Patents

Literature

59results about How to "Stable internal pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Seabed seismic station packaging

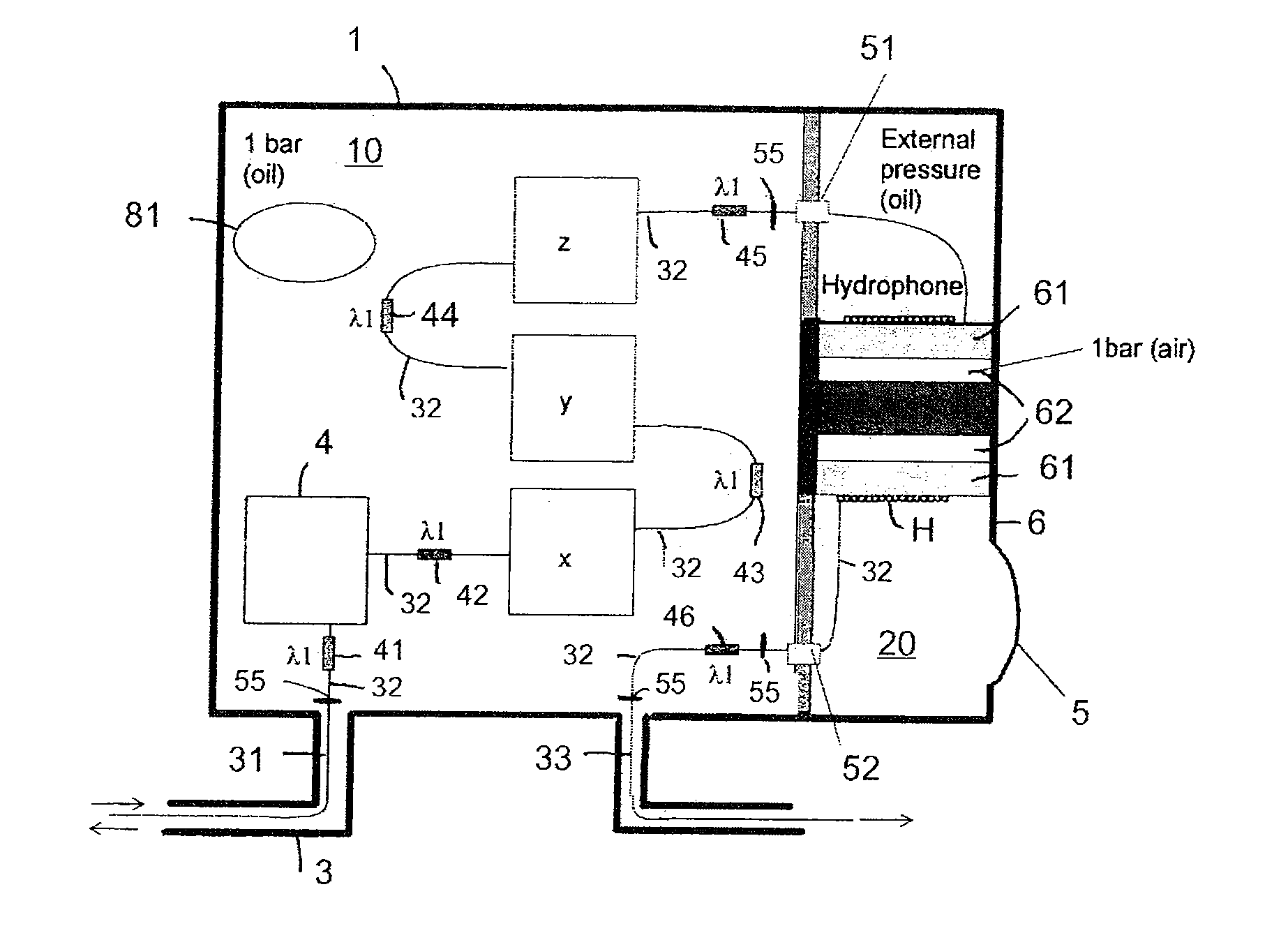

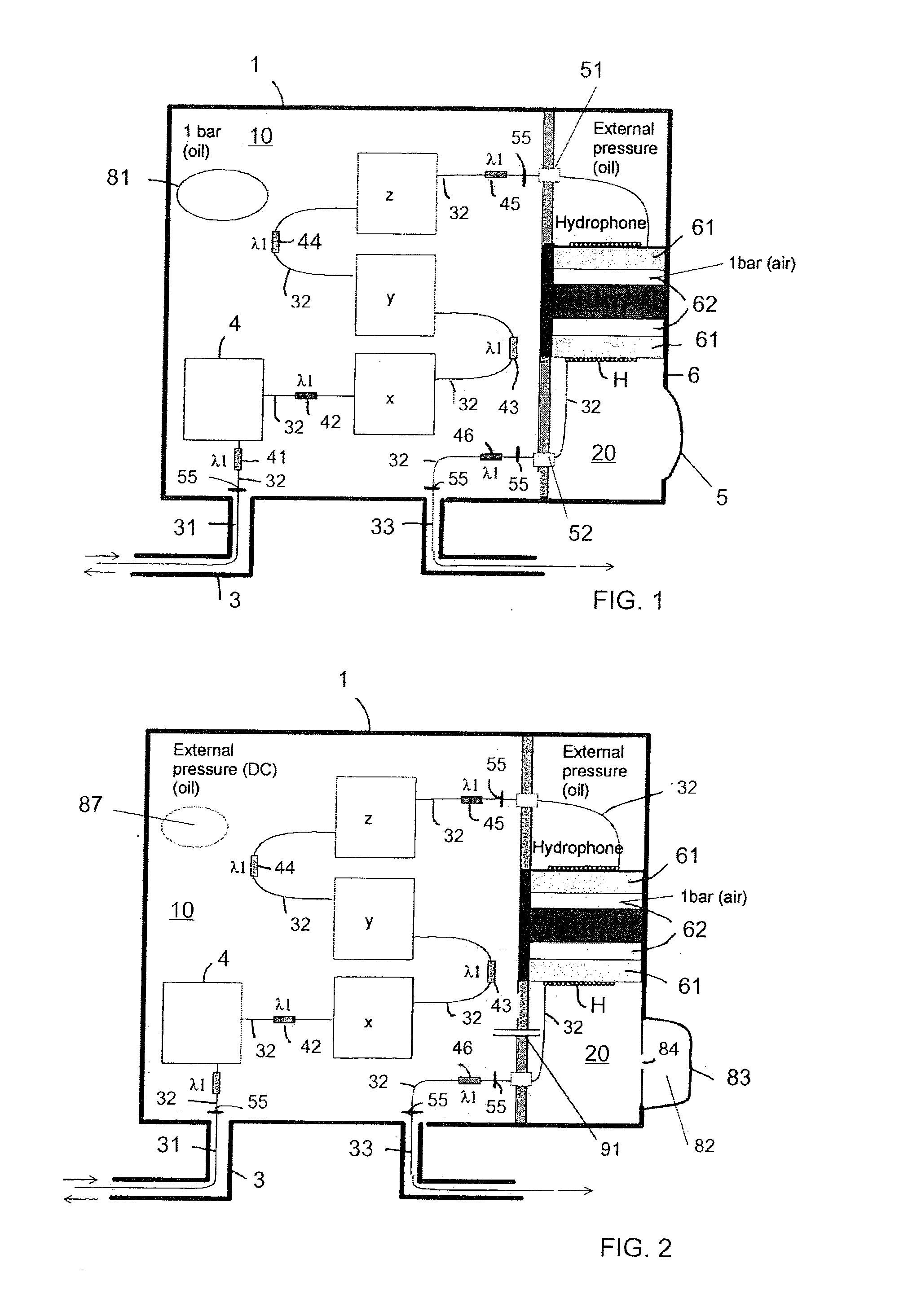

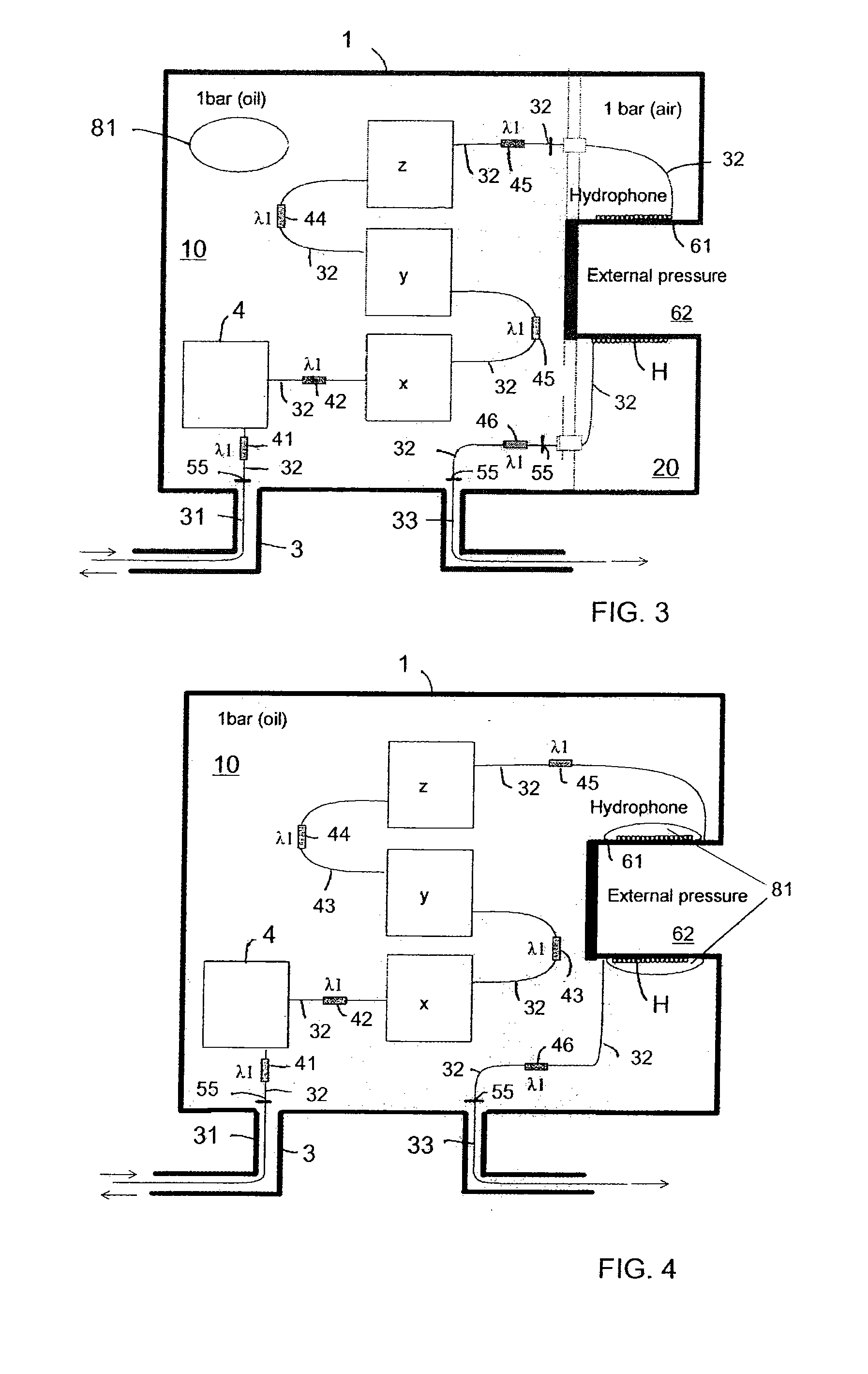

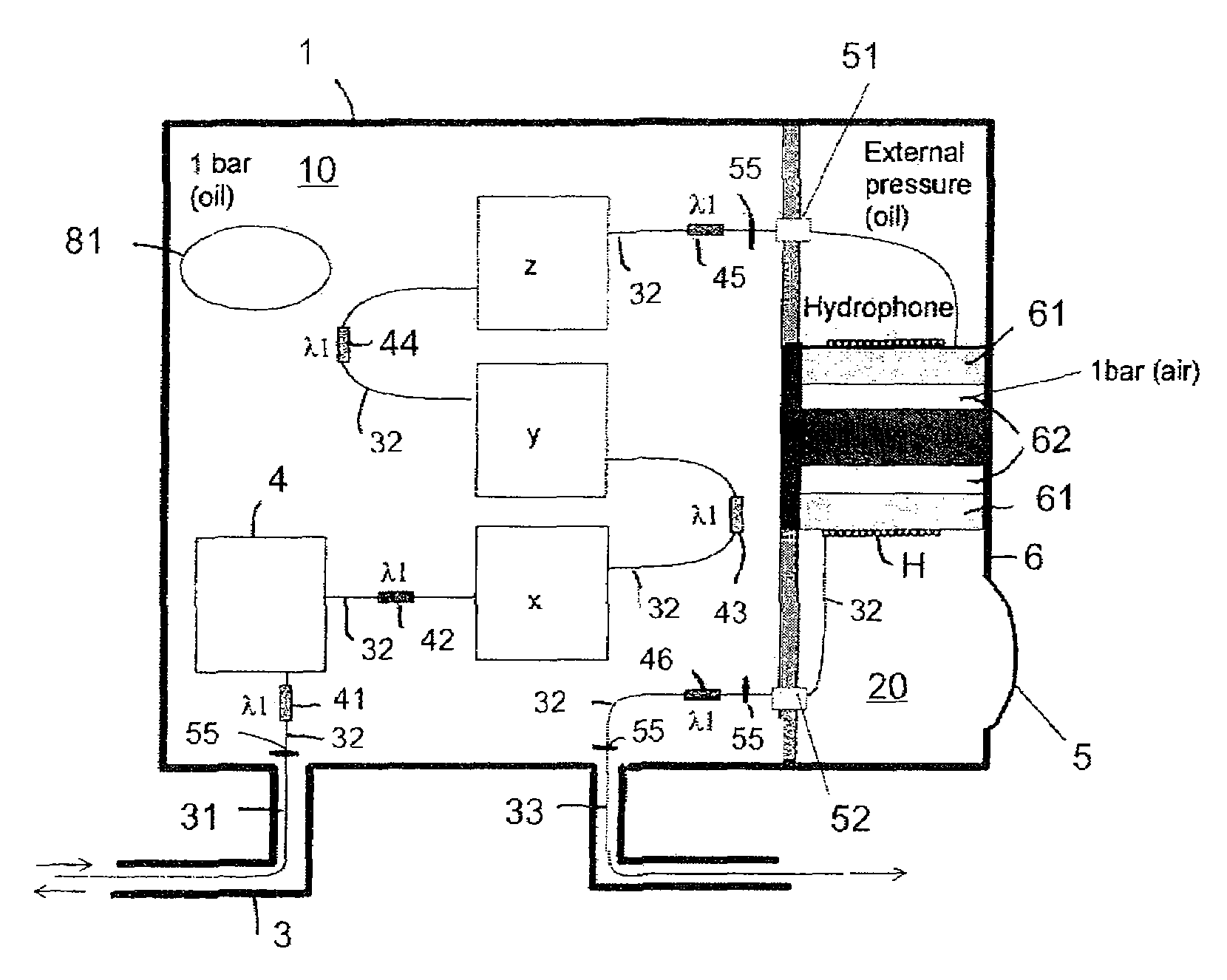

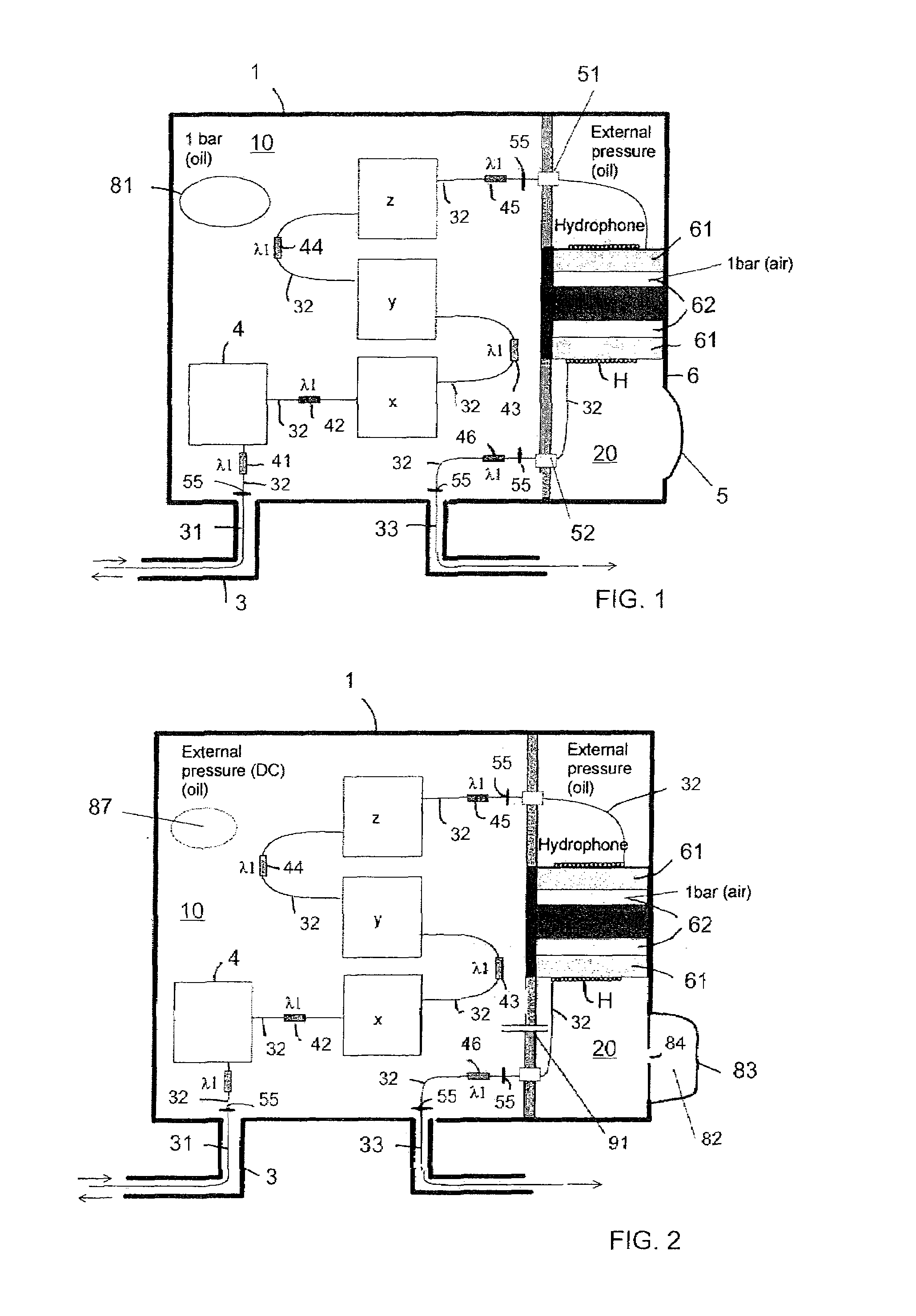

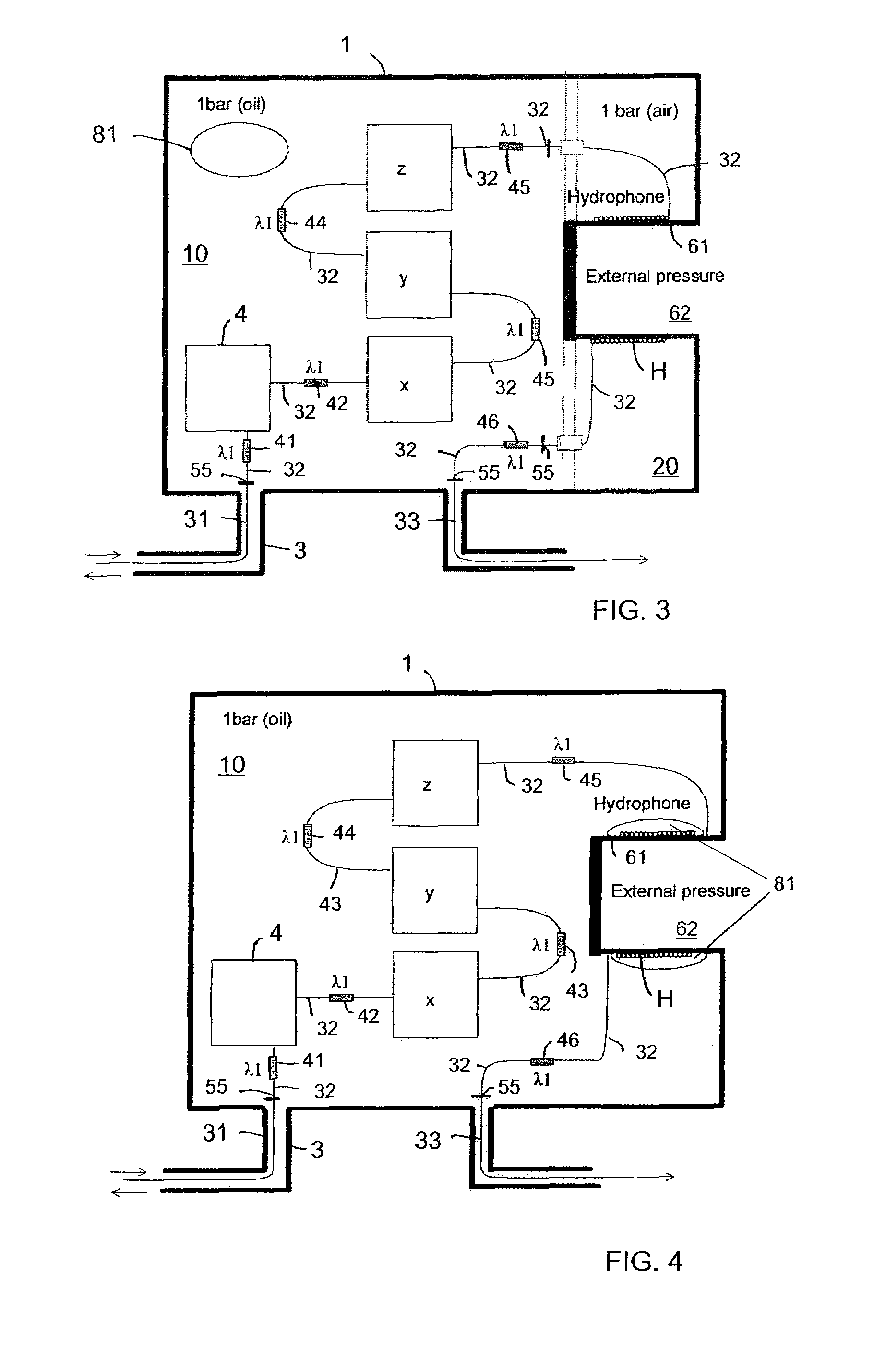

ActiveUS20070258330A1Stabilize internal pressureStable internal pressureSubsonic/sonic/ultrasonic wave measurementSeismic signal receiversEngineeringHydrophone

A seismic sensor station includes a housing containing a fiber optic hydrophone and a fiber optic accelerometer that can both be made from a single length of optical fiber arranged inside the housing. The fiber optic accelerometer is arranged in a liquid / oil filled compartment of the housing for dampening of mechanical resonances in the accelerometer due to mechanical disturbances and pressure fluctuations.

