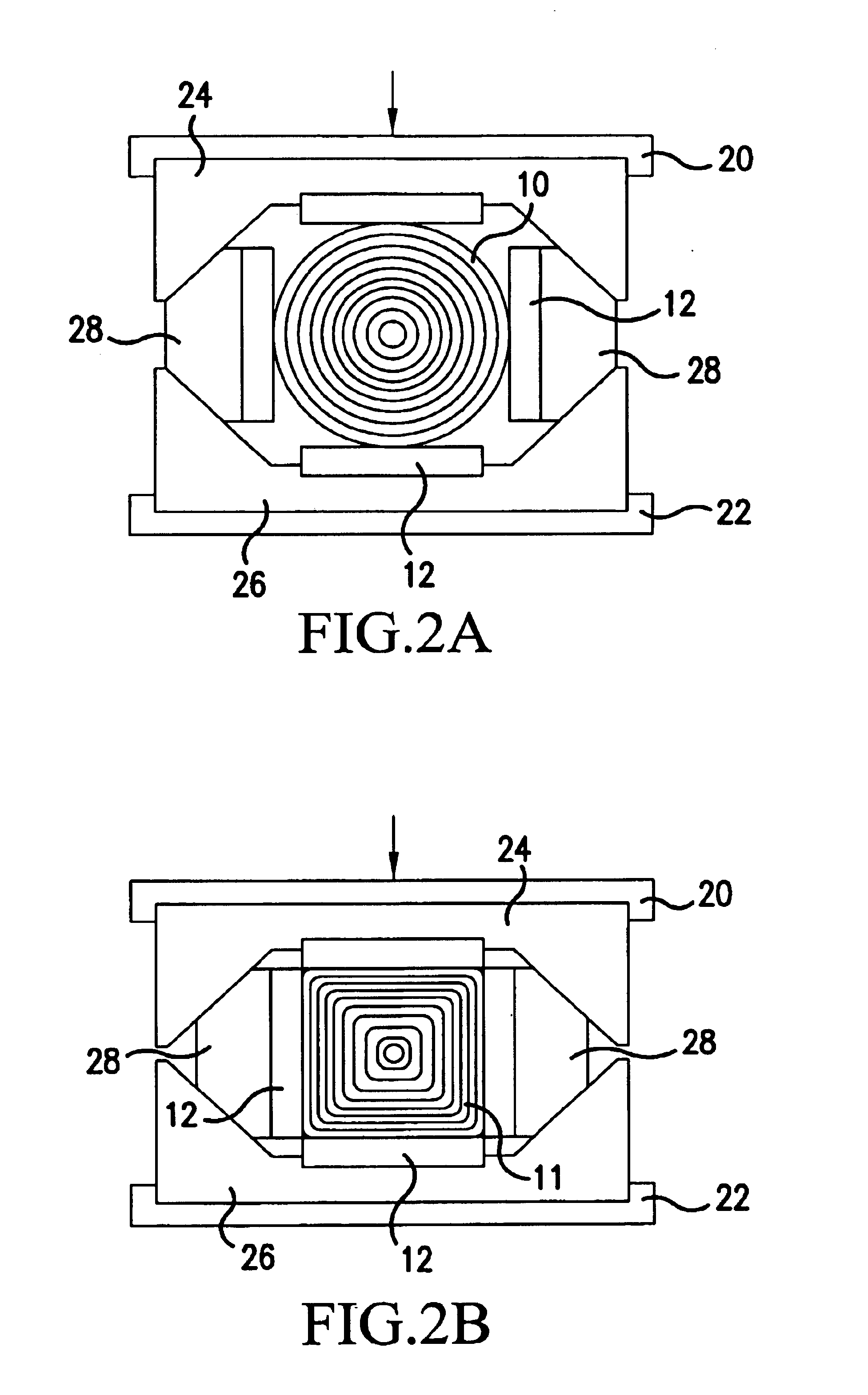

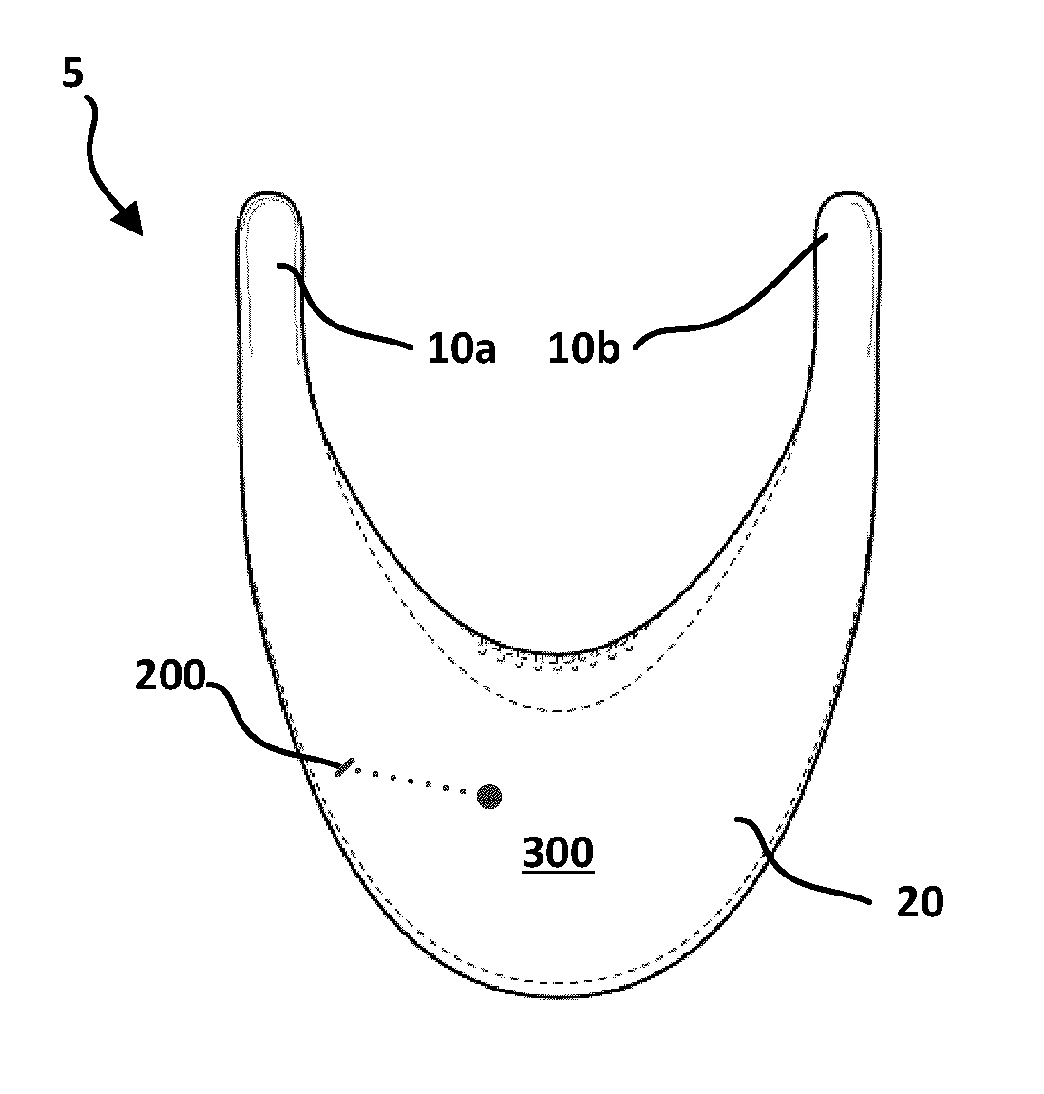

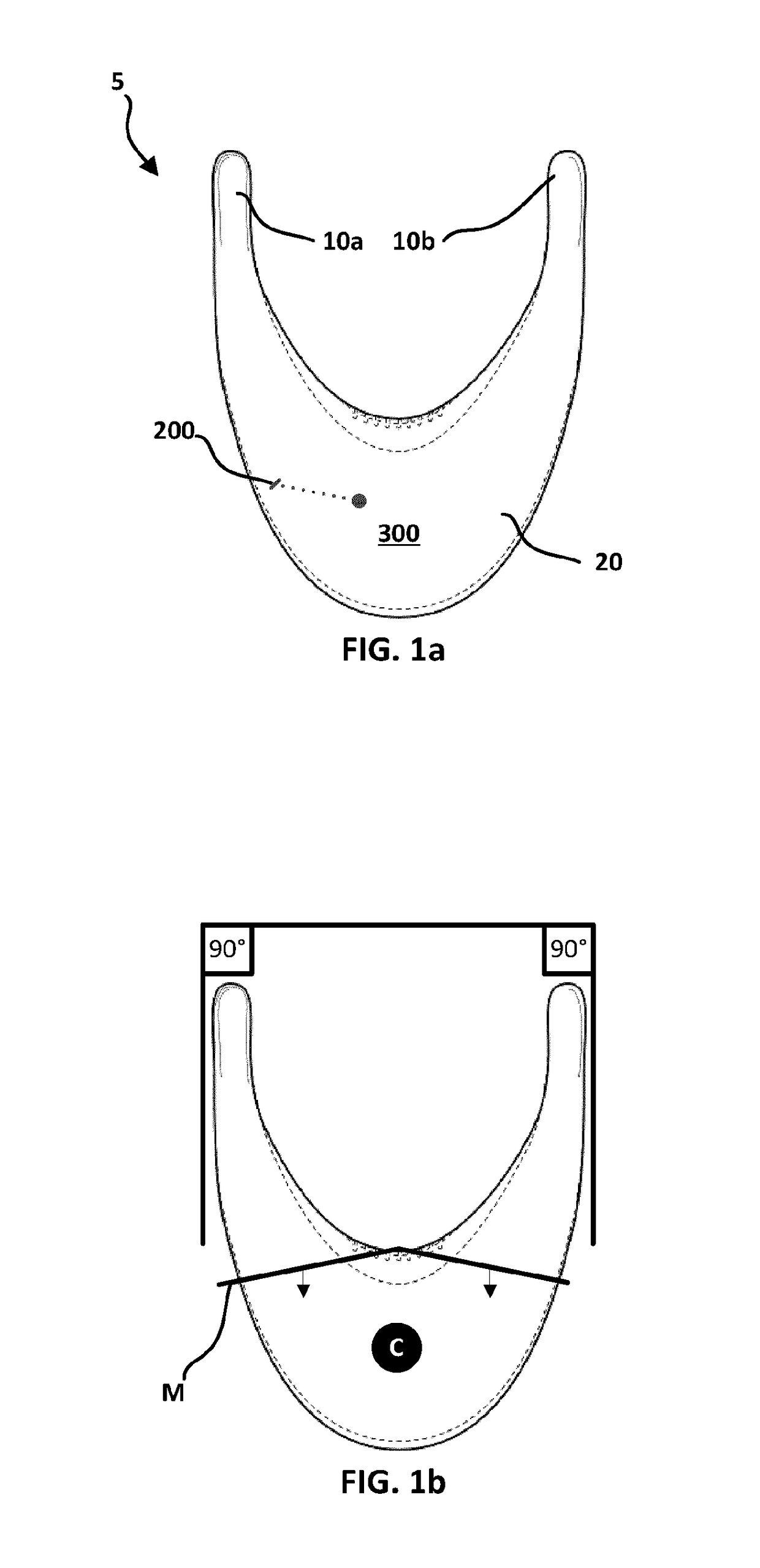

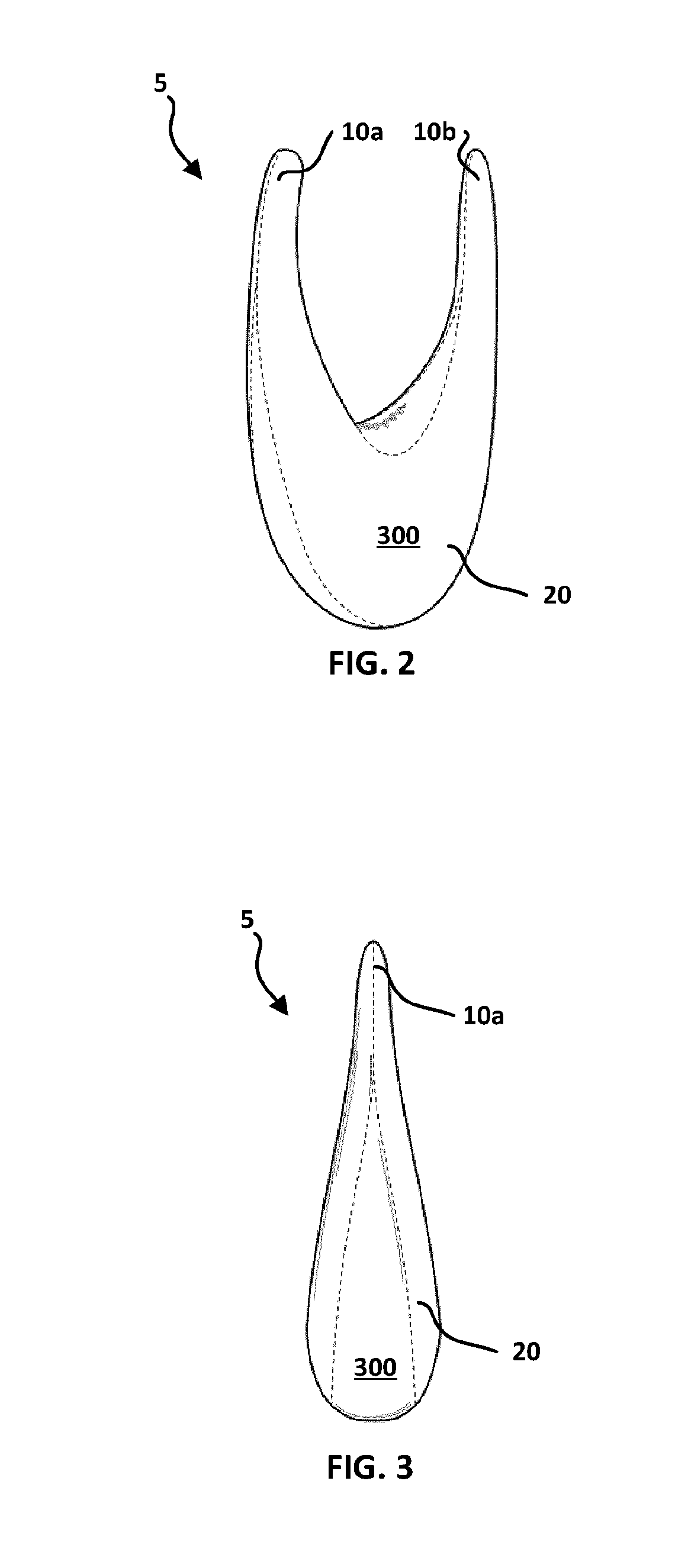

A transcranial magnetic stimulation induction coil device (“TMS coil device”) is manufactured to contain coil windings of a predetermined size and shape and fixedly positioned at a predetermined location within and orientation in relation to a casing of the TMS coil device. In one embodiment, the coil windings are encased in a casting at a predetermined location within and orientation in relation to the casting, and the casting is fixedly positioned at a predetermined location within and orientation in relation to the casing. The size and shape of the coil windings and the casing within, and the location and orientation of the coil windings in relation to each other and the casing of, the TMS coil device are known with a high level of precision, such that navigated brain stimulation can be performed with the TMS coil device with a high degree of accuracy. In another embodiment, the TMS coil device defines a space interposed between the coil windings and the casing and containing a gas which absorbs heat energy generated at the coil windings, thereby reducing the rate of transfer of heat energy from the coil windings to the casing during operation of the TMS coil device.

