Water cooling forming apparatus and method for production of copper powder with uniform particles

A technology of uniform particle size and forming device, applied in the field of copper powder production, can solve the problems of uneven particle size and different size of copper powder particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

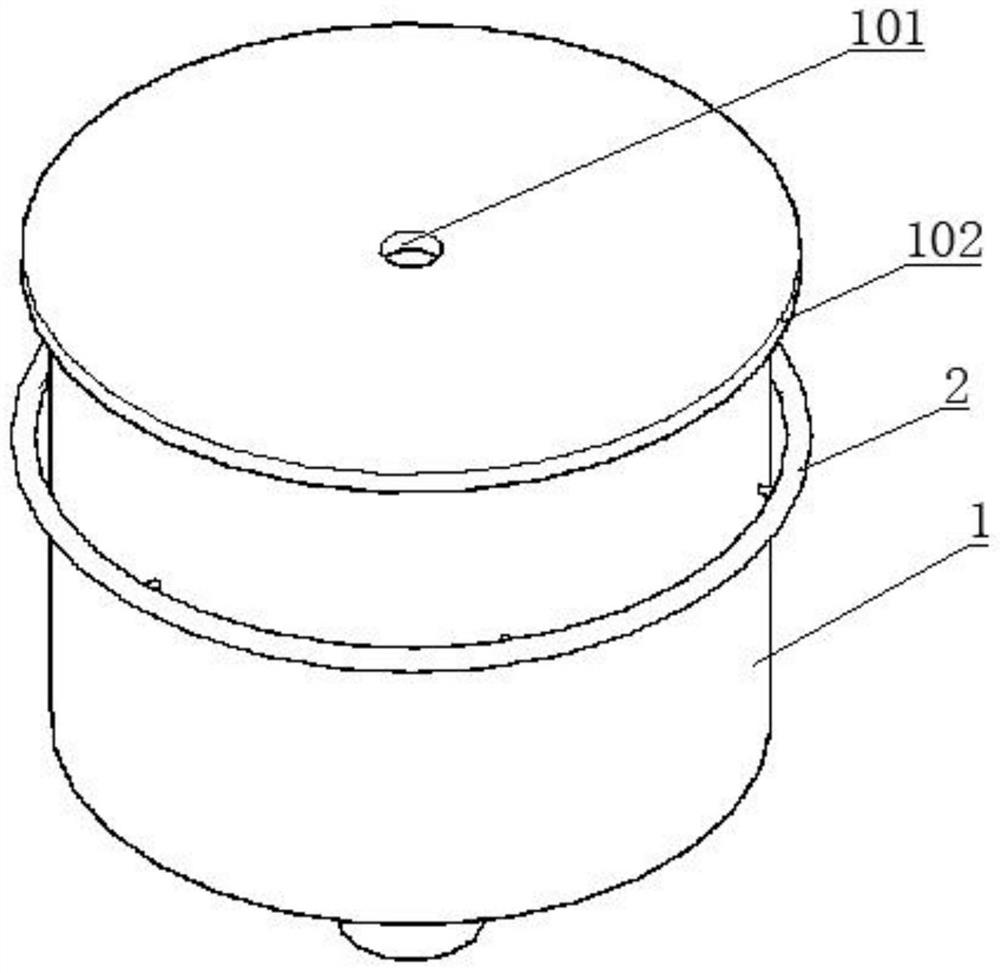

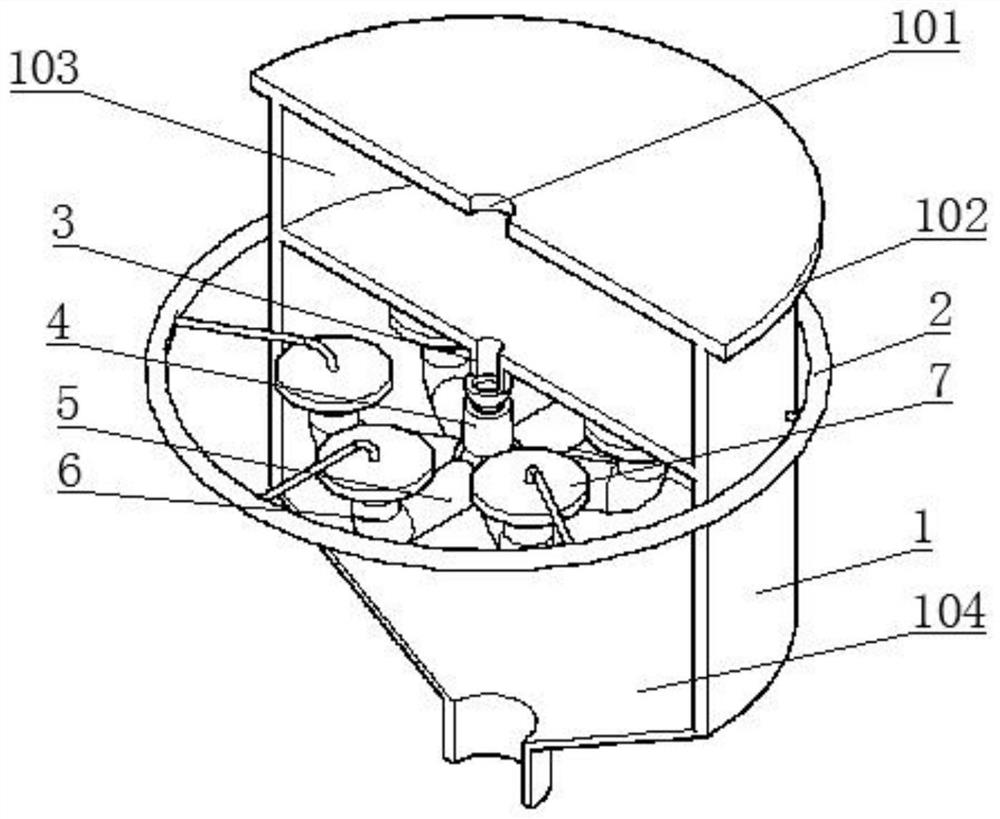

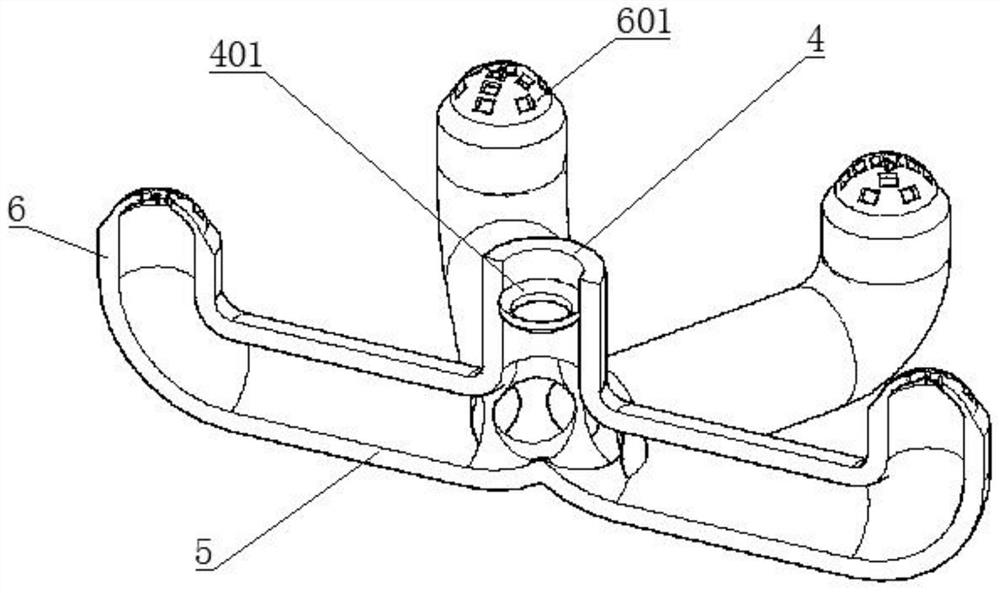

[0038] Such as Figure 1-3 As shown, a water-cooled molding device for production of uniform copper powder includes an atomizing cylinder 1, and the atomizing cylinder 1 includes a liquid storage bin. The liquid pipe 3 is located in the atomization chamber below the liquid storage chamber, and the liquid discharge pipe 3 communicates with the fixed liquid guide cylinder 4 in the atomization chamber. 5. The other end of the catheter tube 5 is provided with a liquid outlet cylinder 6 with the port upward and the port lower than the top of the liquid guide cylinder 4. An expansion grid 601 is arranged at the top of the liquid outlet cylinder 6. The annular water pipe 2 connected inside the tank is connected to the atomized water tray 7 through the inner water pipe 703, and the atomized water tray 7 is coaxially aligned with the liquid outlet cylinder 6 below it.

[0039] When atomizing copper powder, the molten copper is injected into the liquid storage bin from the liquid injec...

Embodiment 2

[0041] Such as Figure 1-4As shown, a water-cooled molding device for producing uniform particles of copper powder includes an atomizing cylinder 1, and the atomizing cylinder 1 includes a liquid storage bin. The liquid pipe 3 is located in the atomization chamber below the liquid storage chamber, and the liquid discharge pipe 3 communicates with the fixed liquid guide cylinder 4 in the atomization chamber. 