Owner:OPTOPLAN

Seabed seismic station packaging

ActiveUS7551517B2Stable internal pressureSubsonic/sonic/ultrasonic wave measurementOptical detectionHydrophoneOcean bottom

A seismic sensor station includes a housing containing a fiber optic hydrophone and a fiber optic accelerometer that can both be made from a single length of optical fiber arranged inside the housing. The fiber optic accelerometer is arranged in a liquid / oil filled compartment of the housing for dampening of mechanical resonances in the accelerometer due to mechanical disturbances and pressure fluctuations.

Owner:OPTOPLAN

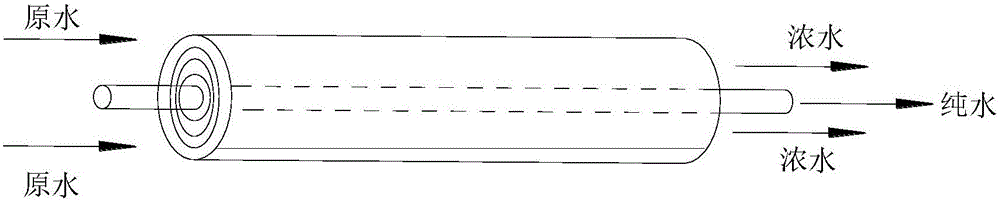

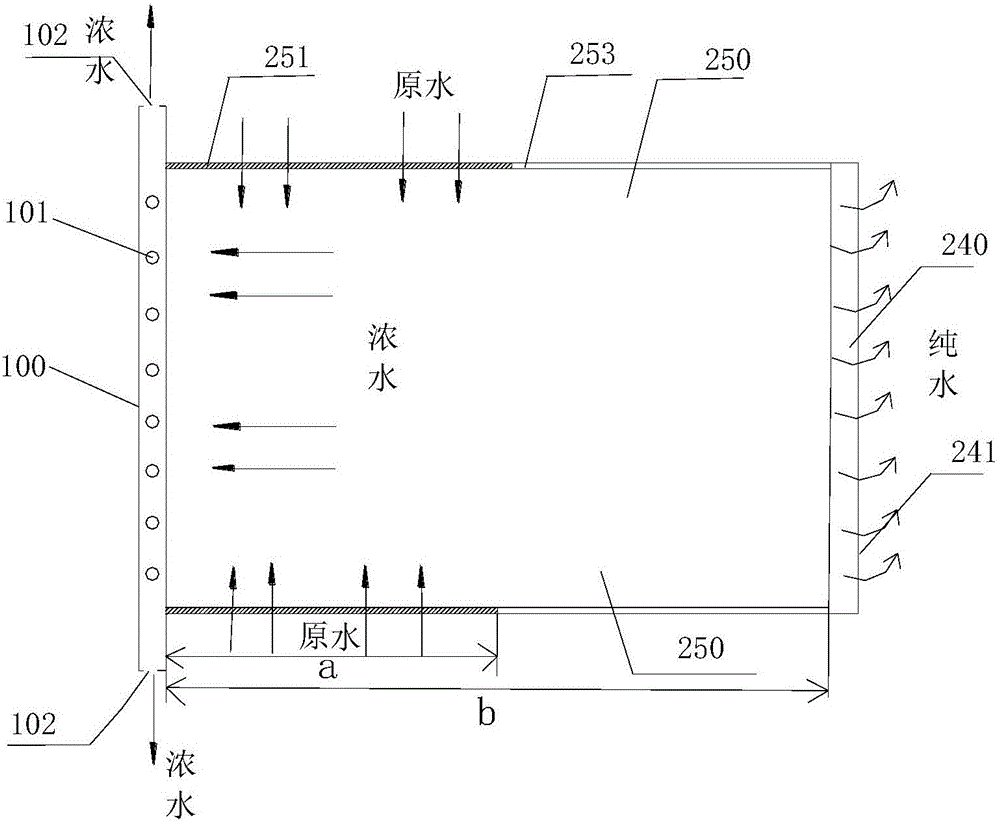

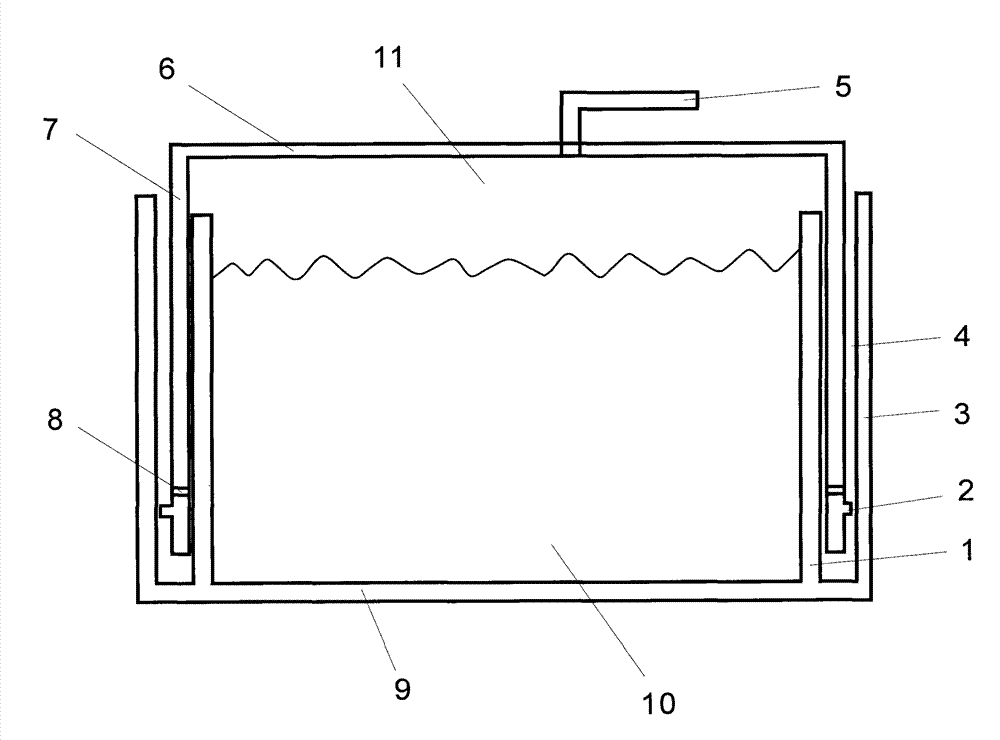

Reverse osmosis membrane element and water purifying device

PendingCN106474925AReduce pollution rateExtended service lifeMembranesReverse osmosisWater productionReverse osmosis

A reverse osmosis membrane element comprises a central tube and a reverse osmosis membrane assembly wound on the central tube, wherein the reverse osmosis membrane assembly comprises a water inlet separating net, a pure water guide net and reverse osmosis membranes; a pure water flow path is formed between the front interlayers of the reverse osmosis membranes; a water inlet flow path is formed between the reverse interlayers of the reverse osmosis membranes; the water inlet separating net is positioned in the water inlet flow path; the pure water guide net is positioned in the pure water flow path; a plurality of concentrated water inlets are formed in the central tube; the end of the central tube is used as a concentrated water outlet of the reverse osmosis membrane element; the reverse osmosis membrane element is provided with two water inlets; the two water inlets are respectively positioned in two end surfaces of the reverse osmosis membrane element; the pure water inlet of the reverse osmosis membrane element is positioned in the circumferential surface of the reverse osmosis membrane element. The reverse osmosis membrane element has the advantages that the pollution speed of the reverse osmosis membrane element can be reduced effectively, the service life of the reverse osmosis membrane element is prolonged, and meanwhile, water production efficiency is improved. The invention further provides a water purifying device.

Owner:GREE ELECTRIC APPLIANCES INC

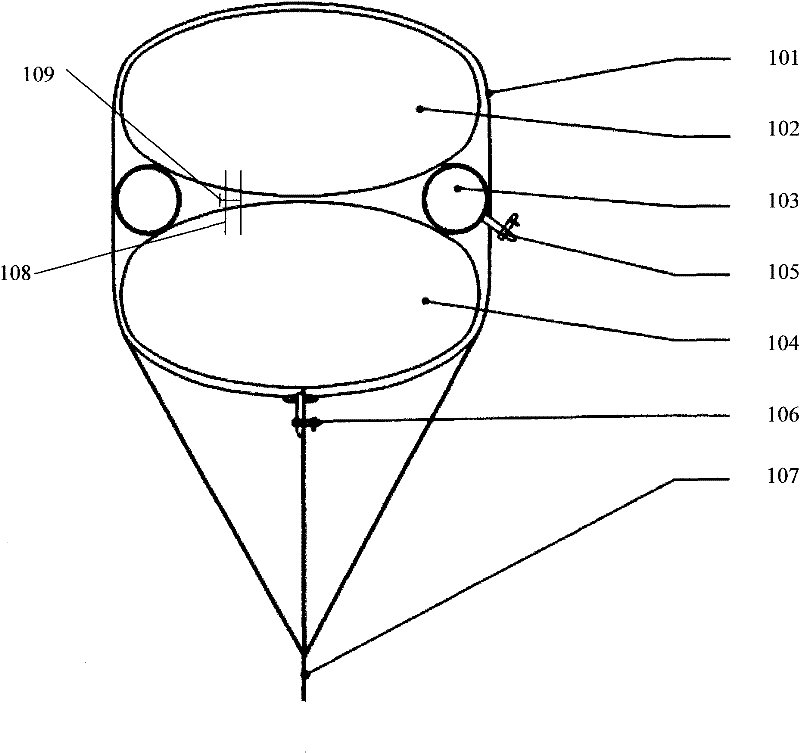

Devices for height entertainment

InactiveCN102275634AStable internal pressureFixed shapeGas-bag arrangementsInternal pressureExplosion protection

The invention provides a device for high-altitude entertainment, which belongs to the field of high-altitude entertainment. At least three gas-filled airbags are built into the cavity of the device. The device includes a barrel-shaped airbag that is filled with helium and expands with heat and contracts with cold, which is explosion-proof and flat-proof. The airbag includes a first airbag, a second airbag and a third airbag, the first airbag and the third airbag are closed airbags filled with helium gas, and the second airbag is an inflatable airbag filled with air. In the present invention, by improving the existing single airbag, the first airbag and the third airbag which are filled with light gas and closed, and the second airbag which is filled with air are set in the inner cavity of the barrel-shaped airbag, and because The second airbag is equipped with a fully automatic inflation and deflation unit to inflate or deflate according to the pressure and temperature of the air, thus ensuring that the inner pressure of the barrel-shaped airbag is stable and the shape is fixed. increased maintenance costs.

Owner:渠仁书

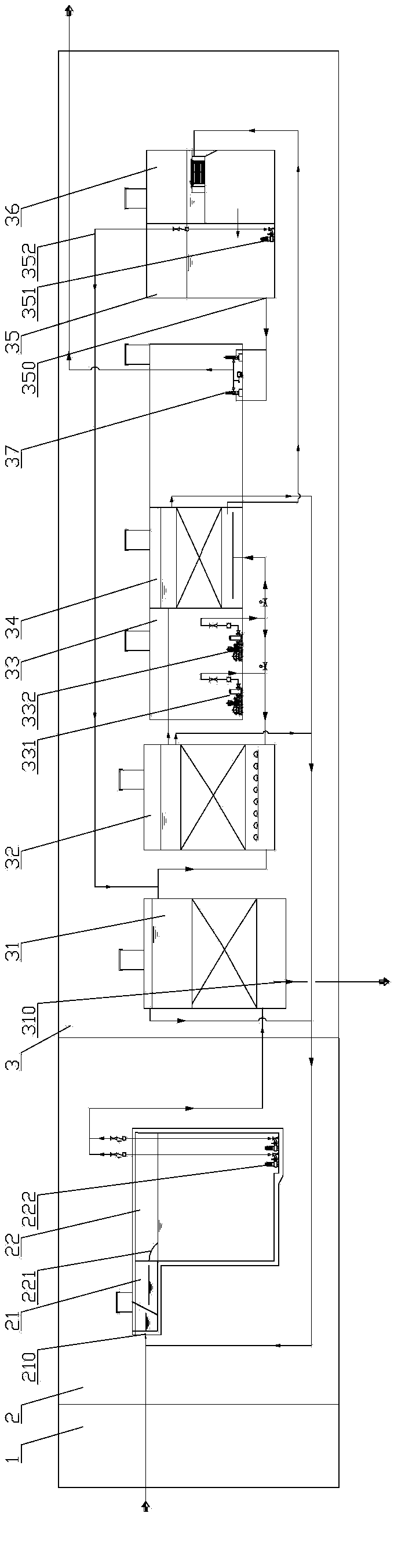

Integrate sewage treatment system

InactiveCN103910461AOff validSave energyWater/sewage treatment by irradiationMultistage water/sewage treatmentFiltrationUv disinfection

The invention discloses an integrated sewage treatment system, and particularly provides an integrated sewage treatment system which has compact structure, low energy consumption and stable internal pressure and realizes good coordination of each part. The integrated sewage treatment system disclosed by the utility model comprises an electric control area, a pretreatment area and a treatment area, wherein the pretreatment area comprises a grille oil separation trench and an adjusting tank which are mutually communicated and fixedly connected; a sewage inlet is formed in the grille oil separation trench; a water level trigger device and a pair of sewage lifting pumps are arranged in the adjusting tank; the water level trigger device and the pair of sewage lifting pumps are communicated with the electric control area; and the treatment area comprises a hydrolysis acidification pool, an aeration biological filtration tank, a fan chamber, a filter tank, a neutral water tank and an ultraviolet disinfection tank which are adjacently distributed and closely arranged sequentially. According to the invention, the floor area of the whole integrated sewage treatment system is effectively reduced, and the construction cost is effectively lowered.

Owner:扬州龙华环境工程有限公司

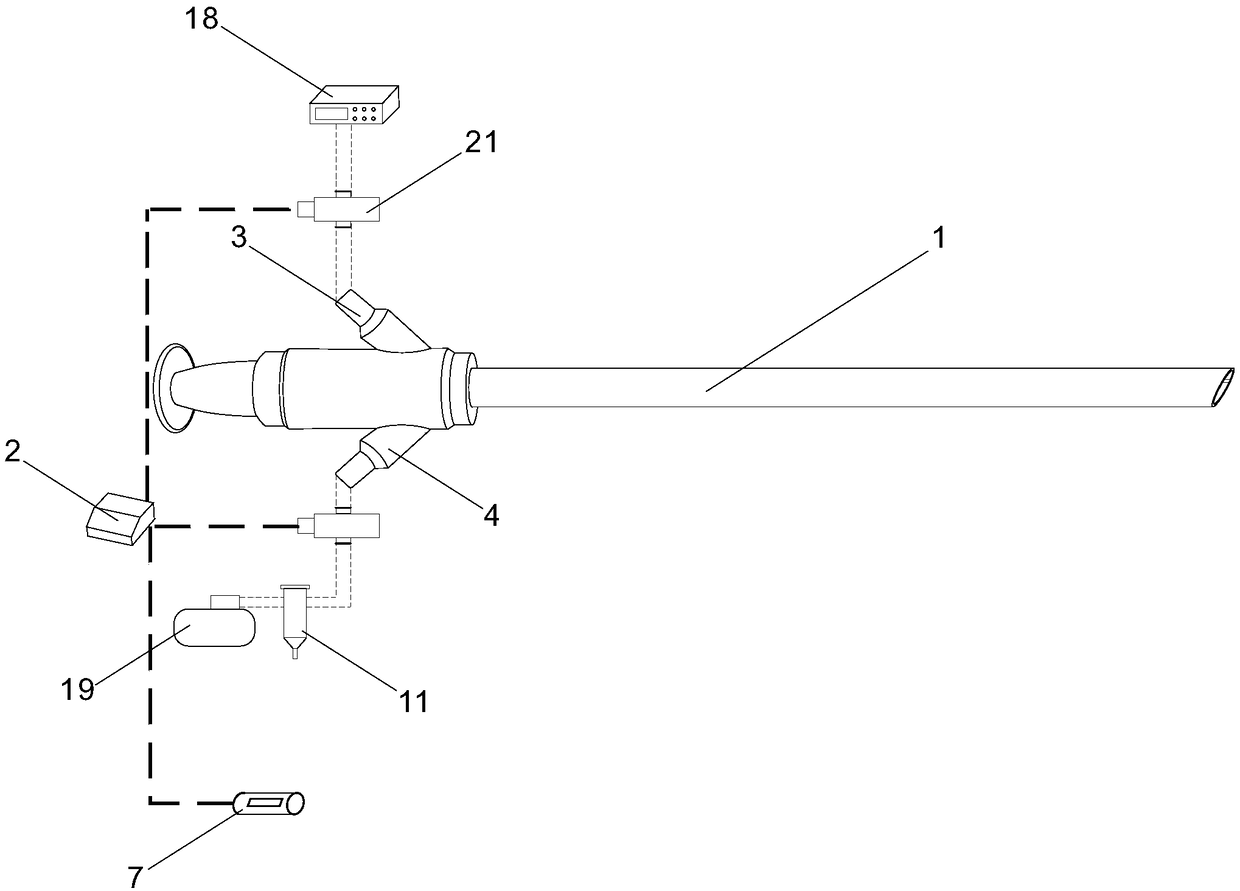

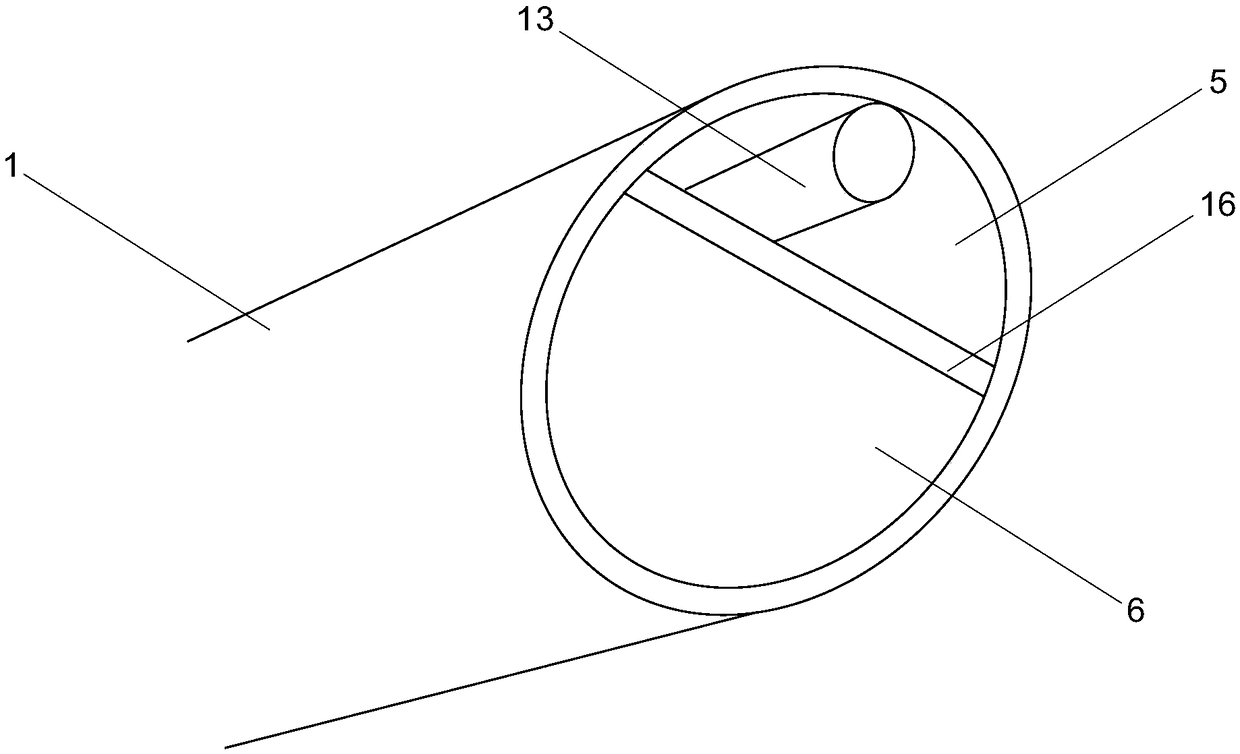

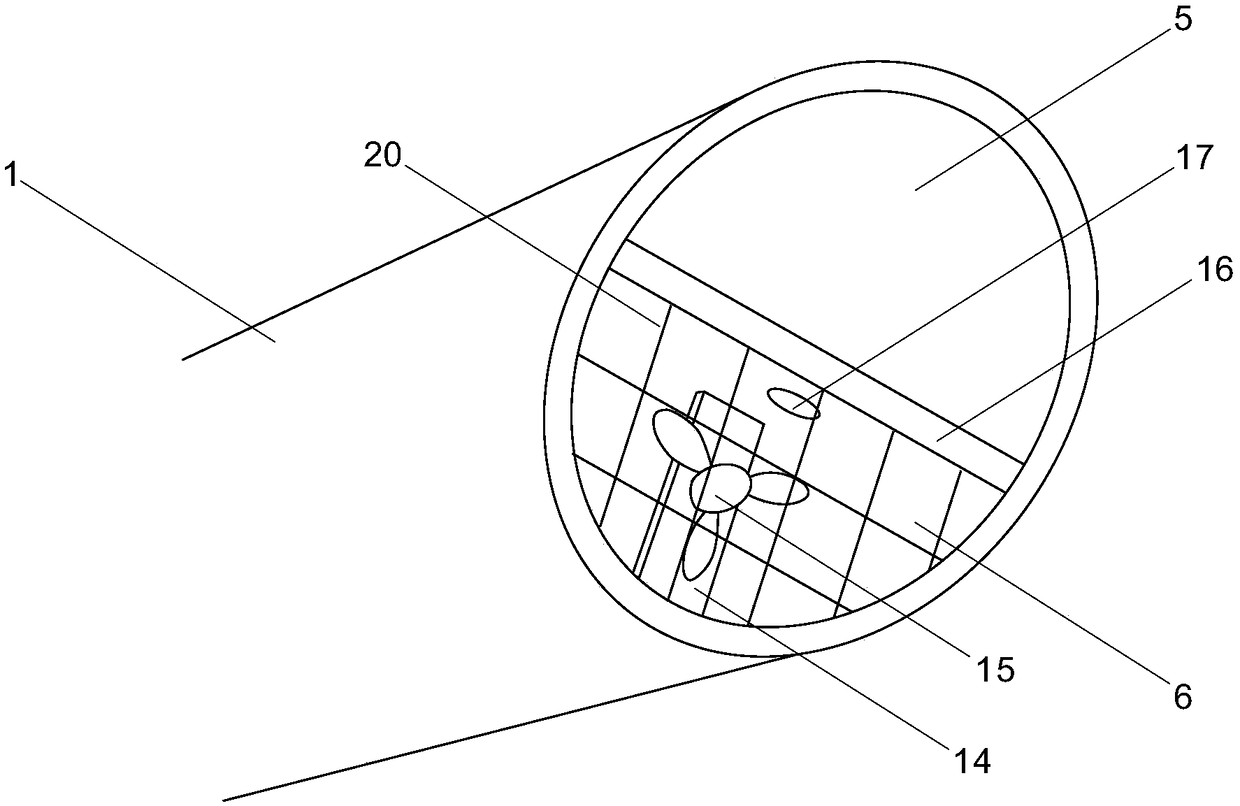

Human necrotic tissue remover

ActiveCN109171889AImprove securityReduce hard contact damageDiagnosticsFluid jet surgical cuttersInternal pressureTissue clearing

The invention discloses a human necrotic tissue remover, including a tube body and a controller, wherein the tube body is provided with an air inlet and an air outlet; the tube body is provided with aflushing cavity passage and an absorption cavity passage separated by a partition plate; the air inlet is communicated with the flushing cavity passage and is connected with a positive pressure air source; the air outlet is communicated with the absorption cavity passage and is connected with a negative pressure air source; and the air inlet and the air outlet are respectively provided with an air valve; and the air valve is electrically connected with a controller. The invention utilizes the gentle impact of the airflow to wash and clean the necrotic tissue, reduces the hard contact injury of the instrument to the human body, on the other hand, the air inlet and exhaust rate can maintain the dynamic balance, maintain the stability of the internal pressure of the human body, avoid the adverse consequences to the human body, improve the safety of the debridement operation, and improve the debridement operation efficiency at the same time.