Owner:NEXSTIM

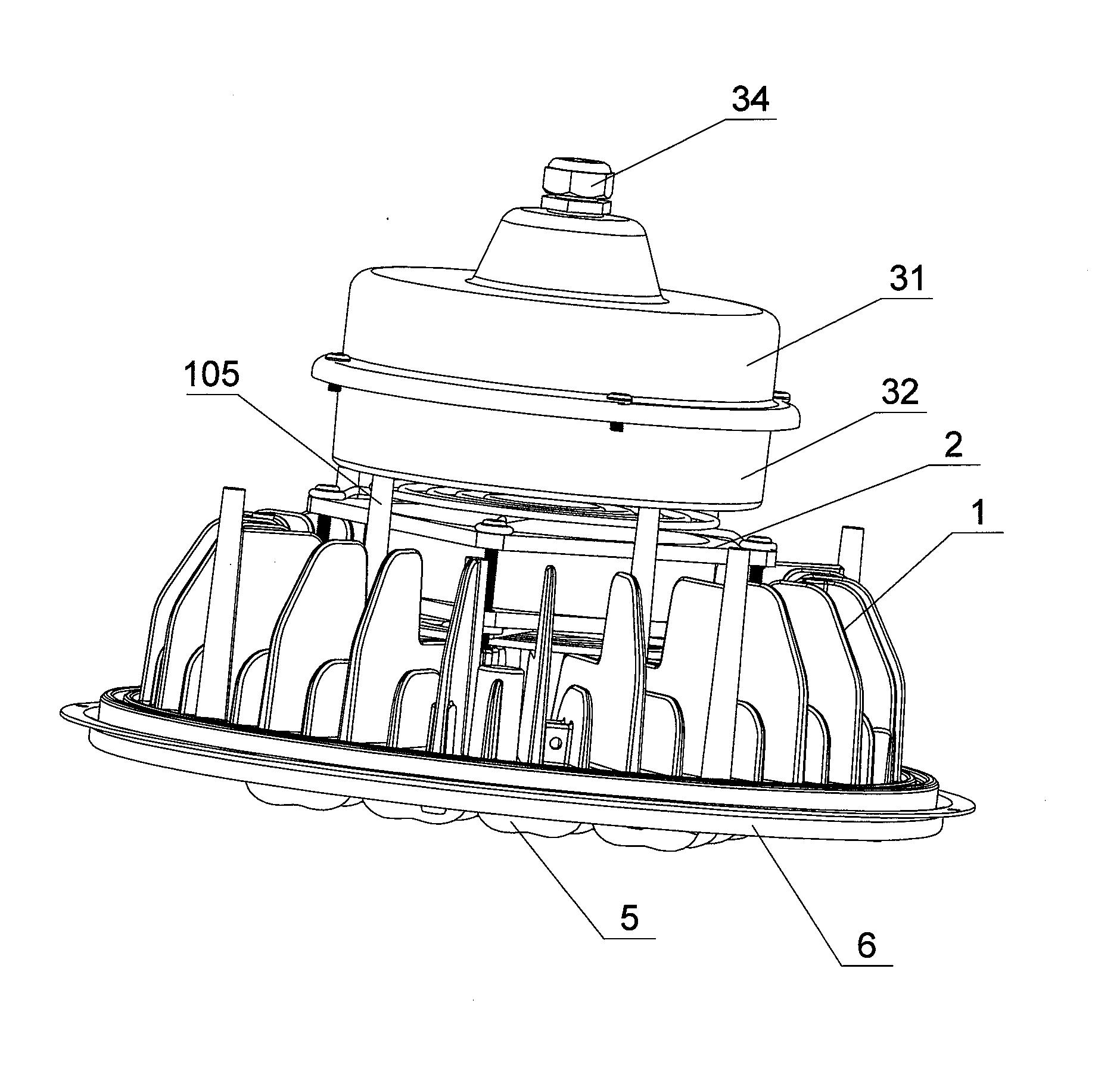

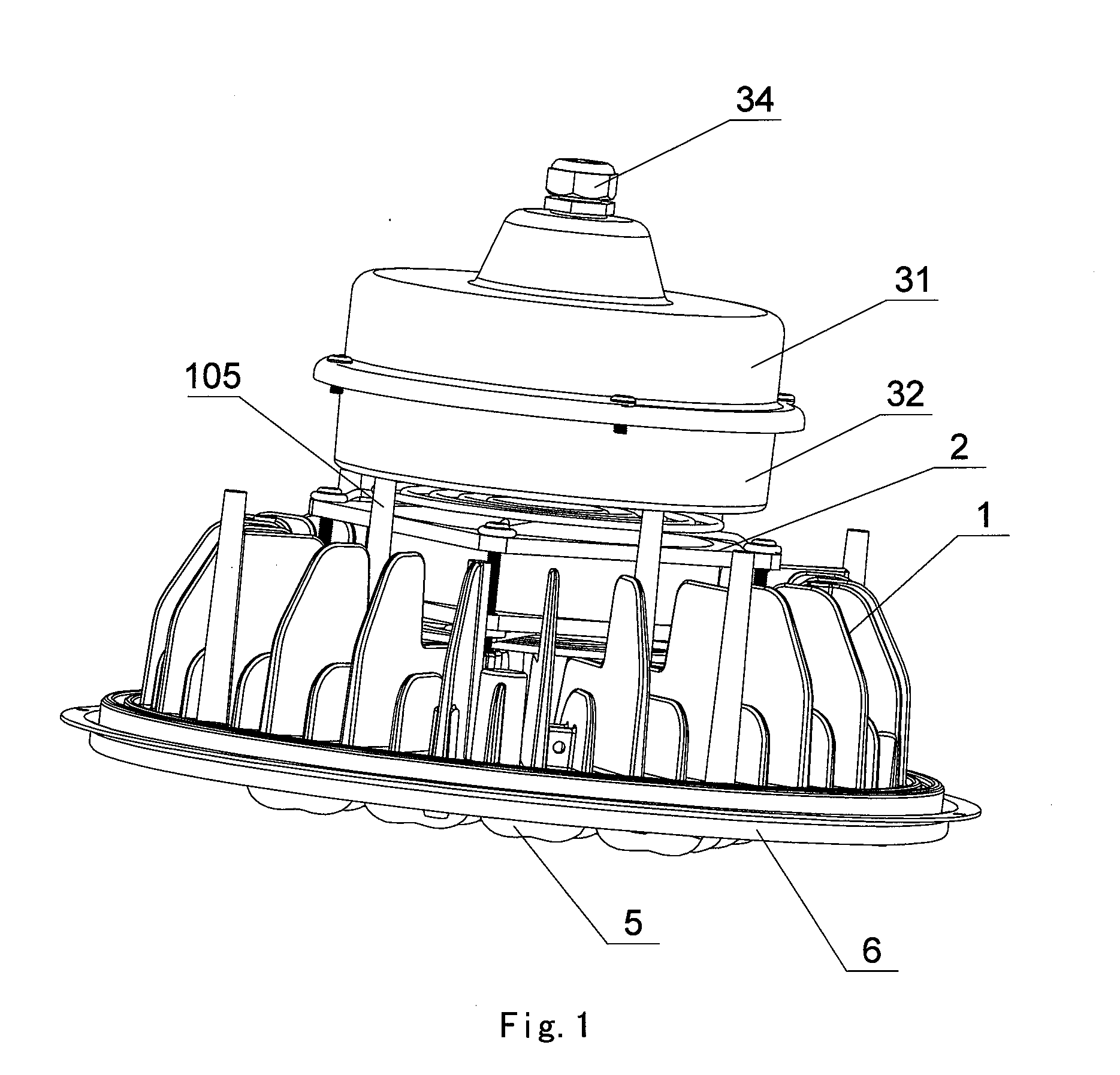

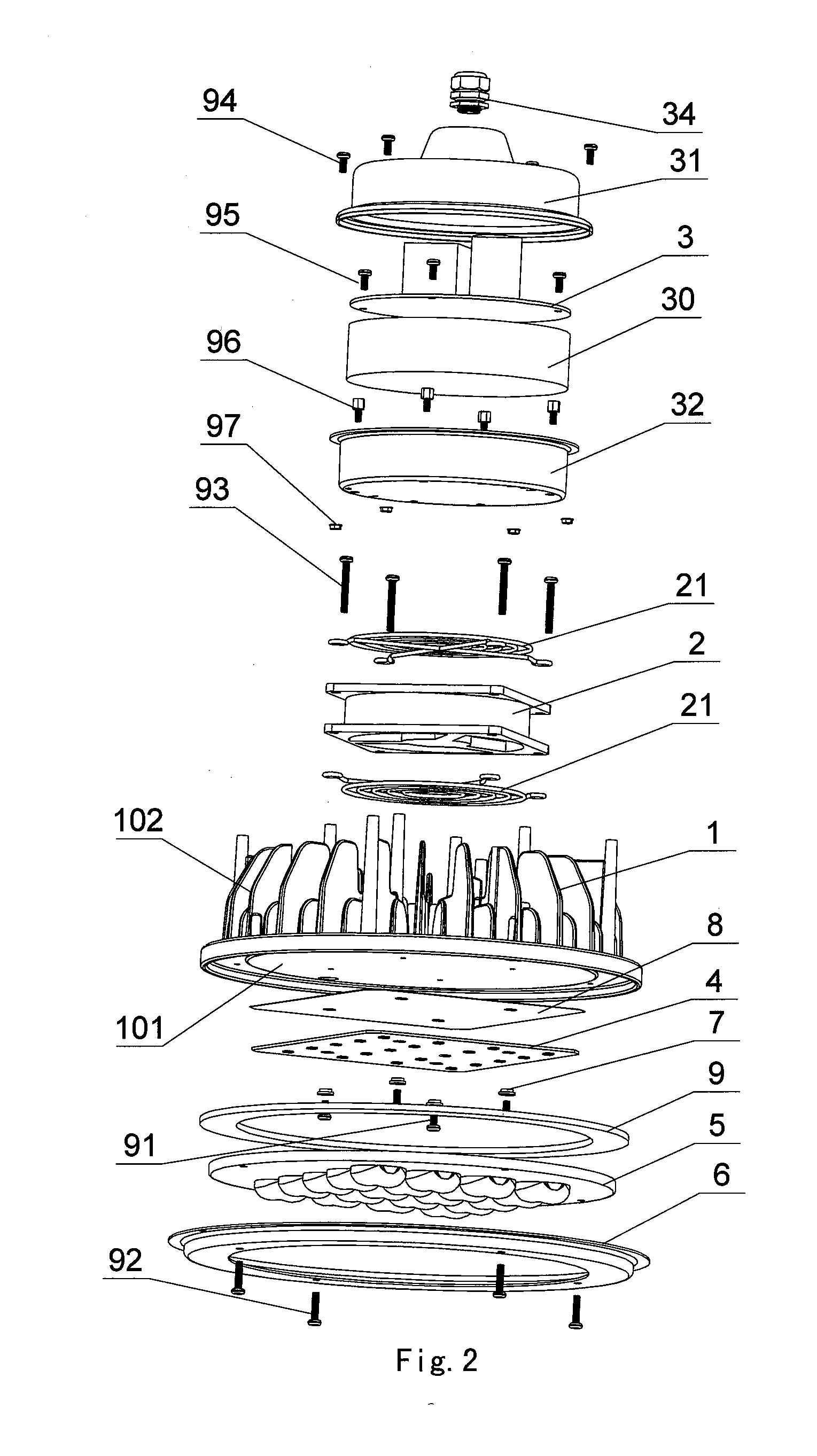

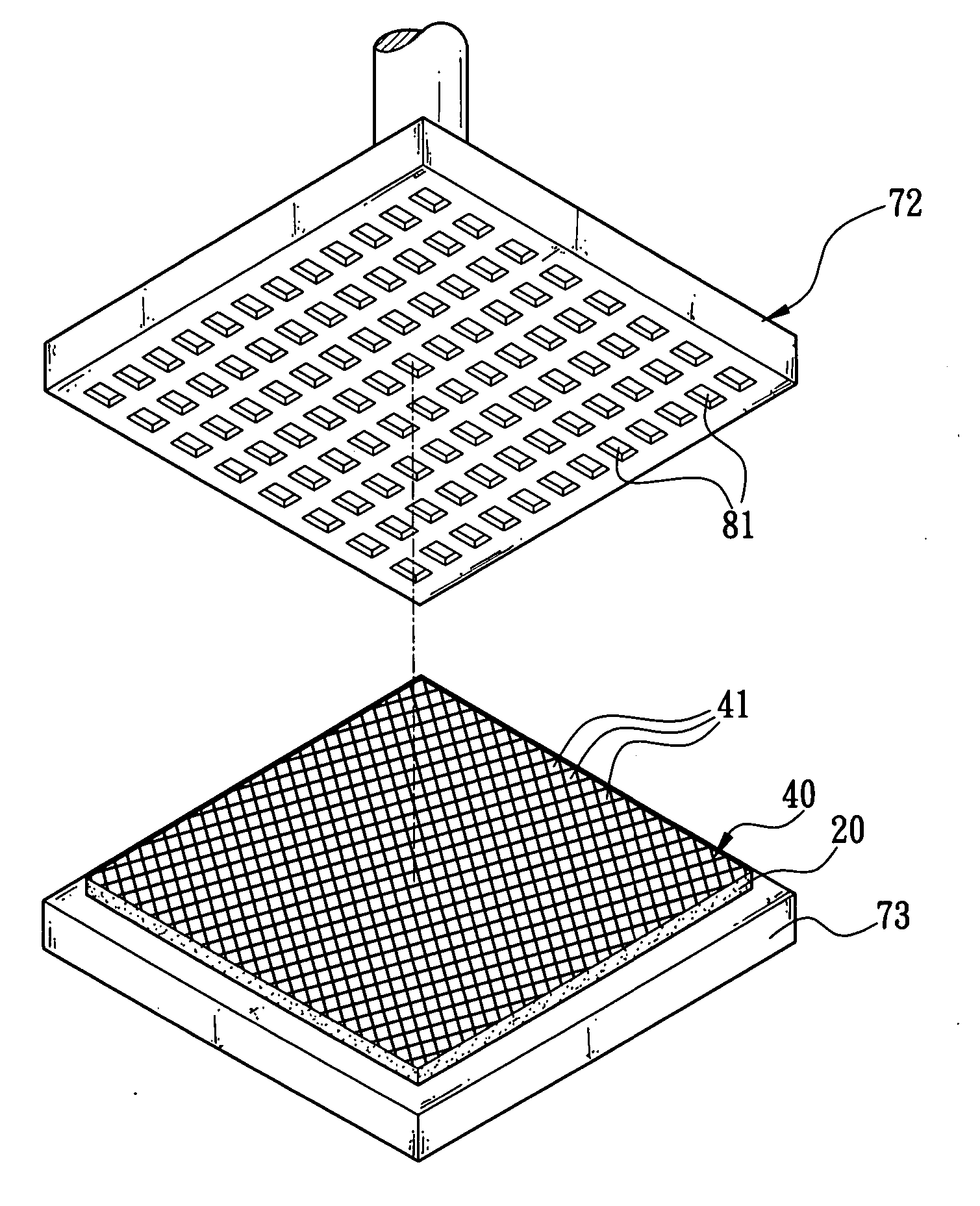

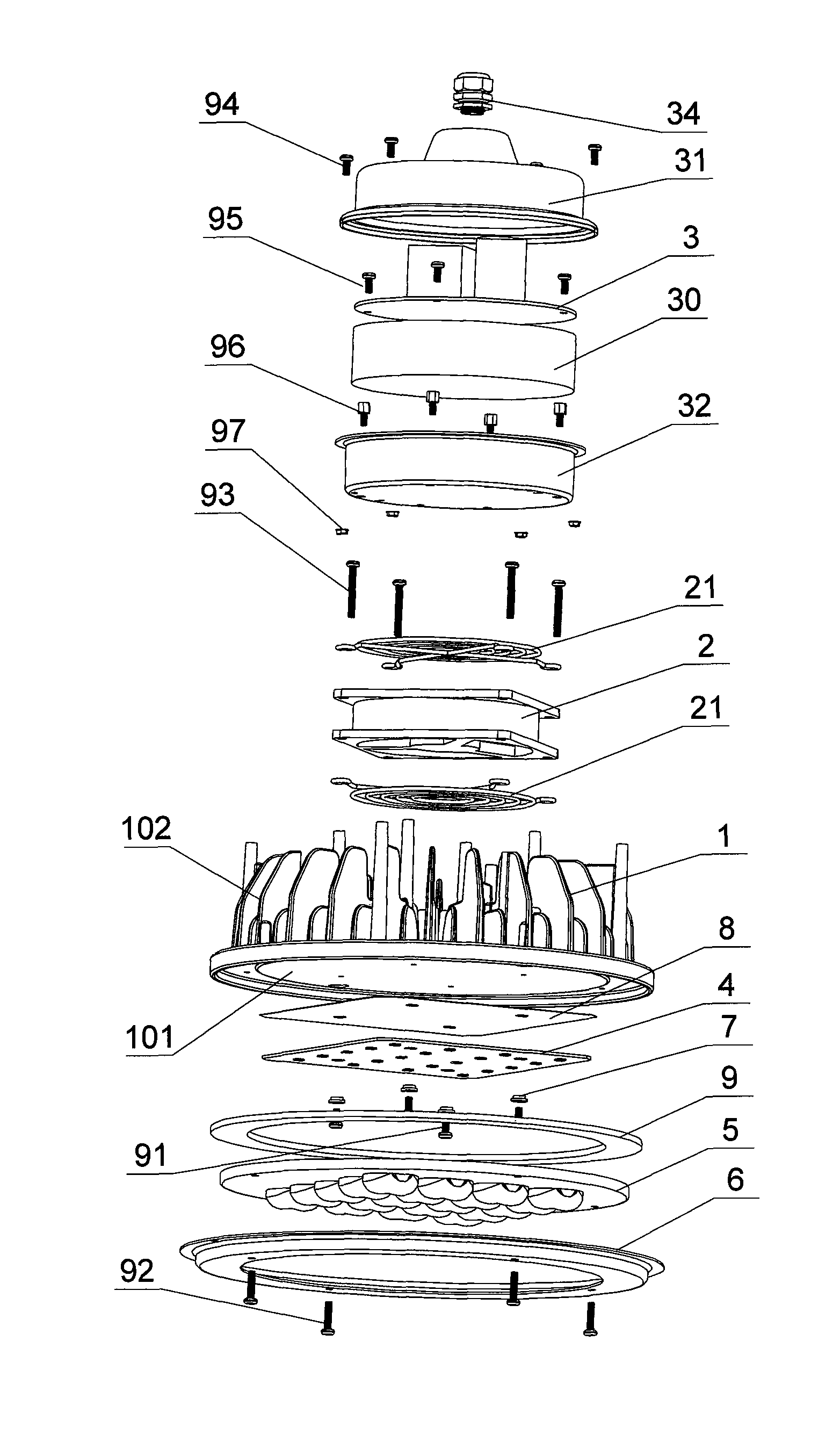

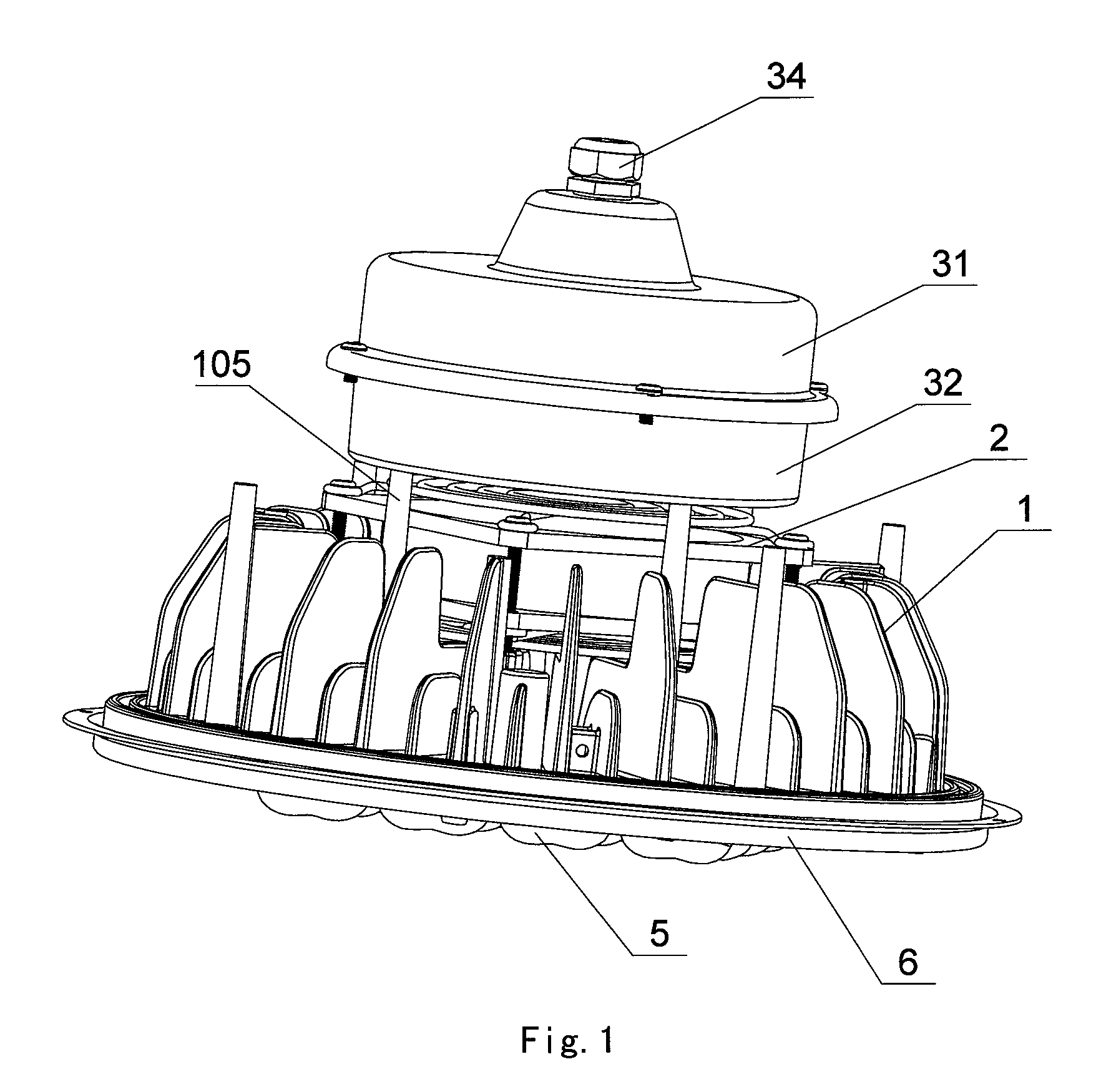

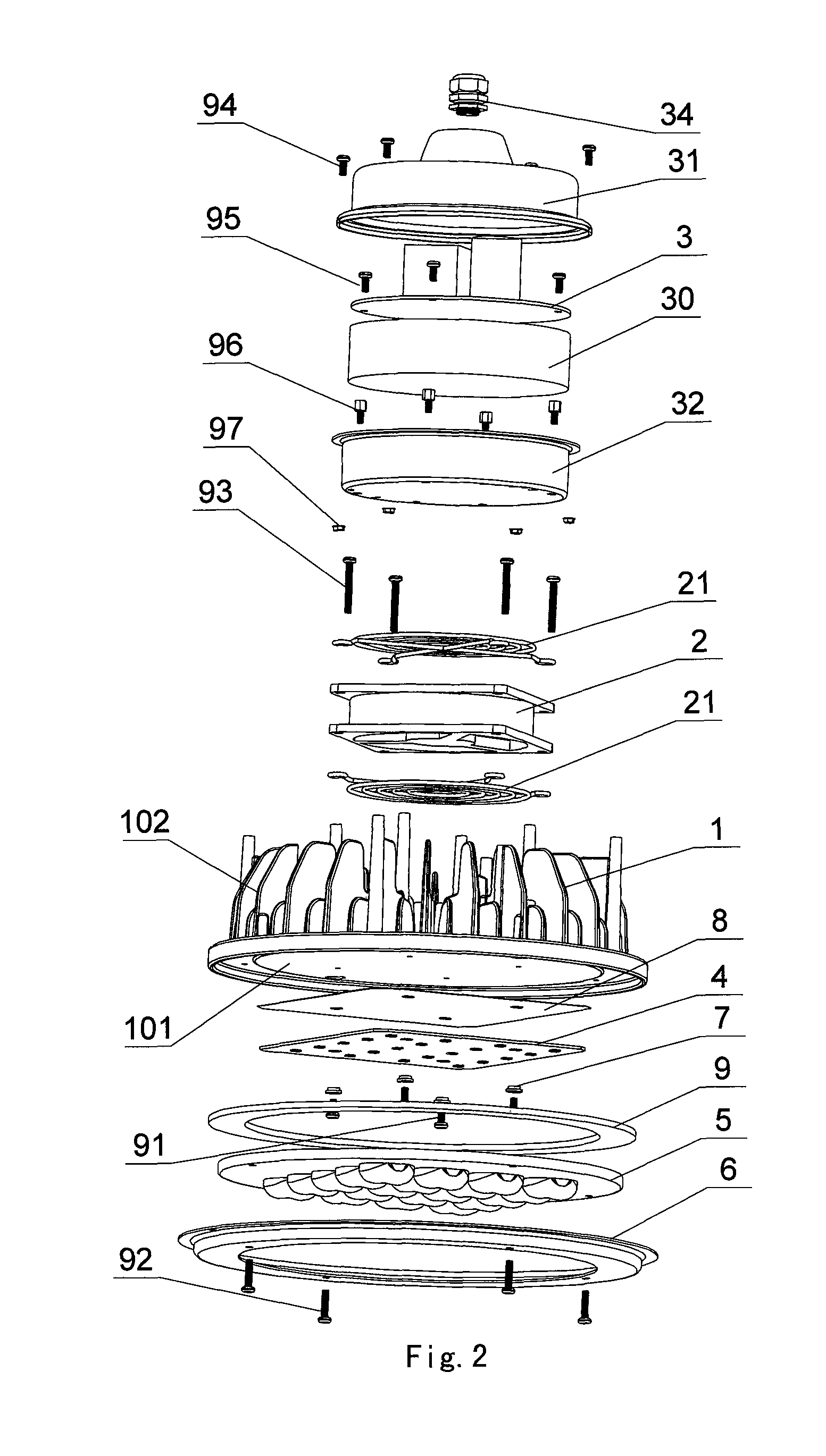

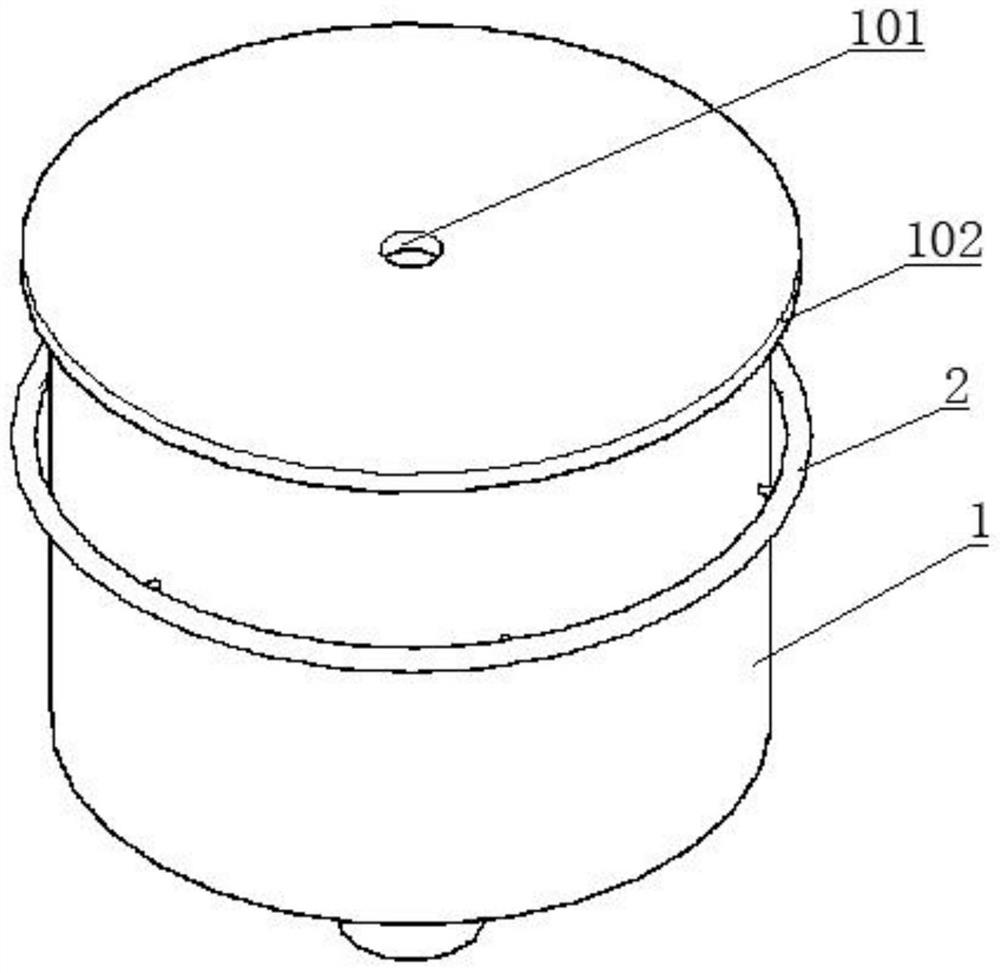

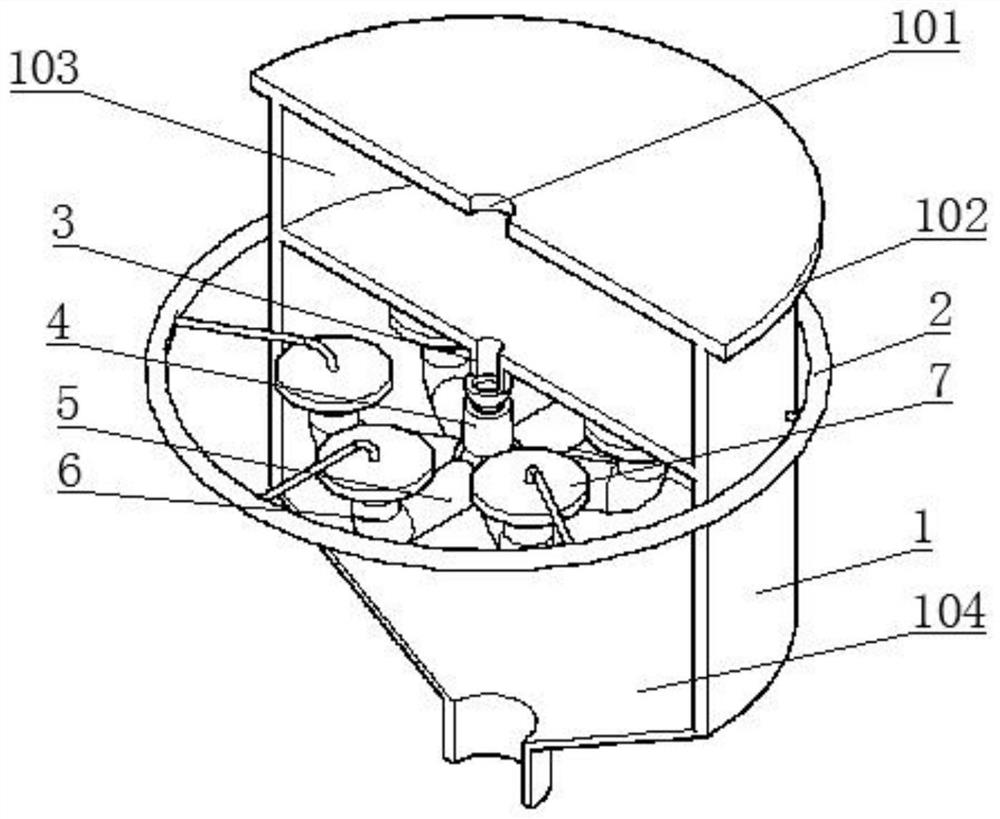

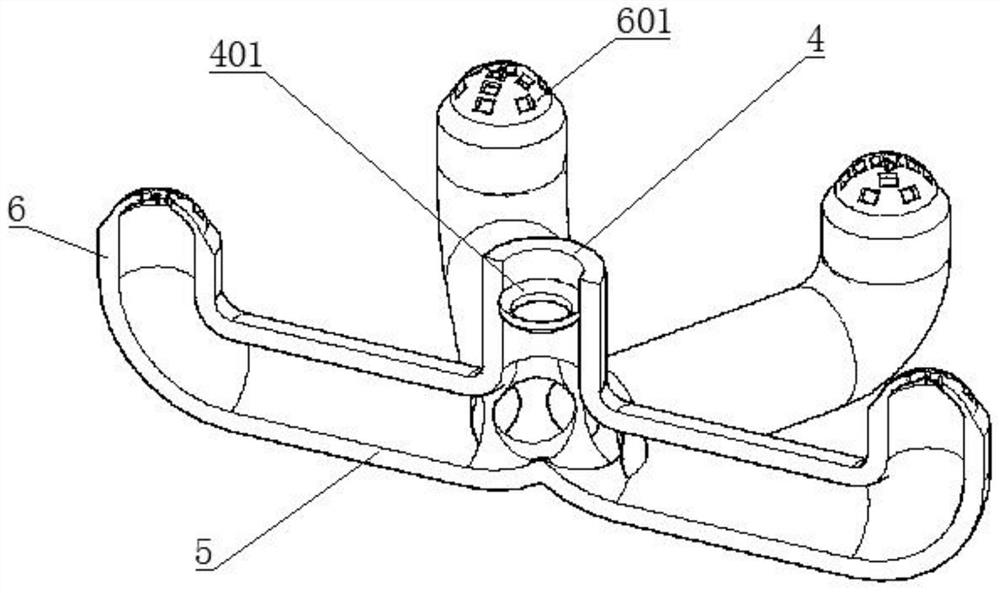

Dustproof and waterproof multipurpose LED-light power source assembly and dustproof and waterproof LED light

InactiveUS20140307441A1Improve insulation performanceImprove flame resistancePlanar light sourcesPoint-like light sourceEngineeringLED lamp

A dustproof and waterproof multipurpose LED-light power source assembly comprises a heat sink, a heat-dispersal fan, a circuit board driver module, an LED light source module, a power-source casing top cover and a power-source casing bottom cover. The LED light source module comprises plural LED chips and an LED heat-dispersing substrate. The heat-dispersal fan is a dustproof and waterproof fan. The heat sink comprises a baseboard to which the LED heat-dispersing substrate is fixedly connected and conducts dispersed heat. At the center of the top of a heat-dispersal member, a space is provided to accommodate the heat-dispersal fan. The power-source casing bottom cover is positioned above the heat-dispersal fan and is fixedly connected to the heat sink. The power-source casing top cover and the power-source casing bottom cover are hermetically connected one to the other. A waterproof bolt assembly is connected to the top of the power-source casing top cover.

Owner:NANKER GUANGZHOU SEMICON MFG

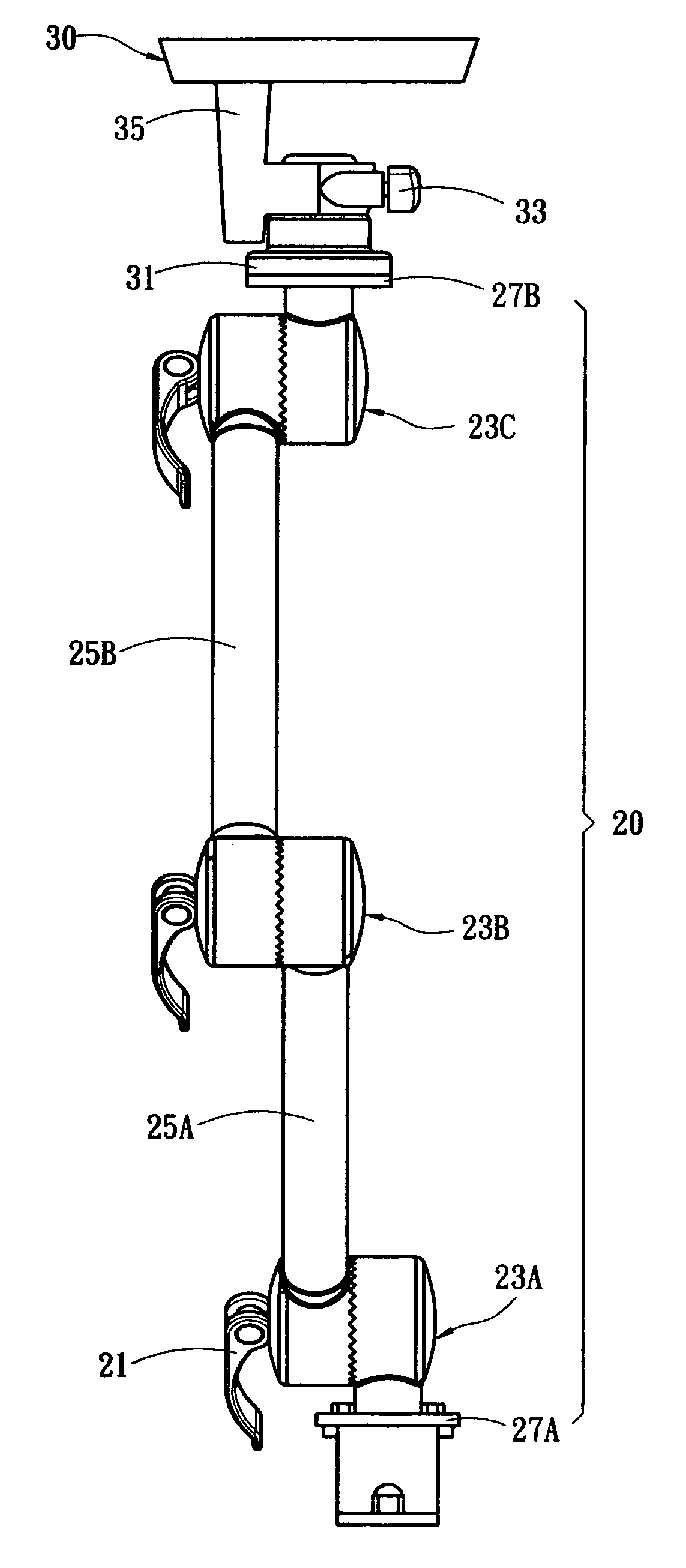

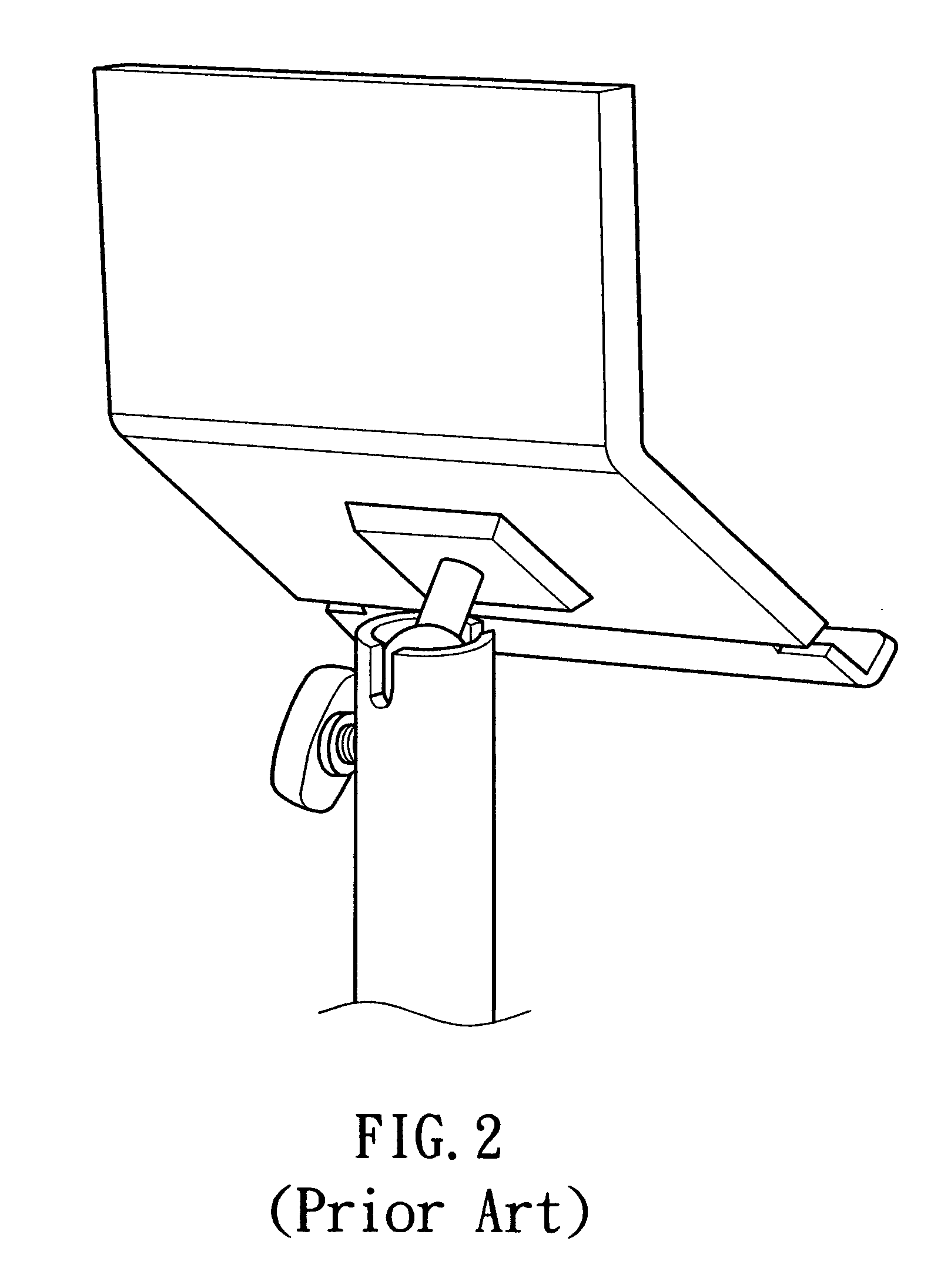

Supporting device for automotive portable electronic instruments

InactiveUS20070145219A1Easy to useEasy to operateStands/trestlesKitchen equipmentCentre of rotationElectronic instrument

A supporting device for automotive portable electronic instruments is formed of a bendable elongated rod with both ends connected to a bracket and a base, respectively. The elongated rod includes plural wheel-like connectors rotatable in vertical and axial directions and plural tubular connecting rods arranged between adjacent connectors. Each connector has two wheel-like casings facing and engaging with each other, and the edge of the connecting surface of each casing is correspondingly provided with waved serrations, such that two wheels can be rotatably engaged with each other and positioned by the serrations. Further, a disc-like knob is connected between the elongated rod and the bracket. The bracket is able to rotate around the knob as the center of rotation. A fixing screw is used to force and fix the position of the bracket. Finally, the base is a bent plate provided with plural screw holes, and both ends of the base are connected to the car body and the elongated rod, respectively, thereby to fix the supporting device in the car.

