Preparation method of nitrogen-doped porous carbon microsphere

A technology of porous carbon and nitrogen doping, which is applied in the preparation/purification of carbon, the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc. It can solve the problems of low specific capacitance and poor wettability, and achieve high electronegativity, The effect of good wettability and simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

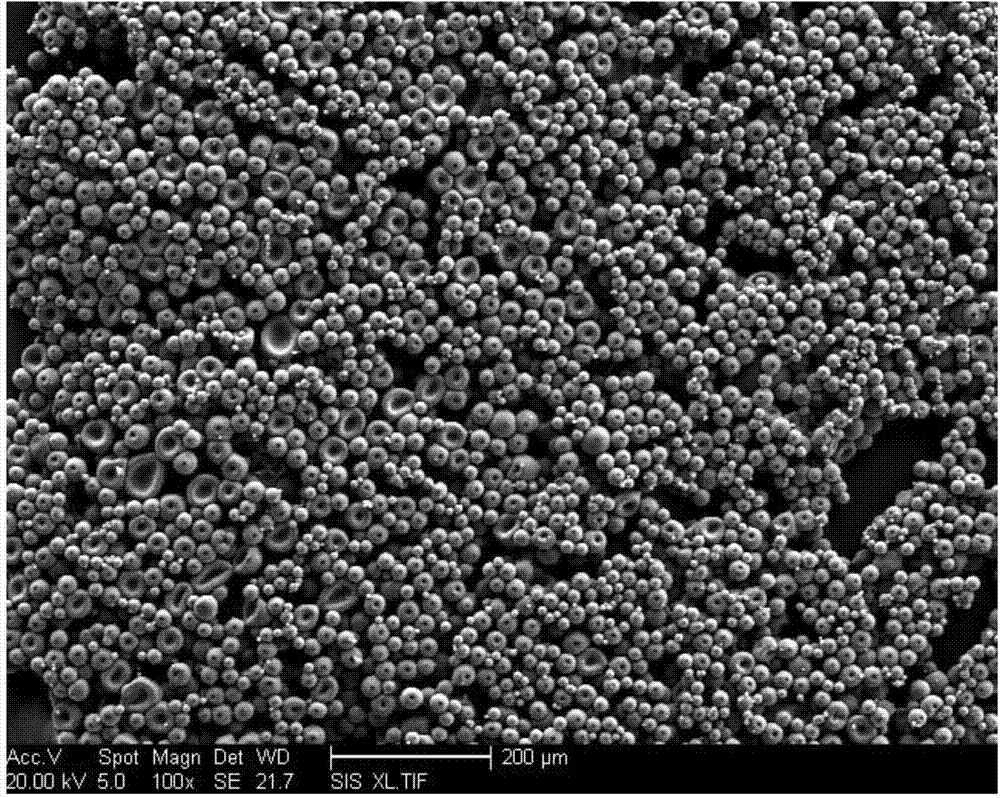

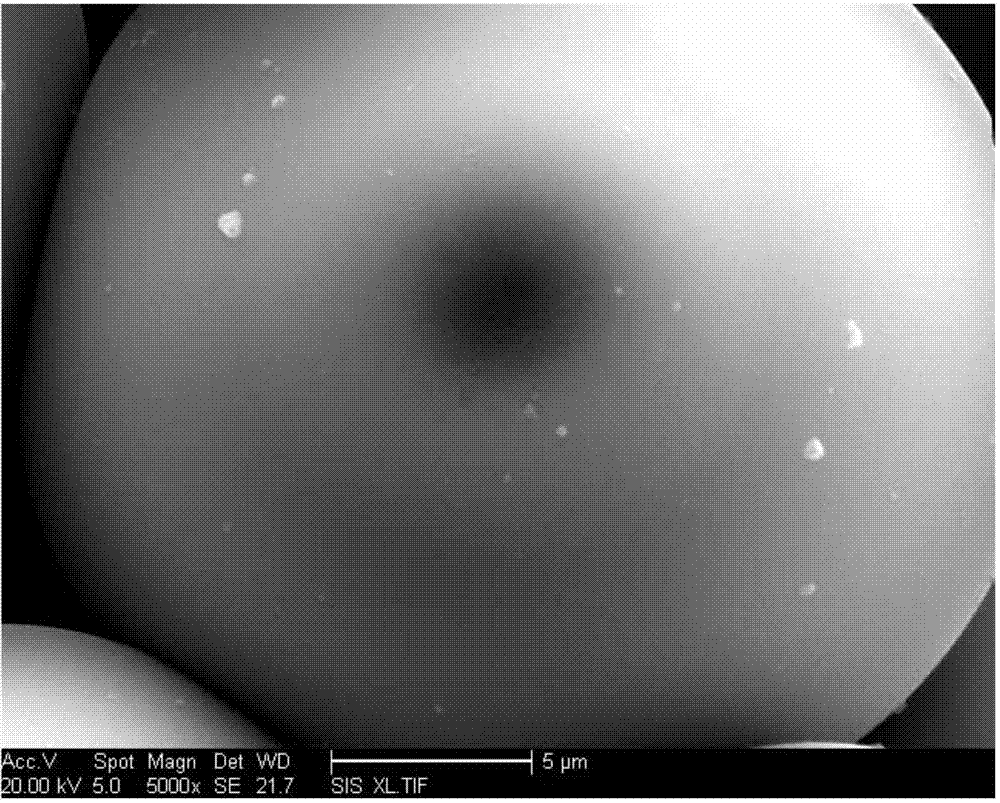

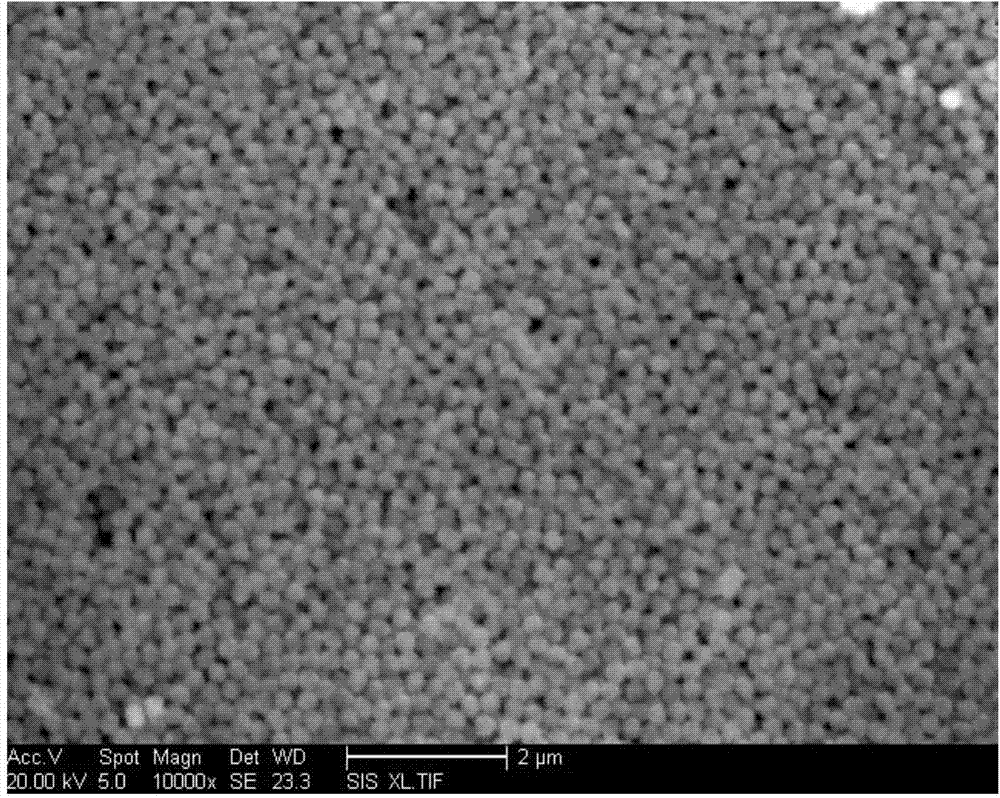

[0020] Specific embodiment one: the present embodiment is a kind of preparation method of nitrogen-doped porous carbon microbead, specifically carries out according to the following steps:

[0021] 1. Mix raw materials to form a solution: mix silica microsphere powder and polyvinylpyrrolidone powder, then add deionized water and stir well to obtain a mixed solution; the silica microsphere powder and polyvinylpyrrolidone powder The quality of each is 0.25g, and the quality of deionized water is 5g;

[0022] 2. Curing and forming: Pour the mixed solution obtained in step 1 into a polypropylene microwave oven box filled with dimethyl silicone oil, stir for 2h to 3h at a temperature of 80°C to 90°C and a rotation speed of 500rpm, and then place it at room temperature Stand still and settle for 12h to 24h to obtain composite microbeads; the volume of the simethicone oil is 500mL;

[0023] 3. Pre-oxidation: the composite microbeads obtained in step 2 are taken out from the polyprop...

specific Embodiment approach 2

[0031] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 2, the mixed solution obtained in step 1 is poured into a polypropylene microwave oven box equipped with simethicone oil, at a temperature of 85°C and a rotating speed of Stirring under the condition of 500rpm for 2.5h, and then settling at room temperature for 20h to obtain composite microbeads. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific embodiment three: the difference between this embodiment and one of specific embodiments one to two is that the step-by-step heating described in step 3 is carried out according to the following steps: heating for 10h at a temperature of 100°C, and then heating up to 150° C. and heated at 150° C. for 11 h, then raised to 280° C. and heated at 280° C. for 2.5 h. Others are the same as one of the specific embodiments 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com