Owner:HANGZHOU FIRST PEOPLES HOSPITAL

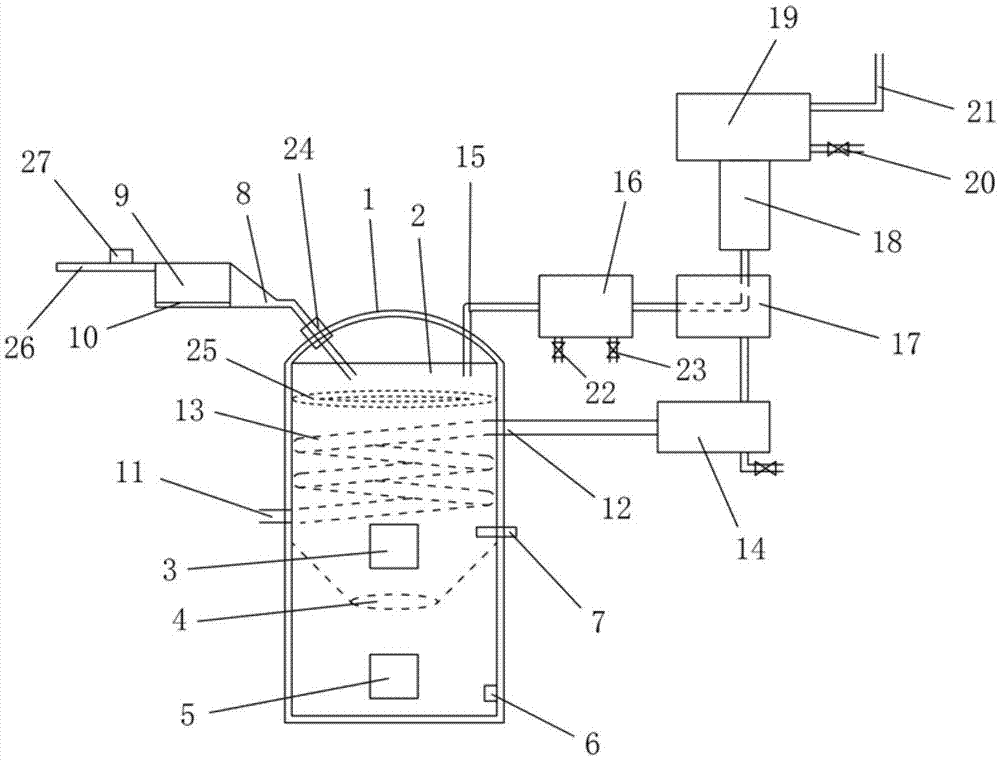

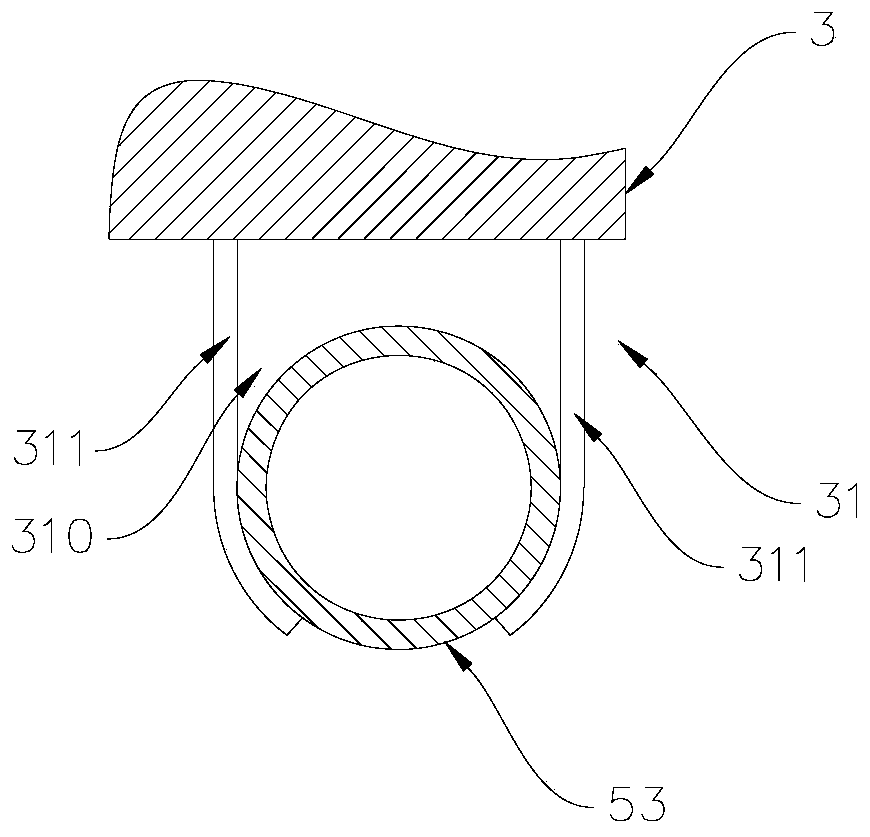

Internal water-seal type methane case

InactiveCN102899240ASimple structureSafe and reliable structureGas production bioreactorsWaste based fuelInter layerEngineering

An internal water-seal type methane case is composed of a methane case body and a case cover. The methane case is characterized in that the methane case body is composed of a base, inner walls and outer walls. Inter-layers are arranged between the inner walls and the outer walls. Seal water is filled in the inter-layers. The methane case cover is composed of a top cove and vertical walls. A methane guide hole is arranged in the top cover and connected with a methane guide pipe. Transverse exhaust holes are arranged on the lower portions of the vertical walls. The methane case cover is covered in the inter-layers of the case body through the vertical walls. Not only the methane case can be used alone, but also a plurality of the methane cases can be connected in series through the methane guide pipe to be used, and the material adding time is staggered, so that methane generating peak and trough periods are complementary.

Owner:高清华

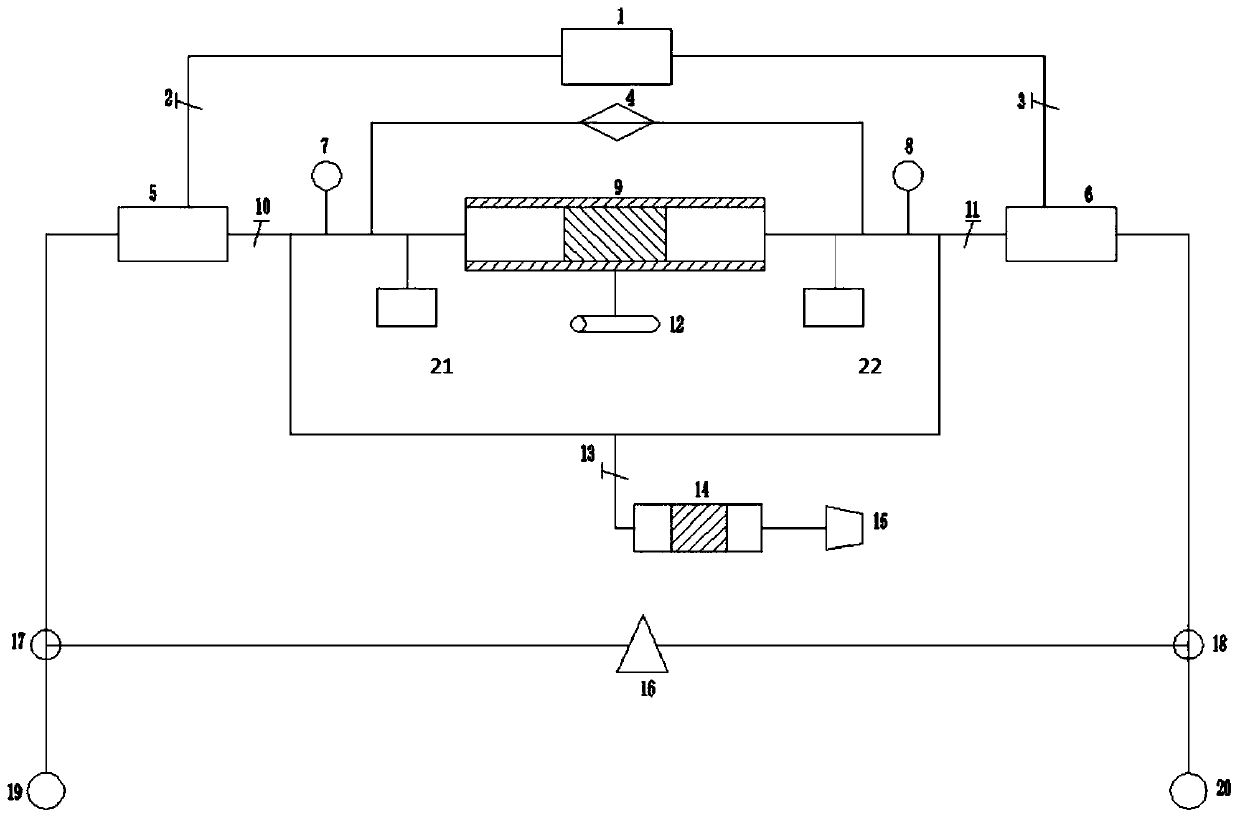

Novel natural gas diffusion coefficient measurement experimental device

ActiveCN110426321ASimple structureEnsure consistencyComponent separationFluid pressure measurementDifferential pressurePressure sense

The invention discloses a novel natural gas diffusion coefficient measurement experiment device which mainly comprises a novel rock core holder, a differential pressure sensor, a pressure gauge, a multi-way valve, a confining pressure pump, a vacuum pump, a hydrocarbon gas source, a nitrogen gas source, a gas chromatograph, an intermediate container, a sample cavity, a pressure stabilizing deviceand a pressure sensing alarm device. The rubber sleeve of the novel rock core holder can prevent the phenomenon that the rock core is clamped in the holder due to improper operation when the rock coreis replaced, the pressure stabilizing device is connected with the sample cavity to ensure that after the sampling is finished, the internal pressure of the cavity is kept stable, one experimental variable is reduced, and the experimental result is more accurate and reliable. The pressure sensing alarm device presets a pressure lower limit value before the experiment is carried out, if the equipment leaks air during the experiment, the pressure is reduced to a lower limit value, the sensing device can sense and send a warning to the mobile equipment of the experimenter in time, which is of great significance to ensure safe performance of the experiment.