Owner:LIN ROOKY

Transcranial Magnetic Stimulation Induction Coil Device and Method of Manufacture

ActiveUS20080058581A1Low transfer rateReduce conductivityElectrotherapyTransformers/inductances casingsEngineeringConductor Coil

A transcranial magnetic stimulation induction coil device (“TMS coil device”) is manufactured to contain coil windings of a predetermined size and shape and fixedly positioned at a predetermined location within and orientation in relation to a casing of the TMS coil device. In one embodiment, the coil windings are encased in a casting at a predetermined location within and orientation in relation to the casting, and the casting is fixedly positioned at a predetermined location within and orientation in relation to the casing. The size and shape of the coil windings and the casing within, and the location and orientation of the coil windings in relation to each other and the casing of, the TMS coil device are known with a high level of precision, such that navigated brain stimulation can be performed with the TMS coil device with a high degree of accuracy. In another embodiment, the TMS coil device defines a space interposed between the coil windings and the casing and containing a gas which absorbs heat energy generated at the coil windings, thereby reducing the rate of transfer of heat energy from the coil windings to the casing during operation of the TMS coil device.

Owner:NEXSTIM

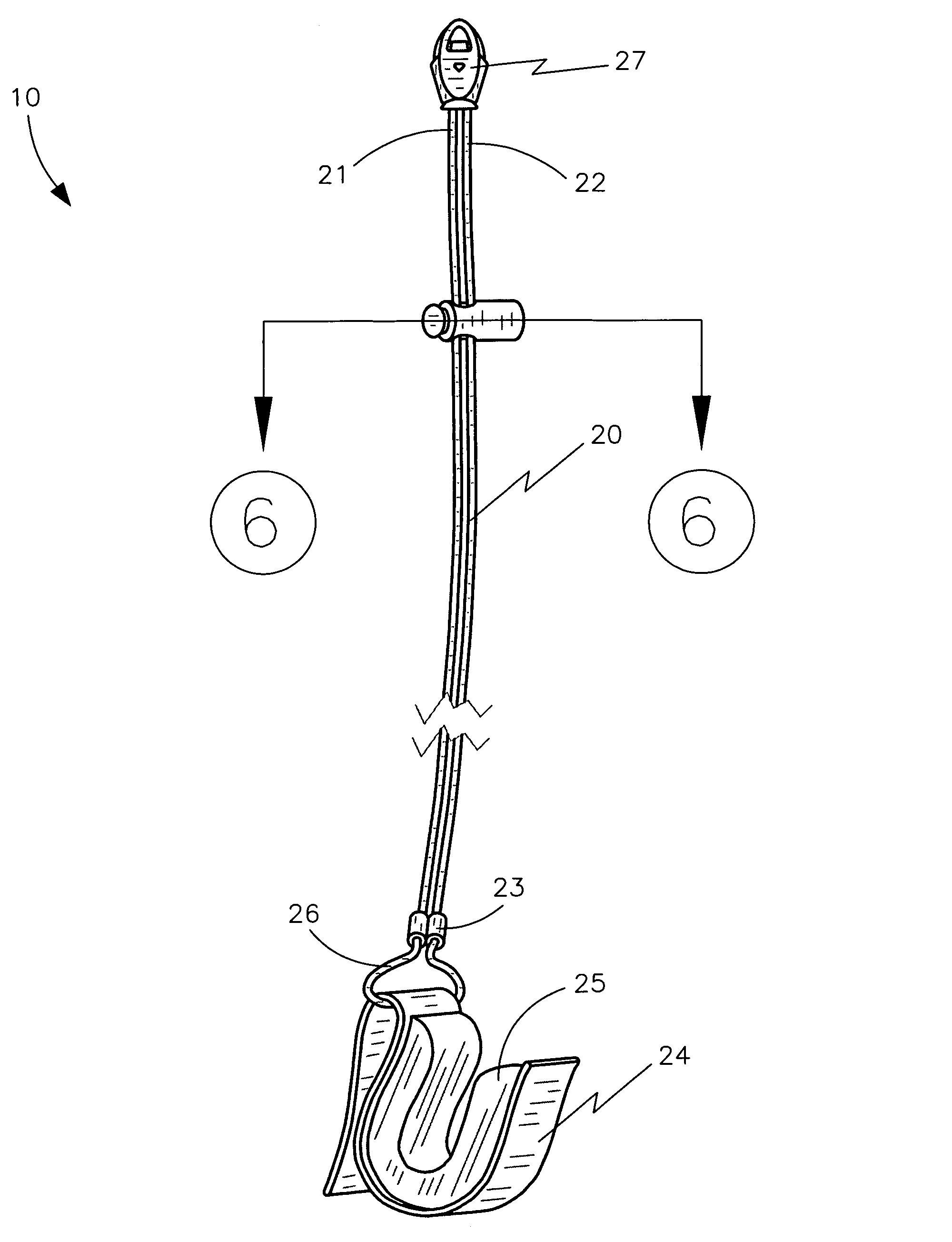

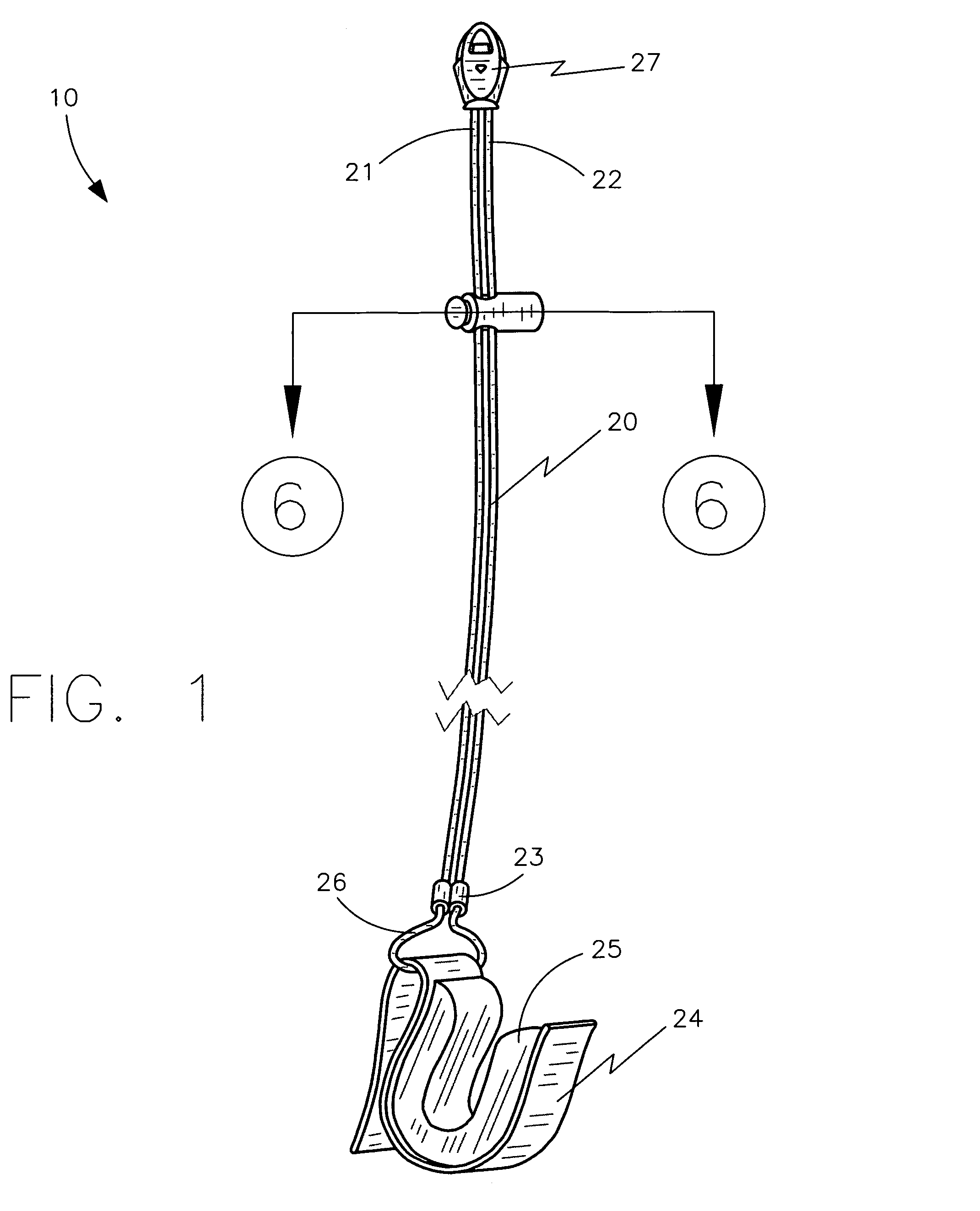

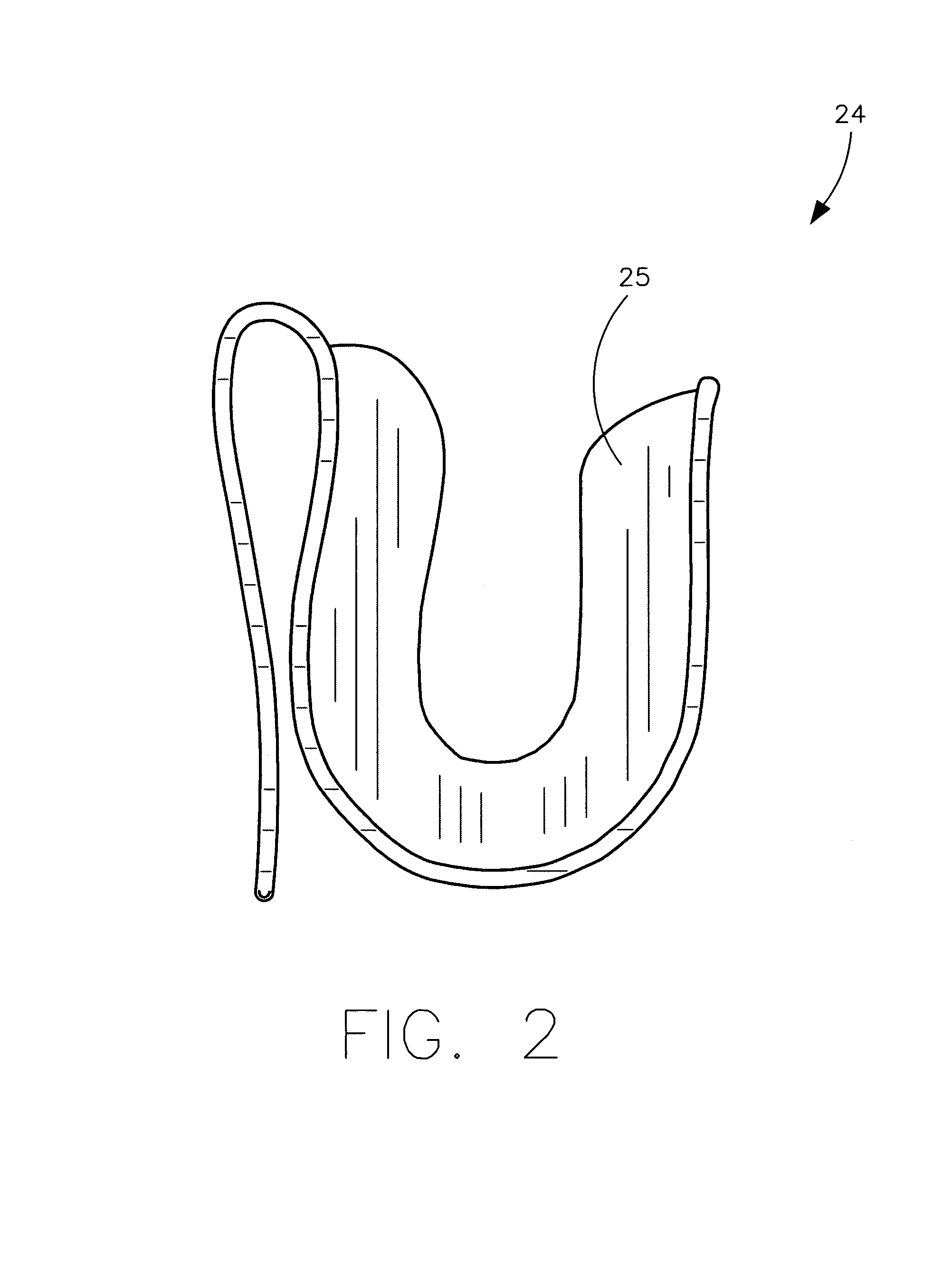

Portable fishing pole and binoculars support apparatus and associated method

InactiveUS7594354B1Conveniently formedFixed shapeTravelling sacksTravelling carriersAnimal scienceEngineering

A portable fishing pole and binoculars support apparatus includes a flexible shock cord with adjacently disposed first and second ends respectively. Such a shock cord further includes a cable crimp directly attached thereto such that a loop is formed in a medial portion of the shock cord. The support apparatus further includes a substantially S-shaped holder removably secured to the shock cord. Such a holder is formed from rigid and durable material such that the holder maintains a fixed shape during operating conditions. The holder includes a deformably resilient and cushioned material statically affixed to an inner surface of a selected curved portion of the holder. The support apparatus further includes an audible signaling device attached to the shock cord and a mechanism for adjustably attaching the apparatus about a user neck during operating conditions.

Owner:CHADWICK KAREN

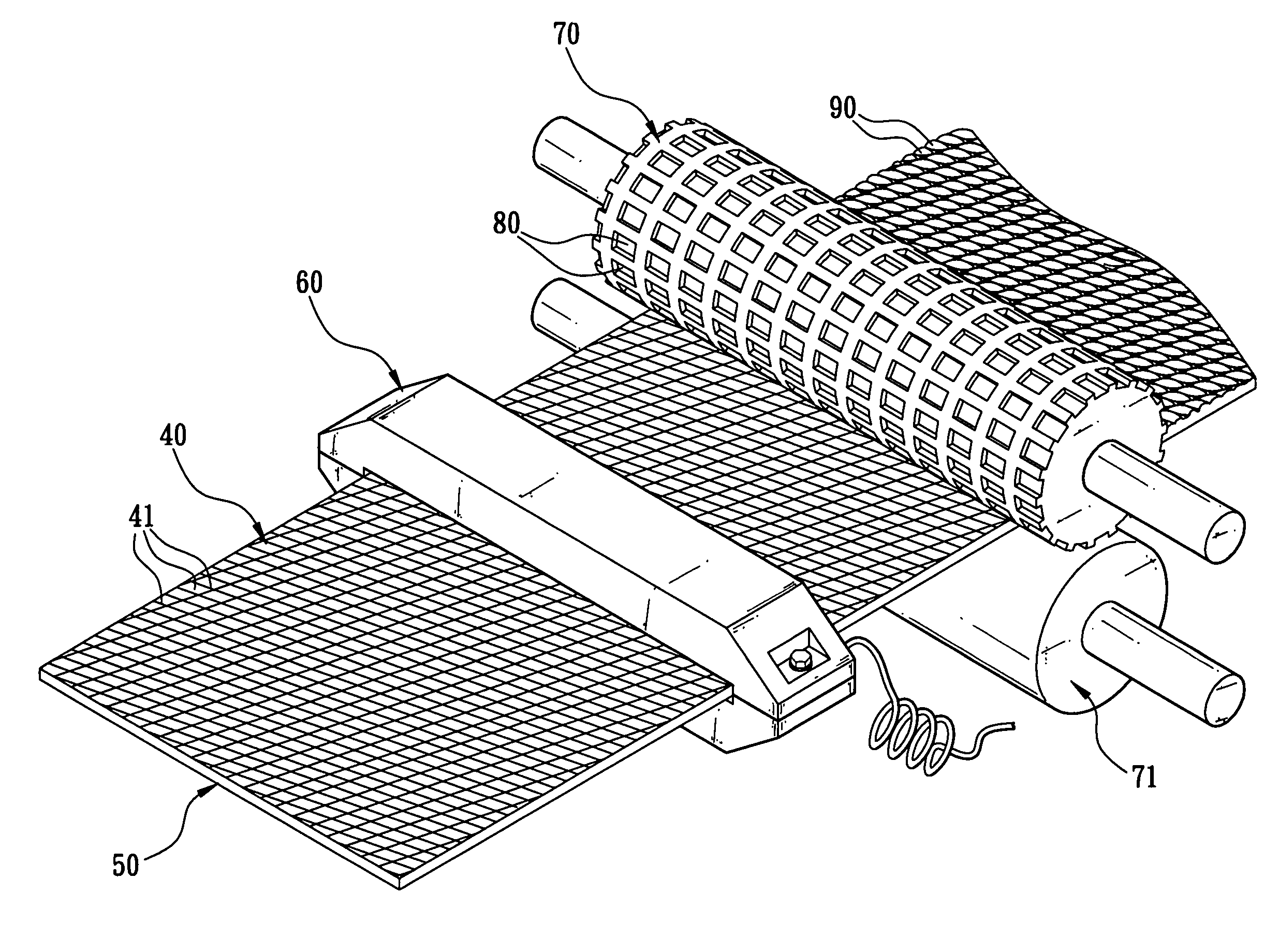

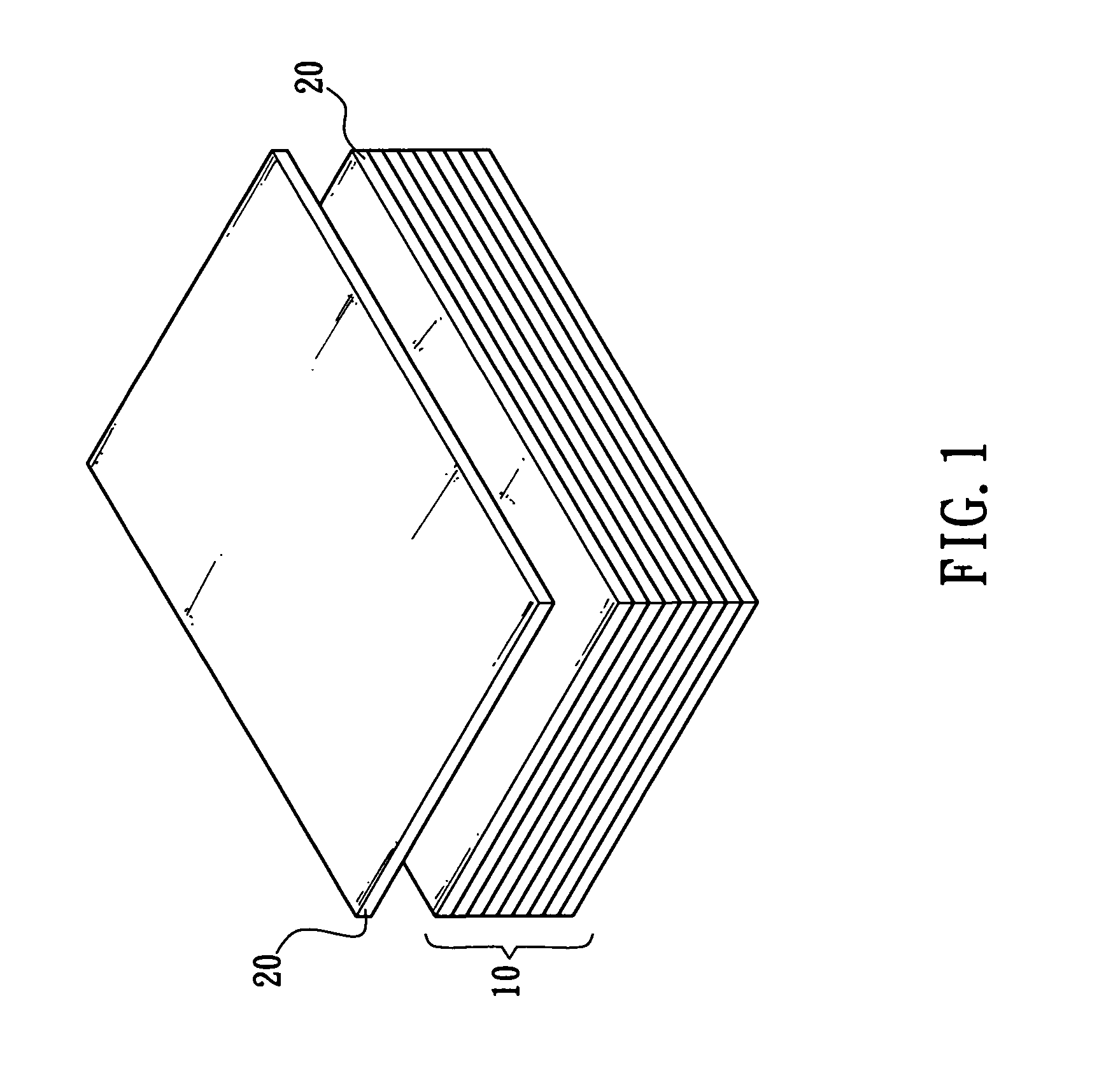

Method for manufacturing slippery-proof foam materials having protruded threads

ActiveUS20050275127A1Reduce the temperatureFixed shapeSemi-permeable membranesCeramic shaping apparatusMetallurgyThermoplastic elastomer

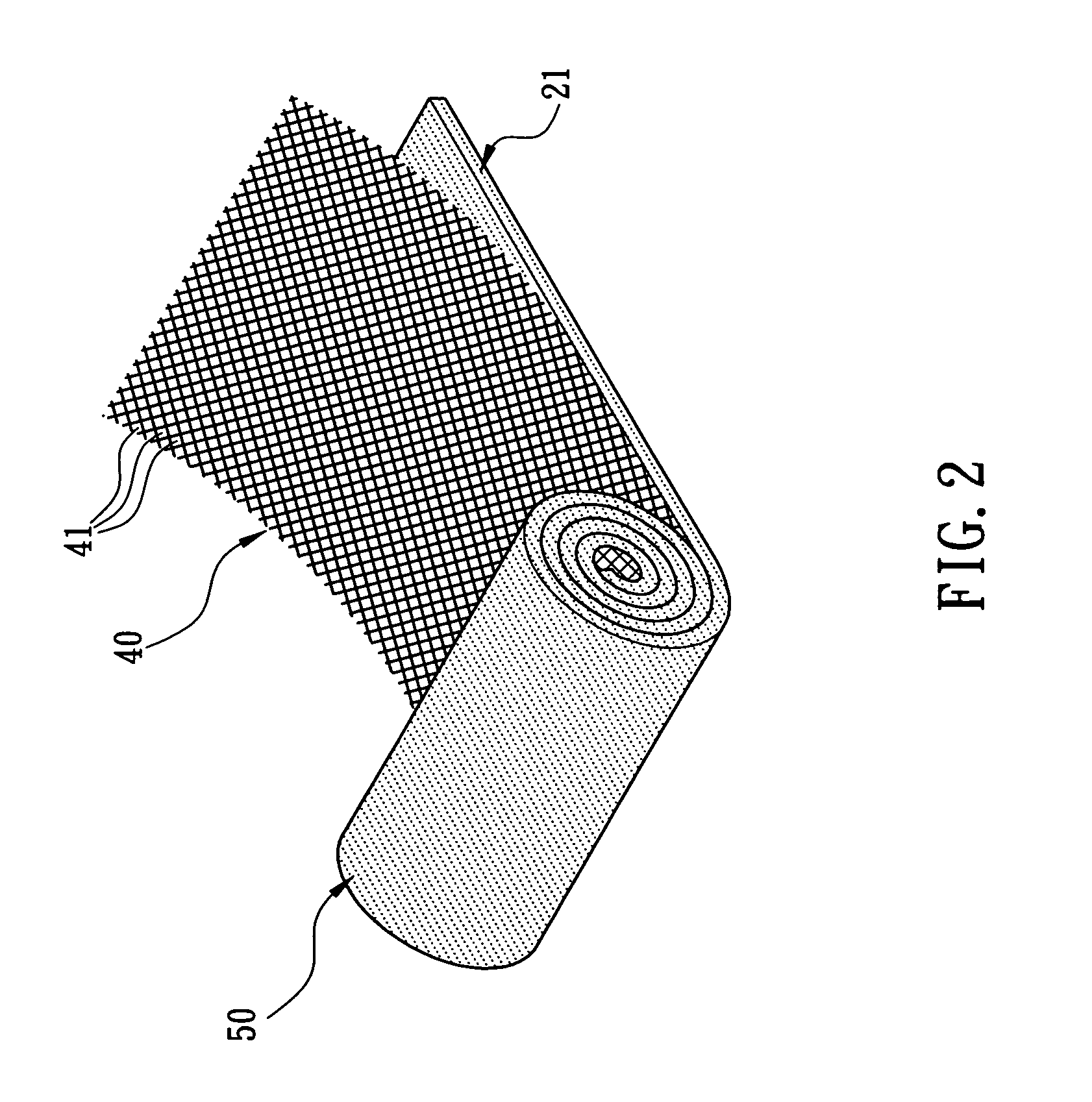

The present invention discloses a method for manufacturing slippery-proof foam materials having protruded threads, which comprises the steps of foaming Thermoplastic Elastomer (TPE) or EVA pellets into a foam material plate, attaching a high heat resisting mesh cloth onto the surface of the plate, heating the plate by a heating device to soften the material to an extent of being suitable for a plastic formation, rolling and pressing the plate by a rolling mold or a piece of mold having an even surface and a plurality of tiny grooves thereon, so that the section of the plate receiving a larger rolling and pressing force moves towards the section receiving a smaller rolling and pressing force, and then passes through the meshes of the high heat resisting mesh cloth under the condition of being held up by the high heat resisting mesh cloth to form evenly protruded threads on the surface thereof after being cooled immediately.

