Preparation method for palladium/three-dimensional graphene composite microspheres

A graphene composite, graphene technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem of being unsuitable for industrial large-scale production, complex preparation methods of palladium/three-dimensional graphene catalysts, etc. problem, to achieve the effect of novel and unique method, uniform particle size and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

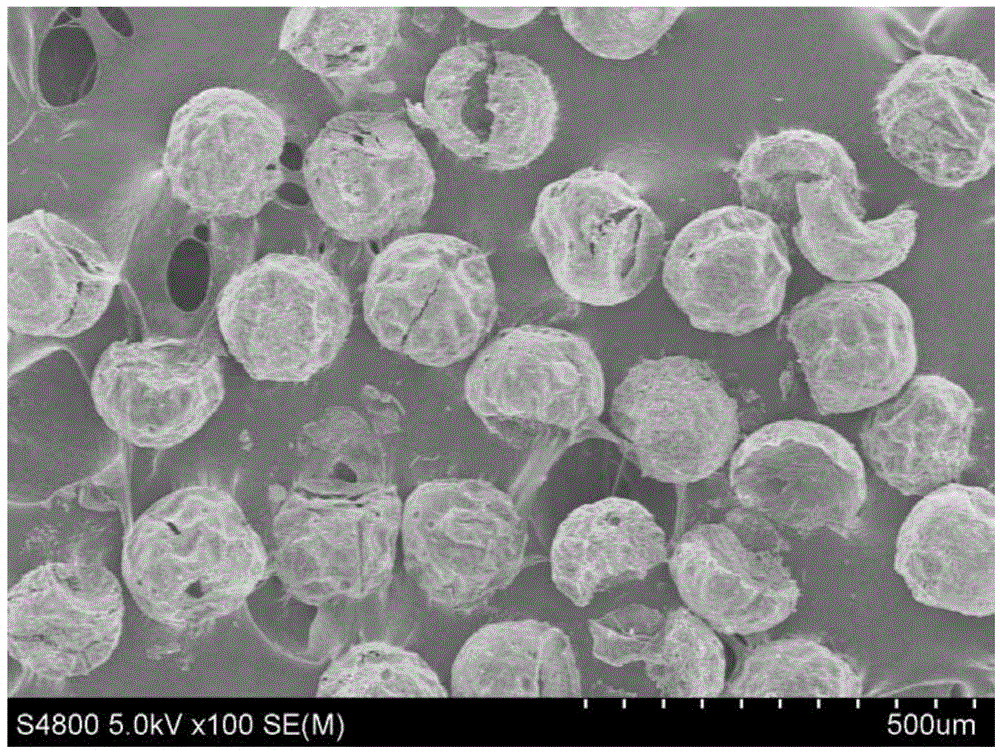

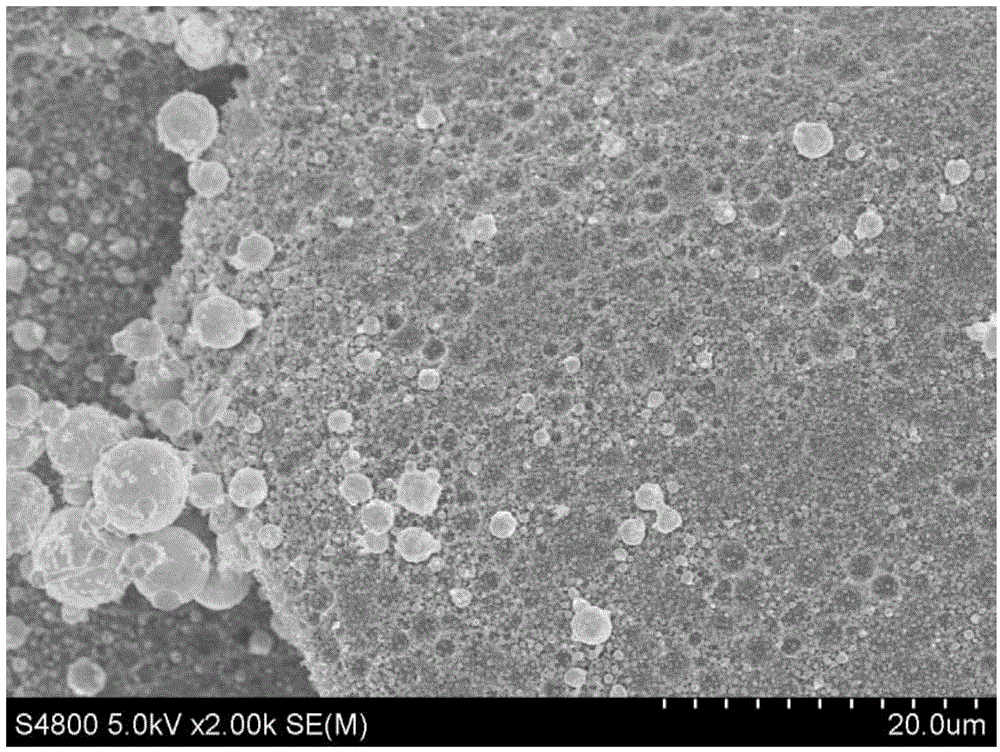

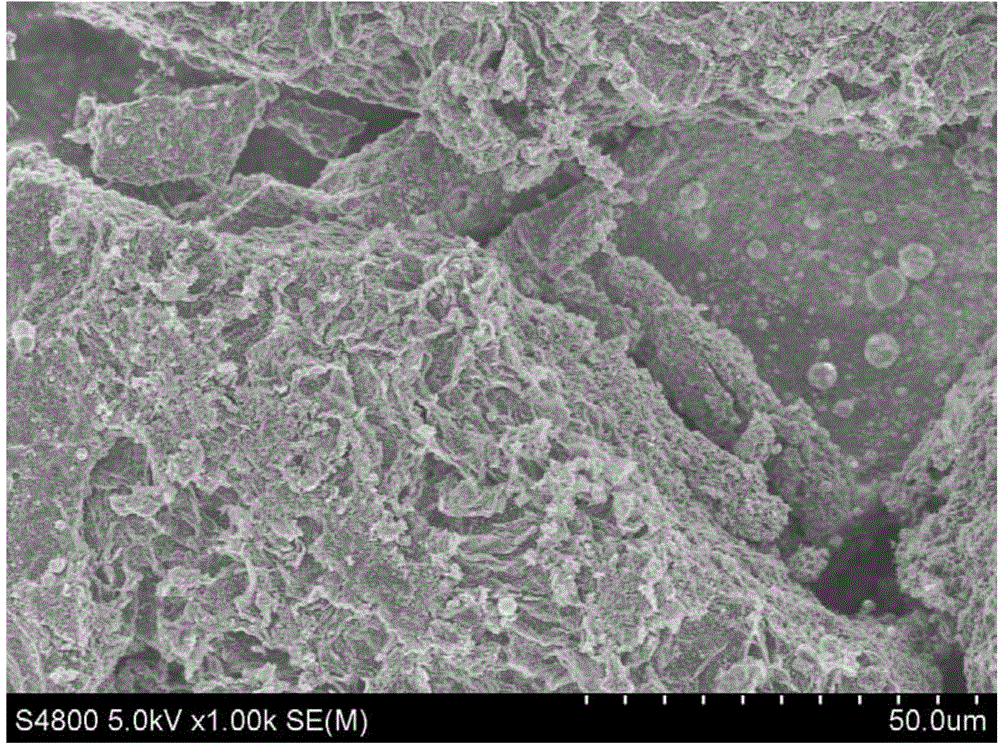

[0020] Specific embodiment one: present embodiment is a kind of preparation method of palladium / three-dimensional graphene composite microbead, is specifically carried out according to the following steps:

[0021] 1. Mix raw materials to form a solution: 5g of graphene oxide solution with a mass fraction of 1% to 1.5%, 0.25g of polyvinylpyrrolidone and 0.0714g of PdCl 2 Mix evenly to obtain a composite dispersed phase solution;

[0022] 2. Curing and molding: Take 10mL of the composite dispersed phase solution obtained in step 1 and pour it into a syringe, push the syringe with a syringe pump to make the composite dispersed phase solution fall into a circular container containing 50mL of simethicone oil, at a temperature of 60°C Insulate for 12h-24h under the conditions of ~70°C and 500rpm rotation speed to obtain composite microbeads; the material of the circular container is polypropylene;

[0023] 3. Calcination: Take the composite microbeads obtained in step 2 out of the...

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, 5g mass fraction is 1% graphene oxide solution, 0.25g polyvinylpyrrolidone and 0.0714gPdCl 2 Mix evenly to obtain a composite dispersed phase solution. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and one of specific embodiments one to two is: the preparation method of graphene oxide in step one is: take 1.2g of scaly graphite powder and add it into a glass three-necked bottle with a volume of 500mL , then add 50mL of concentrated sulfuric acid, put the glass three-necked bottle into an ice-water bath and stir for 30min at a stirring speed of 250r / min, then slowly add 10g of potassium permanganate and 1.5g of sodium nitrate, and stir at a stirring speed of 250r / min. Stir at 200r / min and ice-water bath for 2h, take the glass three-neck flask out of the ice-water bath and stir for 2h at room temperature and at a stirring speed of 250r / min, then in a water bath at 35°C and at a stirring speed of Stir at 250r / min for 24 hours, then add 10mL to 15mL of hydrogen peroxide solution with a mass fraction of 30% and 10mL of aqueous hydrochloric acid with a mass fraction of 36% to 38% to obtain a viscous soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com