Owner:SOUTHWEST PETROLEUM UNIV

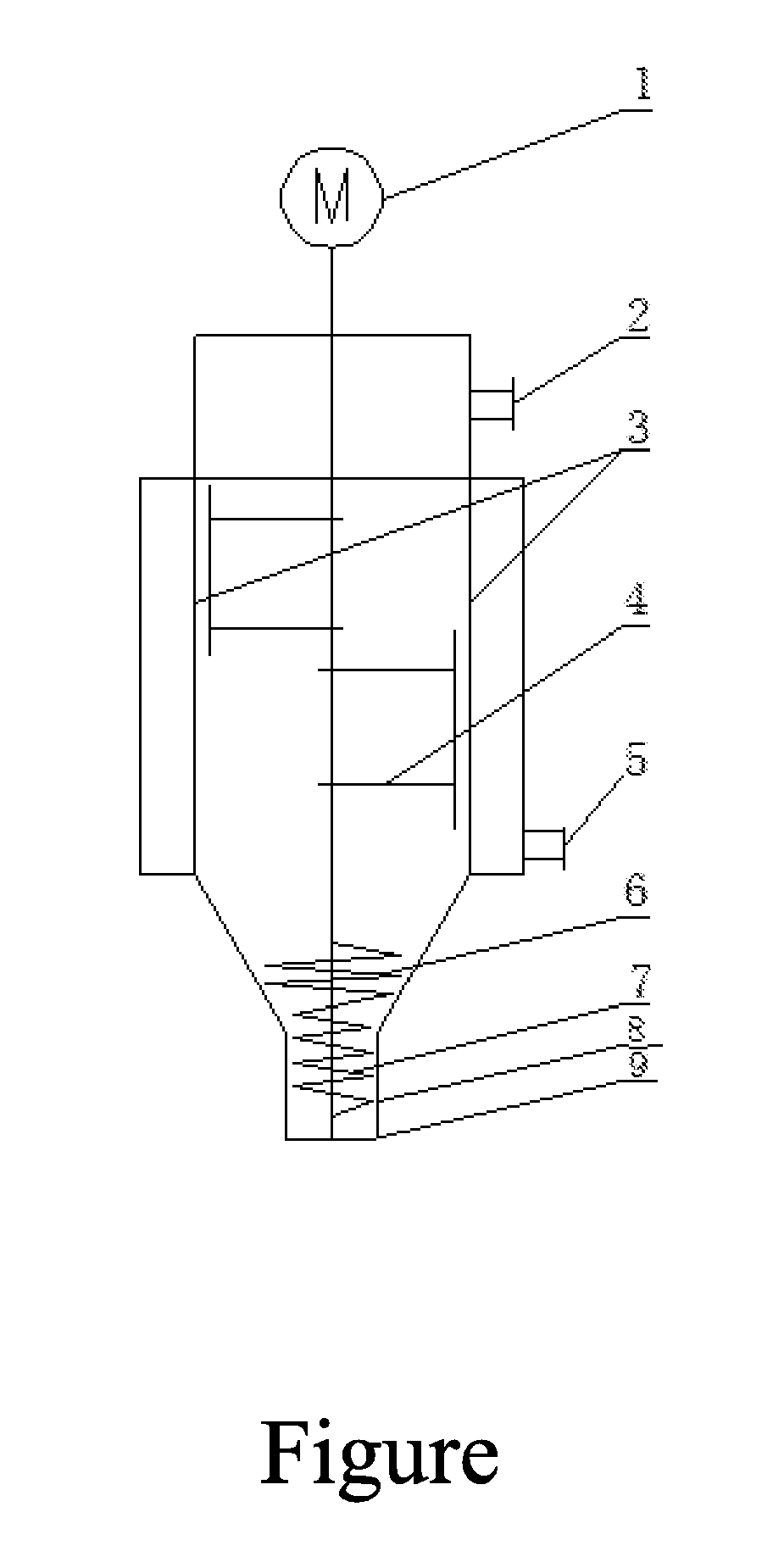

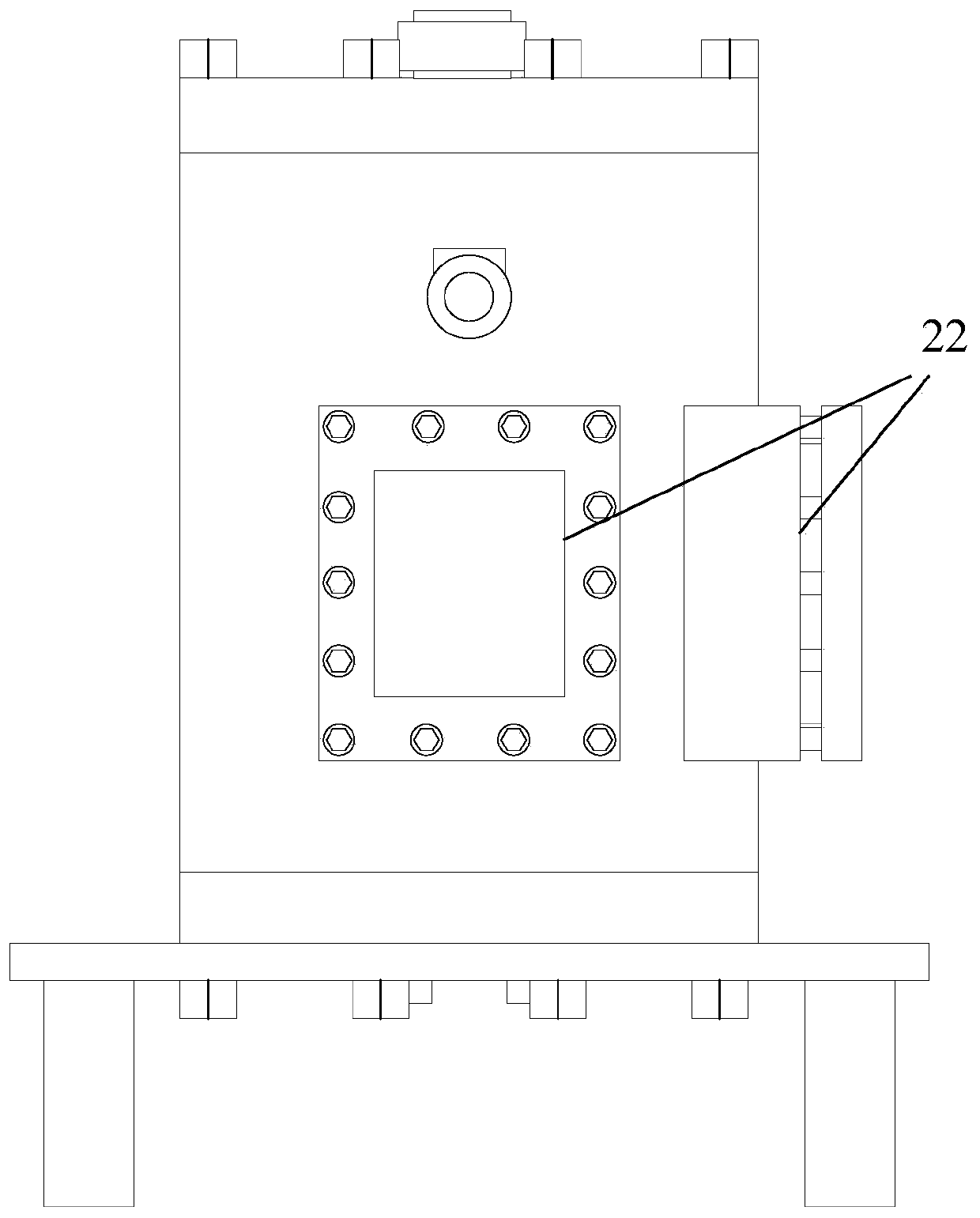

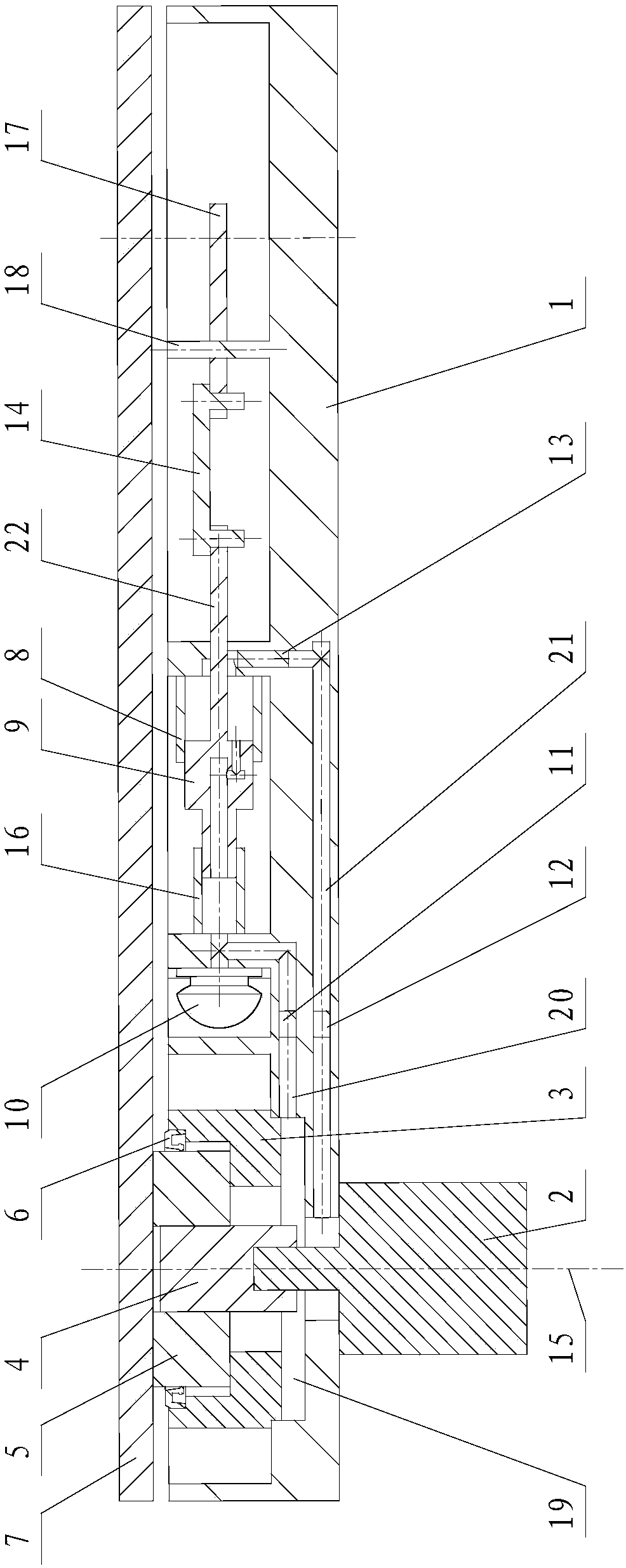

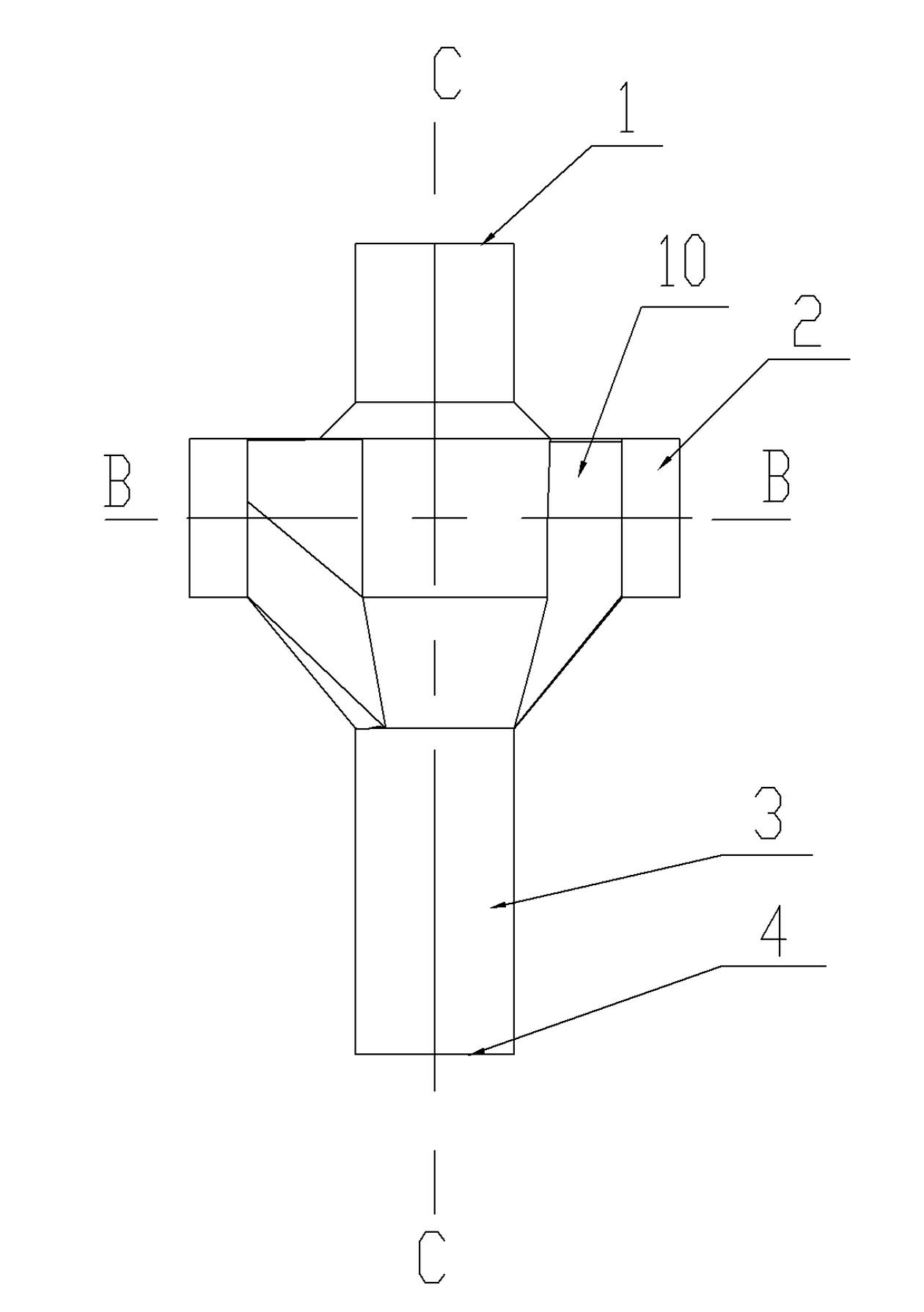

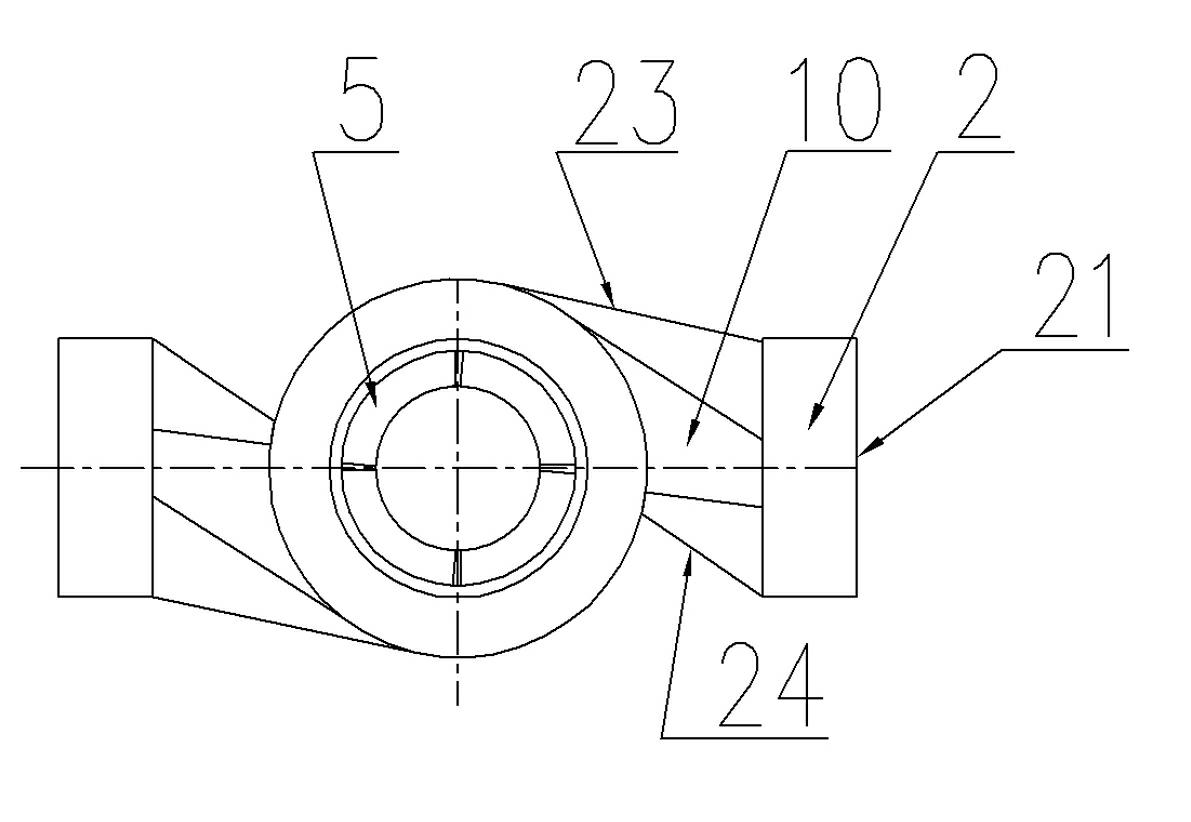

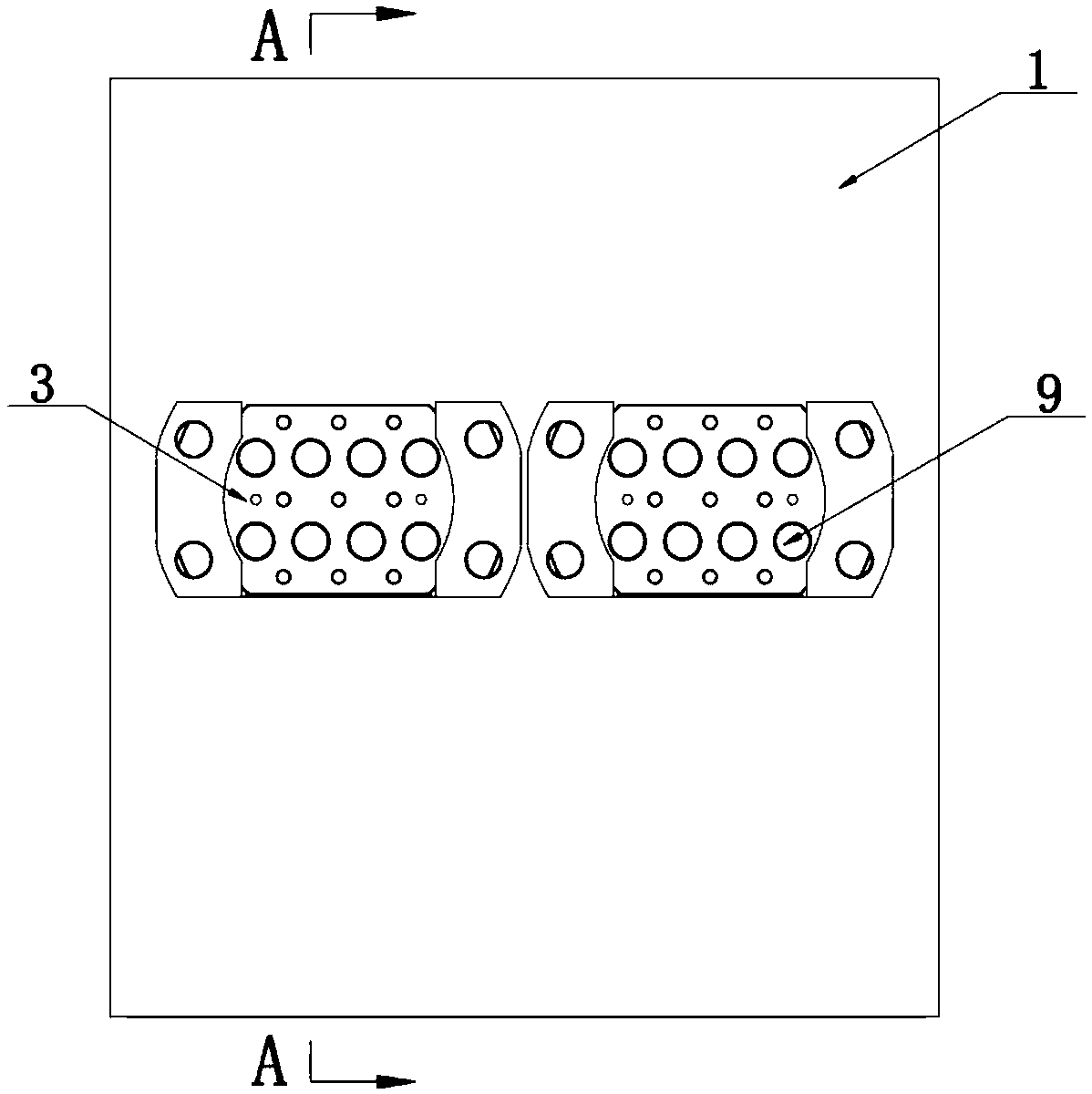

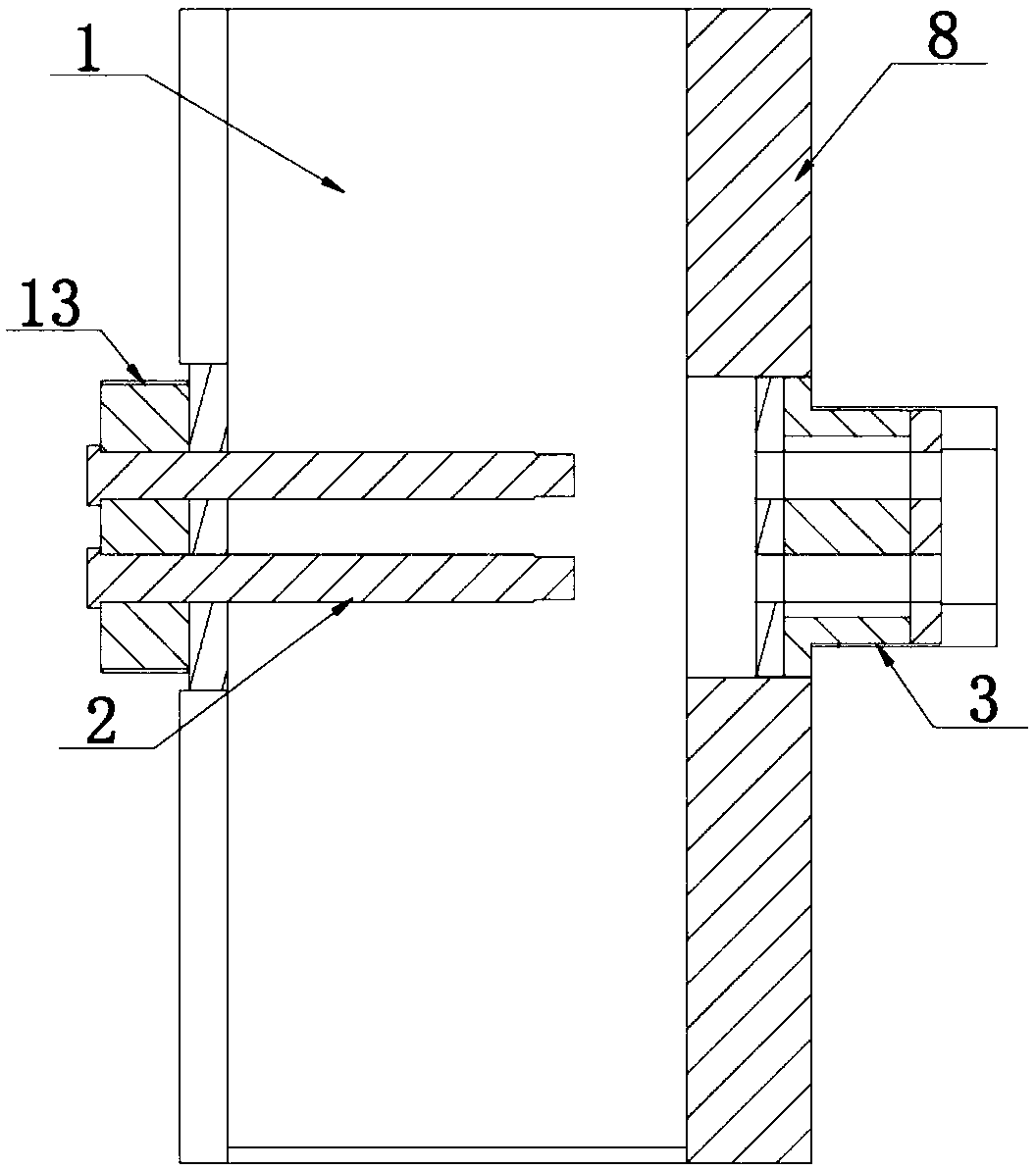

Spiral seal continuous discharge filter for supercritical water treatment process

InactiveUS20170282100A1Easy to operateRational designStationary filtering element filtersSpiral bladeWater treatment

A spiral seal continuous discharge filter for supercritical water treatment process is provided, including: a filter chamber and a motor 1 provided on a top of the filter chamber; wherein a liquid inlet is provided on an up portion of a wall of the filter chamber, a filter screen is provided in the filter chamber, a purified liquid outlet is provided on an external side of the filter screen, a vertical discharge pipe is provided on a bottom portion of the filter chamber, a driving rod rotated by driven of the motor is provided on a central axis of the filter chamber, a plurality of electric scratch brushes are provided on the driving rod, and a two-stage spiral blade unit is provided on a bottom of the driving rod.

Owner:XI AN JIAOTONG UNIV

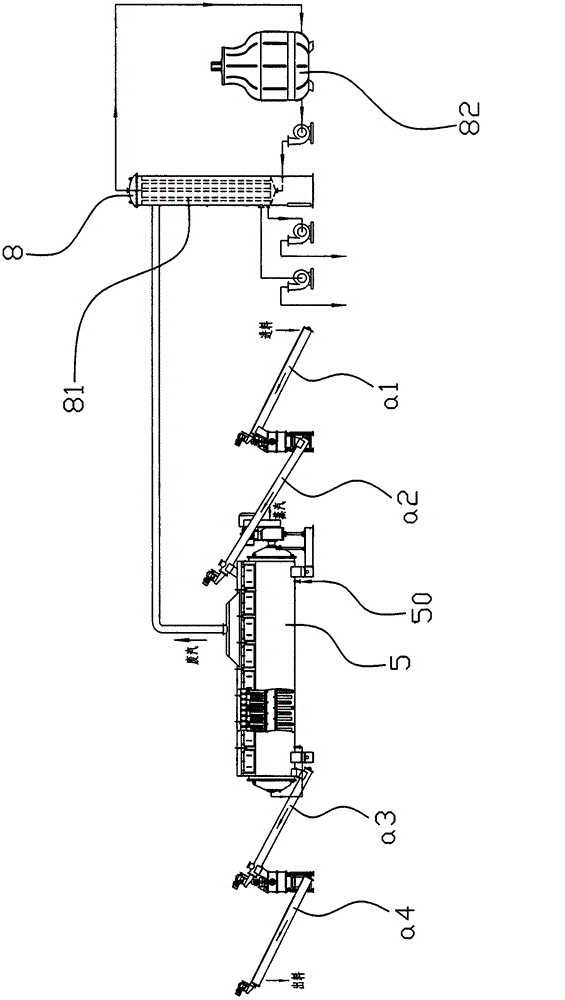

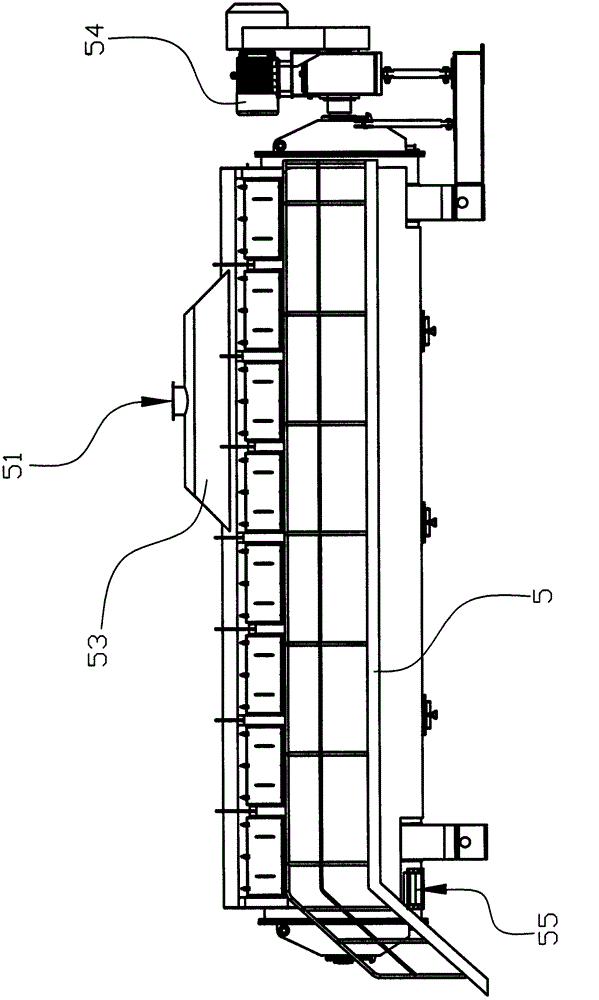

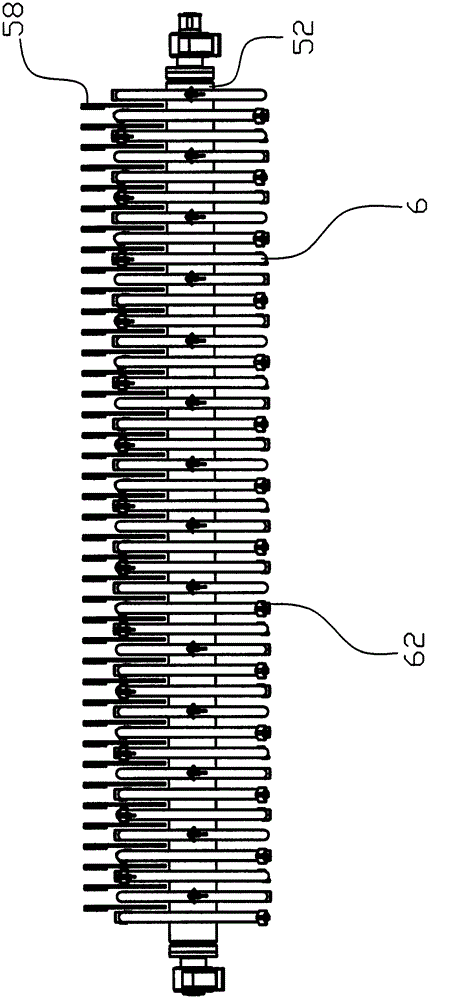

Vacuum low-temperature continuous drying machine

InactiveCN104642496AEasy to handleTemperature controlFood processingMeat/fish preservation by dryingInternal pressureEngineering

The invention provides a vacuum low-temperature continuous drying machine. The machine comprises a raw material drying device, first to fourth raw material conveying devices, a vacuum feeding device, a vacuum discharging device and a condenser; a raw material inlet is formed in one end of the first raw material conveying device, while the other end of the first raw material conveying device is in sealing connection with a feeding opening of the vacuum feeding device; a discharging opening of the vacuum feeding device is in sealing connection with a raw material feeding opening of the second raw material conveying device; a raw material discharging opening of the second raw material conveying device is in the sealing connection with a feeding opening of the raw material drying device; a discharging opening of the raw material drying device is in the sealing connection with a feeding opening of the third raw material conveying device; a discharging opening of the third raw material conveying device is in the sealing connection with the feeding opening of the vacuum discharging device; a discharging opening of the vacuum discharging device is connected with a feeding opening of the fourth raw material conveying device; a waste air outlet is formed in the raw material drying device and connected with a feeding opening of a condenser. The machine has the advantages of being high in sealing performance, stable in internal pressure and temperature, high in finished product quality, and green; materials can be continuous to feed, and energy is saved.