Owner:MICROCELL COMPOSITE CO LTD

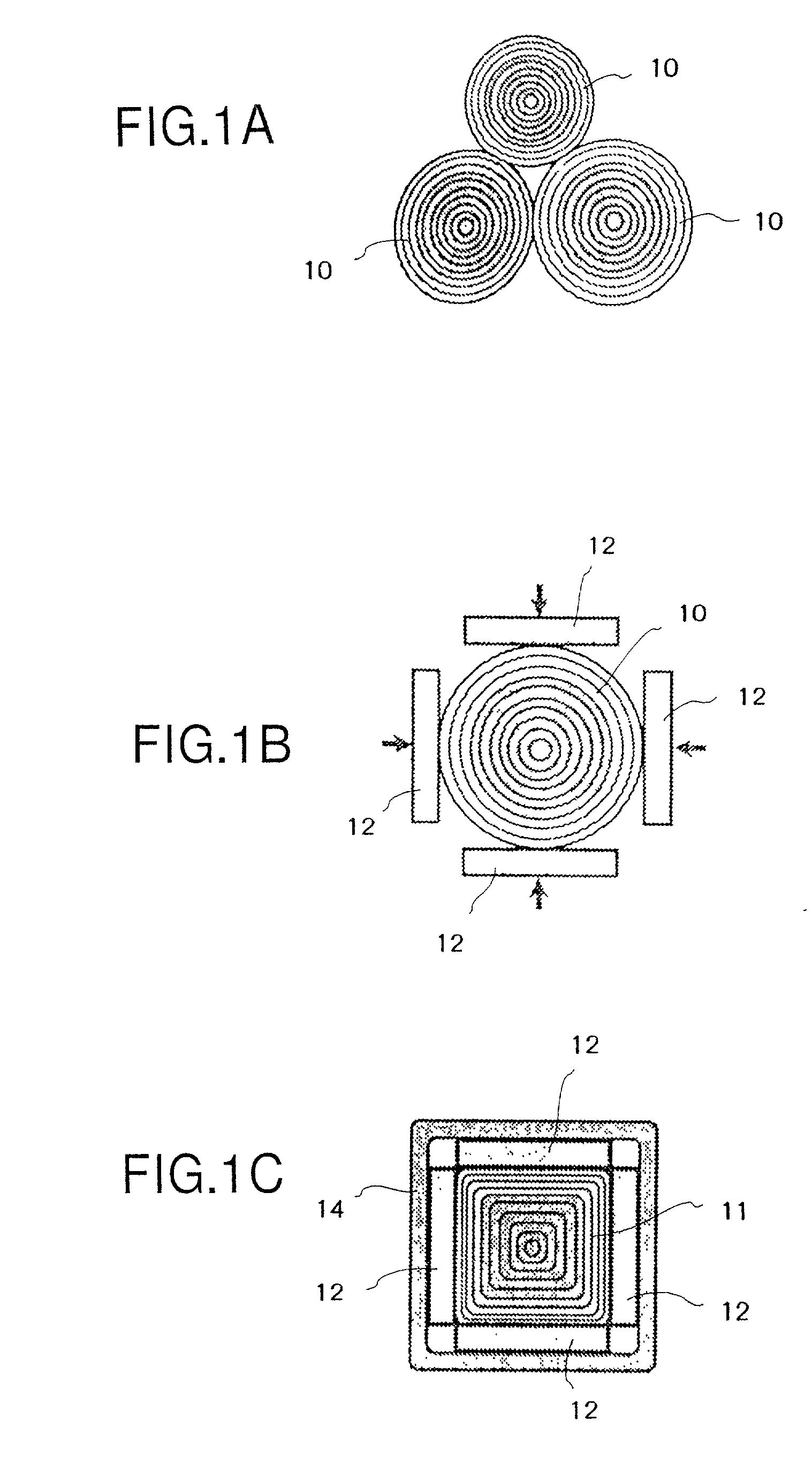

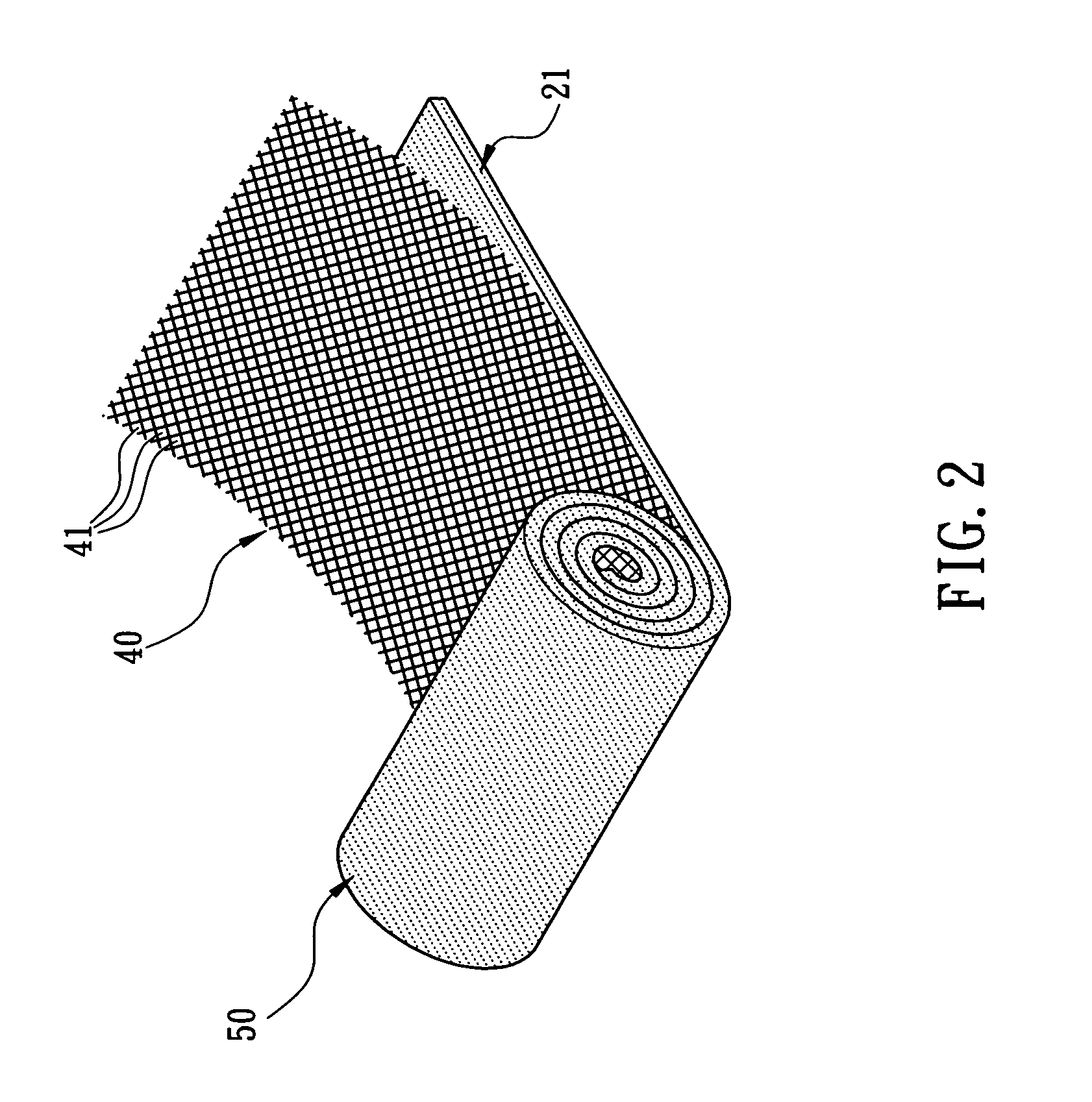

Prismatic wood compression molding method and compression molding device therefor

InactiveUS20020148532A1Fixed shapeEasy to manufactureWooden sticks manufactureWood compressionCompression moldingEngineering

A prismatic wood compression molding method capable of easily producing long-sized lumber usable as pillars or like by compression molding. The method is characterized by comparing the steps of: using a plurality of rigid plate-like bodies such as metal plates to compress an outer face of wood throughout length thereof to compression-mold it into prismatic wood which is polygonal, such as rectangular or hexagonal, in cross section; restraining the plate-like bodies by a restrain jig so as to hold flat surfaces of the prismatic wood in a state in which they are compressed by the plate-like bodies; and applying a heat treatment to the prismatic wood held in the compressed state by the plate-like bodies and the jig so as to permanently fix the shape of the prismatic wood.

Owner:SHINSHU UNIVERSITY +1

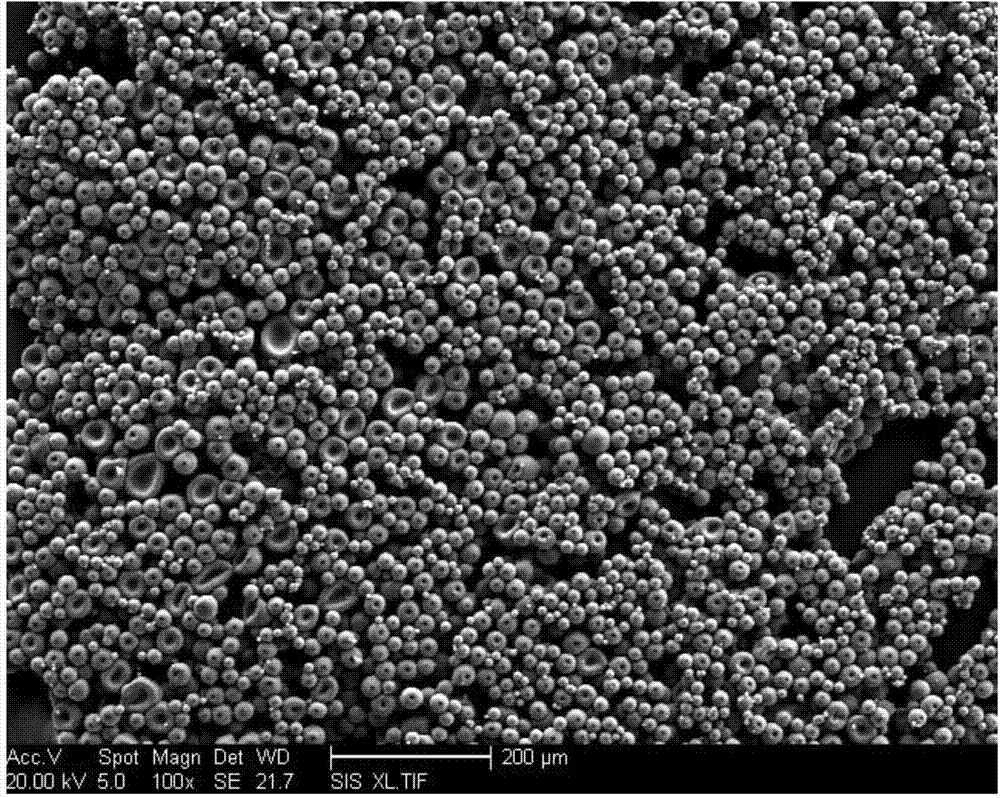

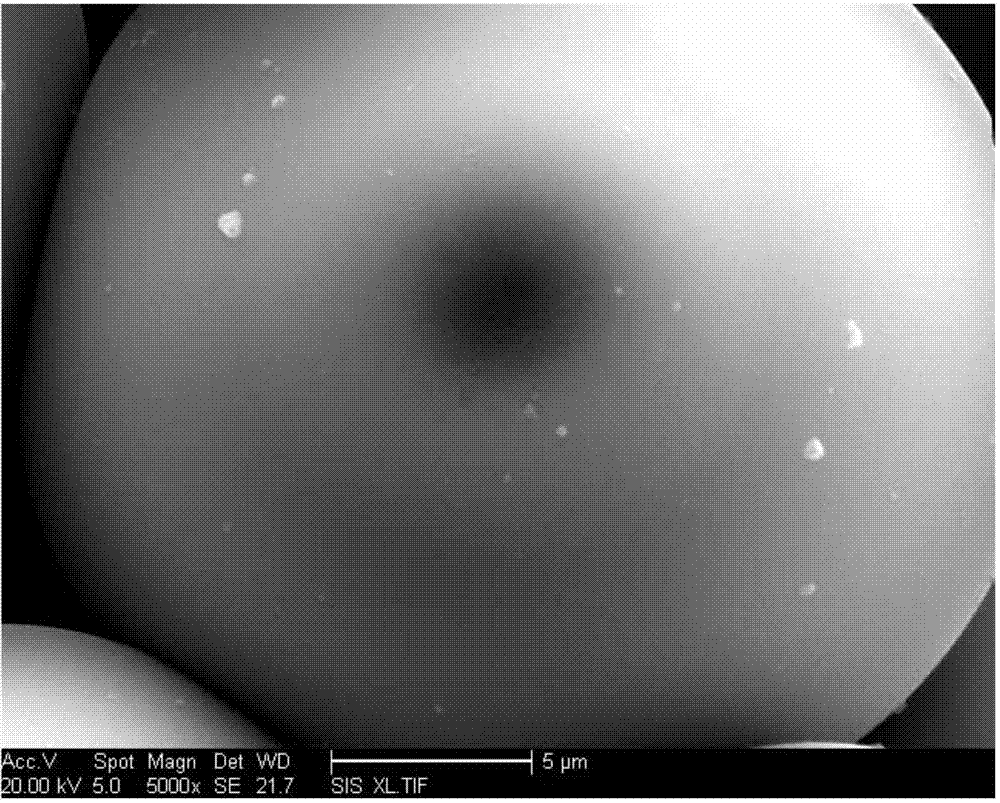

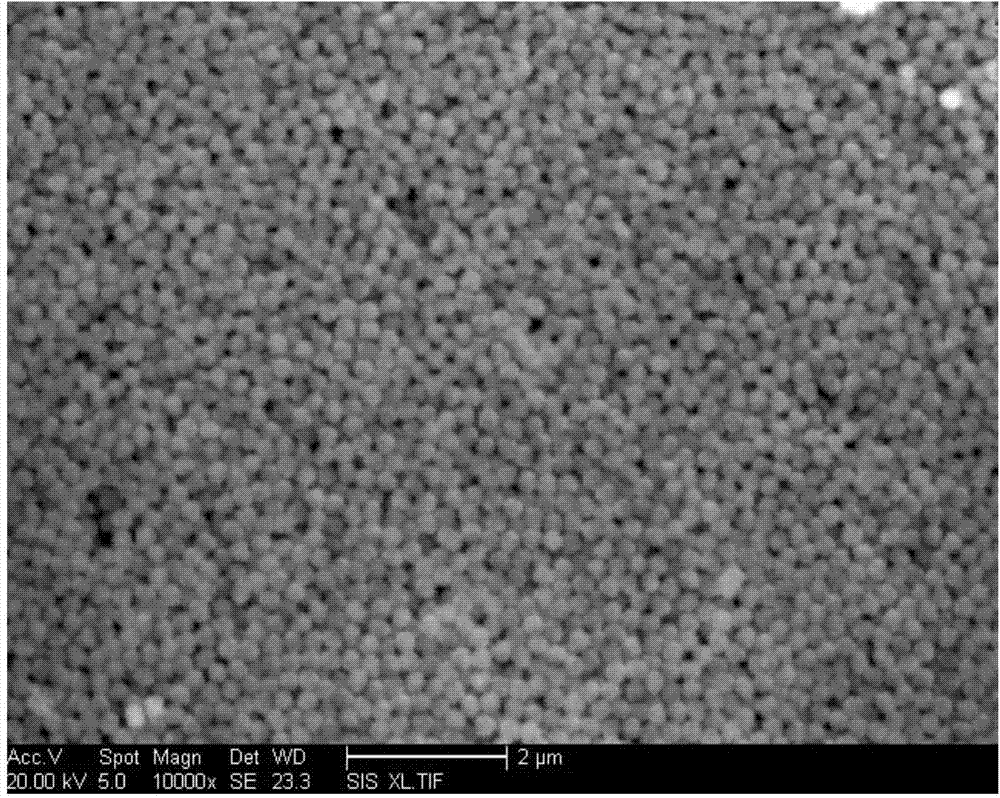

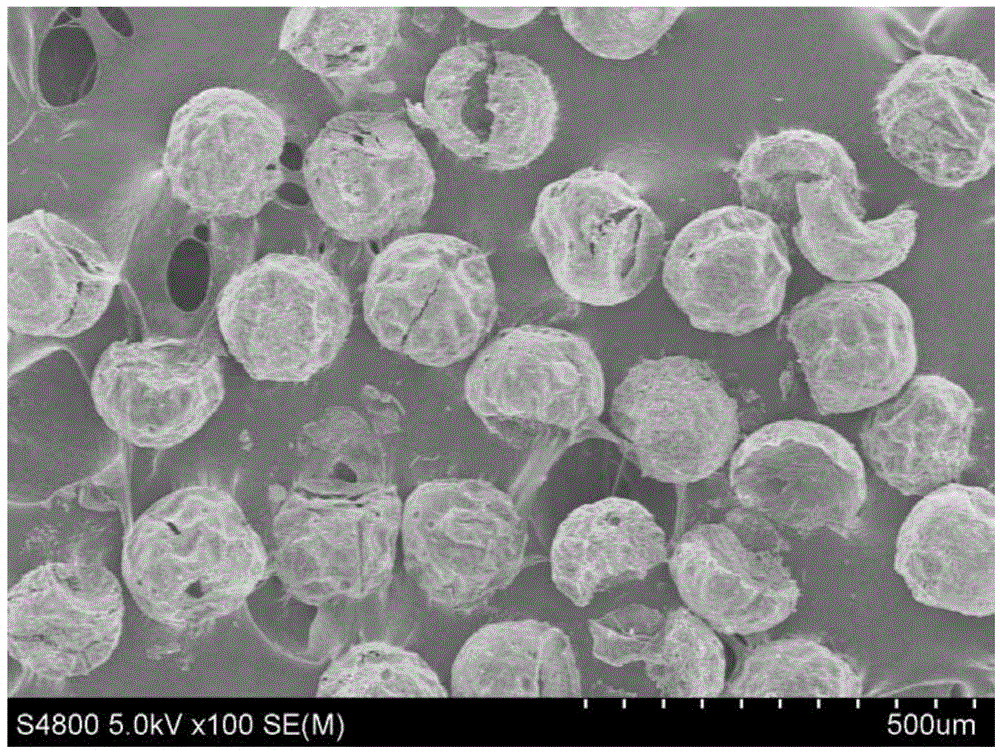

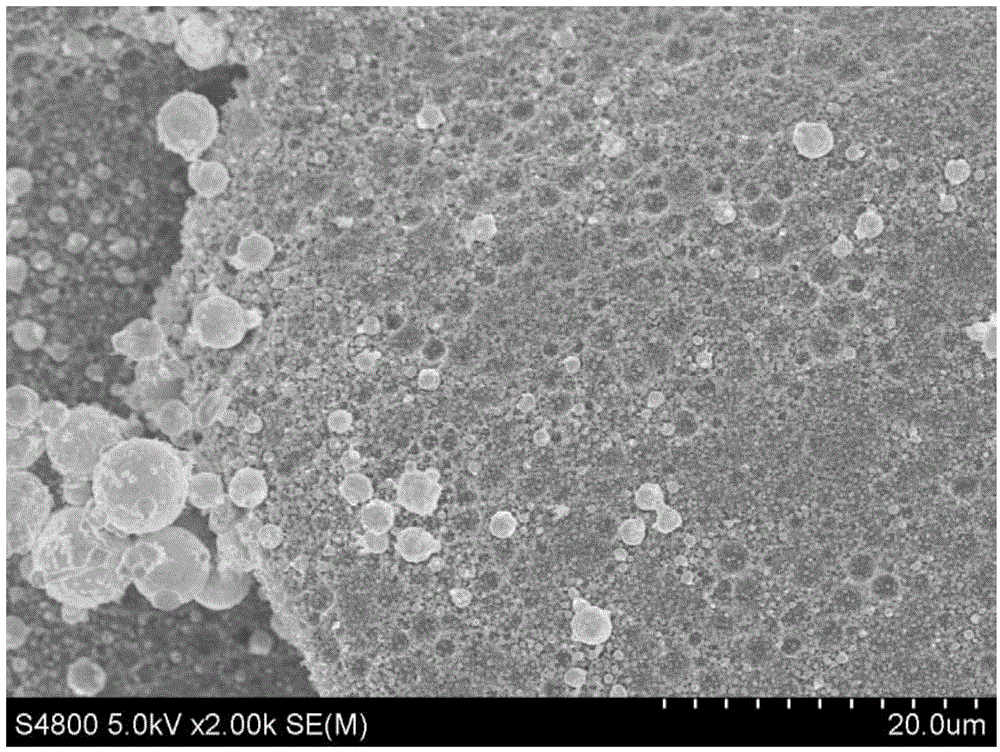

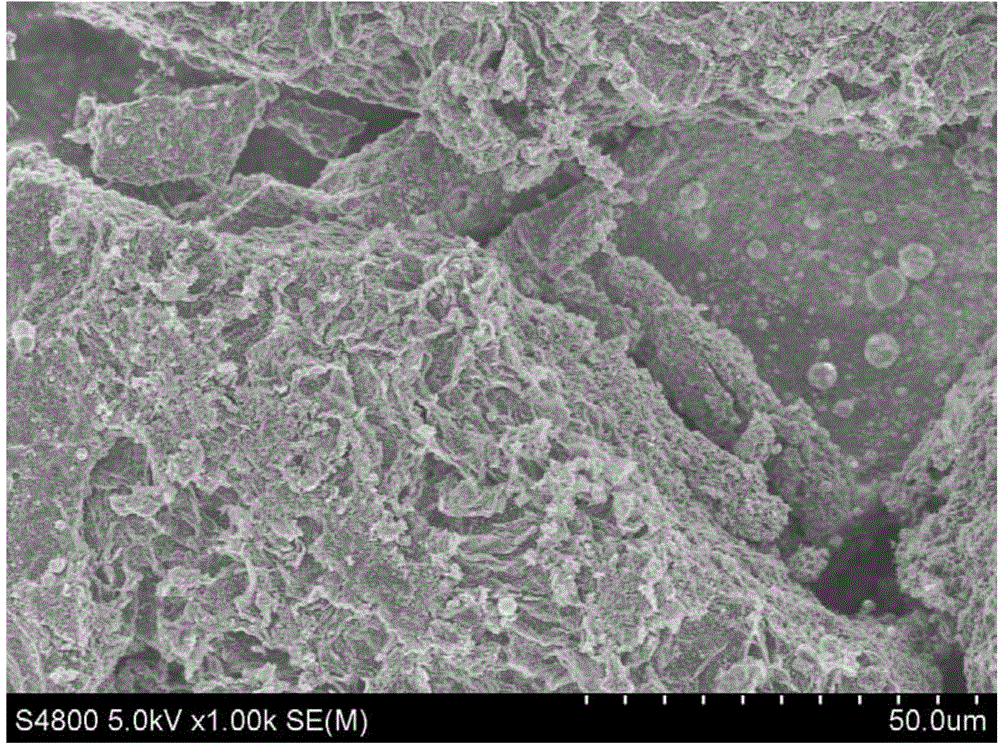

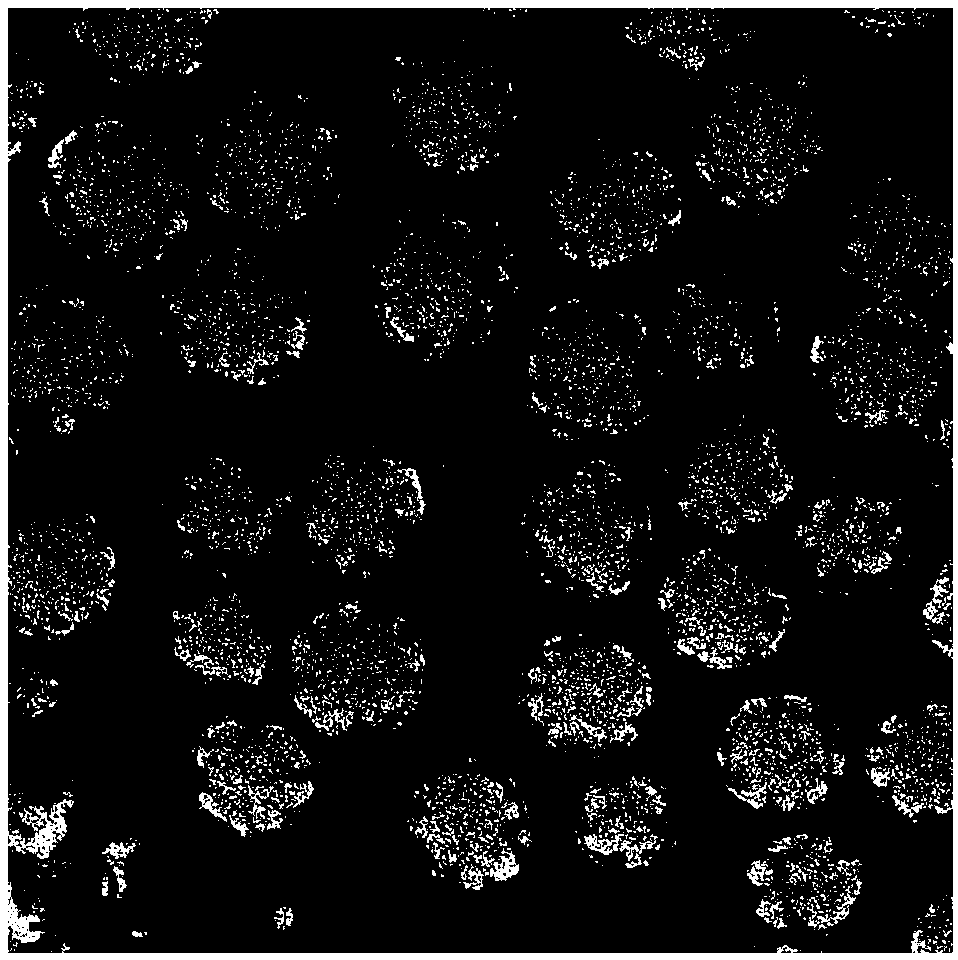

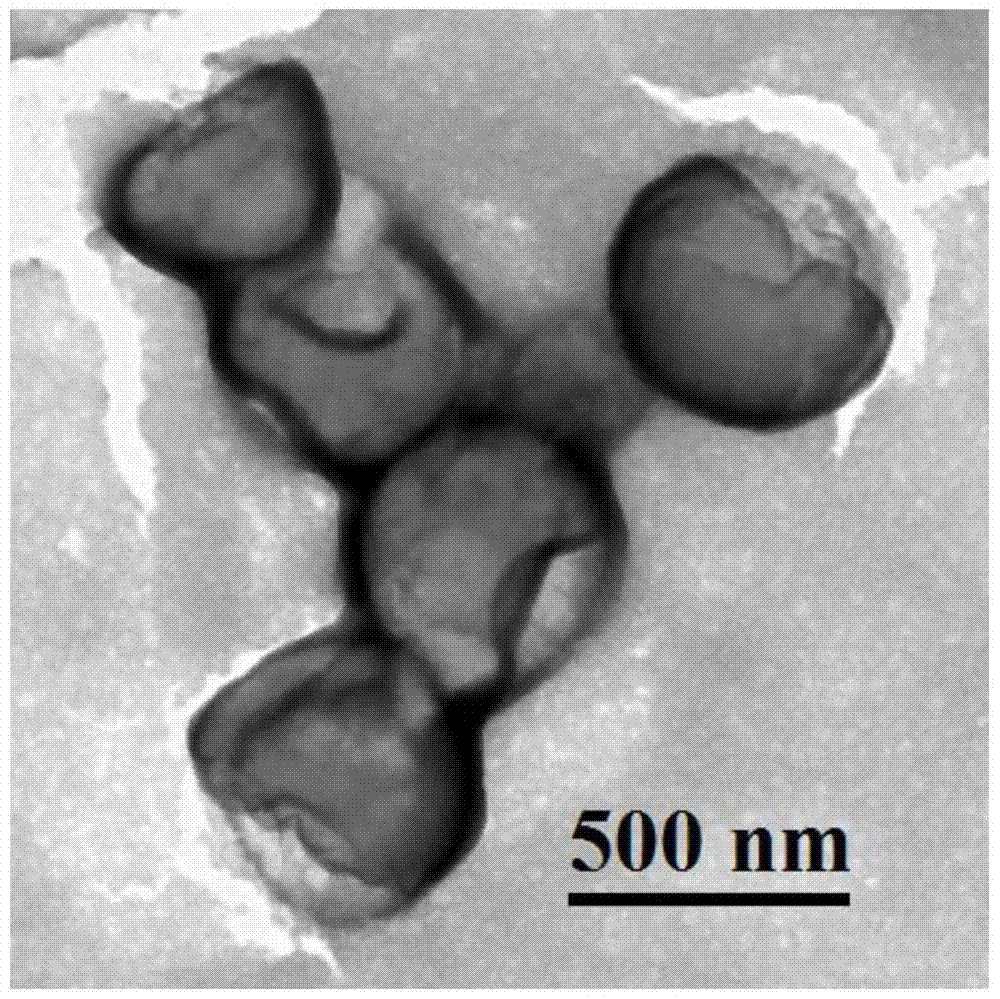

Preparation method of nitrogen-doped porous carbon microsphere

InactiveCN104505268ALower surface energyFixed shapeHybrid capacitor electrodesCarbon preparation/purificationCapacitanceMicrosphere

The invention relates to preparation methods of porous carbon microspheres, particularly to a preparation method of a nitrogen-doped porous carbon microsphere. The preparation method of the nitrogen-doped porous carbon microsphere aims at solving the technical problem that, in the prior art, nano particles serve as hard templates to prepare porous materials to result in poor wettability and low specific capacitance in aqueous electrolytes. The method comprises raw material mixing and solution preparation, solidification, preliminary oxidation, calcinations, and silicon dioxide removal. The preparation method of the nitrogen-doped porous carbon microsphere has the advantages that sticking of composite microsphere drops to box bottom and box walls during a high-speed stirring process can be avoided and the ball shape of the composite microsphere drops can be maintained all the time; the small drops in mixed liquid can solidify quickly and evaporation of water in the drops can be accelerated to fix the shape of the drops within a short time; utilized electrolyte solutions achieve high wettability in carbon materials; by preparing the porous carbon microsphere through a hard template method, the specific surface area of the carbon materials can be increased, and the preparation process is simple and easy to implement and can be well applied to electrode materials for super capacitors.

