Production method of Sinkiang quarenden crisp chips

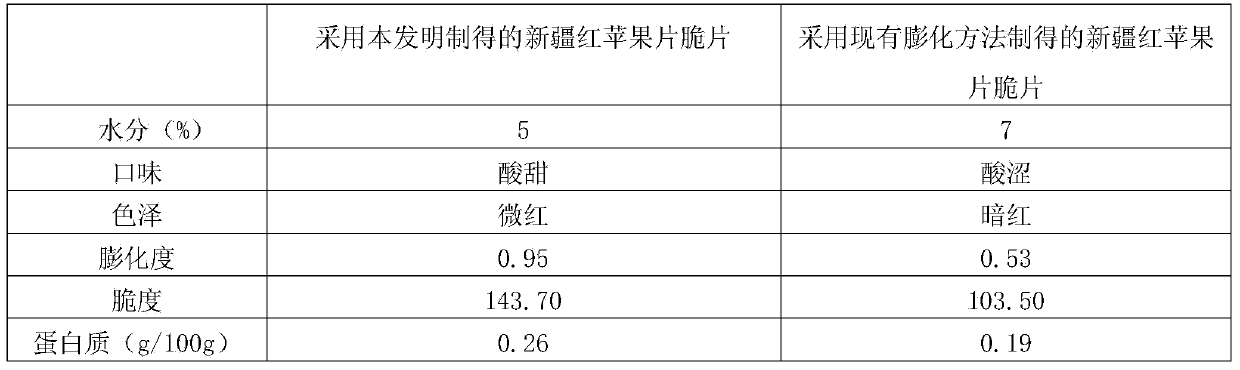

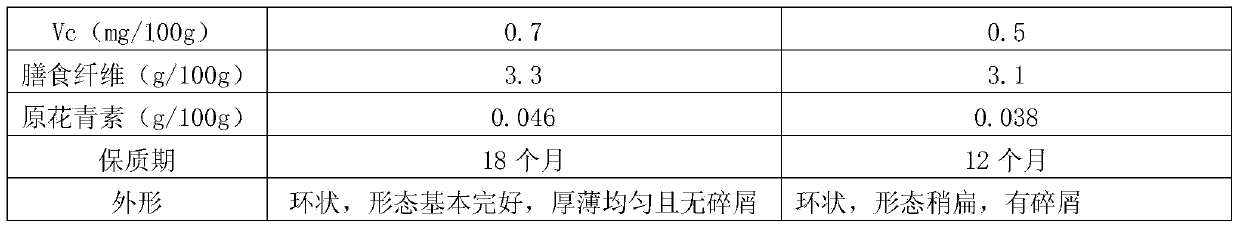

A Xinjiang red apple and production method technology, applied in the field of food processing, can solve problems such as uneven steam distribution, uneven heating of materials, and reduced puffing degree of puffed products, so as to reduce vacuum dehydration time, improve color and puffing degree, and avoid The effect of reducing the swelling degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of production method of Xinjiang red apple chips, the steps are as follows:

[0038] 1. Raw material processing: take fresh and pest-free Xinjiang red crabapple, and peel them mechanically;

[0039] 2. Slicing: Xinjiang red apples after peeling, sliced axially, slice thickness 3mm;

[0040] 3. Color protection: put Xinjiang red apple slices in 2‰ sodium bisulfite solution for 30 minutes;

[0041] 4. Blanching: After the color protection, the Xinjiang red apple slices are blanched with hot water at 100°C for 60 seconds, drained, to kill bacteria and make the pulp cells die, so that white sugar can enter the Xinjiang red apple slices;

[0042] 5. Put the blanched Xinjiang red apple slices into a 20% white sugar solution and soak for 24 hours to increase the solid content and sweetness. After soaking the Xinjiang red apple slices, wash off the white sugar on the surface and drain Dry;

[0043] 6. Freeze the Xinjiang red apple slices soaked in step (5) at -18°C ...

Embodiment 2

[0056] With the production method of the Xinjiang red apple chips described in embodiment 1, the difference is that

[0057] In step 7, once puffing, open the heating valve and heat from the front and rear ends of the heater in the expansion tank at the same time, the heating temperature at the front end is 80°C, and the heating temperature at the rear end is 75°C, until the temperature in the expansion tank rises to 80°C , Open the pressurization valve to increase the pressure of the expansion tank to 0.35MPa.

[0058] In step 8, for secondary expansion, open the heating valve and heat from the front and rear ends of the heater in the expansion tank at the same time. ℃.

Embodiment 3

[0060] With the production method of the Xinjiang red apple chips described in embodiment 1, the difference is that

[0061] In step 7, once puffed, open the heating valve and heat from the front and rear ends of the heater in the puffing tank at the same time, the heating temperature at the front end is 78°C, and the heating temperature at the rear end is 72°C, until the temperature inside the puffing tank rises to 80°C , Open the pressurization valve to increase the pressure of the expansion tank to 0.35MPa.

[0062] In step 8, for secondary expansion, open the heating valve and heat from the front and rear ends of the heater in the expansion tank at the same time. ℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com