Owner:浙江龙源四方机械设备制造有限公司

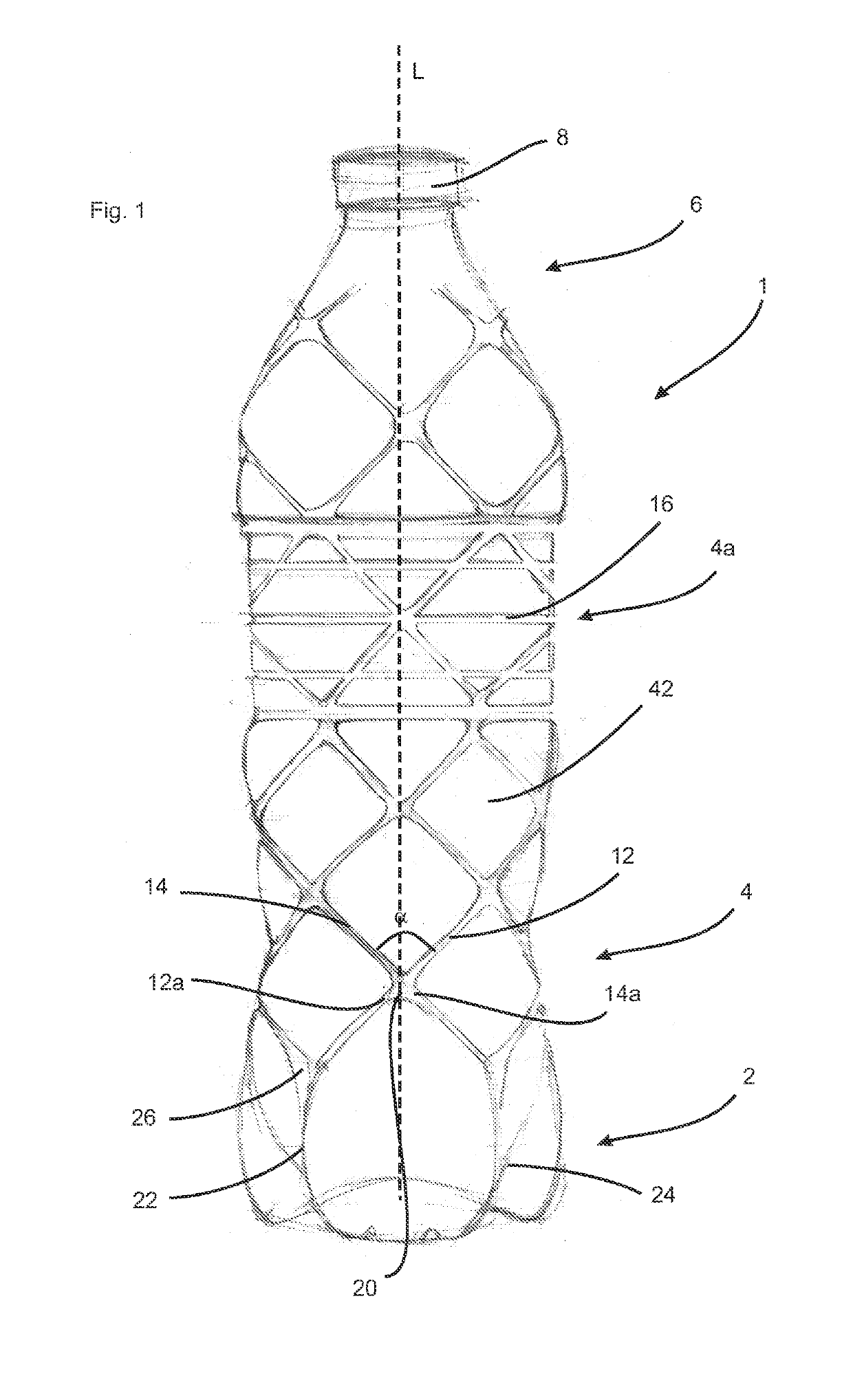

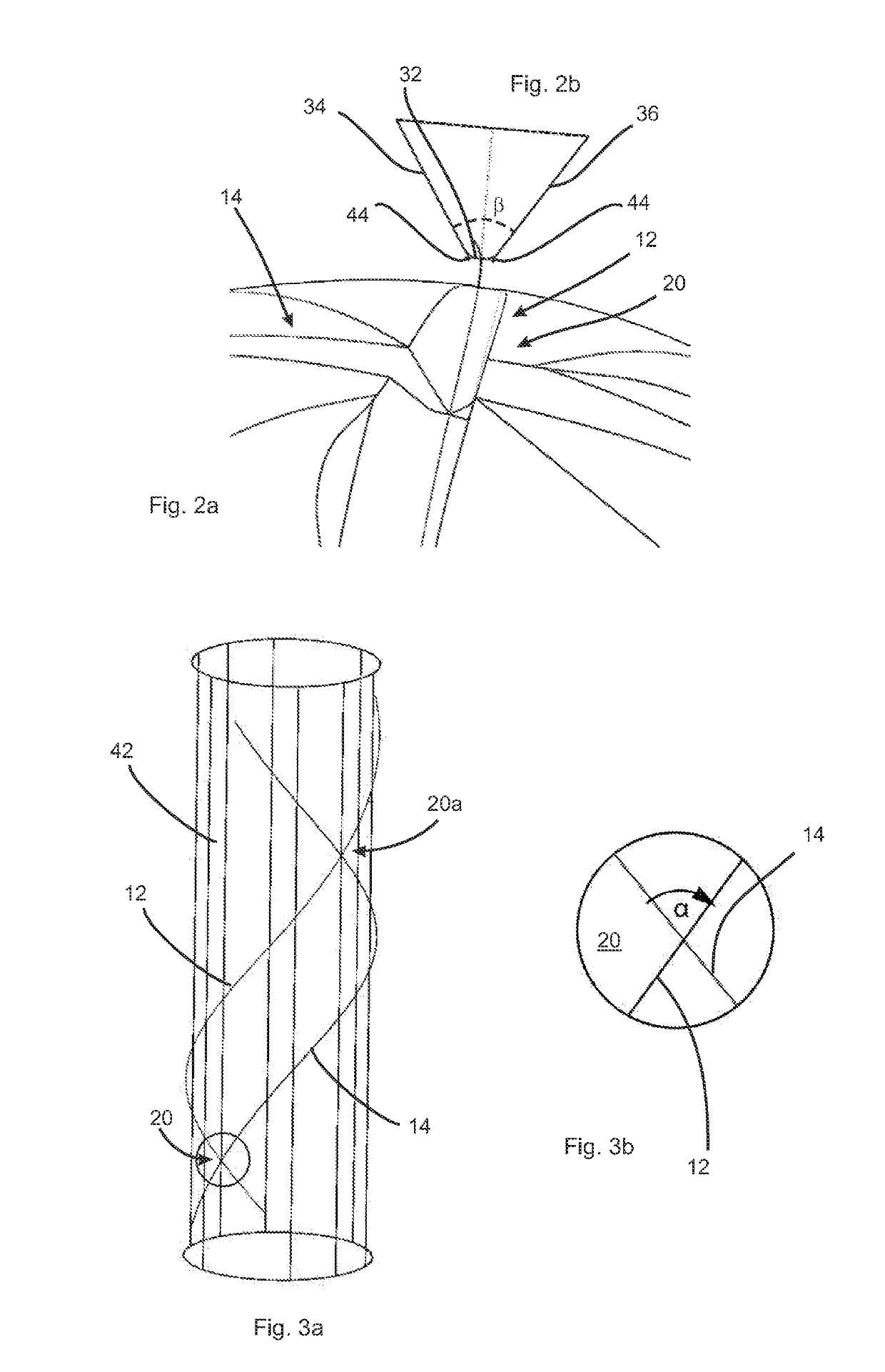

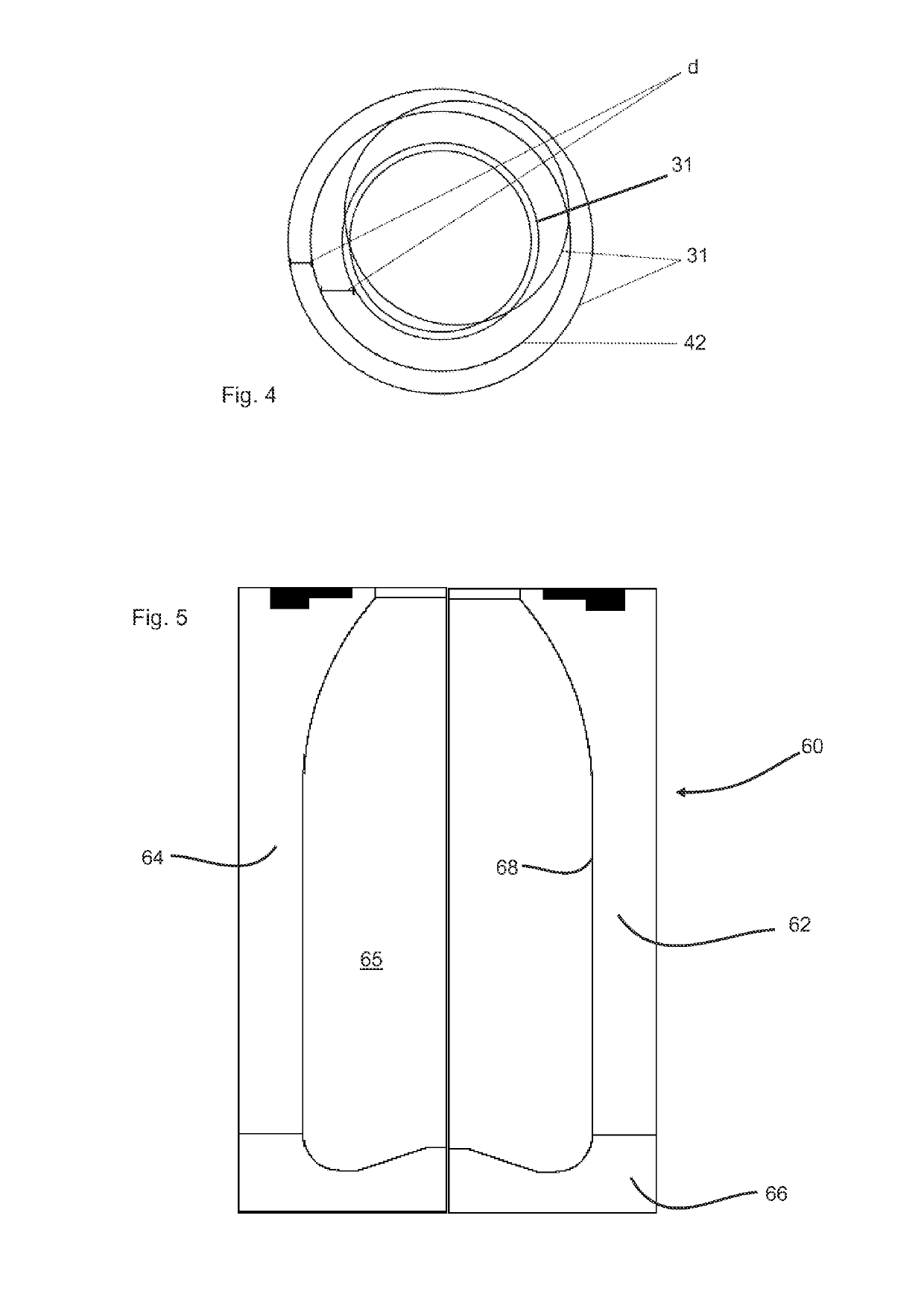

Plastics material bottle with intersecting tension bands

Owner:KRONES AG

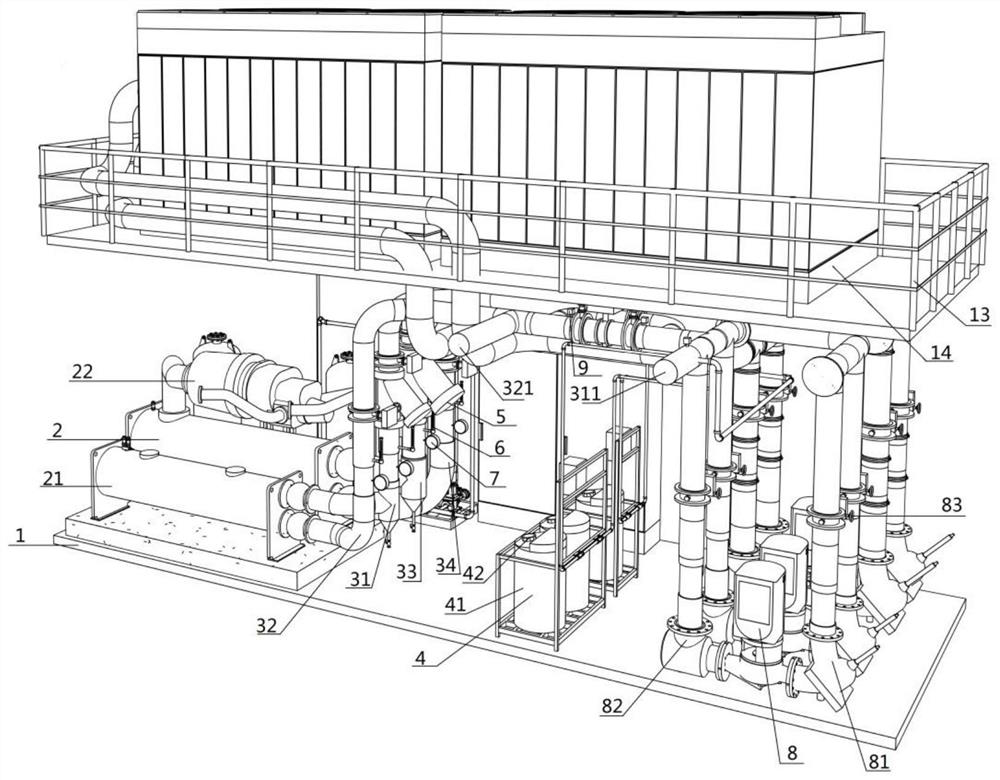

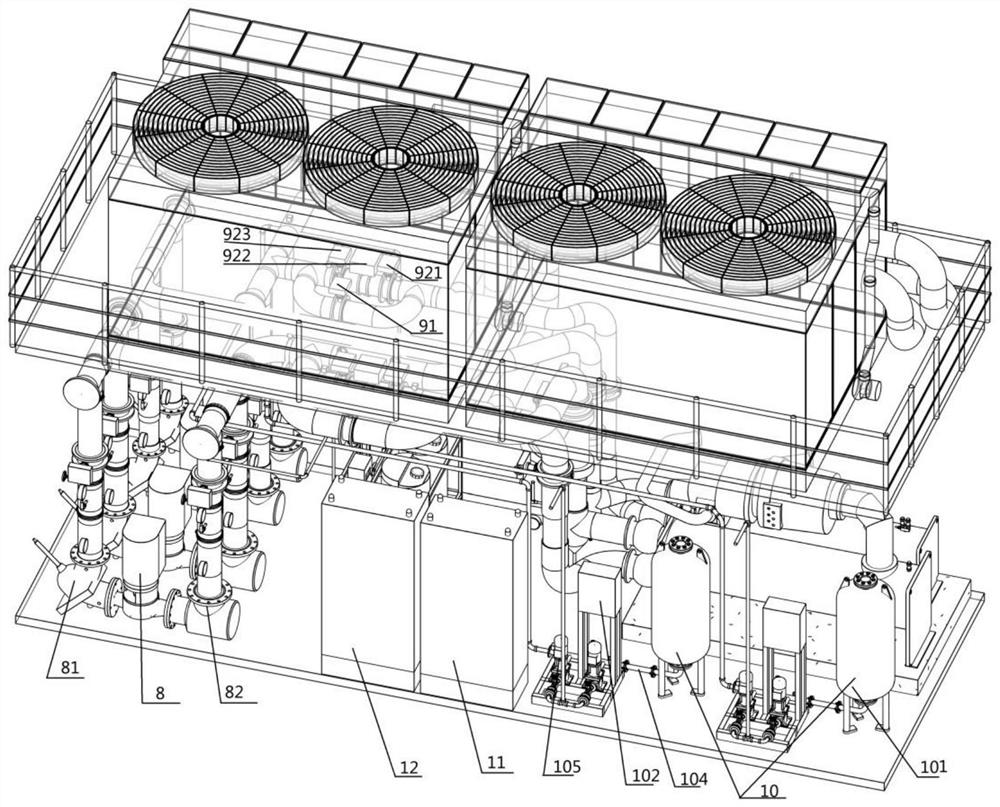

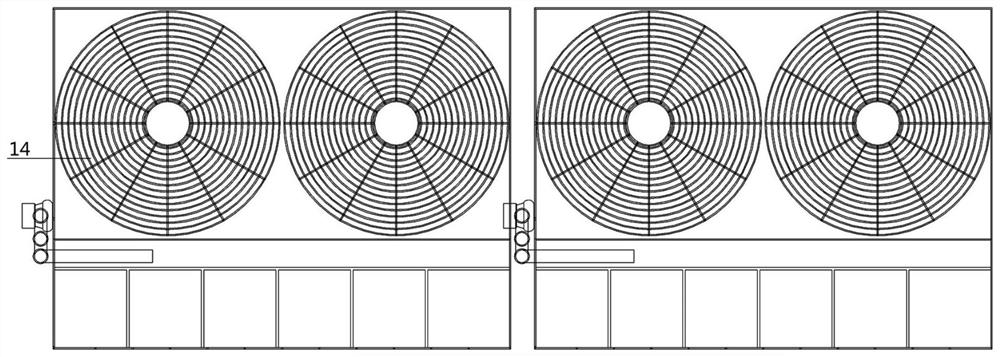

Container type refrigeration station

PendingCN112212587AClear waterStable internal pressureLighting and heating apparatusTreatment involving filtrationProcess engineeringWater pipe

A container type refrigeration station comprises a container body, a refrigerating unit, multiple water pipelines, an automatic dosing device, a Y-shaped filter, a vertical pipeline pump, a constant-pressure water supplementing device, an equipment main power supply, a power cabinet and a closed cooling tower, and is characterized in that the bottom of the closed cooling tower is fixedly connectedwith the top of the container body; the refrigerating unit comprises two compressors, a condenser and an evaporator, the multiple water pipelines are connected with the refrigerating unit; a Y-shapedfilter is arranged at the position, close to the refrigerating unit, of each water pipeline; and the constant-pressure water supplementing device, the equipment main power supply, the power cabinet,the automatic dosing device and the vertical pipeline pump are arranged in the container body; the automatic dosing device, the constant-pressure water supplementing device and the vertical pipeline pump are connected with the water pipelines; and the water pipelines include a chilled water supply pipe, a chilled water outlet pipe, a cooling water supply pipe and a cooling water outlet pipe.