Owner:HEILONGJIANG UNIV

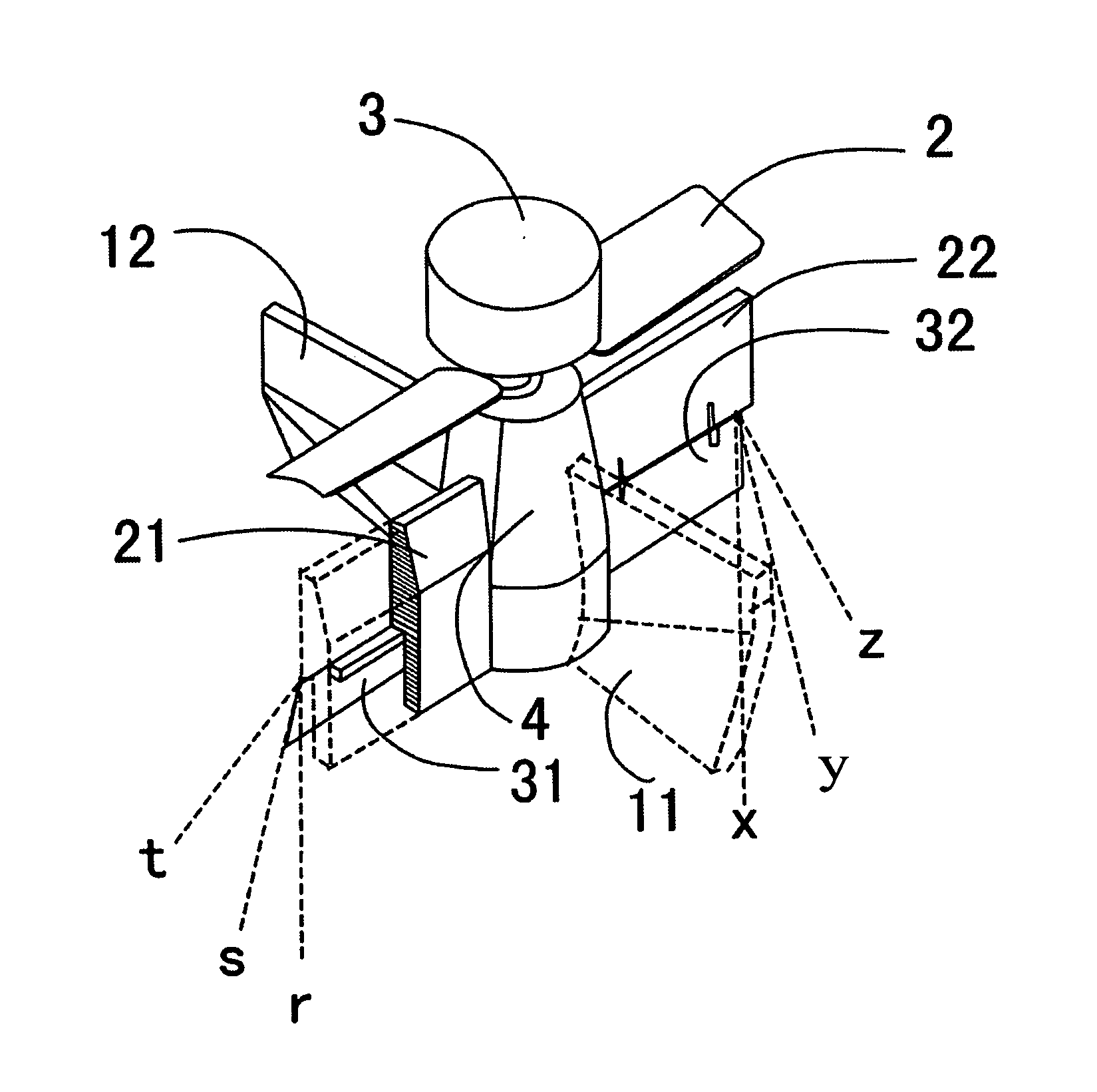

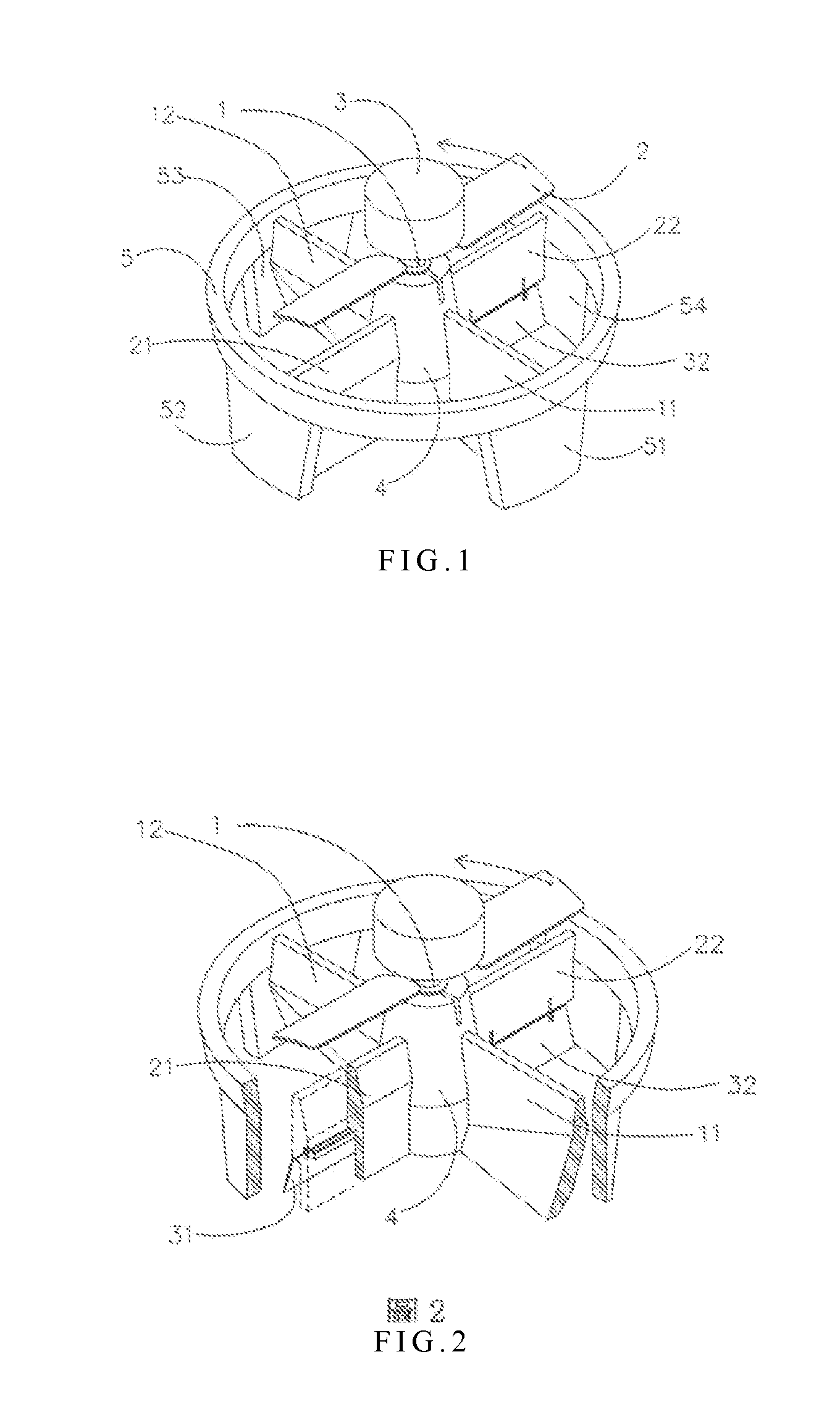

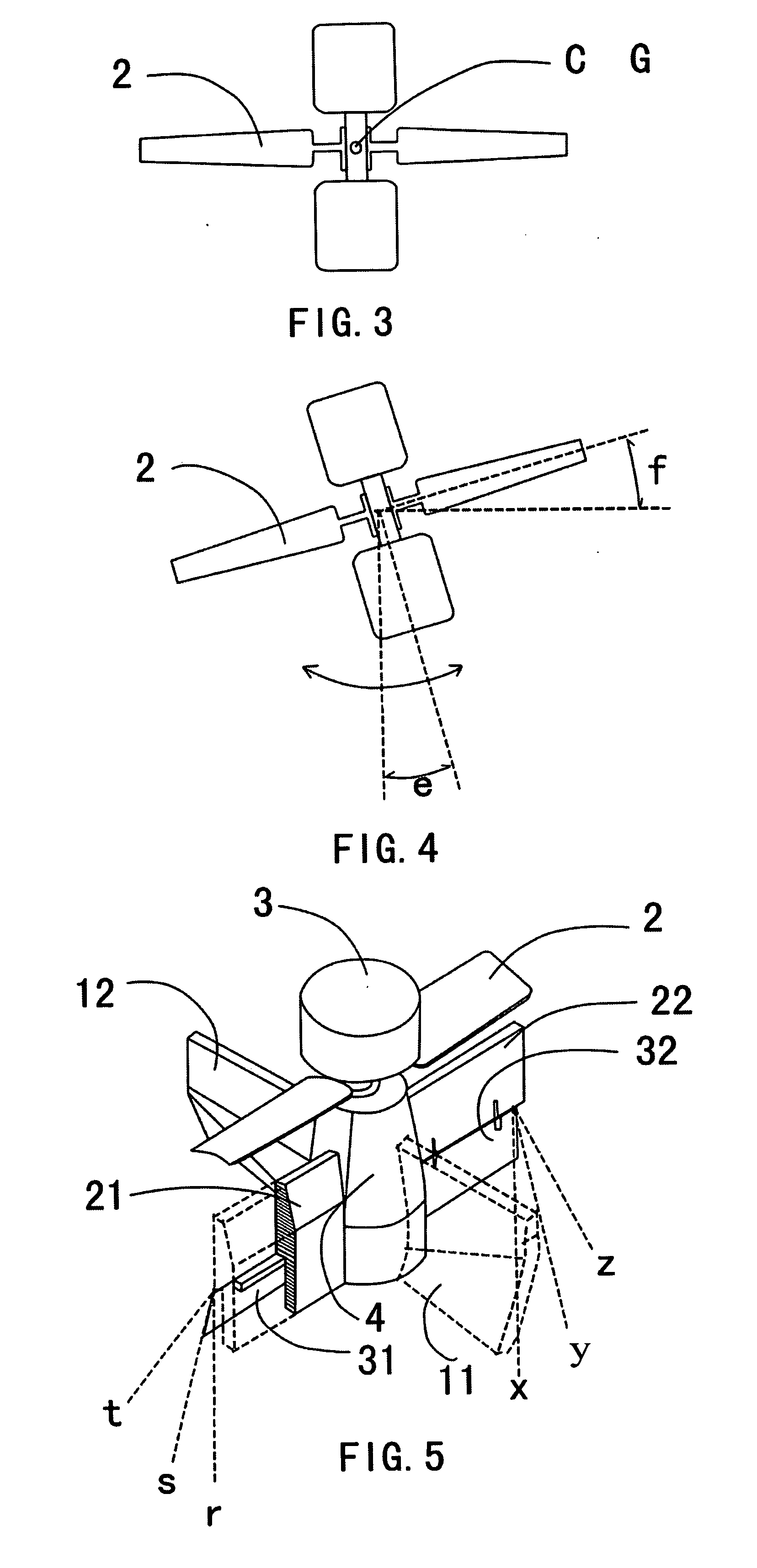

Bottom Blade Type Vehicle

InactiveUS20110024553A1Complex structureDecrease in power efficiencyUnmanned aerial vehiclesMicro-sized aircraftEngineeringElectrical and Electronics engineering

A bottom blade type vehicle includes a fixed screw-pitch leaf horizontally mounted taking a center axis as the center; a power part mounted above the leaf; a controlling part mounted under the leaf; a first and a second fixing plates and a first and a second protecting plates being crossed each other in a cross-shape taking the controlling part as the center, one end of the first and the second fixing plates and the first and the second protecting plates connected to the controlling part and the other end of them connected to a round frame; a bridge plate vertically fixedly mounted under the round frame; and a first and a second adjusting controlled by a controlling device of the controlling part, wherein the first and the second adjusting blades are mounted on the first and the second protecting plates respectively.

Owner:HANLEY CHINA +1

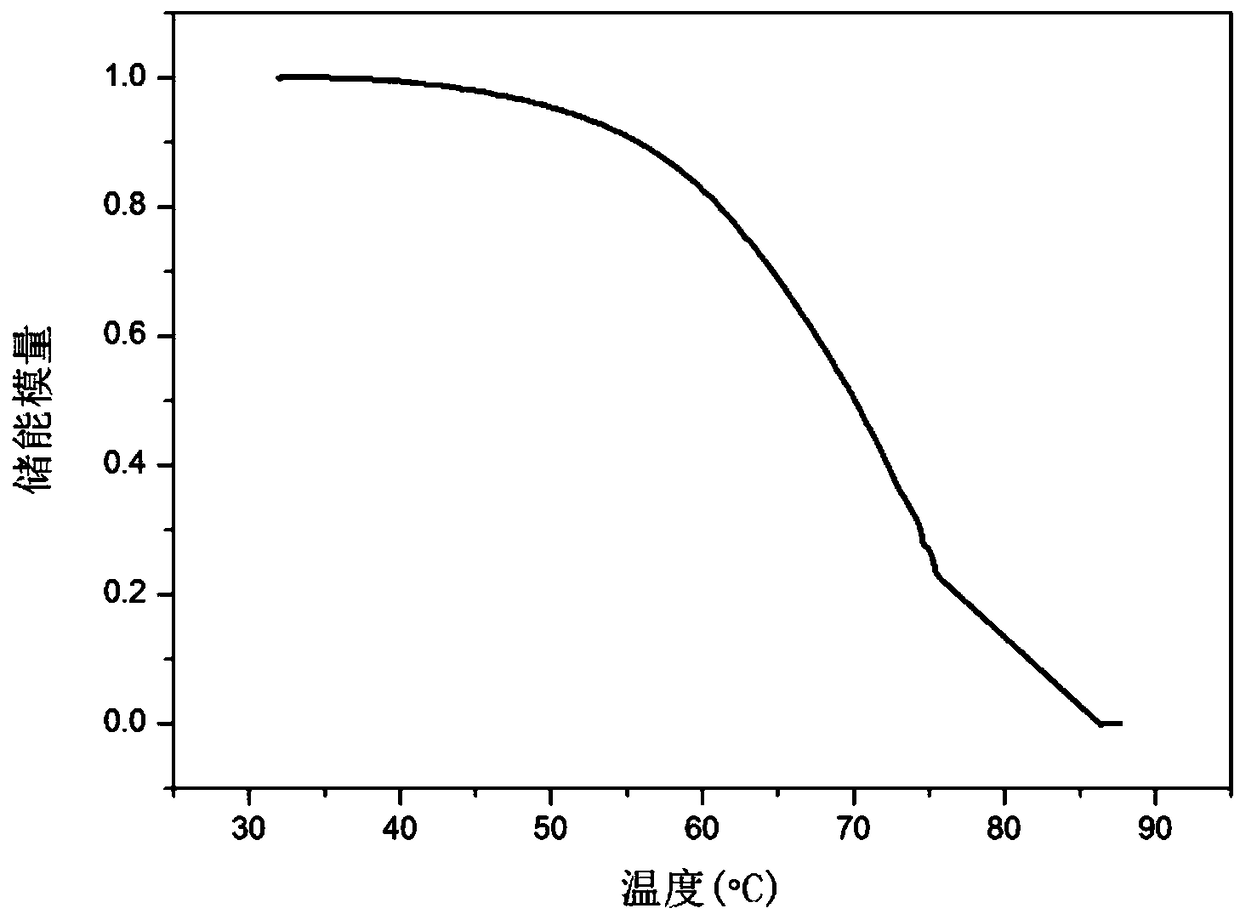

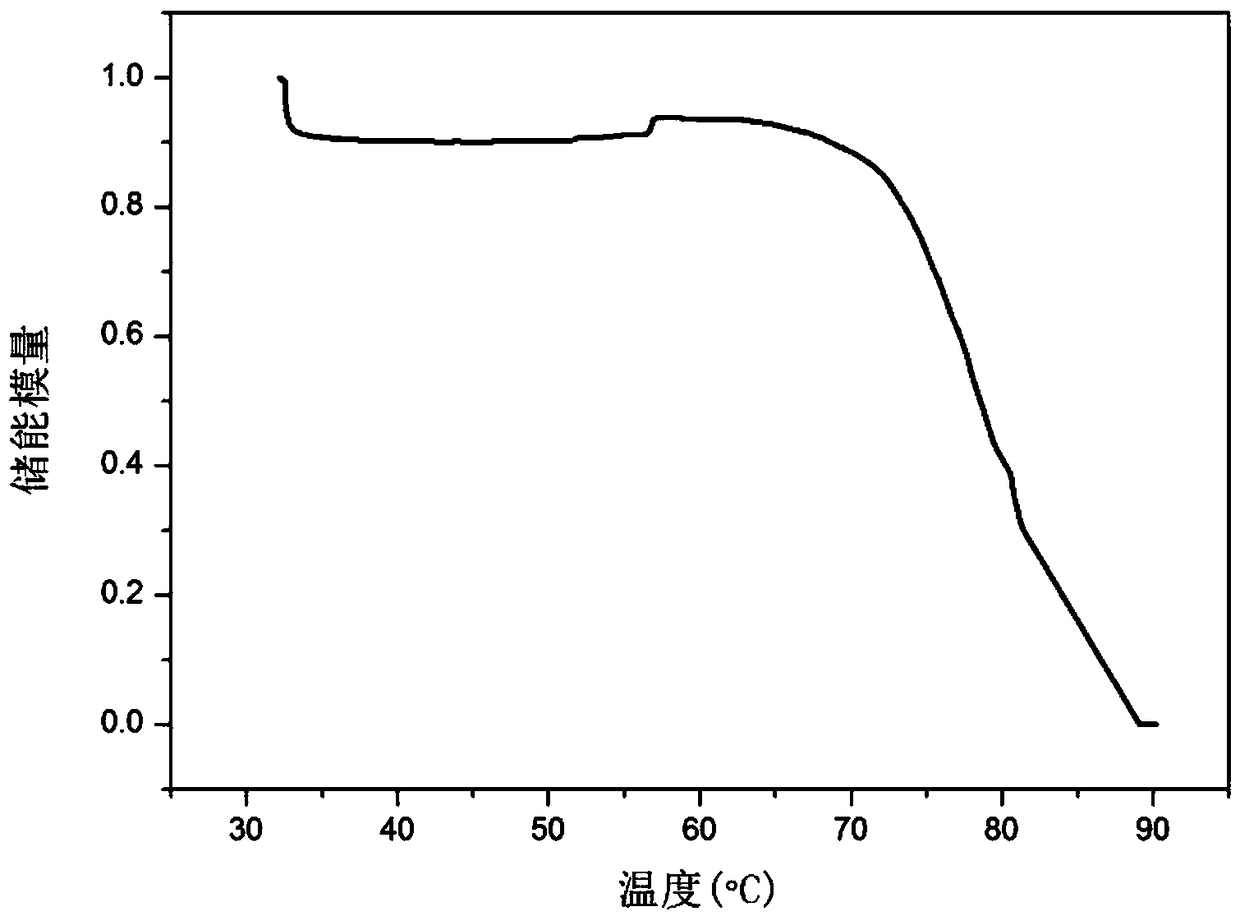

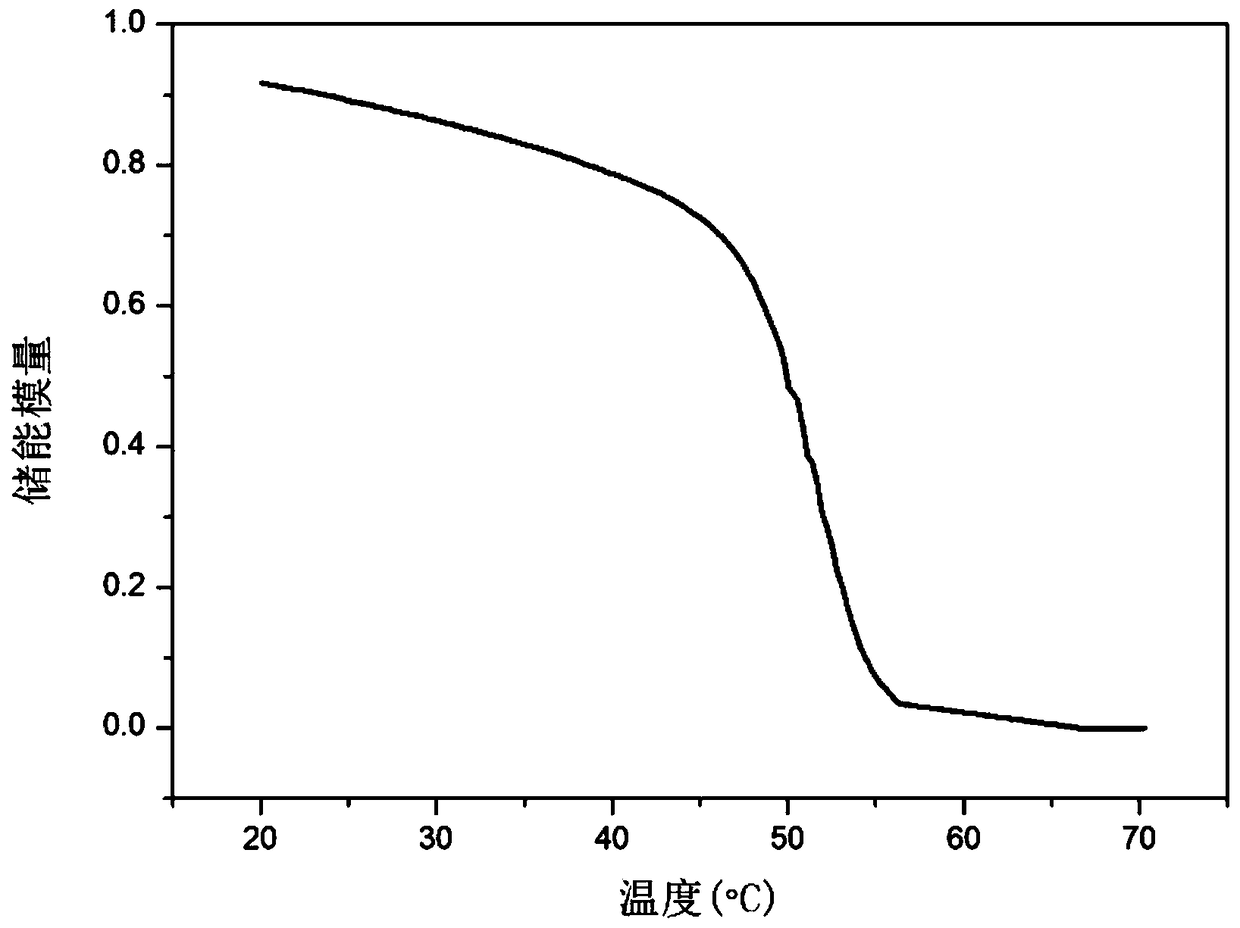

Polymer system and preparation method thereof

The invention belongs to the technical field of polymer materials and particularly relates to a polymer system and a preparation method thereof. The polymer system comprises polyol, a boron-containingcrosslinking agent and a pH regulator, wherein polyol contains at least two diol structural fragments, one boron atom in the boron-containing crosslinking agent directly bonds with one carbon atom atmost, and borate bonds are formed by the diol structural fragments in polyol and boron in the boron-containing crosslinking agent; glass-transition temperature of the polymer system is higher than plasticizing temperature. The polymer system can meet use requirements of different occasions because the glass-transition temperature of the polymer system can be adjusted in a larger range by polyol.

Owner:SHENZHEN LEBOND TECH CO LTD

Dustproof and waterproof multipurpose LED-light power source assembly and dustproof and waterproof LED light

InactiveUS9476581B2Improve stabilityExtended service lifePlanar light sourcesPoint-like light sourceEngineeringLED lamp

A dustproof and waterproof multipurpose LED-light power source assembly comprises a heat sink, a heat-dispersal fan, a circuit board driver module, an LED light source module, a power-source casing top cover and a power-source casing bottom cover. The LED light source module comprises plural LED chips and an LED heat-dispersing substrate. The heat-dispersal fan is a dustproof and waterproof fan. The heat sink comprises a baseboard to which the LED heat-dispersing substrate is fixedly connected and conducts dispersed heat. At the center of the top of a heat-dispersal member, a space is provided to accommodate the heat-dispersal fan. The power-source casing bottom cover is positioned above the heat-dispersal fan and is fixedly connected to the heat sink. The power-source casing top cover and the power-source casing bottom cover are hermetically connected one to the other. A waterproof bolt assembly is connected to the top of the power-source casing top cover.

Owner:NANKER GUANGZHOU SEMICON MFG

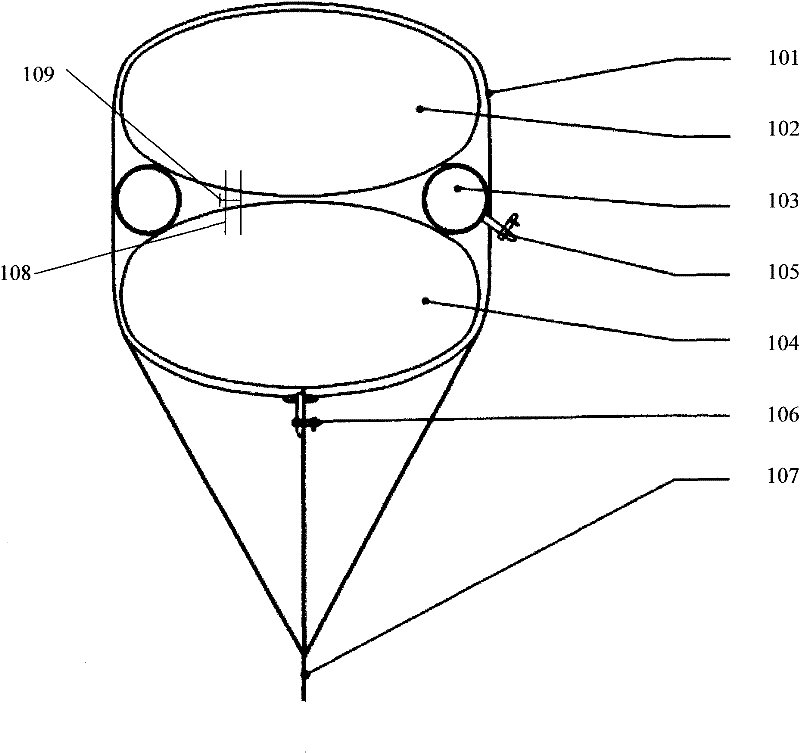

Devices for height entertainment

InactiveCN102275634AStable internal pressureFixed shapeGas-bag arrangementsInternal pressureExplosion protection

The invention provides a device for high-altitude entertainment, which belongs to the field of high-altitude entertainment. At least three gas-filled airbags are built into the cavity of the device. The device includes a barrel-shaped airbag that is filled with helium and expands with heat and contracts with cold, which is explosion-proof and flat-proof. The airbag includes a first airbag, a second airbag and a third airbag, the first airbag and the third airbag are closed airbags filled with helium gas, and the second airbag is an inflatable airbag filled with air. In the present invention, by improving the existing single airbag, the first airbag and the third airbag which are filled with light gas and closed, and the second airbag which is filled with air are set in the inner cavity of the barrel-shaped airbag, and because The second airbag is equipped with a fully automatic inflation and deflation unit to inflate or deflate according to the pressure and temperature of the air, thus ensuring that the inner pressure of the barrel-shaped airbag is stable and the shape is fixed. increased maintenance costs.

Owner:渠仁书

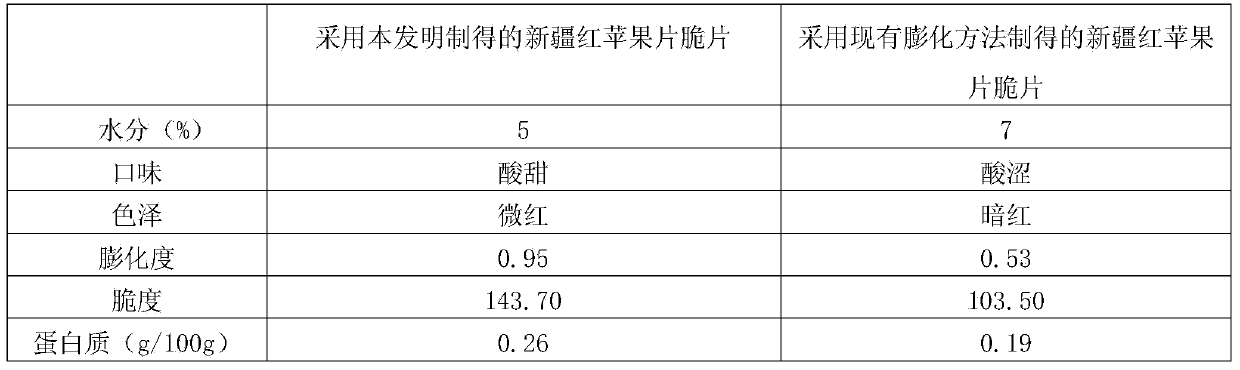

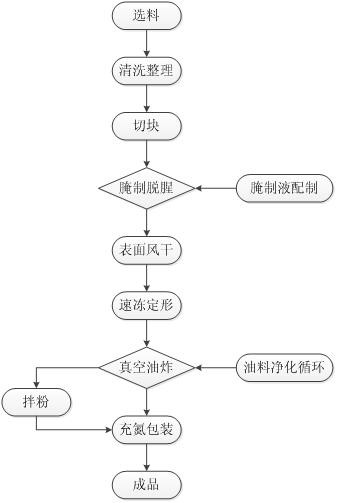

Production method of Sinkiang quarenden crisp chips

InactiveCN103766799AHigh degree of puffingWon't breakFood freezingFood thermal treatmentSugarDrying time

The invention relates to a production method of Sinkiang quarenden crisp chips. The production method comprises the following steps: performing cleaning, mechanical peeling and slicing on fresh and insect-resistant Sinkiang quarendens taken as raw materials; and performing color protection, blanching, sugar immersion, freezing treatment, primary puffing, secondary puffing, drying and cooling on the sliced Sinkiang quarendens so as to finally obtain the Sinkiang quarenden crisp chips. According to the production method of Sinkiang quarenden crisp chips, the technology of the combination of the primary puffing and the secondary puffing is adopted, so that the diffusion of water in the Sinkiang quarenden chips is accelerated; the puffing degree of the Sinkiang quarenden chips is enhanced, the drying time is shortened, the crisp degree of the Sinkiang quarenden crisp chips is improved. The primary puffing and the secondary puffing are both carried out by simultaneously performing the heating from the front end and the rear end of a heater in a puffing tank, so that the situation that materials are unevenly heated in the original puffing tank is overcome. As a result, the product yield of the Sinkiang quarenden crisp chips is improved, namely, the product yield can reach 98%; the color and the luster of the Sinkiang quarenden crisp chips are improved.