5. The other end of the catheter tube 5 is provided with a liquid outlet cylinder 6 with the port upward and the port lower than the top of the liquid guide cylinder 4. An expansion grid 601 is arranged at the top of the liquid outlet cylinder 6. The annular water pipe 2 connected to the interior of the chemical chamber, the annular water pipe 2 communicates with the atomized water tray 7 through the internal water pipe 703, the atomized water tray 7 is coaxially aligned with the liquid outlet cylinder 6 below it, and the outer edge of the top of the liquid outlet cylinder ...

Embodiment 3

[0044] Such as Figure 1-7 As shown, a water-cooled molding device for producing uniform particles of copper powder includes an atomizing cylinder 1, and the atomizing cylinder 1 includes a liquid storage bin. The liquid pipe 3 is located in the atomization chamber below the liquid storage chamber, and the liquid discharge pipe 3 communicates with the fixed liquid guide cylinder 4 in the atomization chamber. 5. The other end of the catheter tube 5 is provided with a liquid outlet cylinder 6 with the port upward and the port lower than the top of the liquid guide cylinder 4. An expansion grid 601 is arranged at the top of the liquid outlet cylinder 6. The annular water pipe 2 connected inside the tank, the annular water pipe 2 communicates with the atomized water tray 7 through the internal water pipe 703, the atomized water tray 7 is coaxially aligned with the liquid outlet cylinder 6 below it, and the bottom end of the drain pipe 3 extends to the guide Inside the liquid tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com