Owner:艾尔科工程技术有限公司

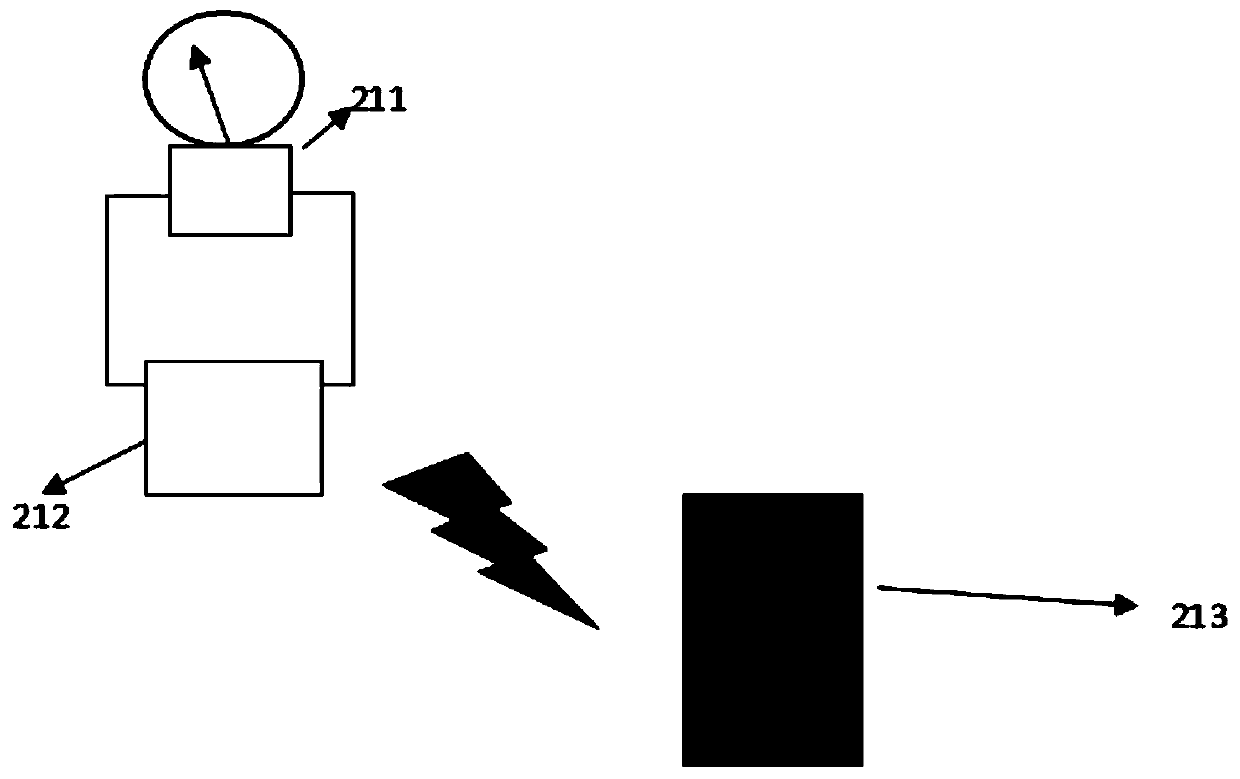

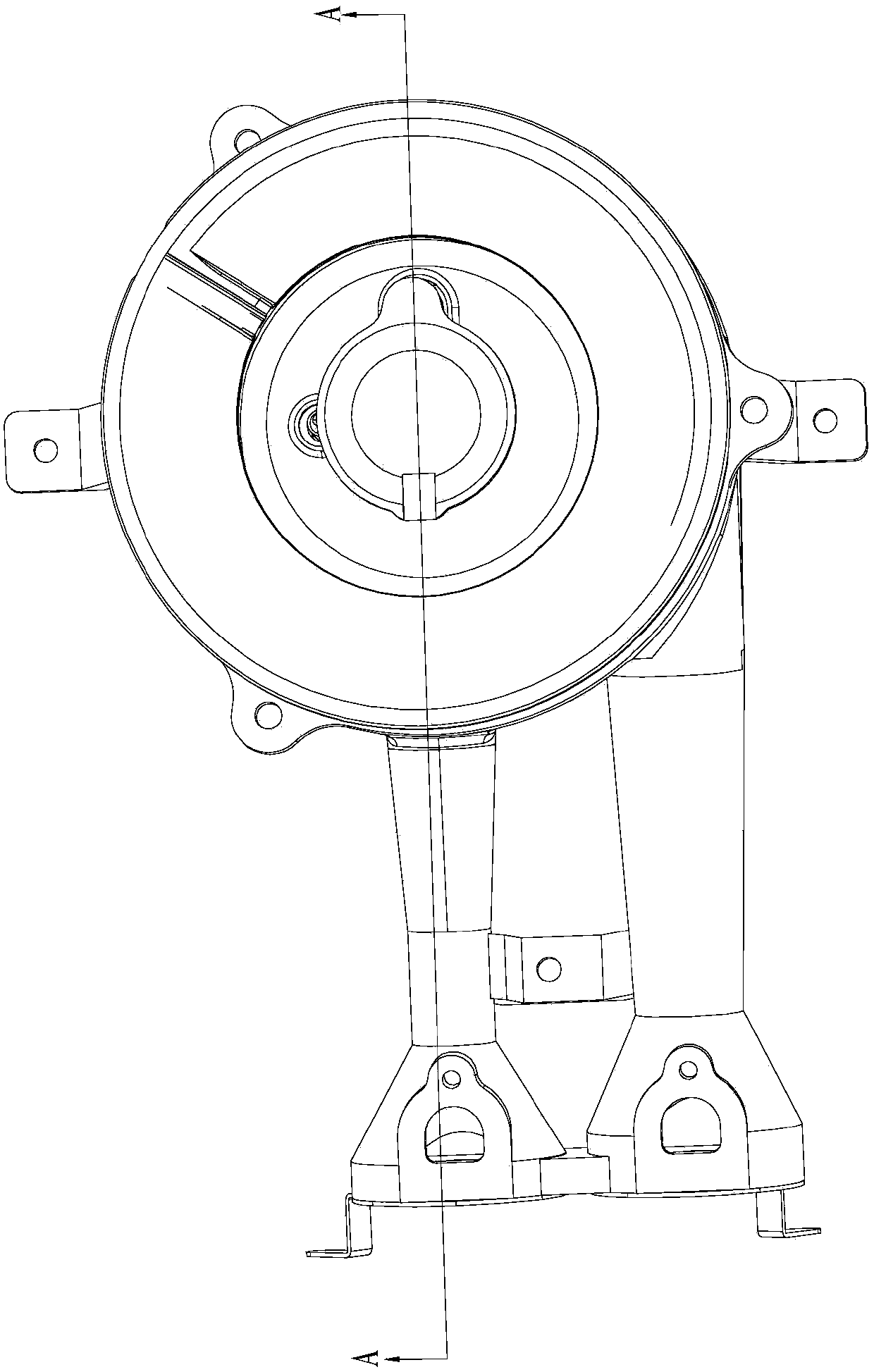

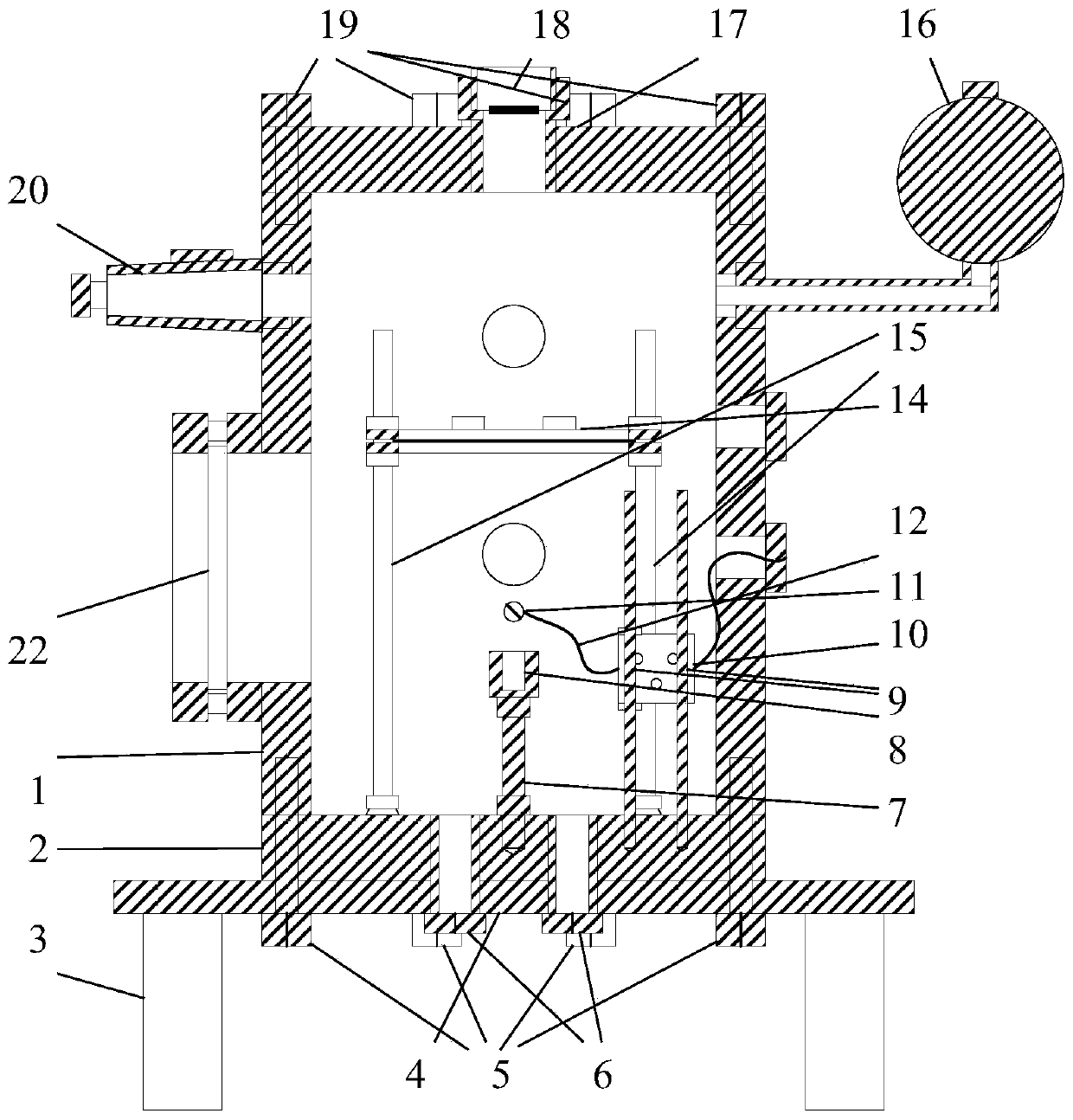

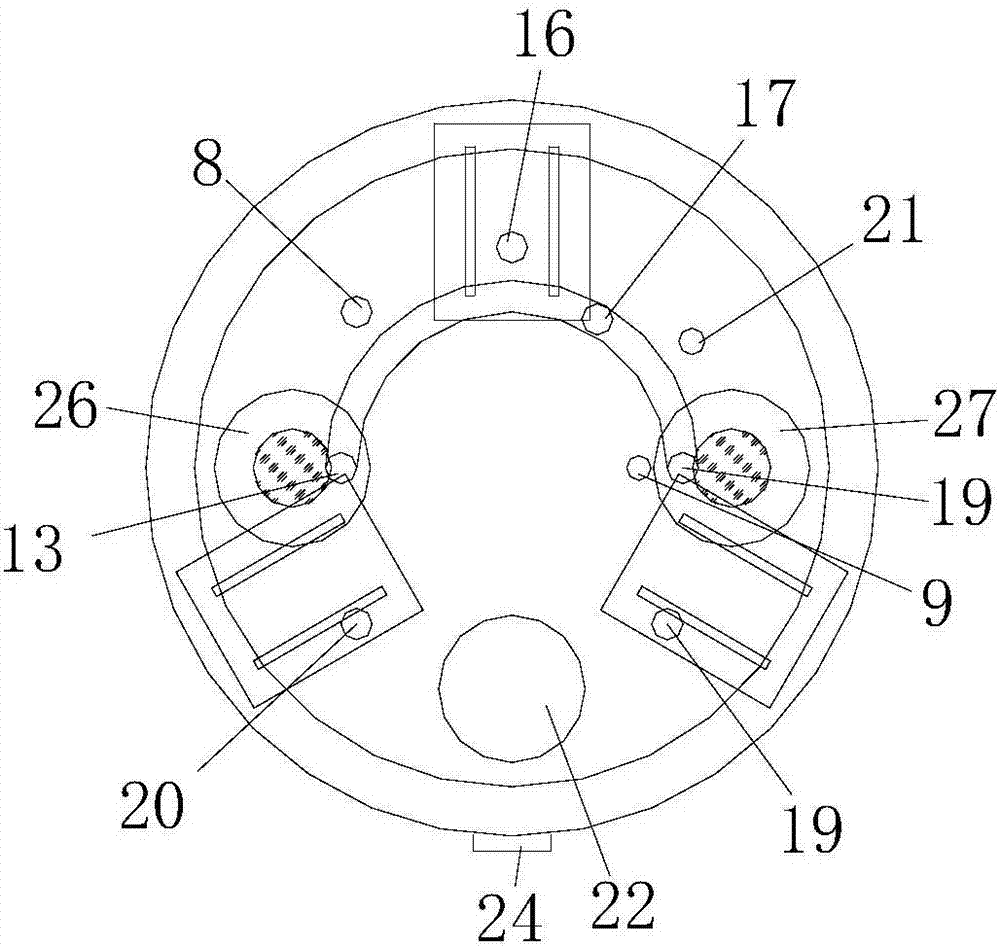

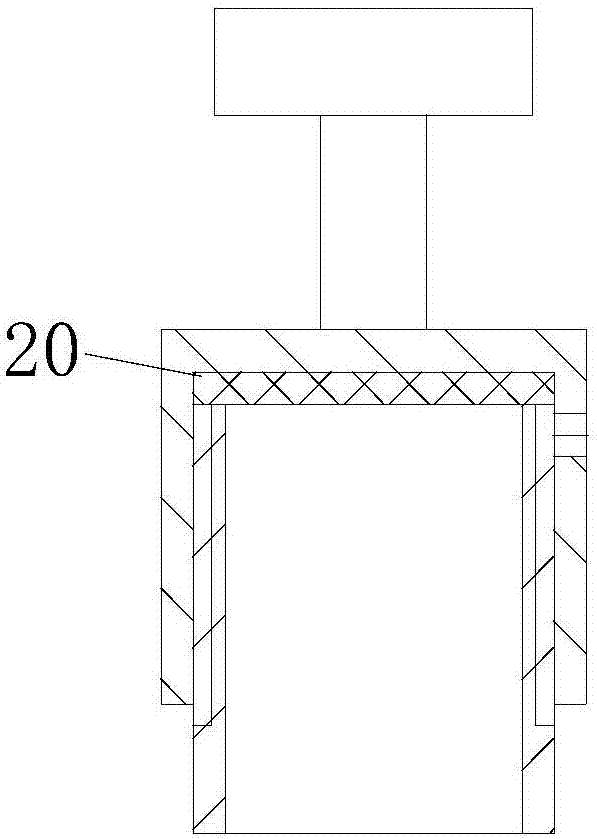

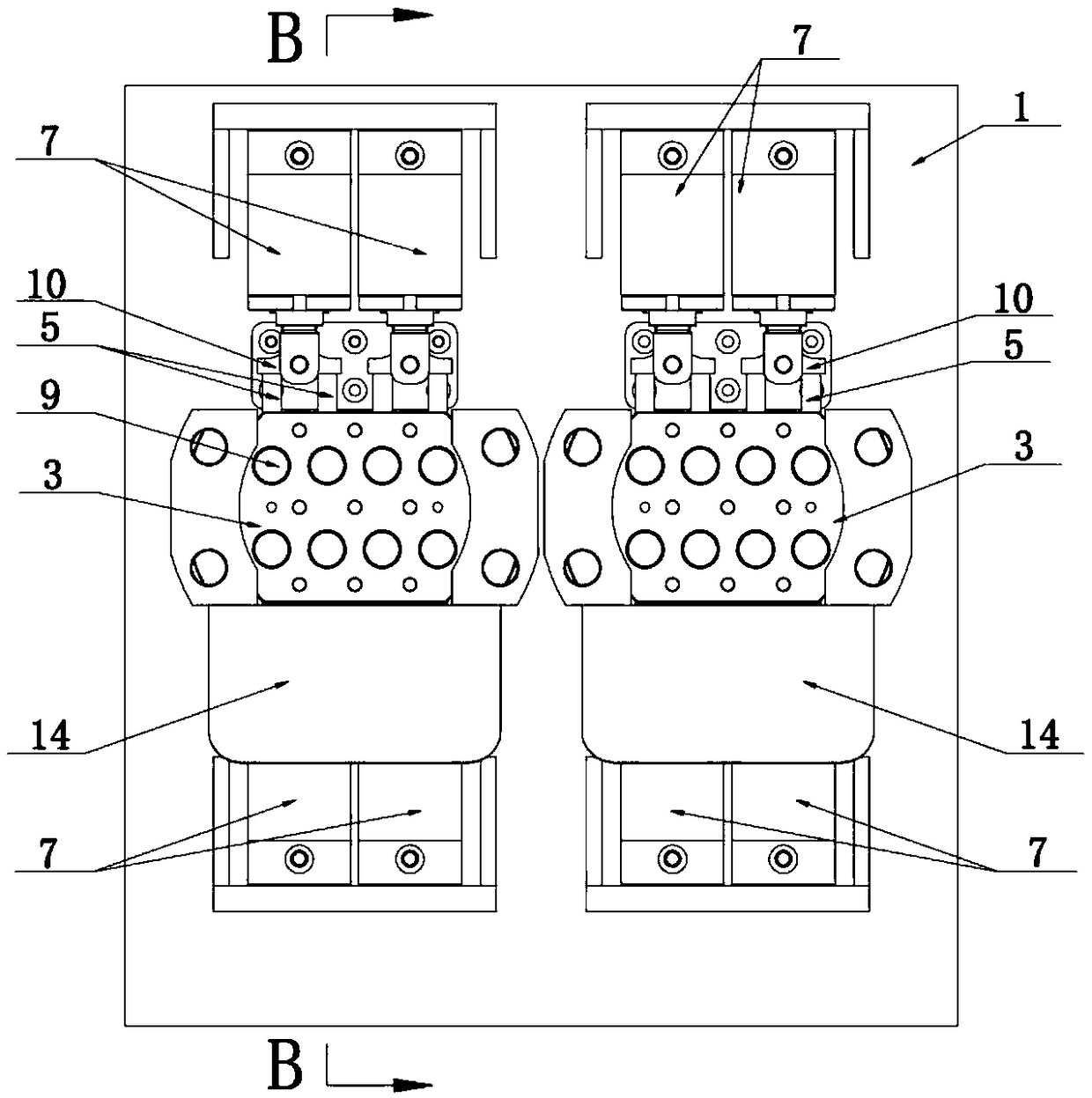

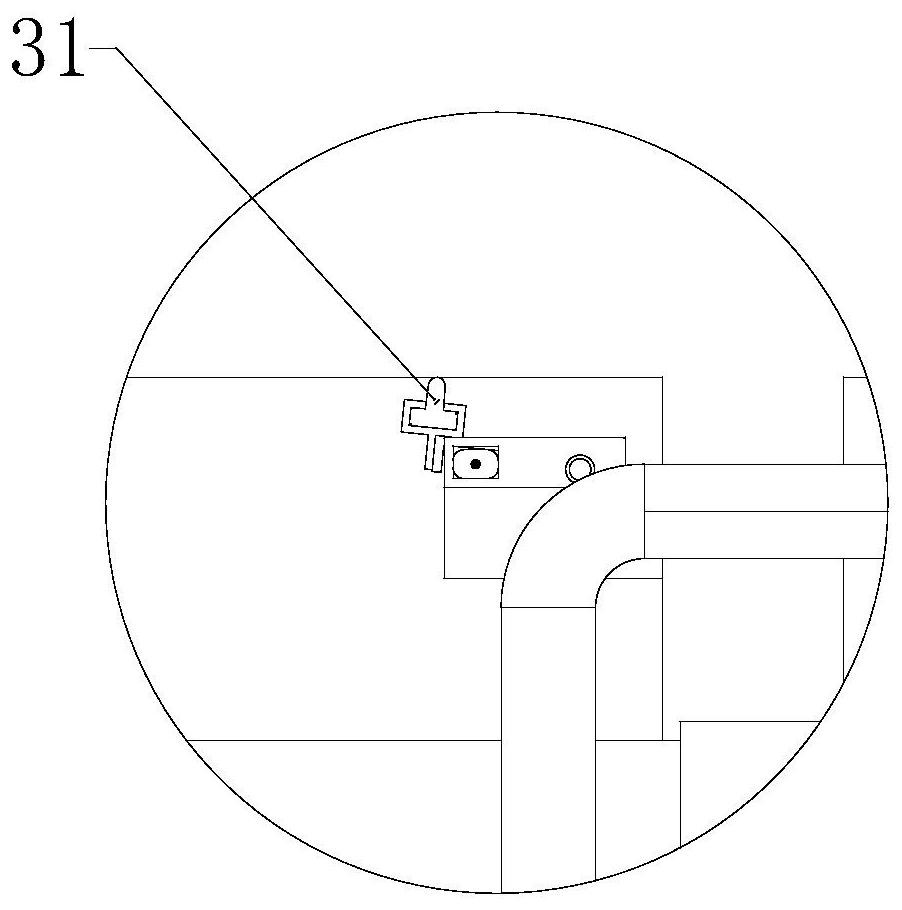

Actuating cam type lubricating self-cleaning mechanism

ActiveCN109807929ALow resistance to joint rotationStable pressureGear lubrication/coolingManipulatorInternal pressureReducer

The invention relates to an actuating cam type lubricating self-cleaning mechanism. A motor is connected to a large arm in a static sealing mode, an output end of the motor is connected with one end of an output shaft of a speed reducer through an input gear shaft of the speed reducer, one end of a shell of the speed reducer is arranged in the large arm in a static sealing mode, the other end of the shell of the speed reducer is connected with the output shaft of the speed reducer in a sealing rotation mode, and the other end of the output shaft of the speed reducer is connected with a small arm in a in static sealing mode; the two ends of an inertia double-head piston are connected with a large cylinder barrel and a small cylinder barrel in a sealing mode to form sliding pairs correspondingly; and a speed reducer inner cavity filled with lubricating grease is arranged in the large arm, the speed reducer inner cavity communicates with the interior of the small cylinder barrel through an oil way A, the interior of the large cylinder barrel communicates with the speed reducer inner cavity through an oil way B, an oil outlet one-way valve allowing oil to flow to the small cylinder barrel only is arranged in the oil way A, an oil return one-way valve allowing oil to flow to the speed reducer inner cavity only is arranged in the oil way B, and a filter element is arranged in the part, close to the large cylinder barrel, of the oil way B. According to the mechanism, the internal pressure of a robot joint can be stabilized, oil leakage is prevented, the energy efficiency is improved, and the energy-saving and environment-friendly effects are better.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Button cell

PendingCN109037510AImprove performanceMitigate the risk of compression deformationFinal product manufactureWound/folded electrode electrodesButton batteryEngineering

The invention relates to the technical field of batteries, in particular to a button battery. A button battery comprising a negative electrode cover, a positive electrode housing, a single layer metalsupport ring and a support retainer ring; The circumferential edge of the negative electrode cover is provided with a sealed plastic insert ring and a positive electrode shell, the negative electrodecover and the sealed plastic insert ring cooperate to form a sealed space, and a winding electrode group and an electrolyte are arranged in the sealed space; The single-layer metal support ring is located between the lower surface of the sealing plastic-inlaid ring and the upper surface of the shell bottom of the positive electrode case, and the inner ring wall of the single-layer metal support ring and the outer surface of the winding pole group are arranged in a gap; The support retainer ring is fixedly connected with the single layer metal support ring, and the outer surface of the supportretainer ring is in contact with the inner surface of the sealing plastic insert ring. The invention can enhance the sealing performance, effectively alleviate the air expansion phenomenon, and improve the charging and discharging performance and the service life.

Owner:SHENZHEN LIYUAN BATTERY TECH CO LTD

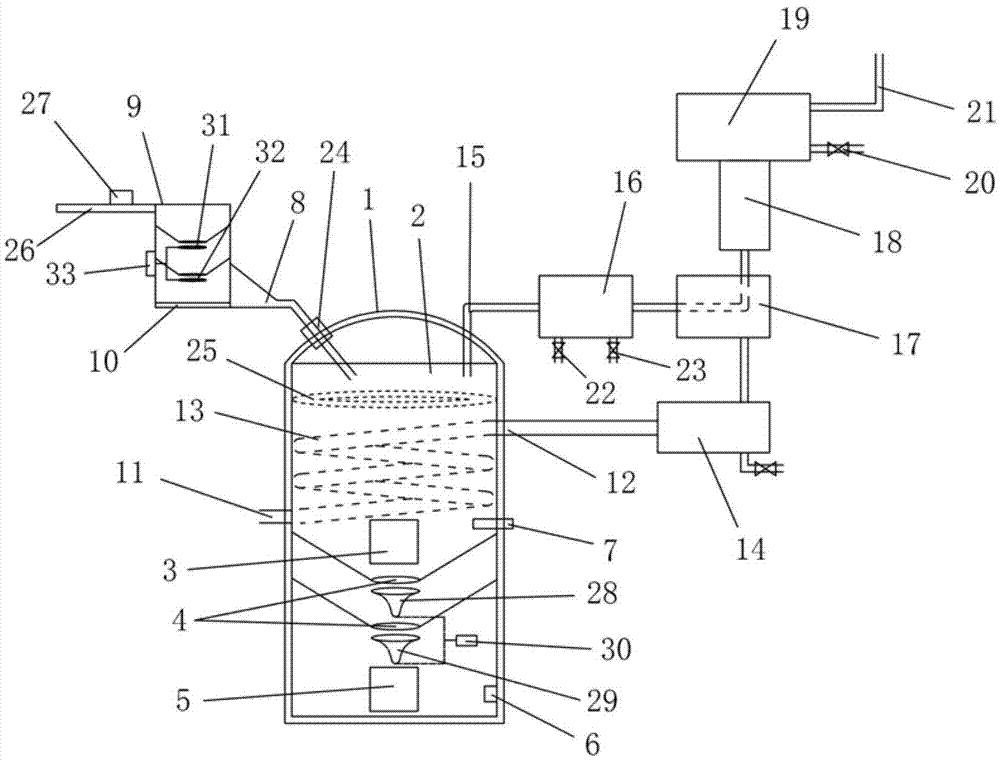

Garbage gasification boiler and application method thereof

ActiveCN105444180AIncrease profitEmission reductionEnergy industryIncinerator apparatusWater storage tankEngineering

The invention discloses a garbage gasification boiler and an application method of the garbage gasification boiler. The garbage gasification boiler comprises a gasification boiler body (1), wherein a hearth (2) is arranged in the gasification boiler body (1), ash discharging outlets (4) are formed in the lower portion of the hearth (2), and a steam collecting pipe (25) is arranged on the upper portion of the hearth (2). The garbage gasification boiler further comprises a gasification boiler waste heat recovery device. The gasification boiler waste heat recovery device comprises a water inlet (11), a water outlet (12), a heat exchange coil pipe (13) and a water storage tank (14), wherein the heat exchange coil pipe (13) is installed inside the hearth (2), and the water storage tank (14) is connected with the water outlet (12). The garbage gasification boiler is high in energy utilization rate and low in cost, convenient to use and repair, and clean and environmentally friendly.