Owner:JINAN INST OF FRUIT PRODS CHINA GENERAL SUPPLY & MARKETING COOP

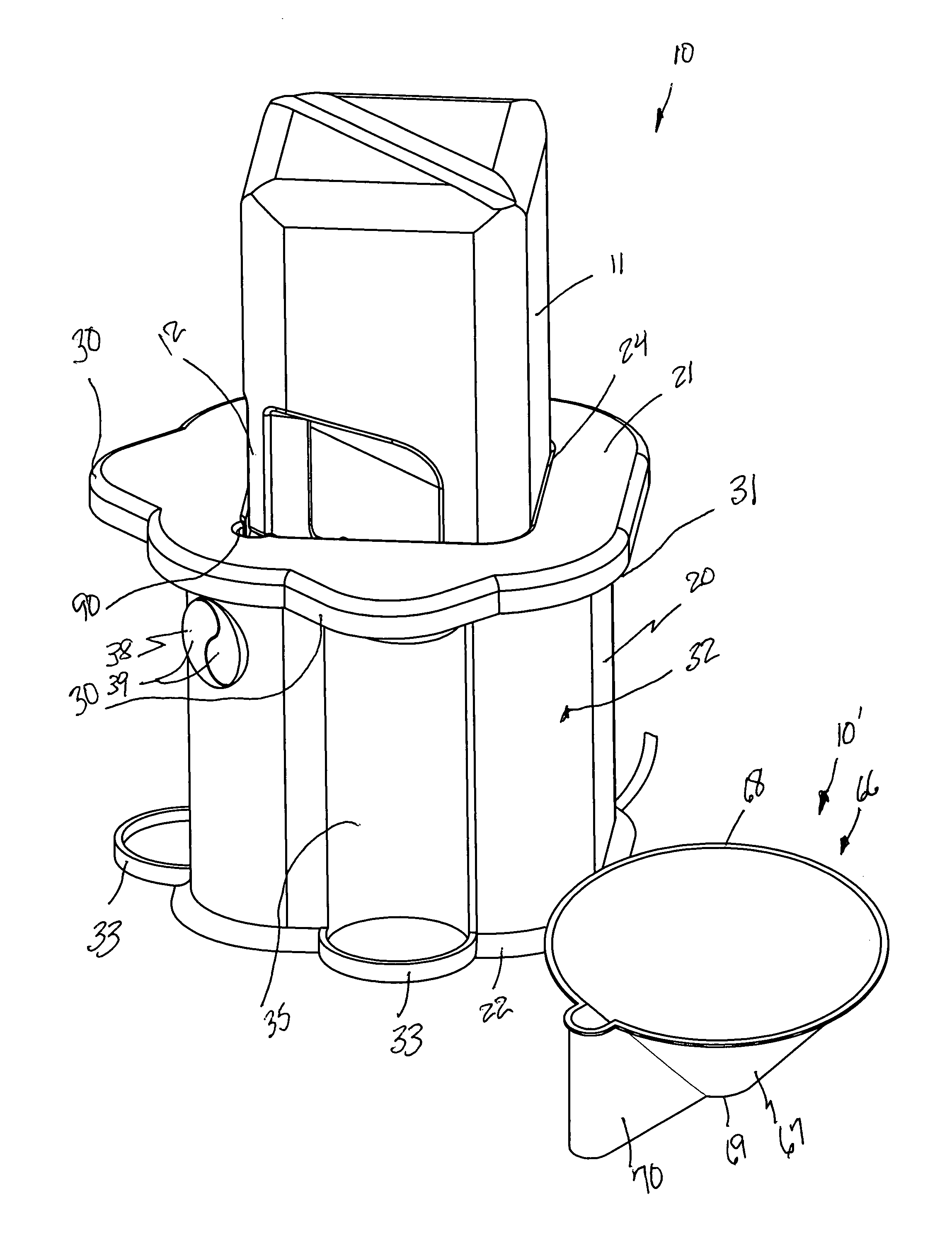

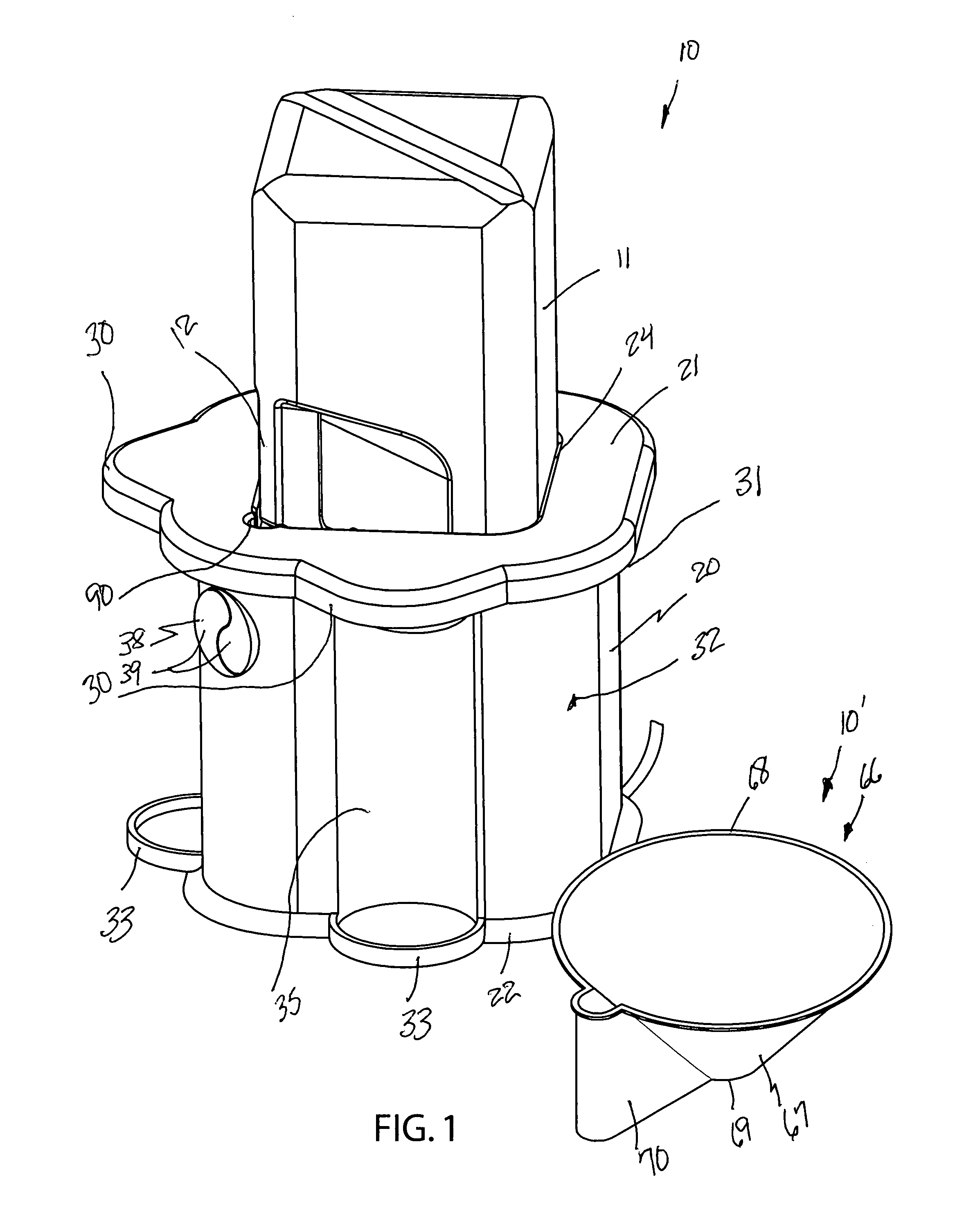

One-gallon hot and cold water dispenser and associated method

InactiveUS8025185B1Maintain it shapeFixed shapeDomestic cooling apparatusLighting and heating apparatusPatent applicationWater bottle

A hot and cold water dispenser includes a base unit that has an open top end and a closed bottom end respectively. The base unit is formed from rigid material such that the base unit maintains a fixed shape when a traditional one gallon, square shaped bottle typically sold at supermarkets and other retail outlets (referred throughout the patent application as an “existing one-gallon water bottle”) is positioned therein. A mechanism heats and cools water contained within the base unit, and is housed within the base unit. A mechanism dispenses the heated and cooled water, and is housed within the base unit and directly connected to the heating and cooling mechanism.

Owner:STEPHANS JACK

Preparation method for palladium/three-dimensional graphene composite microspheres

InactiveCN104525190ALower surface energySpeed up evaporationCell electrodesMetal/metal-oxides/metal-hydroxide catalystsMicrosphereCvd graphene

The invention relates to a preparation method for composite microspheres, in particular to a preparation method for palladium / three-dimensional graphene composite microspheres. The preparation method for the palladium / three-dimensional graphene composite microspheres solves the technical problems that existing preparation methods for the palladium / three-dimensional graphene composite microspheres are complicated and are not suitable for industrial large-scale production. The preparation method comprises the following steps that firstly, raw materials are mixed to prepare a solution; secondly, solidification and forming are conducted; thirdly, calcination is conducted. The preparation method for the palladium / three-dimensional graphene composite microspheres has the advantages that the method is novel and unique, operation is easy, the process is safe, reliable and environmentally friendly, the obtained palladium / three-dimensional graphene composite microspheres are controllable in size and uniform in particle size, the preparation method is one of the ideal preparation methods for the palladium / three-dimensional graphene composite microspheres, and the preparation method is suitable for industrial large-scale production.

Owner:HEILONGJIANG UNIV

Method for producing one-piece compressed hard glass fish collecting lamp bulb shell

InactiveCN102249517AGood consistencyBlister shape fixedGlass blowing apparatusHigh intensityGraphite

The invention discloses a method for producing one-piece compressed hard glass fish collecting lamp bulb shell. The method comprises the following steps of: (1) selecting the specific size of a standard bulb shell to design the scheme of forming dies in advance, wherein in die materials, graphite or high-strength heat-resisting alloy can be used as blanks; (2) designing the bulb shell dies; (3) designing the two dies which have the same size, and forming feed holes with the diameters of between 30 and 50 millimeters uniformly at the upper ends of the two dies, wherein the two dies can be opened or closed under the mechanical control; (4) blanking hard glass melts continuously from a blanking opening and melting in a hard glass electric kiln at the high temperature of 1,200 DEG C, and conveying the hard glass melts into the dies directly from the feed holes of the dies; (5) after the hard glass melts are conveyed into the dies from the feed holes of the dies, introducing compressed air from the feed holes of the dies, and blowing; and (6) opening the dies, and cooling slowly to form the fish collecting lamp bulb shell. The method has the advantages that: the lamp bulb shell is fixed in a shape, uniform in outer diameter and wall thickness, standard in length and high stability and consistency; a large number of glass materials are saved; and the cost is reduced.

Owner:周玉春

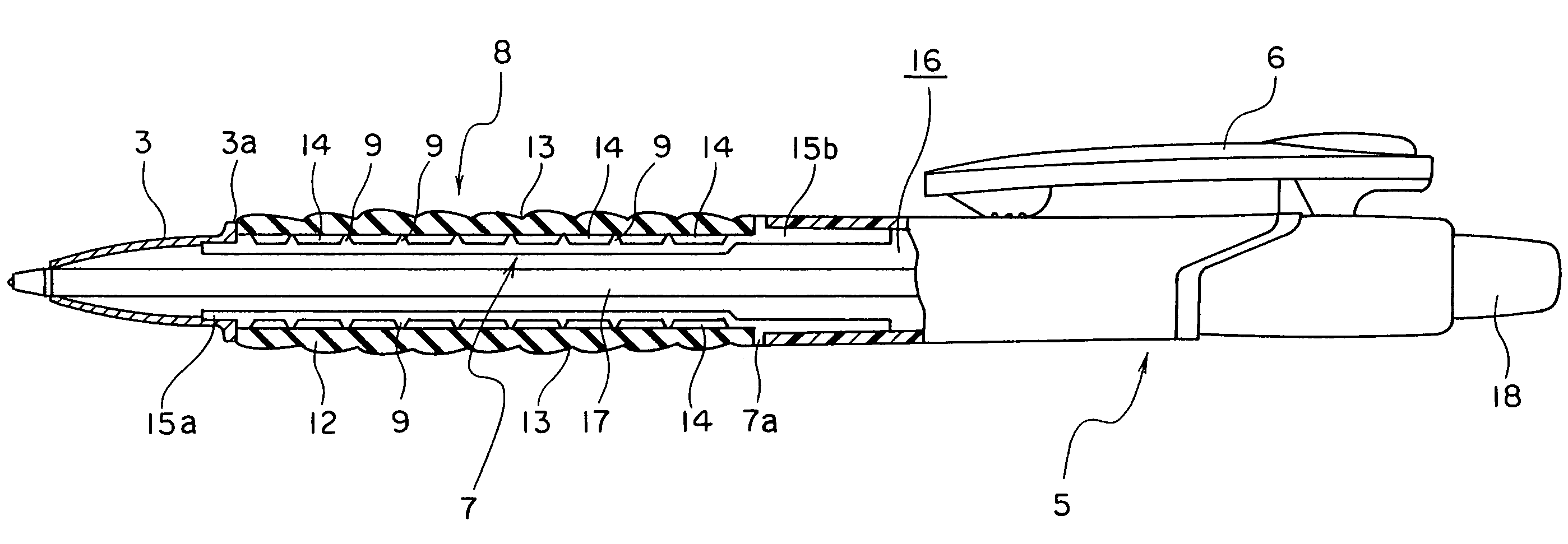

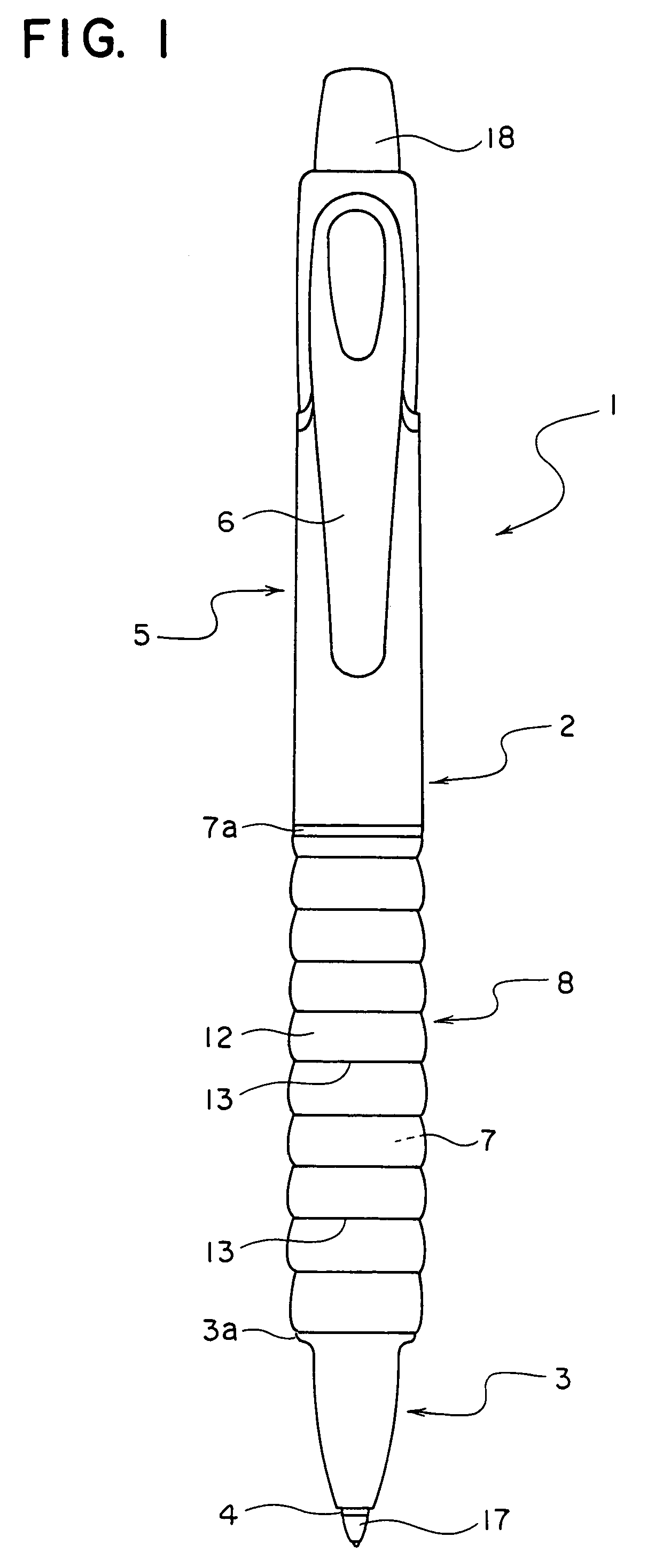

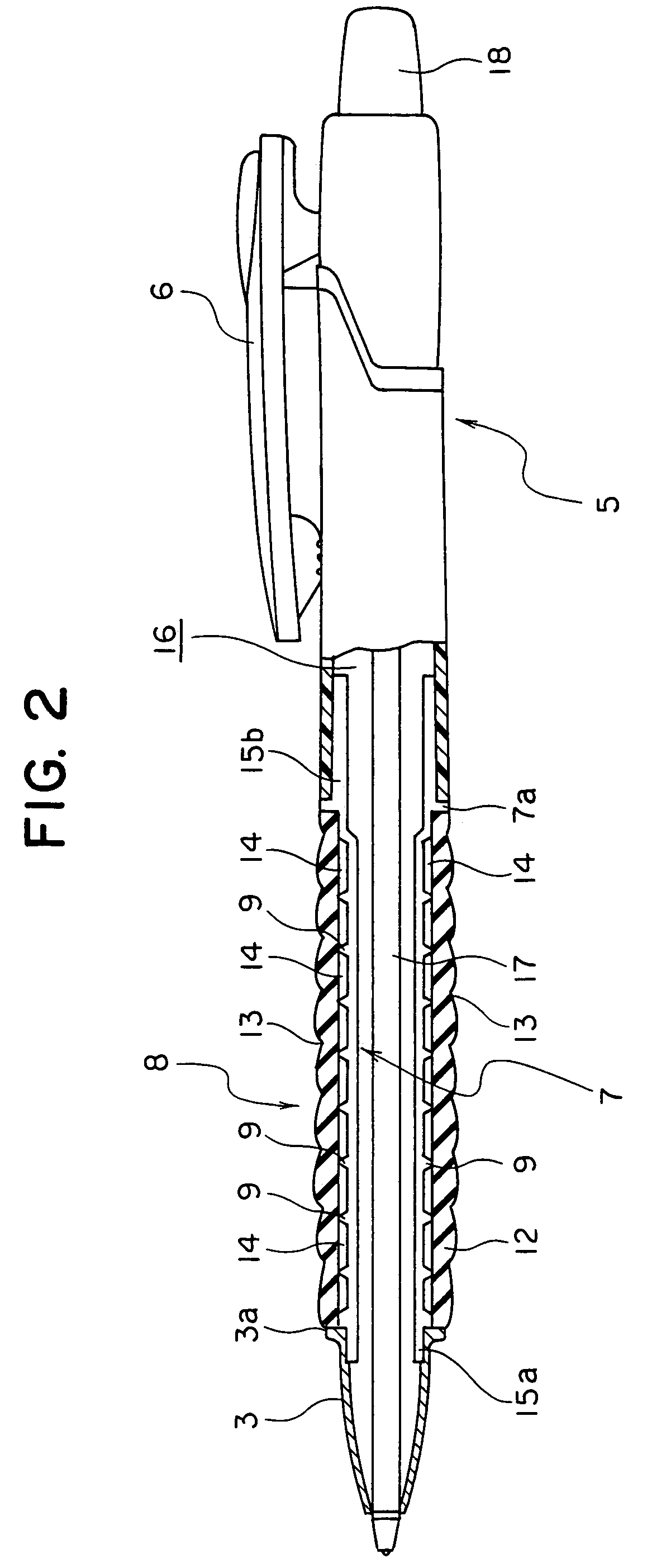

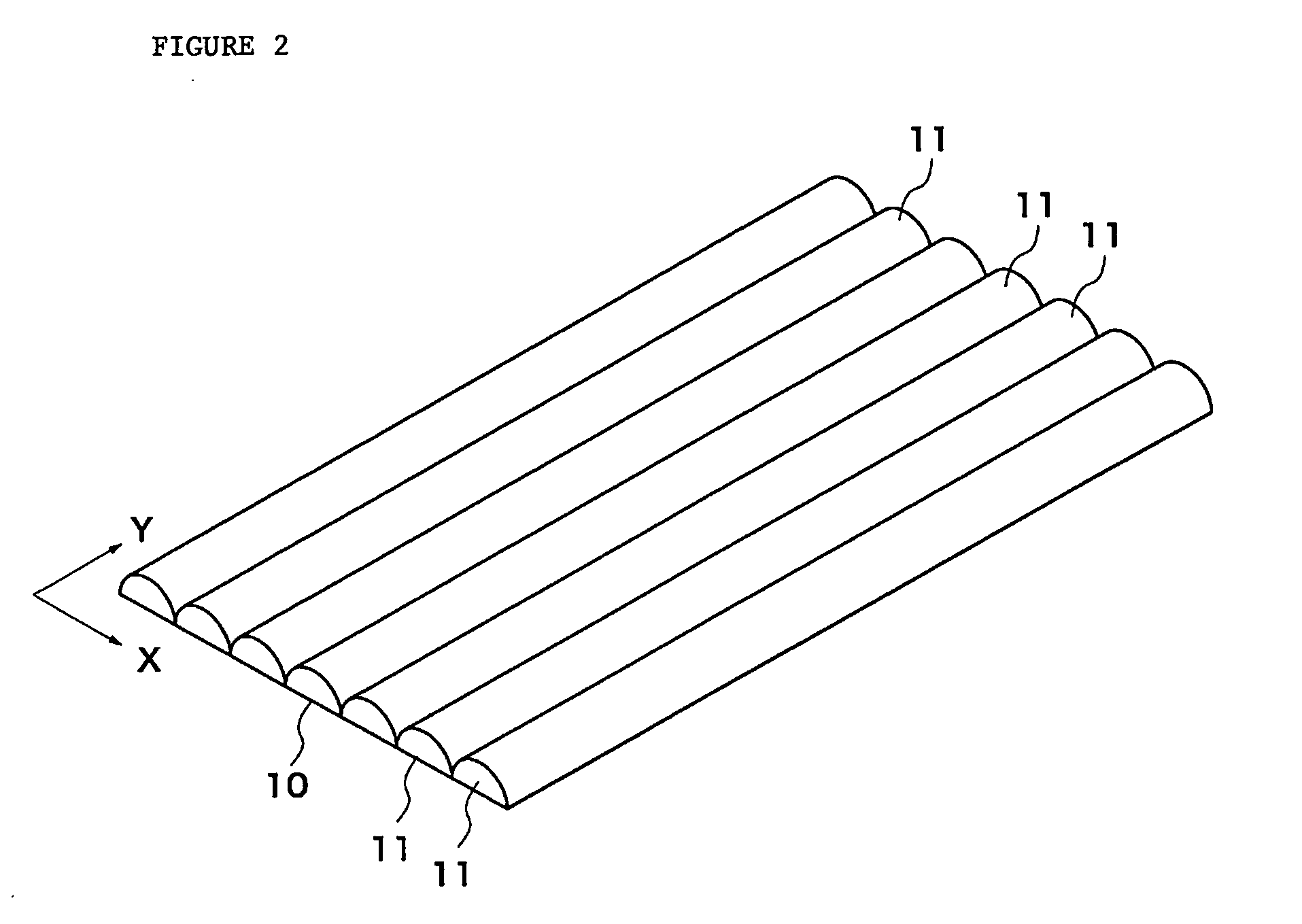

Grip of writing material

InactiveUS7241064B2Easy to transformReduce the burden onWriting connectorsBrush bodiesMedial axisEngineering

A grip of a writing material is formed by providing a plurality of flange-like on a surface of a middle shaft portion of a shaft cylinder and in parallel across an axis of the shaft cylinder, the plurality of flange-like projections projecting in a radial direction of the shaft cylinder, and integrally covering the flange-like projections with a cylindrical cover in a closable manner so that spaces are formed inside the cover. When a user grips the grip of the writing material with his or her fingers, the pressure allows the cover to be borne by the adjacent flange-like projections, while moving air inside the spaces to deform the cover. The deformation absorbs the pressure from the fingers. Further, the adjacent flange-like projections limits the deformation of the cover, thus enabling the initial positional relationship of the fingers to be maintained. The user can thus use the writing material for a long time.

Owner:PLATINUM PEN

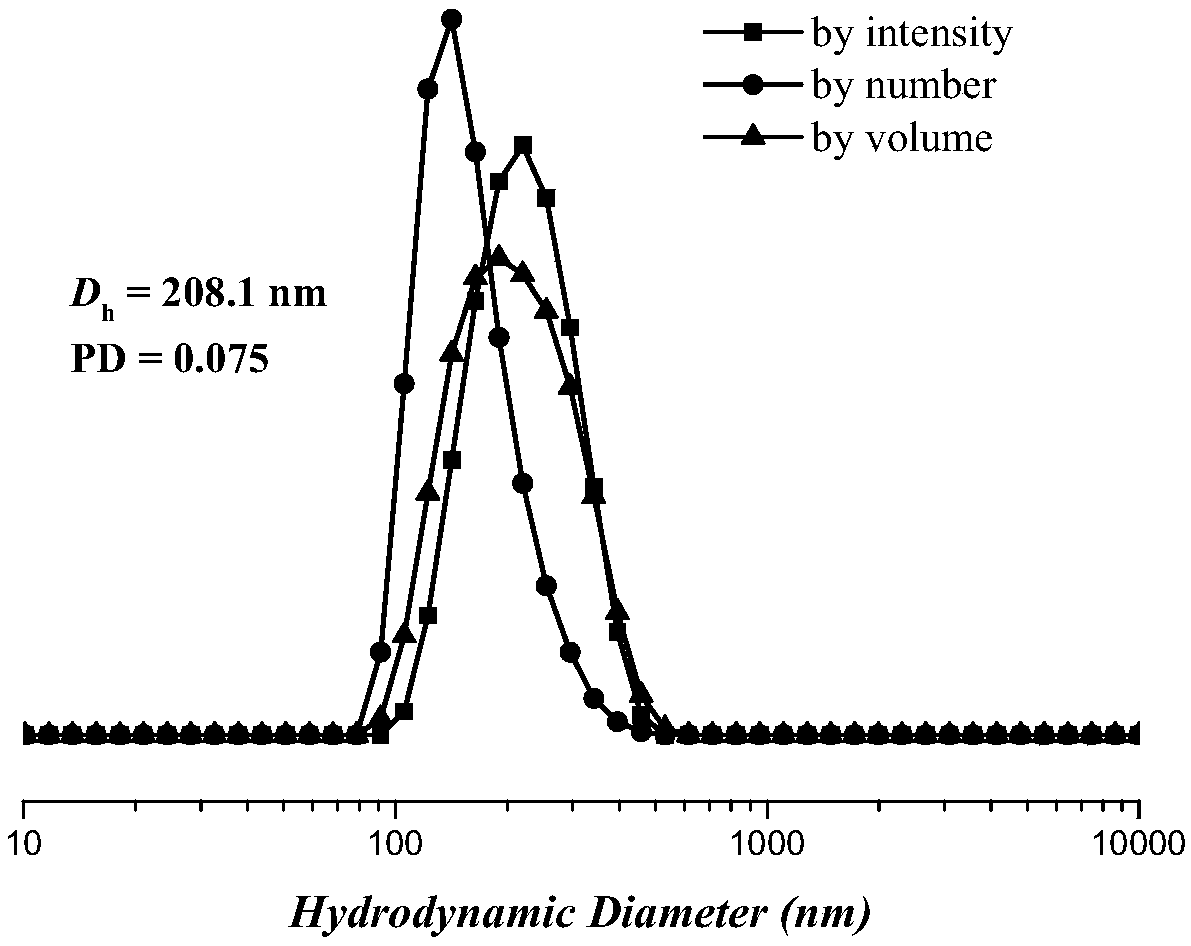

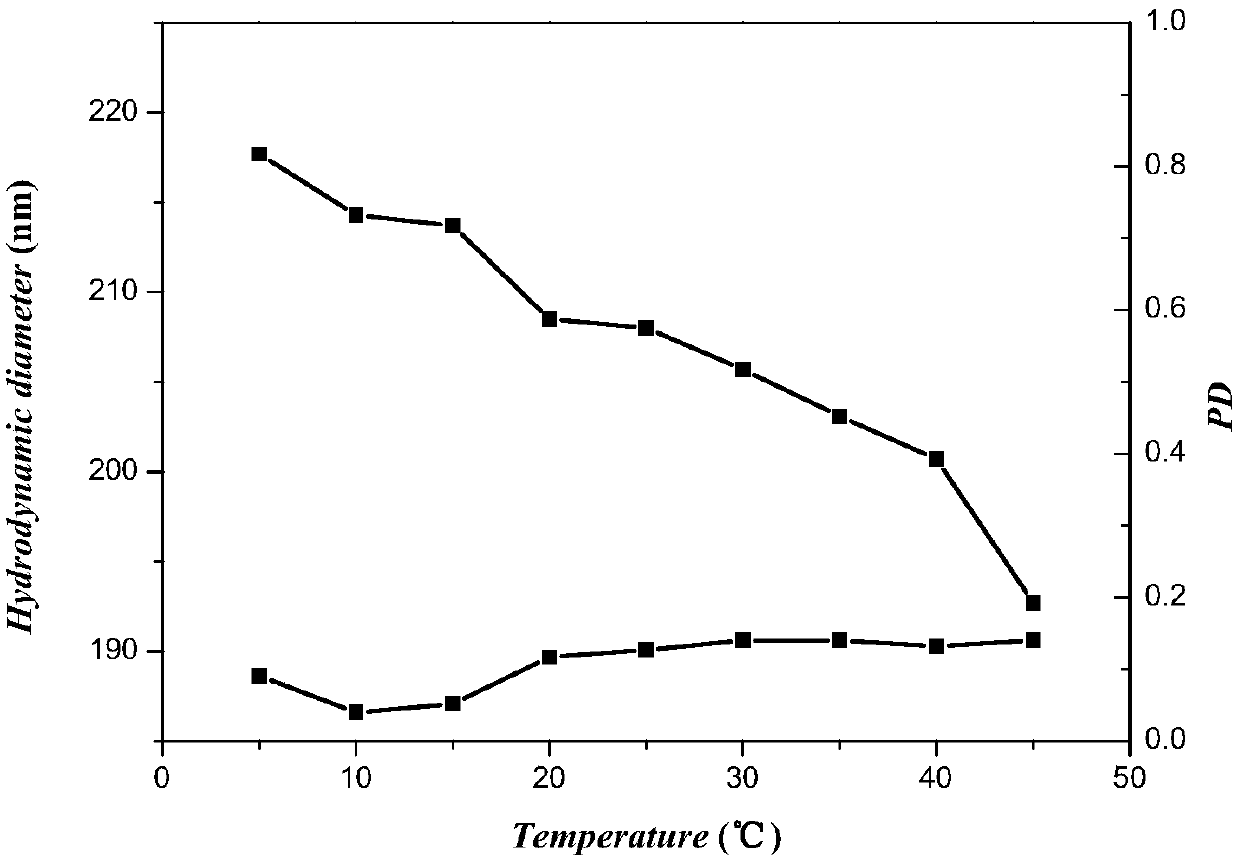

Thermosensitive polymer vesicle and preparation method and application thereof

ActiveCN109620965APromote proliferation and differentiationEasy to rebuildDigestive systemPharmaceutical non-active ingredientsBiotin-streptavidin complexPeriodontal ligament stem cells

The invention relates to a thermosensitive polymer vesicle and a preparation method and an application thereof. The thermosensitive polymer vesicle includes a vesicle body assembled by amphiphilic thermosensitive block-containing polymers, and a biotin-modified Biotin-CD146 monoclonal antibody and streptavidin (SA) targeting to periodontal ligament stem cells (PDLSCs) and combined on the vesicle body. The thermosensitive polymer vesicle can be used as a hydrogen sulfide vector for application. Compared with the prior art, the thermosensitive polymer vesicle has the PDLSCs targeting property, can improve the proliferation and differentiation ability of the PDLSCs, promotes periodontal tissue remodeling under an inflammation environment, improves the orthodontic curative effect and safety inan inflammation state, and provides technical support for clinical application of gas molecules.