Owner:卢国全

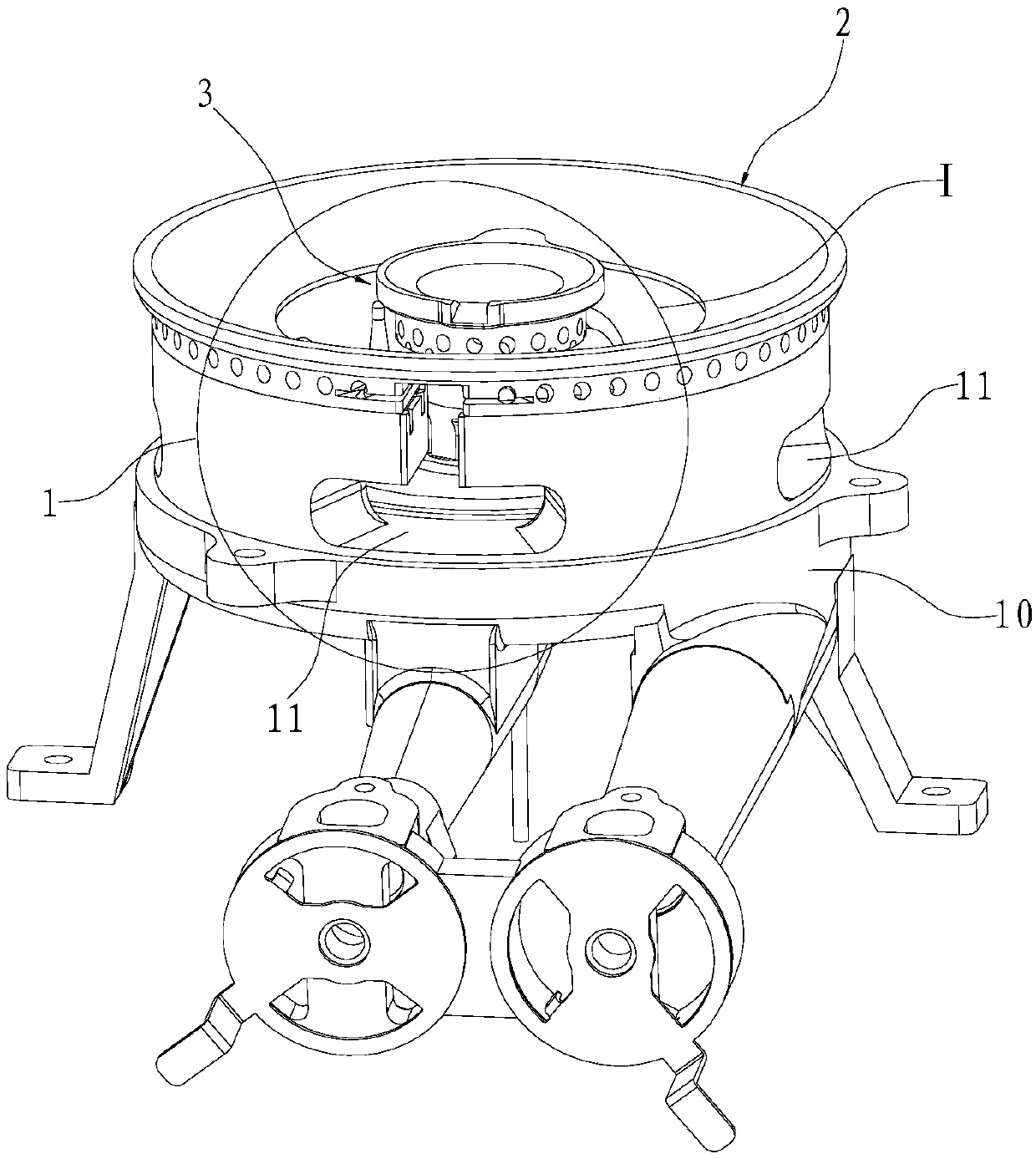

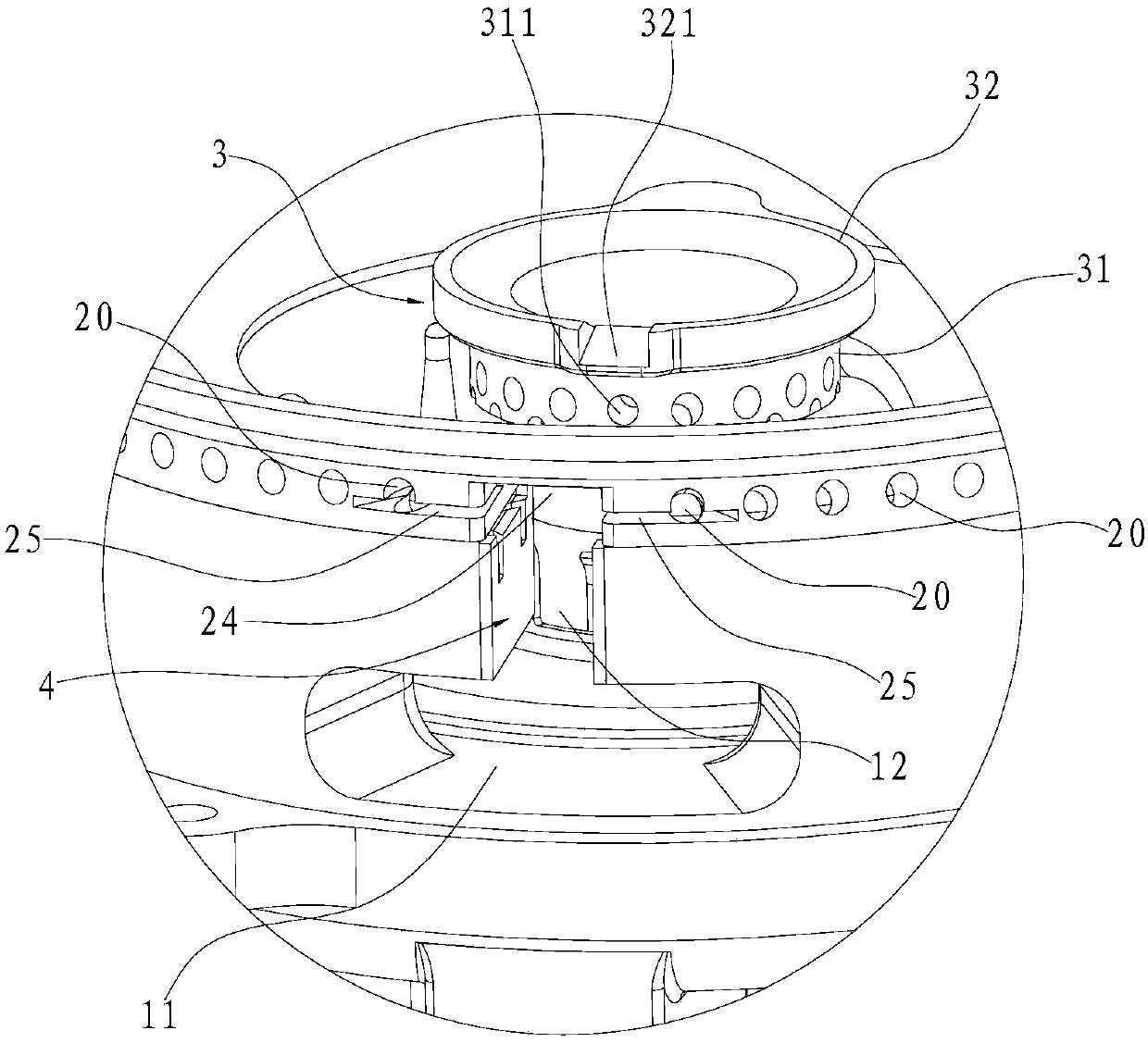

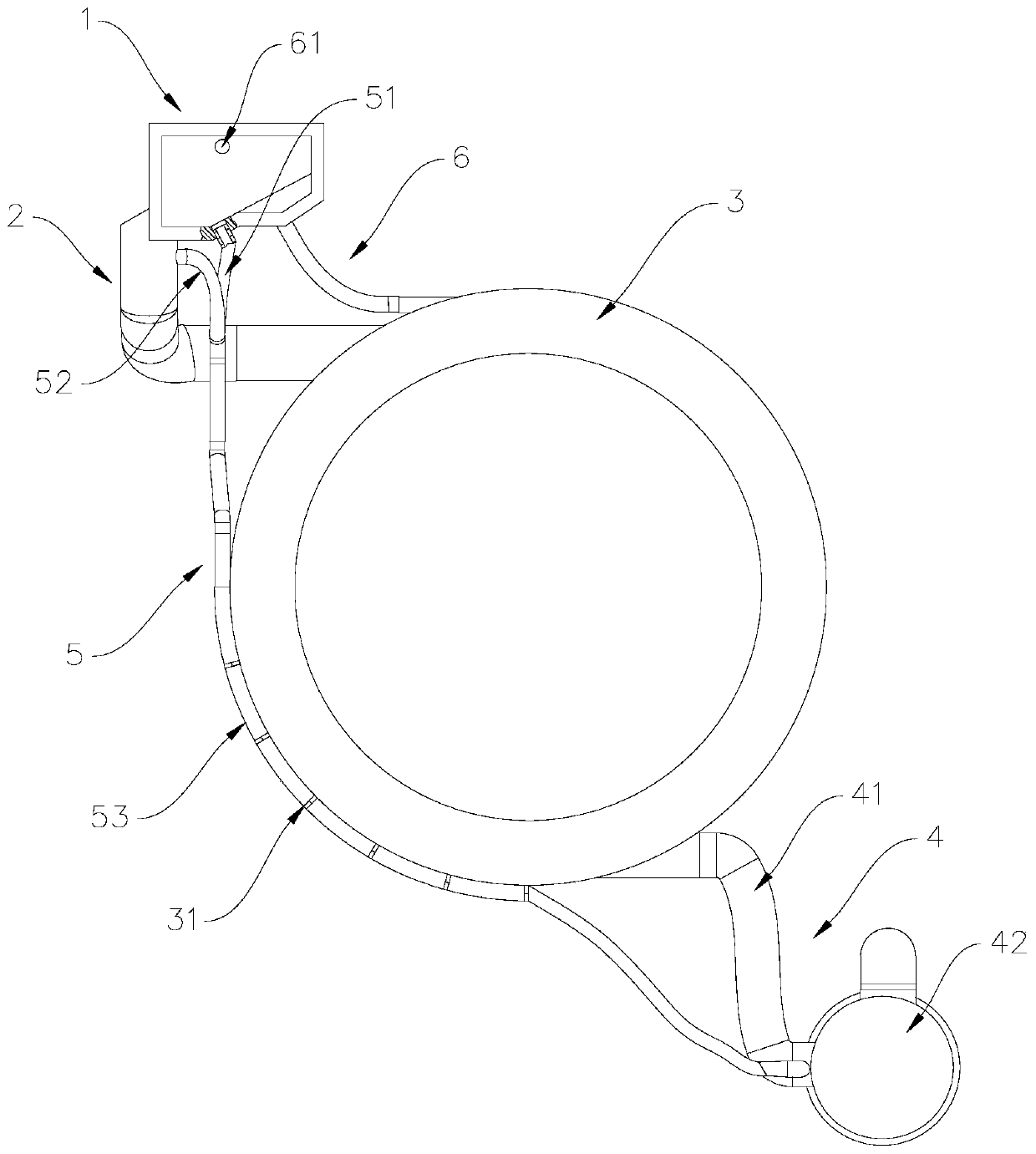

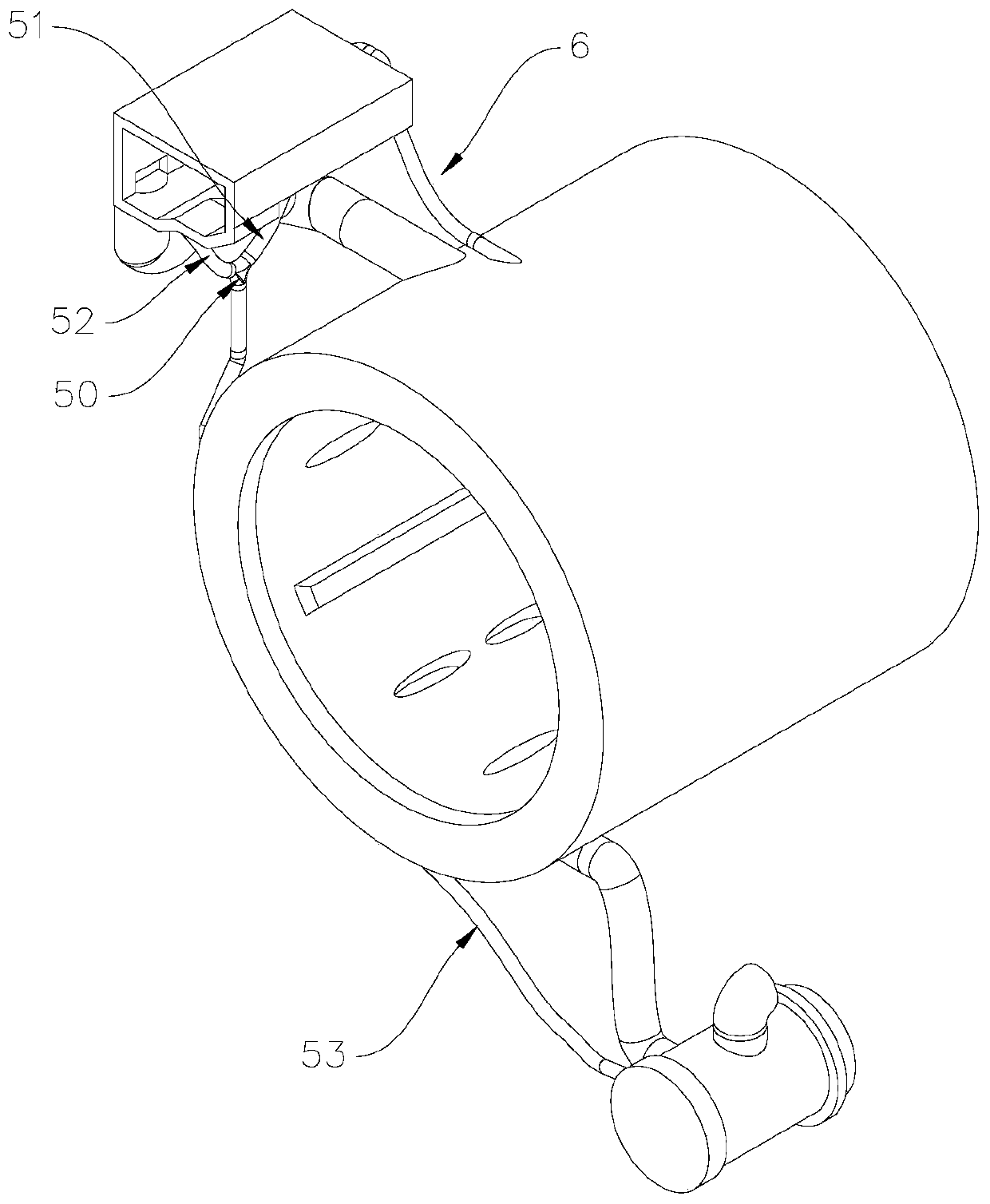

Gas burner capable of stably transferring fire

PendingCN110440257ARealize directional supplementationStable internal pressureGaseous fuel burnerInternal pressureTransmission channel

The invention provides a gas burner capable of stably transferring fire. The burner comprises a gas mixing chamber, an burner ring with an annular burner ring body and a burner cap, wherein a secondary air supply channel communicating with a secondary air annular channel inside the gas mixing chamber is formed in the side wall of the gas mixing chamber, a main fire transmission groove radially extending is formed in the bottom of the burner ring body, the local upper wall of the secondary air supply channel corresponding to the main fire transmission groove penetrates upwards to form a throughgroove, and a main fire transmission groove cover is arranged at the top end of the through groove to form a fire transmission channel. According to the burner, a part of secondary air in the secondary air supply channel is supplemented into the fire transmission channel, so that the sufficient, efficient and stable combustion of flame in the fire transmission channel is promoted; meanwhile, theresidual secondary air is continued to be supplemented into the secondary air annular channel, so that stable combustion of inner ring fire is guaranteed; and at the moment of ignition of the fire transmission channel, the secondary air supply channel below the fire transmission channel can serve as a pressure diffusion cavity, so that the stability of the inner pressure in the fire transmission channel is ensured, and the stable and rapid fire transmission is realized.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

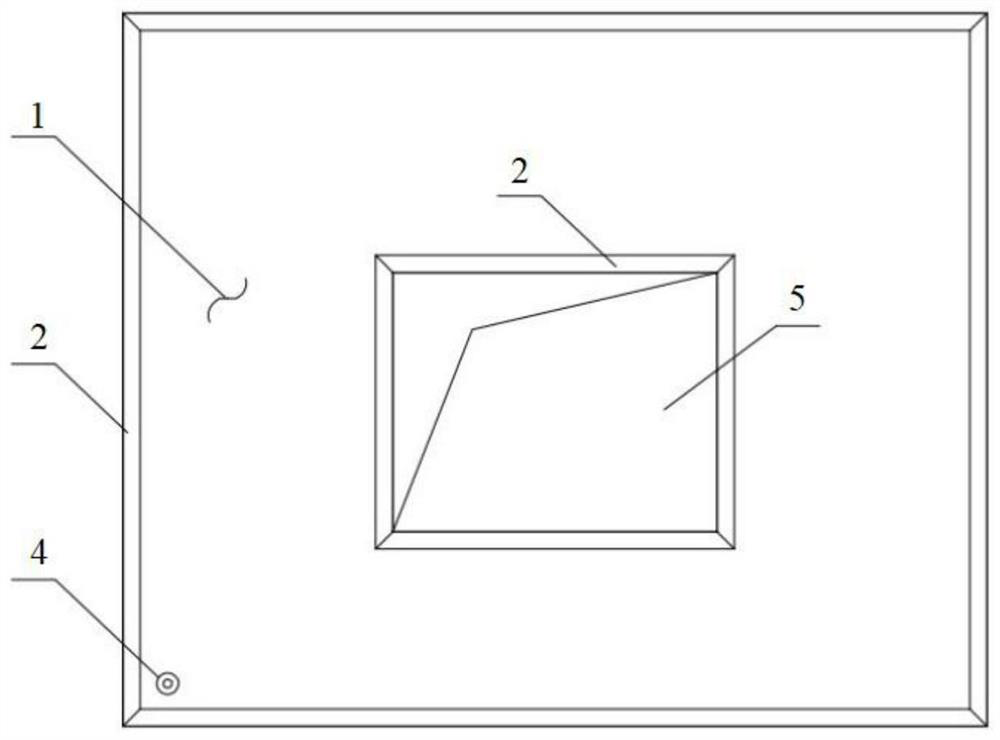

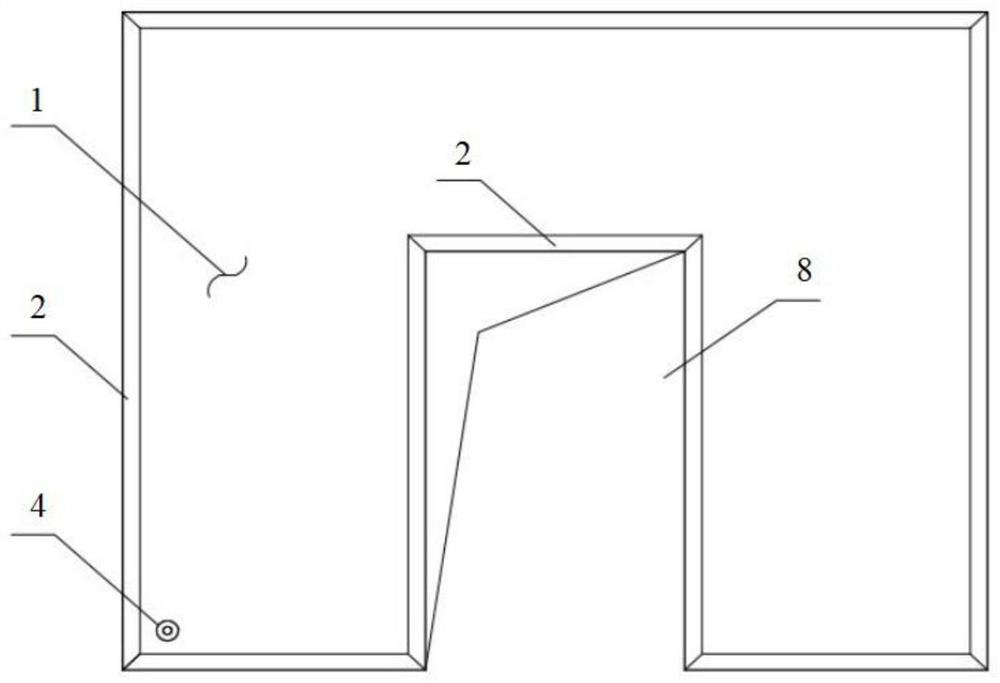

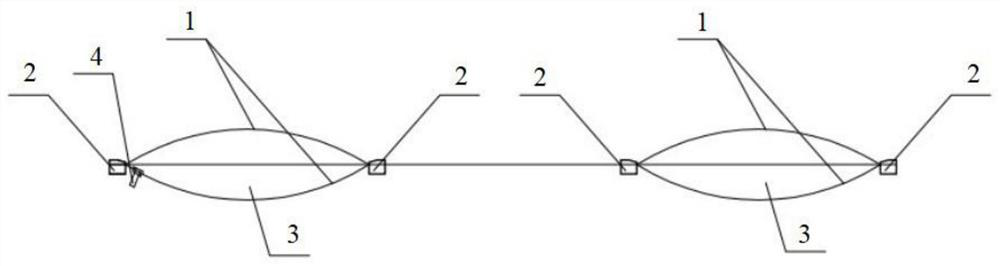

Air bag type inflatable membrane structure

The invention provides an air bag type inflatable membrane structure, and belongs to the technical field of buildings. The inflatable membrane structure comprises at least two membrane materials, wherein the edges of the membrane materials are bonded and fixed through a clamp to form at least one sealed air bag with a cavity; at least one air valve is arranged on the surface of the air bag; the air valve communicates with an air supply device; the air supply device and the air valve are used for inflating the air bag; at least one hole is formed in the air bag, and the edge of the hole is fixed through the clamp to keep the air bag sealed; and a plurality of inflatable membrane structures can be spliced through clamps to construct an inflatable membrane building. The inflatable membrane structure is simple, light, easy to mount and dismount, capable of being widely applied to maintenance structures such as outer walls and roofs of building houses and structures, and particularly suitable for stadiums, exhibition houses, sunlight houses, movable houses, ecological houses, temporary houses for earthquake relief work and the like.