Owner:TONGJI UNIV

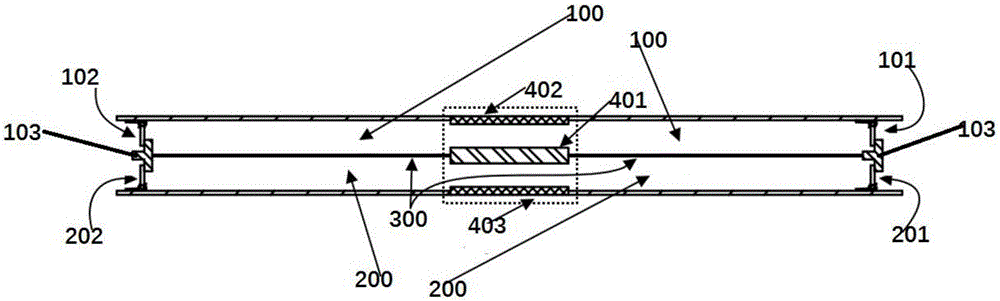

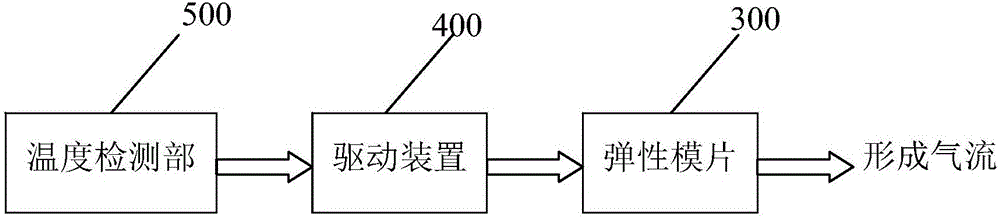

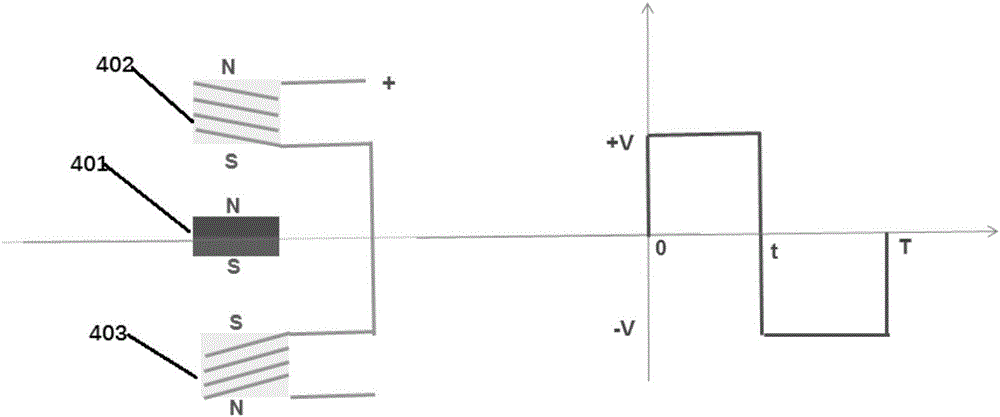

Cooling device and electronic device

InactiveCN106686955ASimple structureFixed shapeCooling/ventilation/heating modificationsElastic membraneAirflow

The invention provides a cooling device and an electronic device. The cooling device comprises a first chamber, a second chamber and a drive device for driving an elastic membrane to vibrate, wherein the first chamber and the second chamber are spaced apart through the elastic membrane; and the drive device is arranged to form intake airflow in one of the first chamber and the second chamber and to form outlet airflow in the other chamber separately through driving alternate vibration of the elastic membrane in two opposite directions. The cooling device and the electronic device have the characteristics that the structures are simple and continuous air can be provided.

Owner:HEFEI LCFC INFORMATION TECH

Method for manufacturing slippery-proof foam materials having protruded threads

ActiveUS7097805B2Reduce the temperatureFixed shapeSemi-permeable membranesCeramic shaping apparatusMetallurgyThermoplastic elastomer

The present invention discloses a method for manufacturing slippery-proof foam materials having protruded threads, which comprises the steps of foaming Thermoplastic Elastomer (TPE) or EVA pellets into a foam material plate, attaching a high heat resisting mesh cloth onto the surface of the plate, heating the plate by a heating device to soften the material to an extent of being suitable for a plastic formation, rolling and pressing the plate by a rolling mold or a piece of mold having an even surface and a plurality of tiny grooves thereon, so that the section of the plate receiving a larger rolling and pressing force moves towards the section receiving a smaller rolling and pressing force, and then passes through the meshes of the high heat resisting mesh cloth under the condition of being held up by the high heat resisting mesh cloth to form evenly protruded threads on the surface thereof after being cooled immediately.

Owner:MICROCELL COMPOSITE CO LTD

Boot shape maintaining body

Owner:INED BUSINESS FASHION PLANNING

Processing method of lemon-flavor duck crisp chips

The invention relates to a processing method of lemon-flavor duck crisp chips. The lemon-flavor duck crisp chips contain the following raw material components in parts by weight: 10000 parts of duck breast meat and 10000 parts of pickling liquid, wherein the pickling liquid contains the following components in parts by weight: 100 parts of cooking wine, 100-250 parts of table salt, 9-110 parts ofmonosodium glutamate, 70-85 parts of fresh ginger, 40-60 parts of green onion, 15-30 parts of anises, 20-40 parts of folia perillae acutae powder, 40-70 parts of fresh lemon slices and 8500-9500 partsof water. The processing method comprises the steps of selecting the fresh or frozen duck breast meat, carrying out cleaning, cutting the fresh or frozen duck breast meat into meat blocks, putting the meat blocks into the prepared pickling liquid for pickling, carrying out leaching, blow-drying and quick-freezing, carrying out vacuum frying on the frozen raw material, mixing the material with curry powder and spice powder, and carrying out drying, carrying out sieving by virtue of a sieving net, and carrying out packaging. By utilizing a method for combining folia perillae acutae with the lemon slices, the fishy smell of the duck meat is effectively removed, and a special flavor is brought to a product. A quick-freezing process is utilized before the vacuum frying, so that the shape of the product is fixed; moisture in intercellular spaces is acutely vaporized and swelled in the subsequent vacuum frying process, so that the form of the product is stabilized, and meanwhile, the productbecomes crispier.

Owner:JIANGSU LAOHOU ZHENQIN FOOD

Prismatic wood compression molding method and compression molding device therefor

InactiveUS6817394B2Fixed shapeEasy to manufactureWooden sticks manufactureWood compressionCompression moldingEngineering

A prismatic wood compression molding method capable of easily producing long-sized lumber usable as pillars or like by compression molding. The method is characterized by comparing the steps of: using a plurality of rigid plate-like bodies such as metal plates to compress an outer face of wood throughout length thereof to compression-mold it into prismatic wood which is polygonal, such as rectangular or hexagonal, in cross section; restraining the plate-like bodies by a restraining jig so as to hold flat surfaces of the prismatic wood in a state in which they are compressed by the plate-like bodies; and applying a heat treatment to the prismatic wood held in the compressed state by the plate-like bodies and the jig so as to permanently fix the shape of the prismatic wood.

Owner:SHINSHU UNIVERSITY +1

Portable training device

InactiveUS20170203141A1Rigid enoughFixed shapeDumb-bellsResilient force resistorsRest positionEngineering

A portable training device includes a structural component including a weighted mass; and first and second elongate arms associated with and extending symmetrically from opposite sides of the weighted mass, the arms being resiliently biased to a rest position in which the arms form a fixed, generally U-shape together with the weighted mass, the arms being universally manipulable against the bias out of the rest position.

Owner:UDURANCE

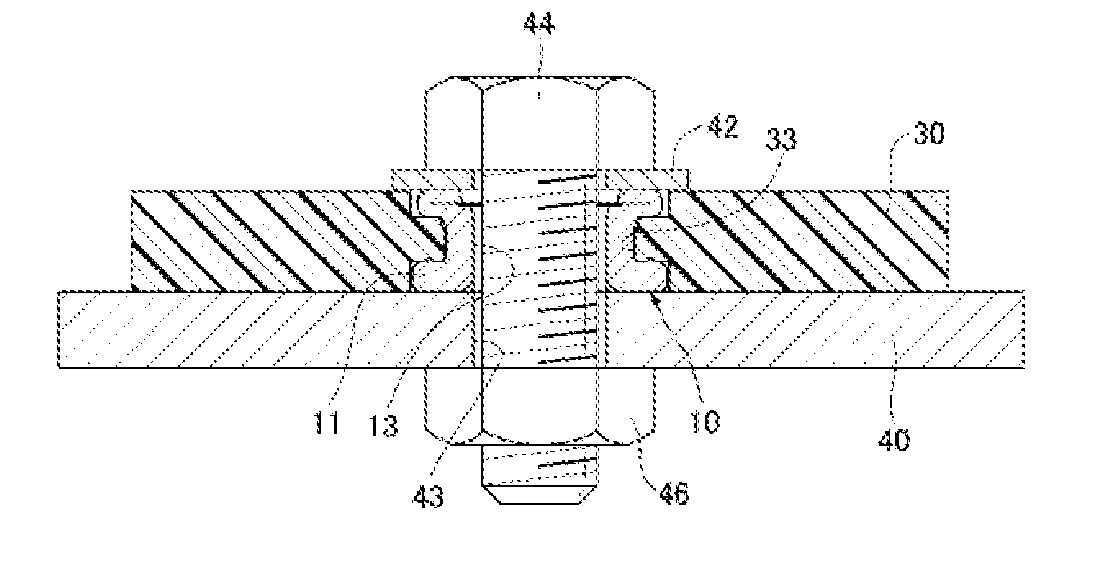

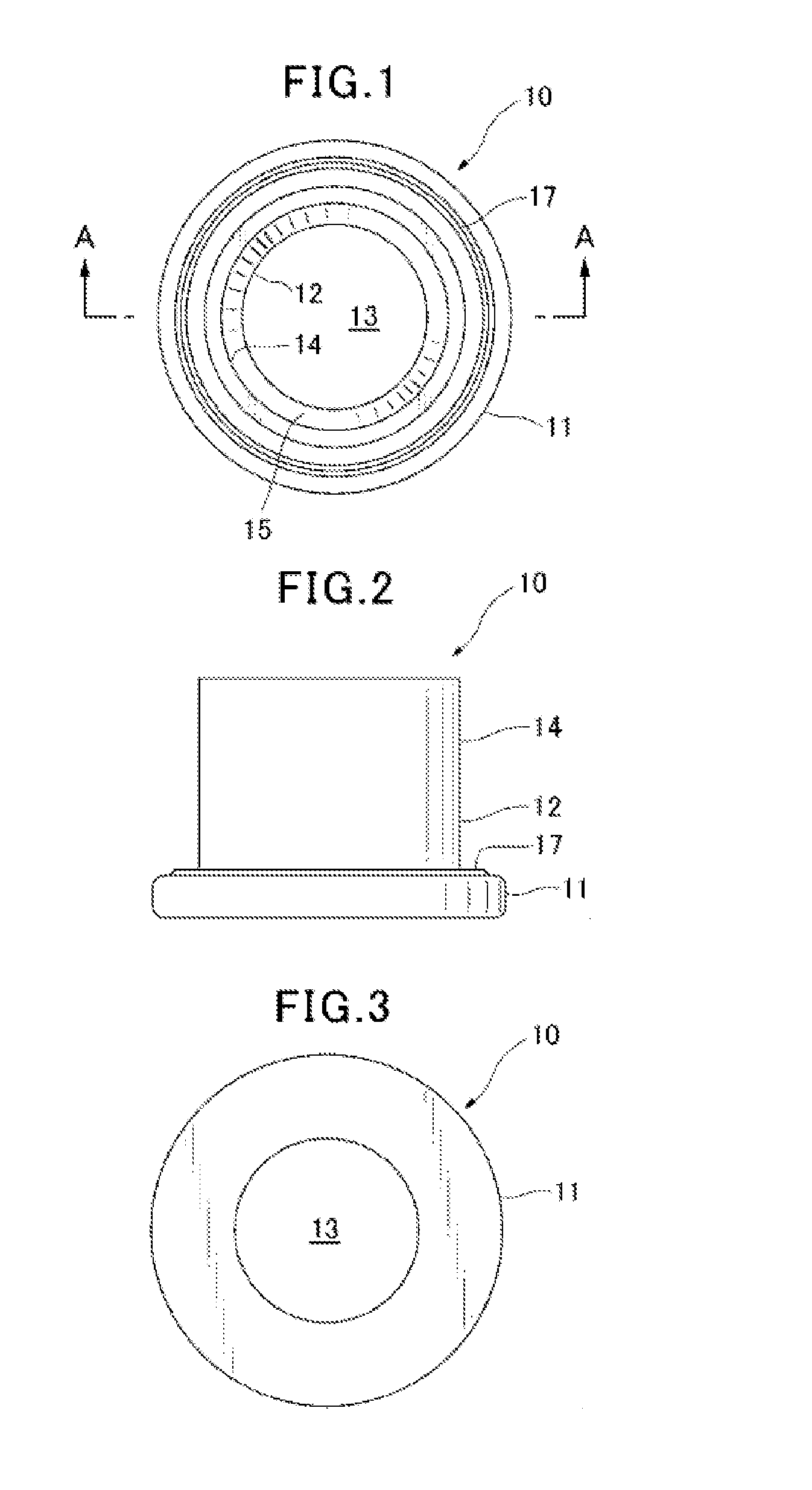

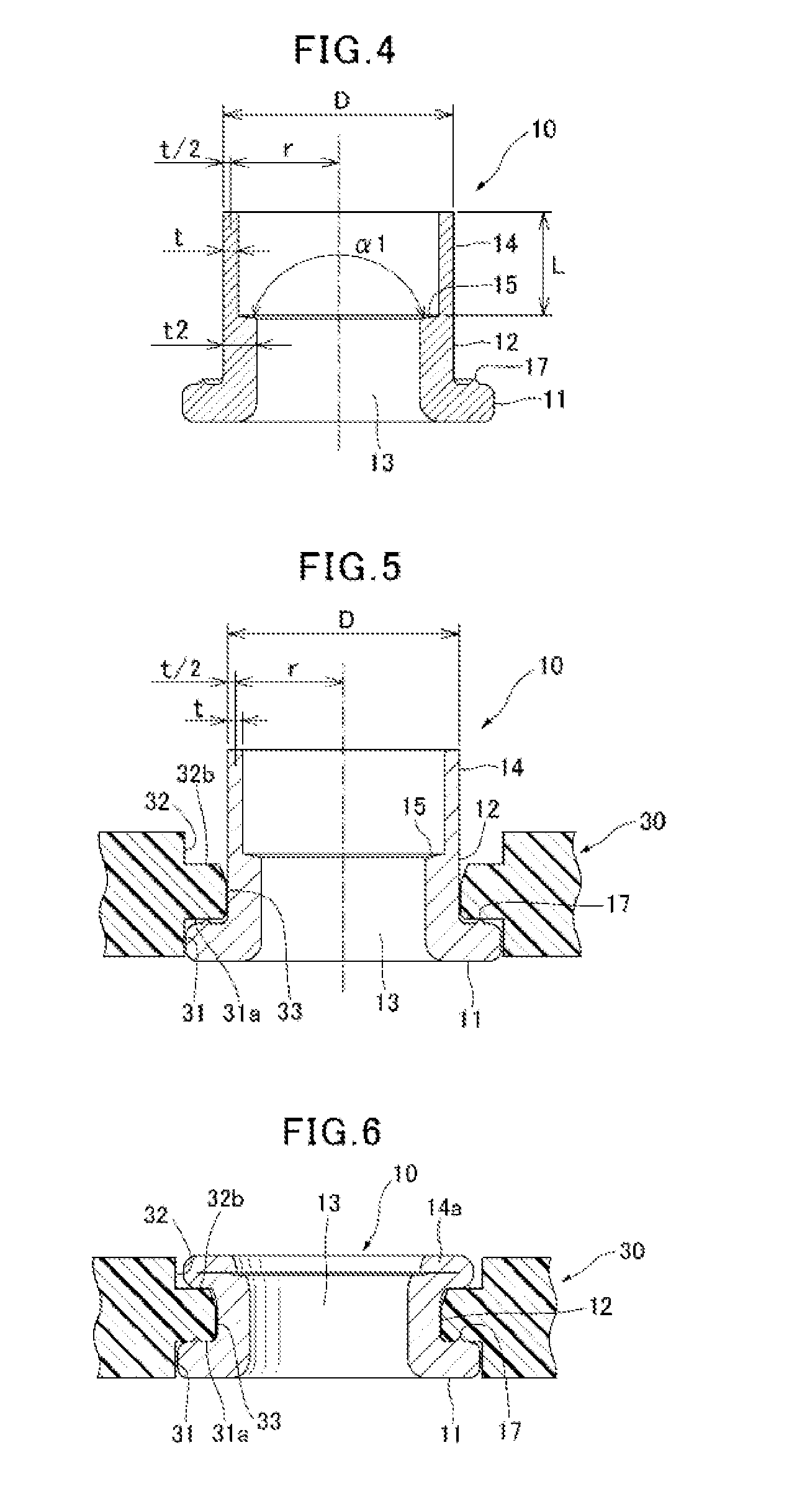

Swaged collar and swaged nut

The self-locking collar comprises a sleeve having a thick wall portion and a thin wall portion which has a thinner wall than the thick wall portion and a step portion between the thick wall portion and the thin wall portion; and a flange adjacent the thick wall portion of the sleeve. A through hole penetrates through the flange and the sleeve. The sleeve is inserted into a mounting hole of a resin component, the thin wall portion is collapsed to form a collapsed portion, and the resin component is sandwiched between the flange and the collapsed portion. The outer diameter of the thin wall portion is D, the wall thickness is t, the length is L, the Poisson ratio is γ, and:r=(D-t) / 2;m=Lπ4r2t212(1-γ2);and1.2<m<1.8

Owner:NEWFREY

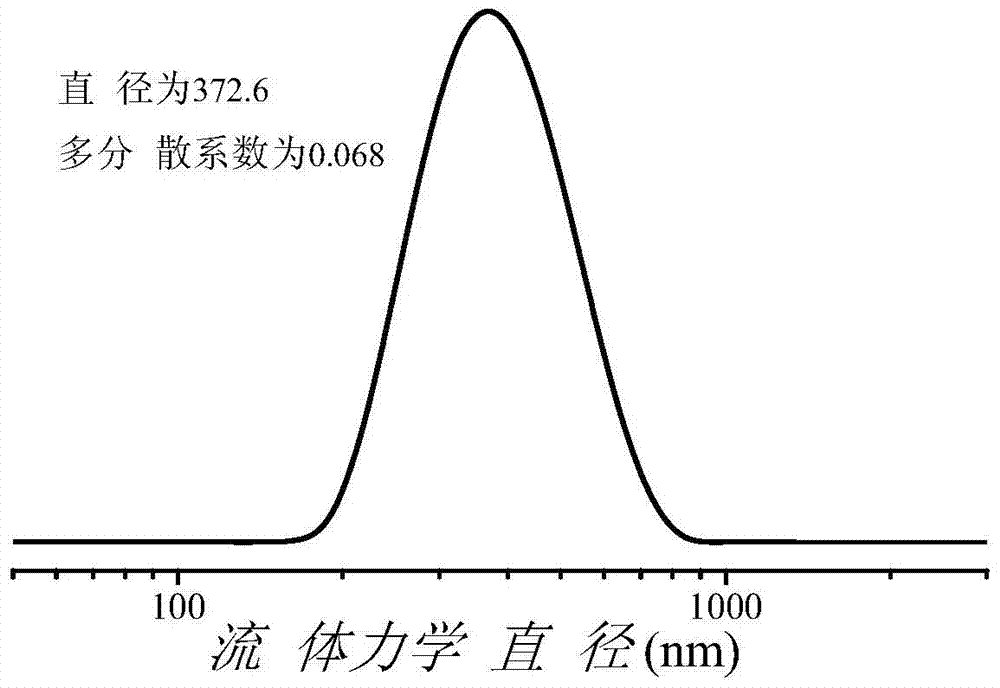

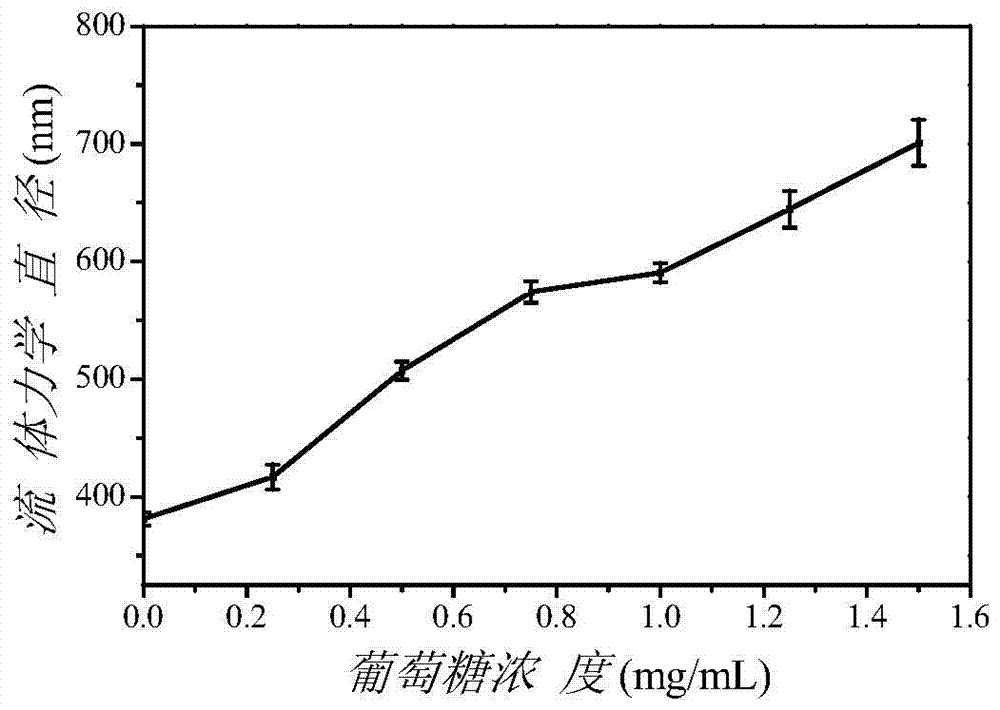

Preparation method and application of a polymer vesicle with sugar sponge function

ActiveCN105037755BImprove stabilityFixed shapeSurgeryBlood vessel filtersMANNITOL/SORBITOLConcanavalin A assay

The present invention relates to a polymer vesicle with the function of sugar sponge and its preparation method and application. Concanavalin on the above; its preparation method is: at first synthesizing the amphiphilic sugar-based polymer with at least initiator and polymerized monomer, then making the amphiphilic sugar-based polymer assemble into polymer vesicles, and finally Concanavalin is combined with polymer vesicles to form sugar-responsive polymer vesicles; the sugar-responsive polymer vesicles of the present invention can respond to changes in the concentration of glucose or mannose in the external environment and are not affected by the pH value. It has good stability and can be used as a buffer for glucose or mannose or a non-drug buffer for treating diabetes.

Owner:TONGJI UNIV

Water cooling forming apparatus and method for production of copper powder with uniform particles

The invention provides a water cooling forming apparatus for production of copper powder with uniform particles, and relates to the field of copper powder production. The apparatus comprises an atomization cylinder; the atomization cylinder comprises a liquid storage bin; a liquid discharge pipe communicating with the liquid storage bin is provided at the bottom end of the liquid storage bin; theliquid discharge pipe is positioned in an atomization bin under the liquid storage bin; the liquid discharge pipe communicates with a liquid guide cylinder fixed in the atomization bin; the bottom endof the liquid guide cylinder is closed, and the side surface communicates with multiple liquid guide pipes arranged in an annular array; a liquid outlet cylinder whose port is upwards and lower thanthe top end of the liquid guide cylinder is provided at the other ends of the liquid guide pipes; and an expansion net frame is provided at the top end of the liquid outlet cylinder. In the invention,by adopting the principle of a communicator, copper liquid is fed in the liquid guide cylinder and discharged by the liquid outlet cylinder; and due to a higher surface tension effect among the molecules of the copper liquid, the expansion net frame is provided at the end portion of the liquid outlet cylinder, and more uniform powder particles are formed under the impact of high-pressure water currents, so that the number of larger copper powder particles is reduced, and the product quality is improved.

Owner:铜陵铜基粉体科技有限公司

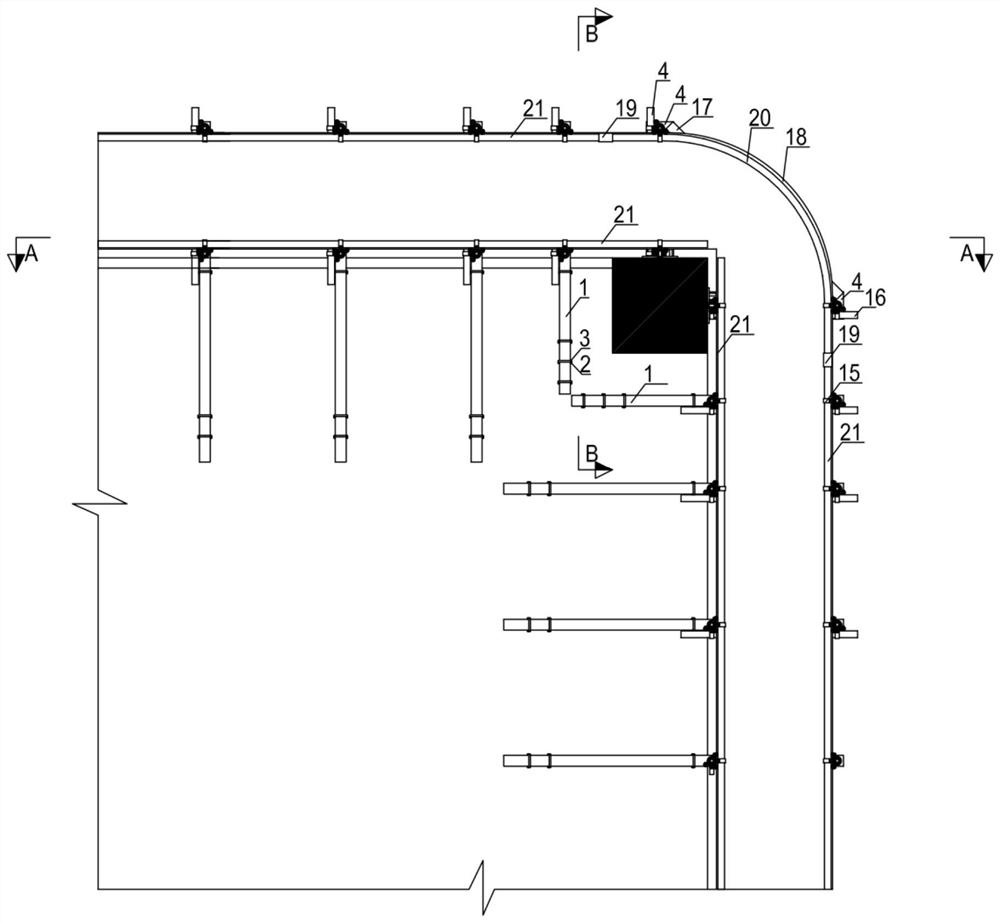

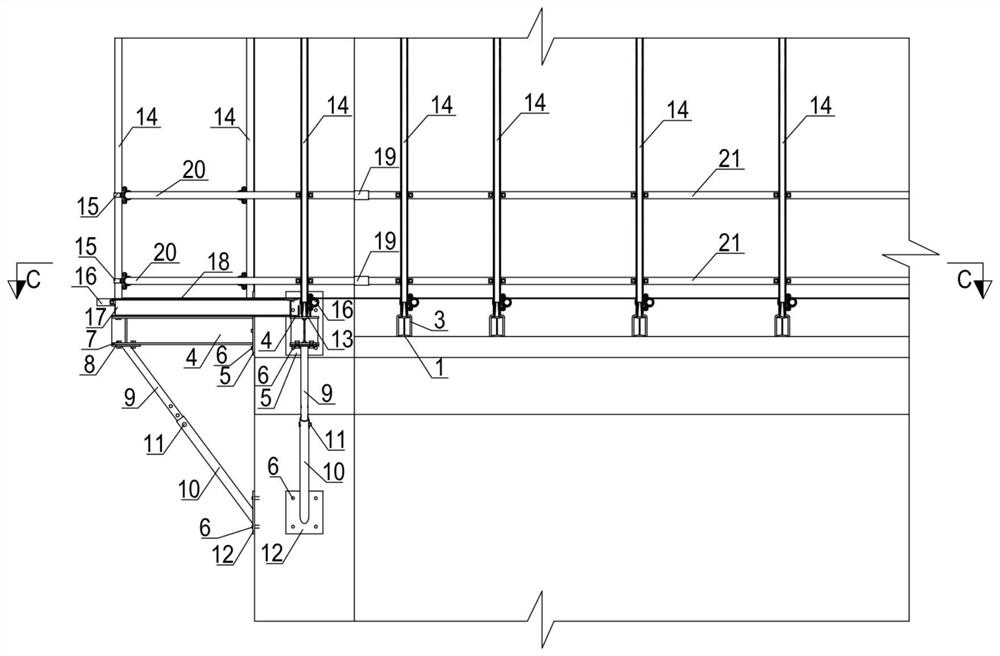

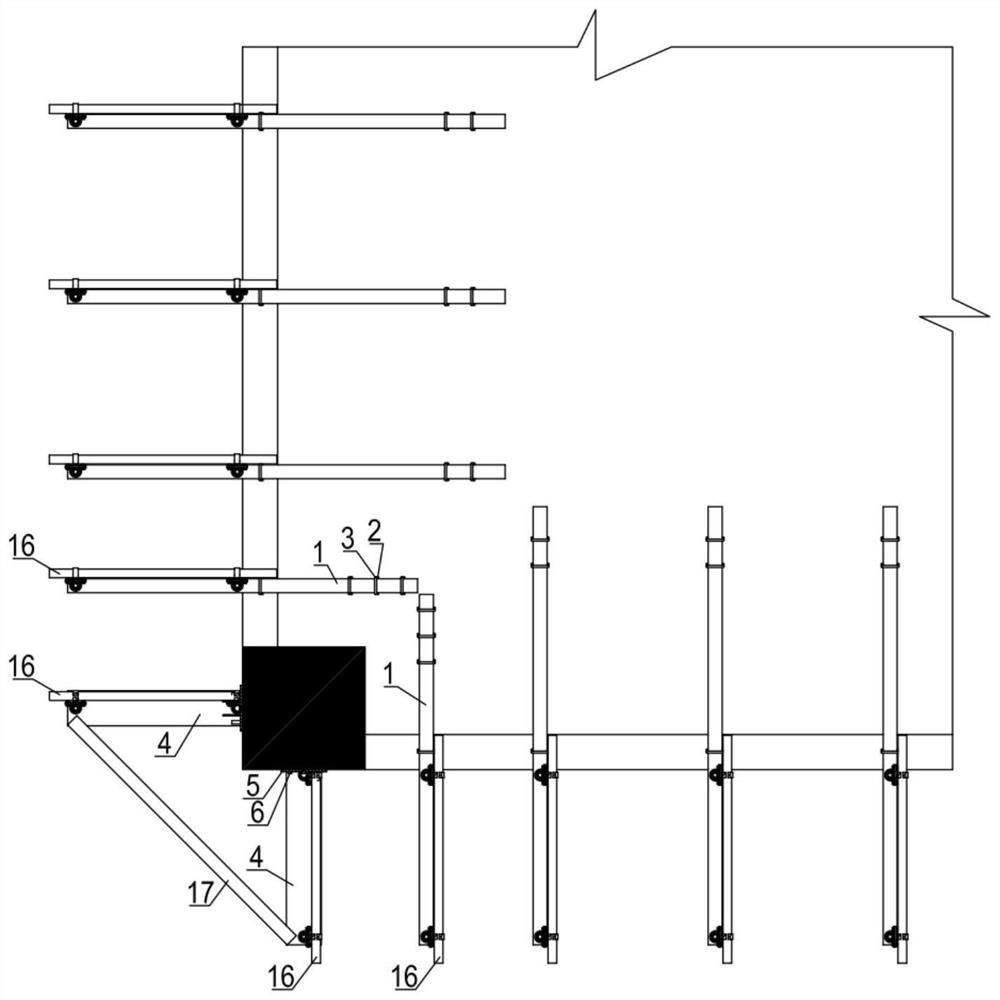

Building floor corner cantilever outer frame supporting system

PendingCN112854716ASolve the layout difficultiesFixed shapeScaffold accessoriesBuilding support scaffoldsSafety coefficientTreadle

The invention discloses a building floor corner cantilever outer frame supporting system. The building floor corner cantilever outer frame supporting system comprises column side platform beams, corner platform beams, platform beam base plates, countersunk head anchor bolts, connecting bolts, connecting plates, supporting rod sleeves, adjustable supporting rod sleeves, pins, supporting rod base plates, vertical rod bases, vertical rods, short transverse rods, corner lap beams, platform pedals, corner arc-shaped transverse rods and long transverse rods. According to the building floor corner cantilever outer frame supporting system, a cantilever external scaffold replaces a traditional floor type scaffold, the cost is reduced, and the safety coefficient is increased; and a triangular supporting system with an adjustable bevel edge is adopted at the corner of an outer frame, H-shaped steel beams do not need to penetrate into a building floor to be anchored and are borne through the triangular supporting frame, the problem that the outer frame is difficult to arrange at the corner is solved, and the application range is wide.

Owner:广西建工第五建筑工程集团有限公司

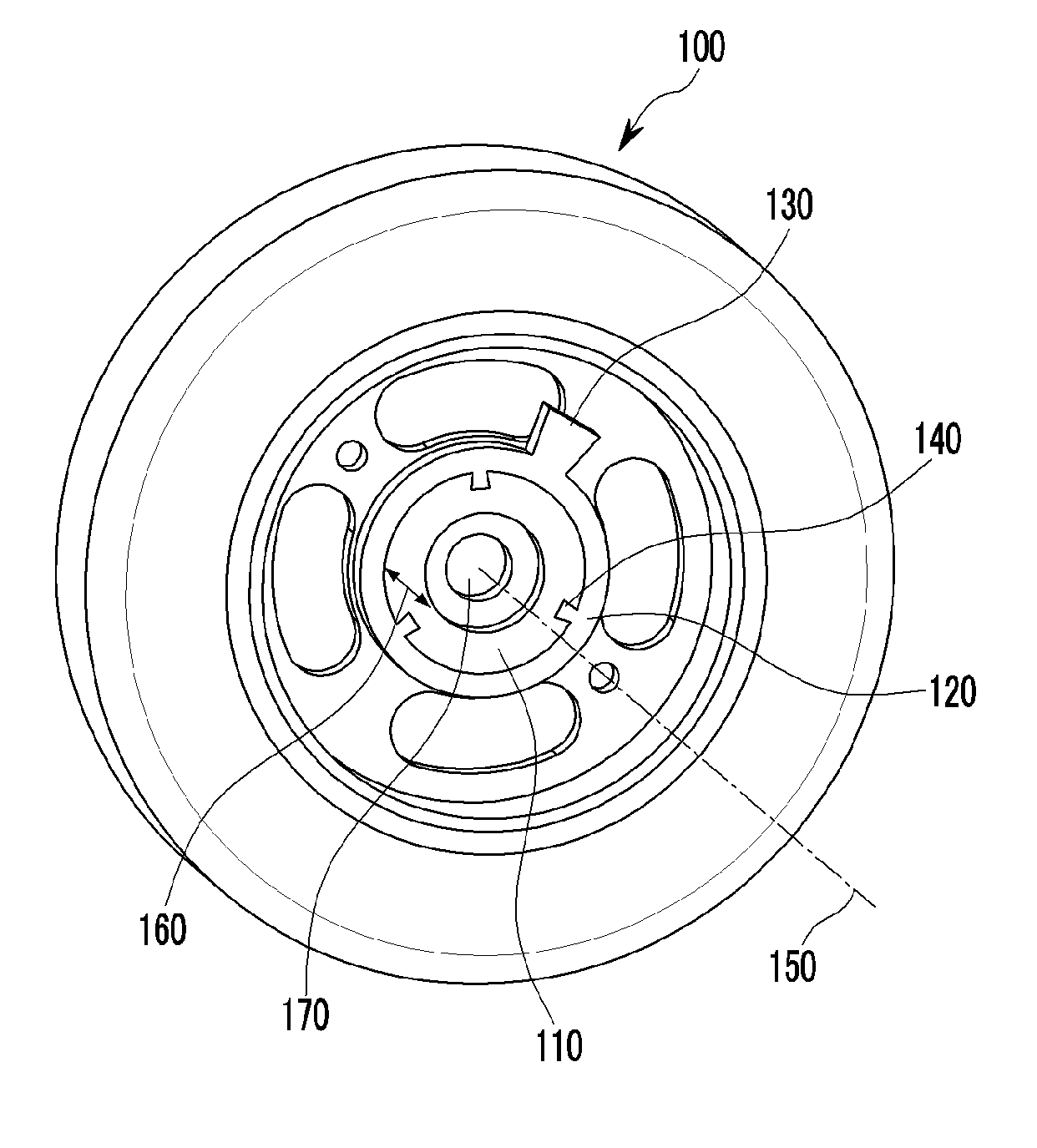

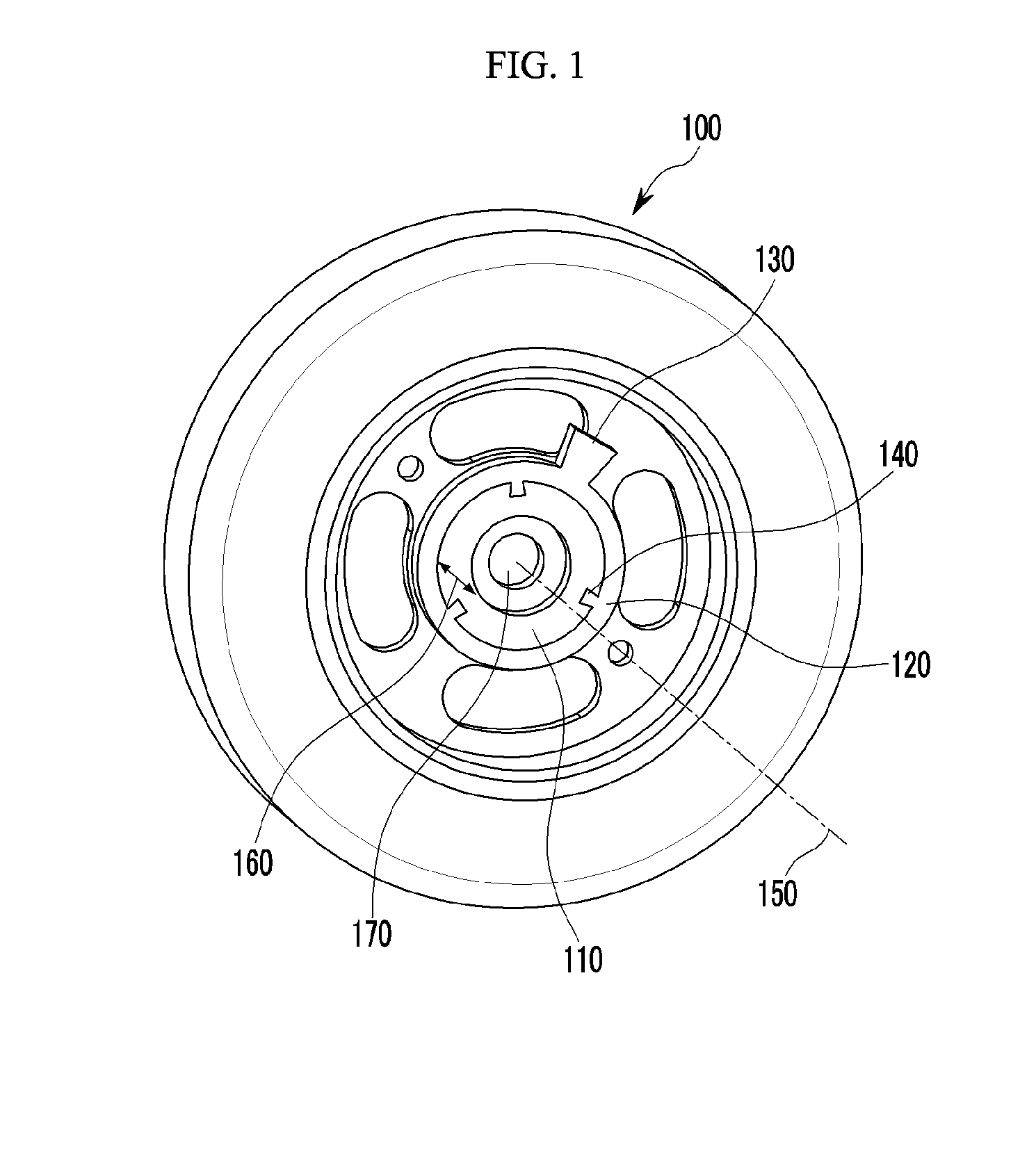

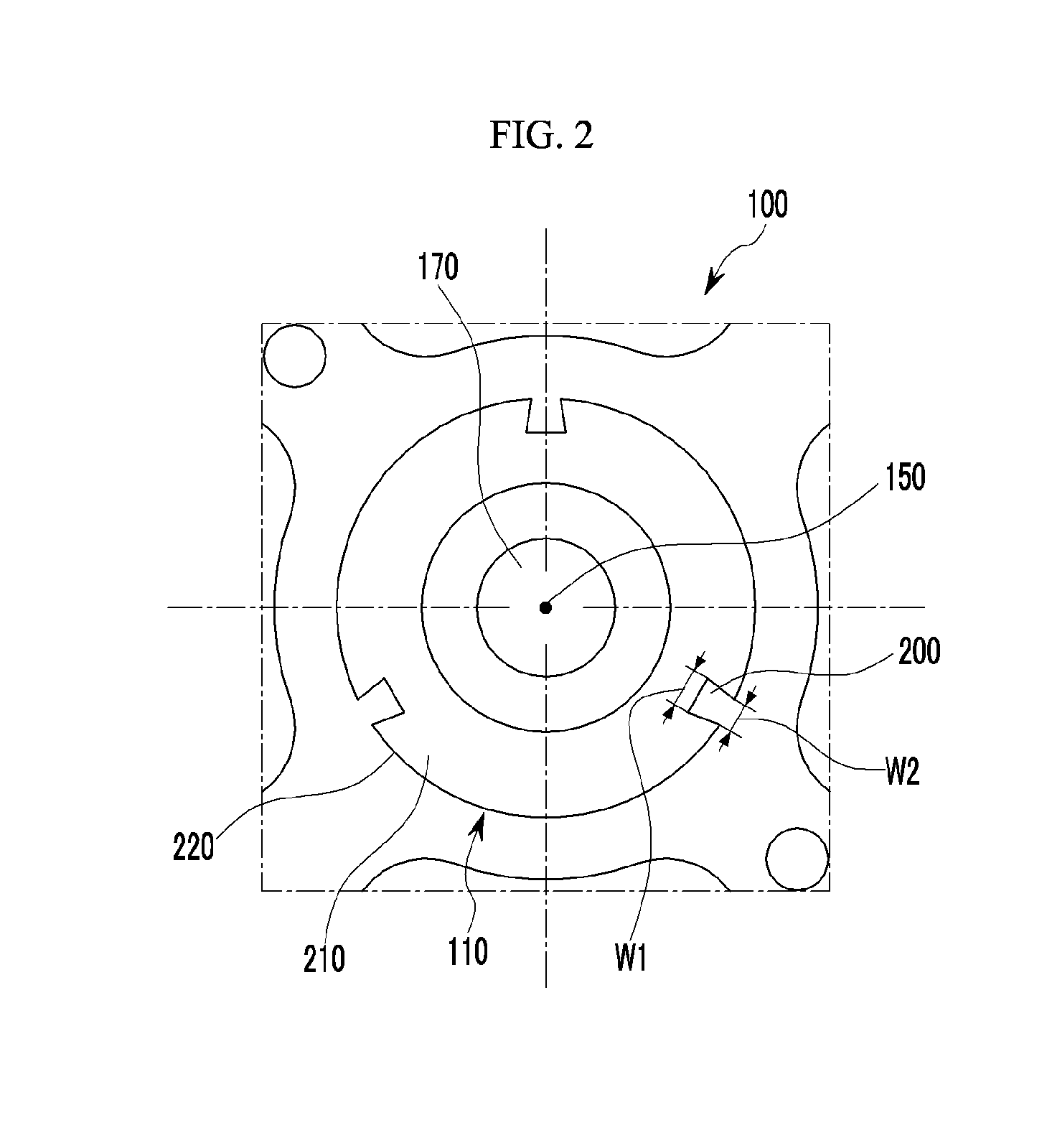

Balance adjustment device of rotating body and power delivery system using balance adjustment device

ActiveUS20140056689A1Easy to adjustAssembly safetyYielding couplingRotating bodies balancingEngineeringDelivery system

Owner:HYUNDAI MOTOR CO LTD

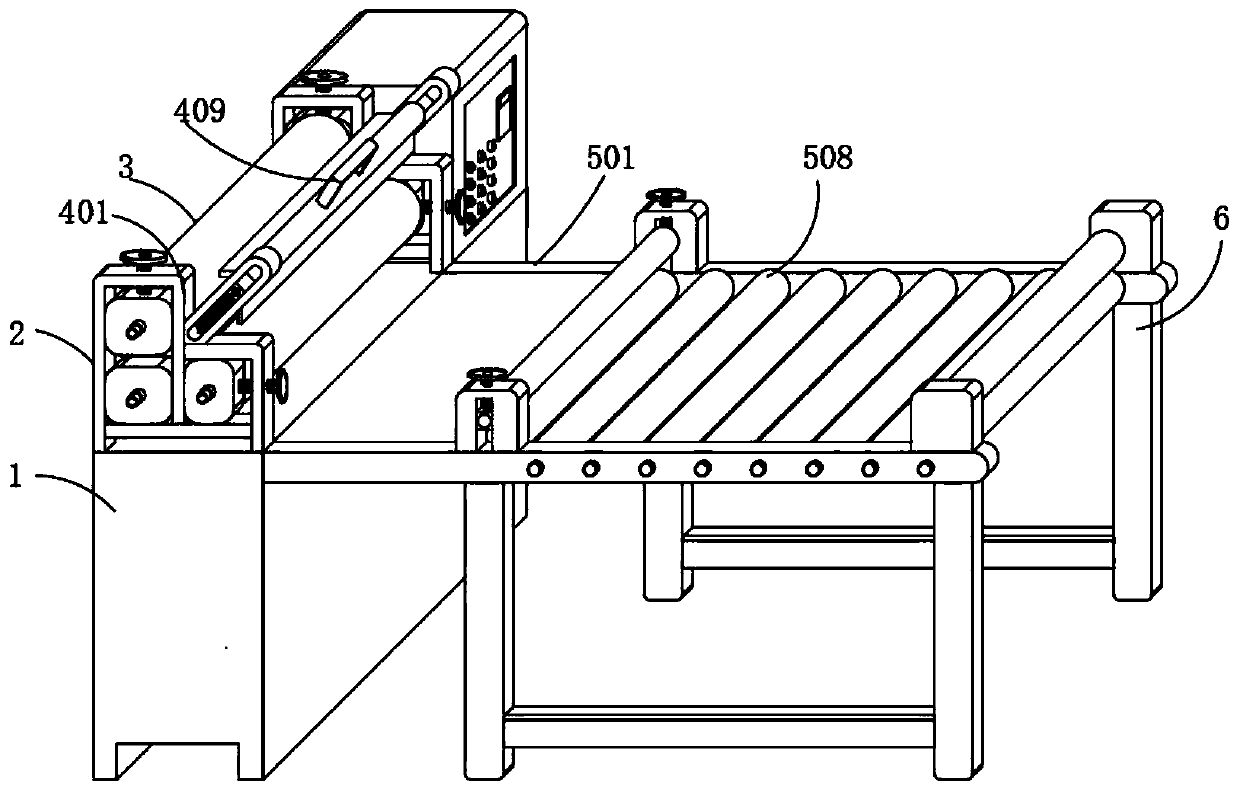

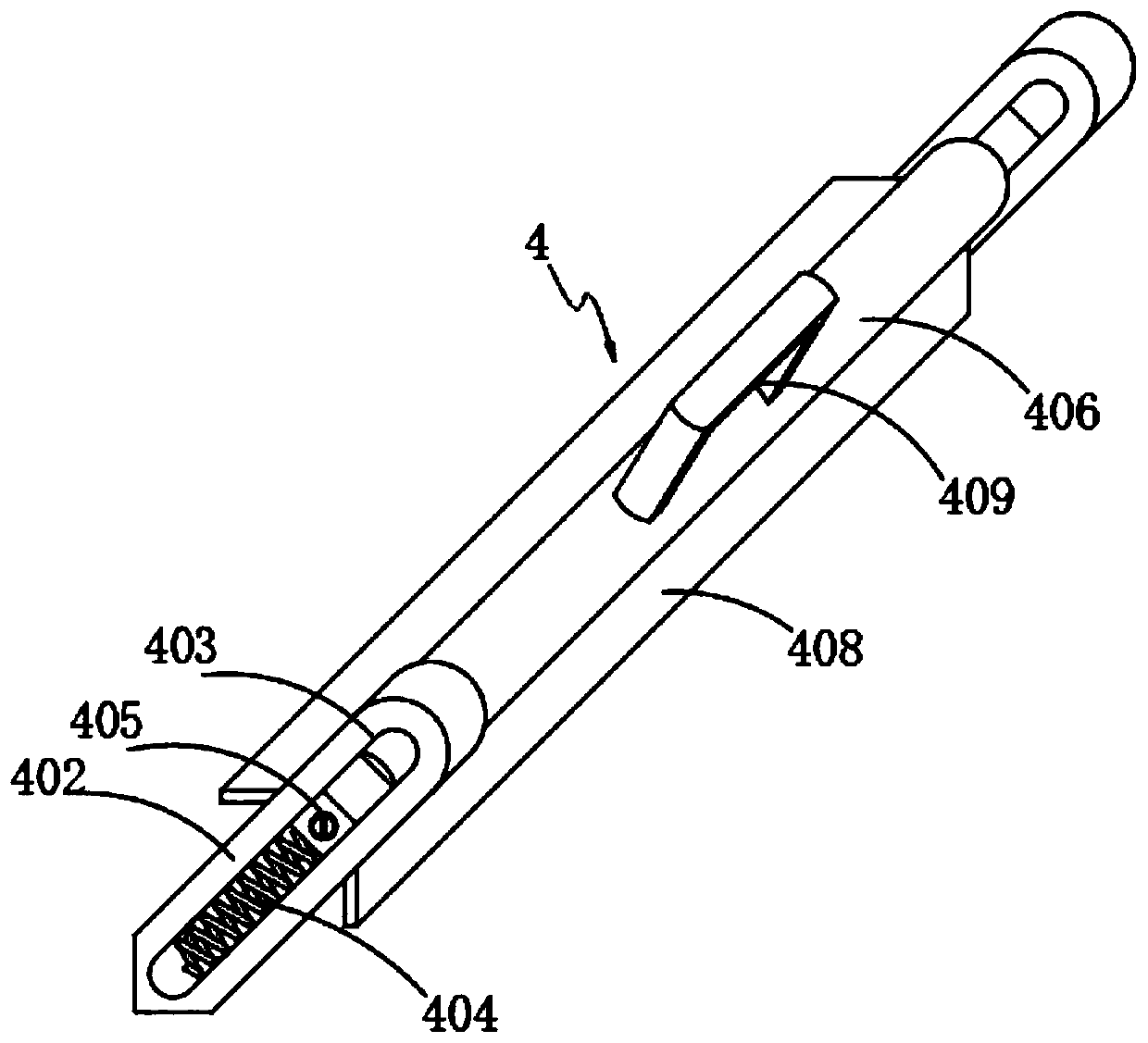

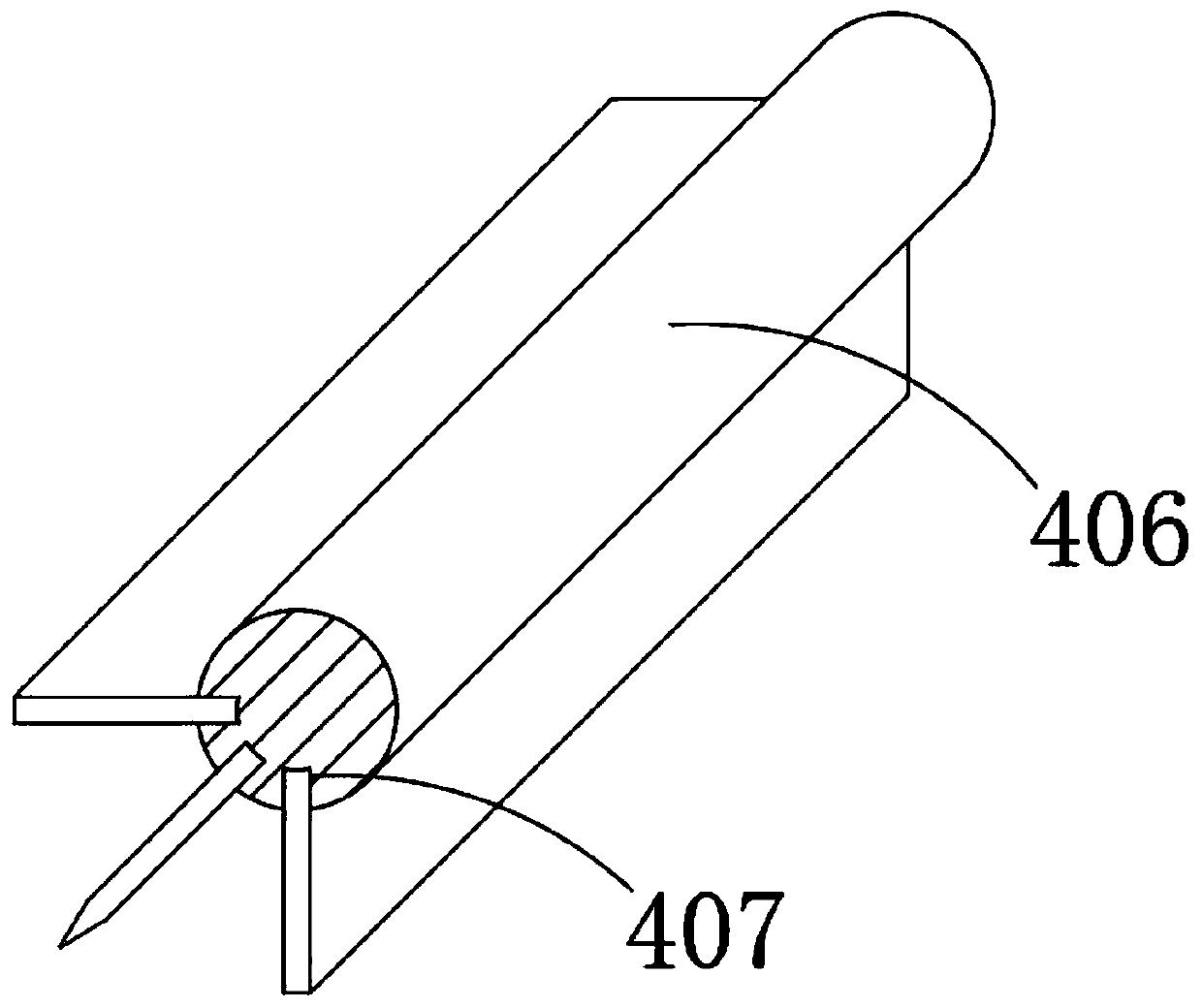

Efficient calendaring device for fluoroplastic products

The invention discloses an efficient calendaring device for fluoroplastic products. Calendaring rollers are uniformly installed in a roller frame, a cleaning assembly is arranged at one end of the roller frame, an installation rod is fixed at one end in an installation groove through a screw, scrapers are embedded in positioning grooves, a guide assembly is installed on one side of a calender body, a heat conducting plate is installed at one ends of guide rods, an installation base is welded to the positions, located at one end of the heat conducting plate, of the top faces of the guide rods,a tension roller is installed between two spring openings, and cold water pipes penetrate in the middles of cooling rollers. When fluoroplastic blocks are adhered to the surfaces of the calendaring rollers, the scrapers are embedded in the positioning grooves corresponding to the calendaring rollers, the installation rod is fixed in the installation groove through the screw, cleaning rods are pushed to enable the scrapers to be close to the calendaring rollers, the fluoroplastic blocks or other impurities are scraped off, cleaning is convenient, the smoothness of the surfaces of the calendaring rollers is guaranteed, and the fluoroplastic product is tightened by the tension roller. When the fluorine product passes through cooling rollers, the shape of the fluorine product is fixed, and subsequent collection is convenient.

Owner:湖州博创氟材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com