Owner:王建平

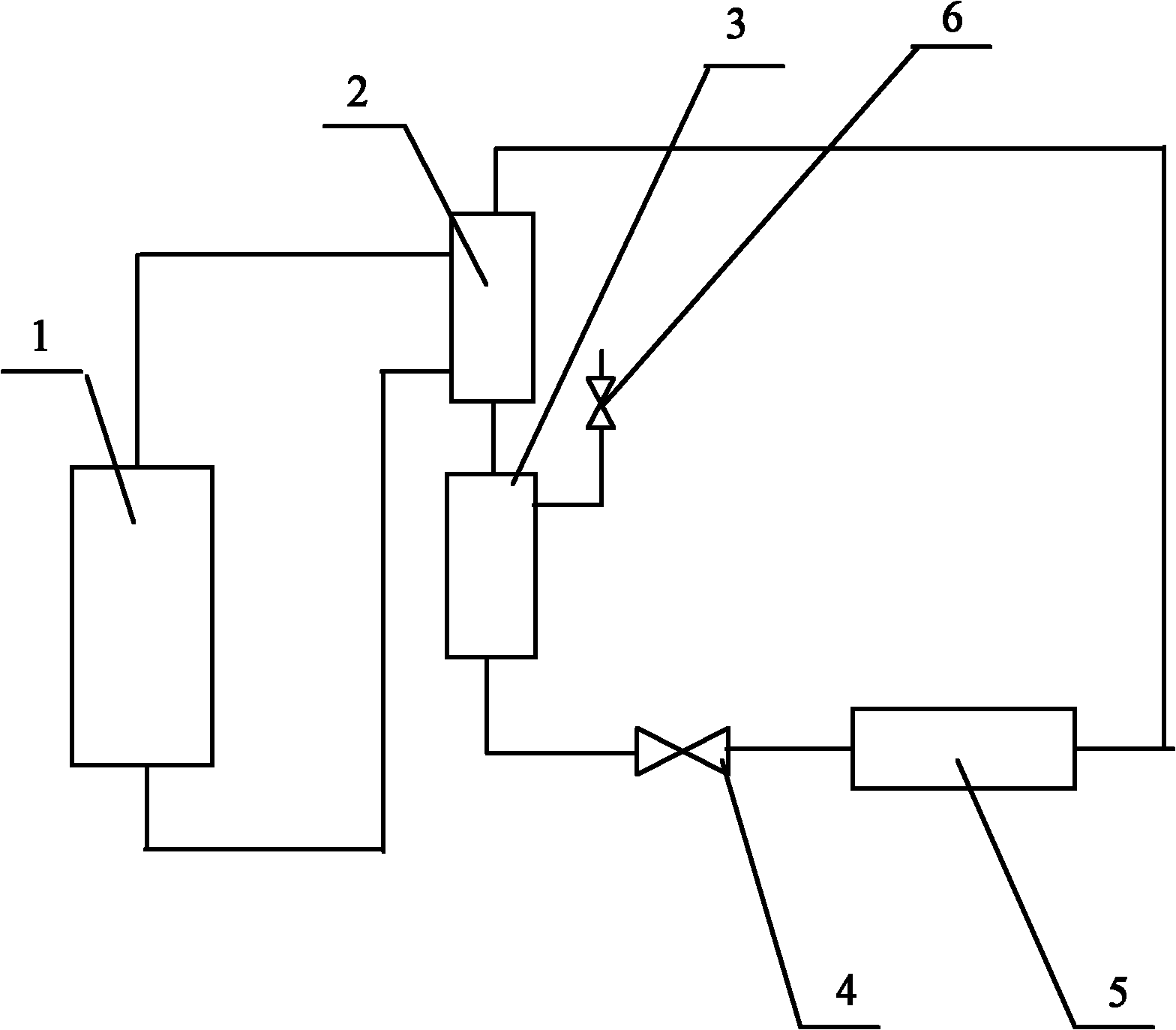

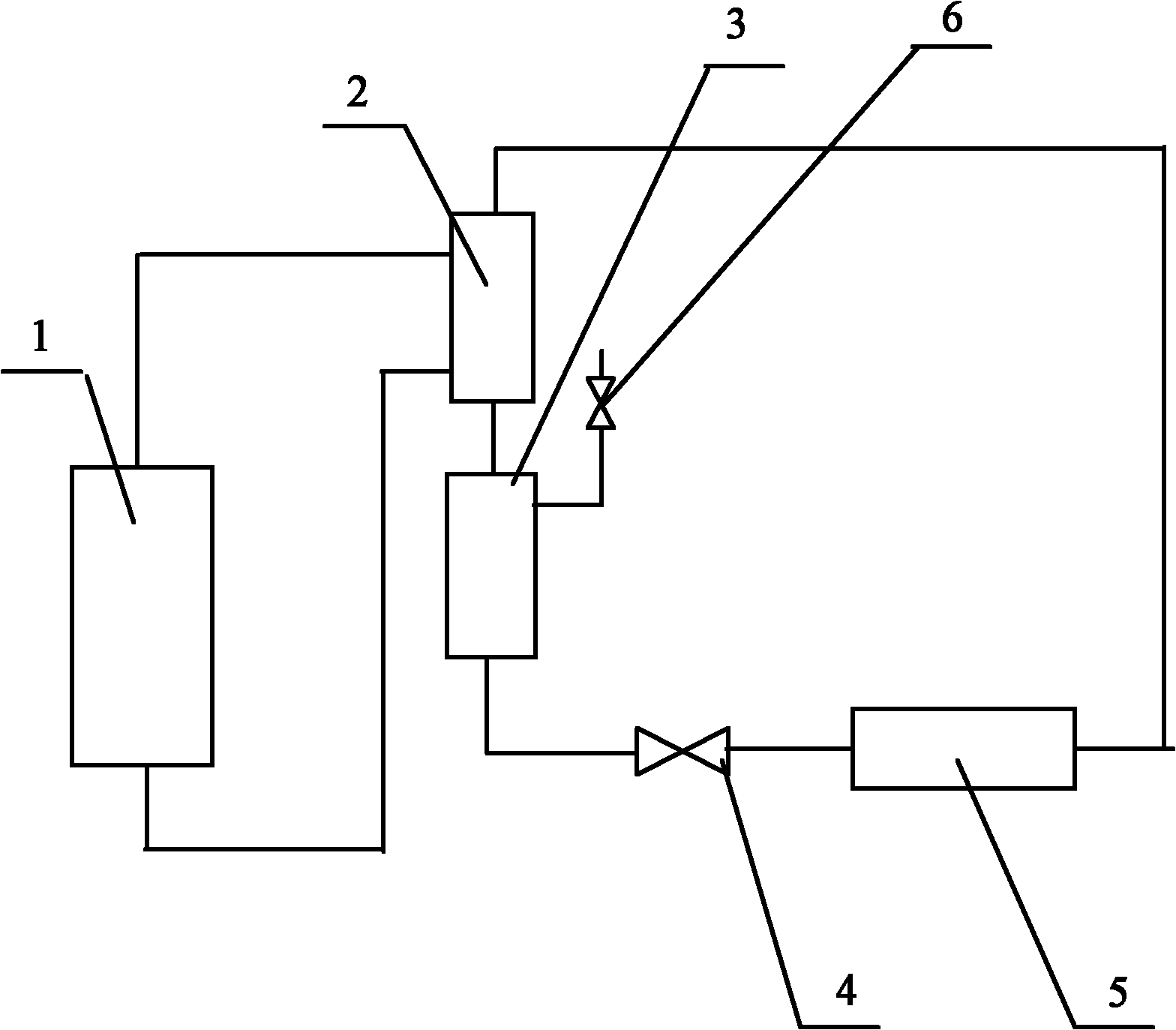

Refrigerating system using carbon dioxide as secondary refrigerant

InactiveCN102072603AStable internal pressureEnsure safetyCorrosion preventionRefrigeration safety arrangementContinuous operationRefrigerant

The invention discloses a refrigerating system using carbon dioxide as a secondary refrigerant, and aims to provide a refrigerating system which can ensure the continuous operation of a carbon dioxide cyclic part and is safe in use. The refrigerant outlet of a low-temperature refrigerating unit is connected with the refrigerant inlet of a carbon dioxide condensation evaporator; the refrigerant inlet of the low-temperature refrigerating unit is connected with the refrigerant outlet of the carbon dioxide condensation evaporator; the carbon dioxide outlet of the carbon dioxide condensation evaporator is connected with the inlet of a carbon dioxide liquid storage device; the outlet of the carbon dioxide liquid storage device is connected with the carbon dioxide inlet of a carbon dioxide air cooler through a defrosting valve; the carbon dioxide outlet of the carbon dioxide air cooler is connected with the carbon dioxide inlet of the carbon dioxide condensation evaporator; the carbon dioxide liquid storage device is connected with a safety valve; potential difference for making the carbon dioxide continuously cycled exists between the carbon dioxide liquid storage device and the carbon dioxide air cooler; and the defrosting valve ensures that the system is continuously operated at a defrosting stage, and the safety valve ensures the stability of internal pressure when the system is shut down.

Owner:TIANJIN UNIV OF COMMERCE

Test device and test method for ignition combustion of energetic material powder and lossless cooling of condensed-phase combustion product

ActiveCN111413454AImprove reliabilityGood repeatabilityBurnersChemical analysis using combustionChemistryCombustion products

The invention discloses a test device and a test method for ignition combustion of energetic material powder and lossless cooling of a condensed-phase combustion product. The device comprises a combustor main body, a sample bracket located in an inner cavity of the combustor main body, an ignition assembly, a condensed-phase combustion product cooling assembly and a pressure protection assembly located outside the combustor main body. The condensed-phase combustion product cooling assembly is used for carrying out lossless cooling on the condensed-phase combustion product of the energetic material powder, and the risk that the substance composition and the morphology structure of the condensed-phase combustion product are changed in the cooling process can be remarkably reduced.

Owner:SOUTHEAST UNIV

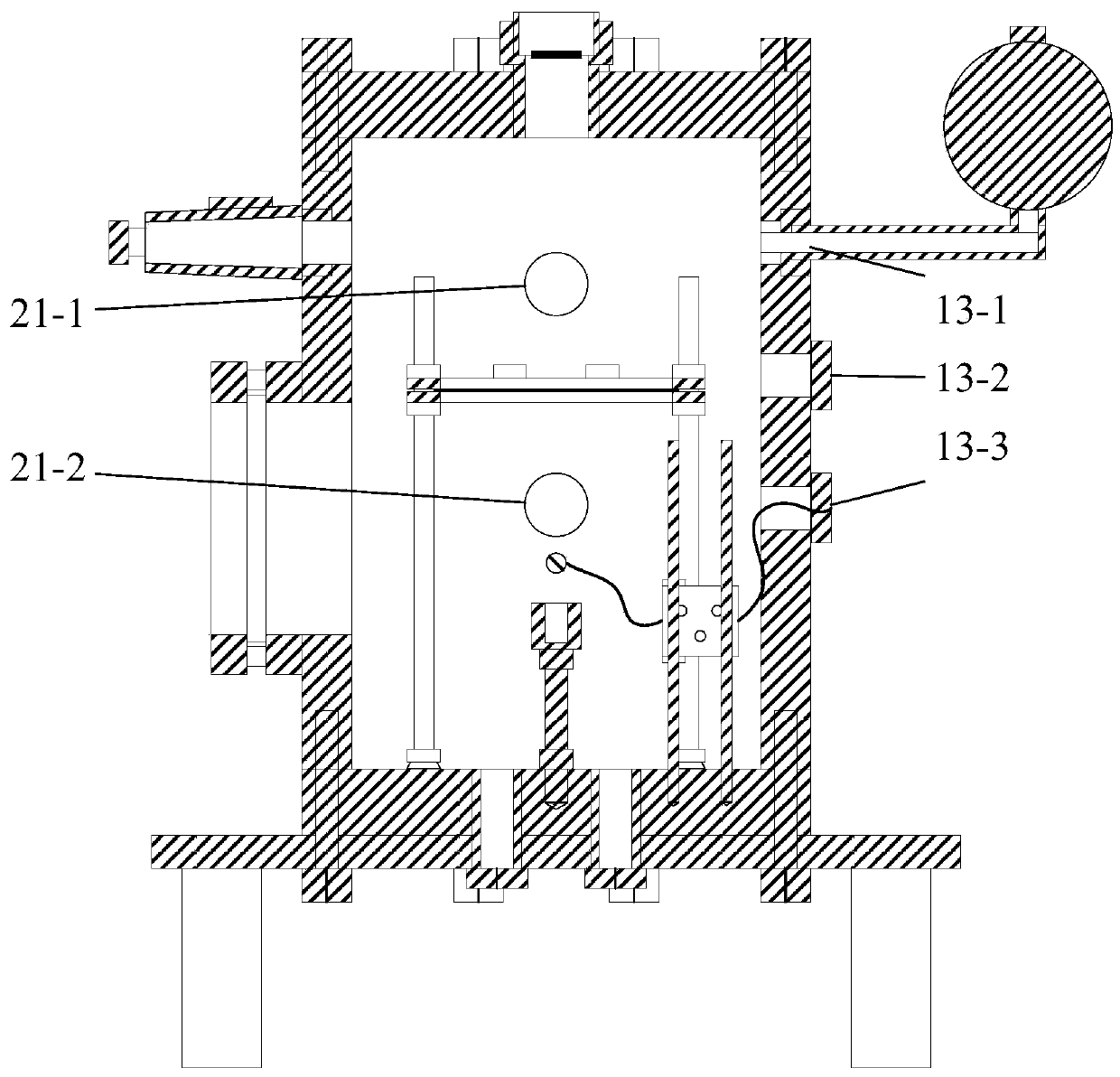

Passive pendulum bob type lubricating self-cleaning mechanism

The invention relates to a passive pendulum bob type lubricating self-cleaning mechanism. The passive pendulum bob type lubricating self-cleaning mechanism is characterized in that a motor is fixedlyconnected to a big arm in a static sealing manner, the output end of the mechanism is connected with one end of a speed reducer output shaft through a speed reducer input gear shaft, one end of a speed reducer shell is arranged in the big arm in a static sealing mode, the other end of the speed reducer shell is in sealing rotation connection with the speed reducer output shaft, the other end of the speed reducer output shaft is in static sealing connection with a small arm, the two ends of a double-head piston rod are correspondingly connected with a large cylinder barrel and a small cylinderbarrel to form a movable pair and are in sealed connection, a pendulum bob is hinged to the big arm and is connected with the double-head piston rod through a connecting rod, a speed reducer inner cavity is arranged in the big arm, the speed reducer inner cavity communicates with the interior of the small cylinder barrel through an oil way A, the interior of the large cylinder barrel communicateswith the speed reducer inner cavity through an oil way B, an oil outlet one-way valve is arranged in the oil way A, an oil return one-way valve is arranged in the oil way B, and a filter element is arranged in the oil way B close to the large cylinder barrel. According to the passive pendulum bob type lubricating self-cleaning mechanism, the internal pressure of a joint of a robot can be stabilized, oil leakage is prevented, the energy efficiency is reduced, and the energy-saving and environment-friendly effects are better.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

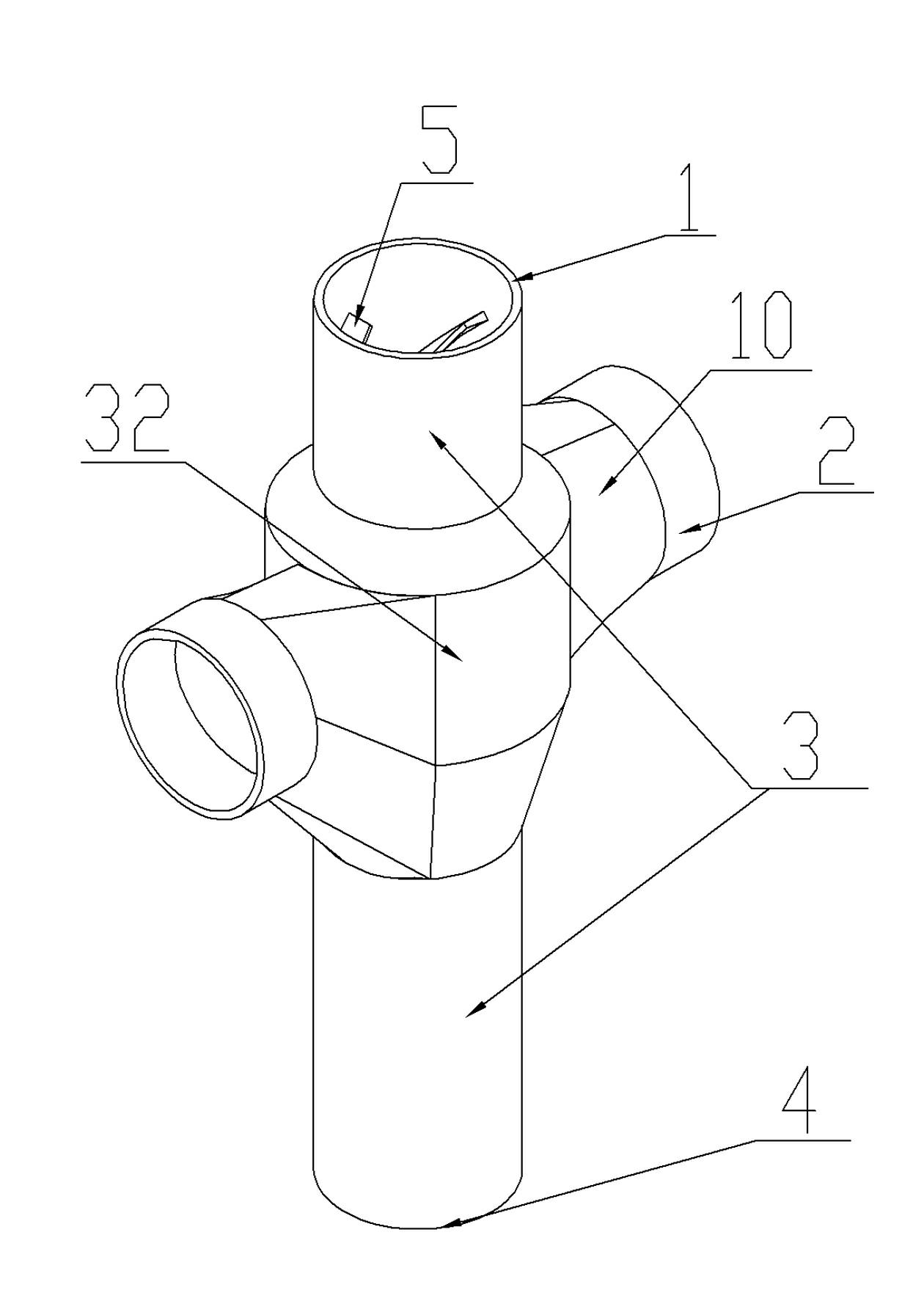

Joint of vortex drain tube

InactiveCN102095041AReduce the impact of water flowIncrease the cross-sectional areaBranching pipesVertical tubeInlet channel

The invention discloses a joint of a vortex drain tube, which comprises a vertical tube, wherein an upper water inlet is correspondingly arranged at the upper end of the vertical tube; a drain outlet is correspondingly arranged at the lower end of the vertical tube; spiral guide vanes which axially extend along the vertical tube are arranged between the upper water inlet and the drain outlet on the inner wall of the vertical tube; at least one side water inlet tube is arranged at the side of the vertical tube; a water outlet for communicating the side water inlet tube and a cavity at the middle part of the vertical tube is formed on a connecting part of the vertical tube and the side water inlet tube; a water inlet channel in the position of the water outlet of the side water inlet tube is communicated with the cavity at the middle part of the vertical tube along a tangential line; and the length of a cross section in the position of the water outlet of the connecting part of the side water inlet tube and the vertical tube along the axial direction of the vertical tube is larger than the length of a cross section in the position of the water inlet of the side water inlet tube along the axial direction of the vertical tube.

Owner:禹州市新光铸造有限公司

Washing box anti-overflow device and washing machine

PendingCN111088665ASolve the overflow problemNo more overflow problemsOther washing machinesTextiles and paperMechanical engineeringEnvironmental engineering

The invention provides a washing box anti-overflow device and a washing machine. The washing box anti-overflow device comprises a washing box, a water inlet pipe, an outer drum and a water discharge pipe in sequential communication. The washing box anti-overflow device also comprises a flow guide pipe assembly; the flow guide pipe assembly communicates between the washing box and the water discharge pipe; and the flow guide pipe assembly communicates between the water inlet pipe and the water discharge pipe. The washing machine comprises the washing box anti-overflow device. The internal pressure of the washing box is atmospheric pressure. Through such arrangement, the problem of air pressure abnormality of the water discharge pipe can be solved. Water in the washing box gradually enters the flow guide pipe assembly from the water inlet pipe, and finally flows out from the water discharge pipe; in the process, foam in the water inlet pipe and the water discharge pipe is gradually eliminated and taken away by the water flow; the internal pressure of the water inlet pipe and the internal pressure of the water discharge pipe tend to normal change; the amount of the water flow enteringthe inner drum through the water inlet pipe gradually rises back to eliminate the foam in the drum, and the air pressure in the washing box, the water inlet pipe, the drum and the water discharge pipe recovers to a normal state; at the moment, the foam in the drum can be effectively eliminated when water is continuously supplemented; and the water overflow problem of the washing box cannot occuragain.

Owner:GREE ELECTRIC APPLIANCES INC

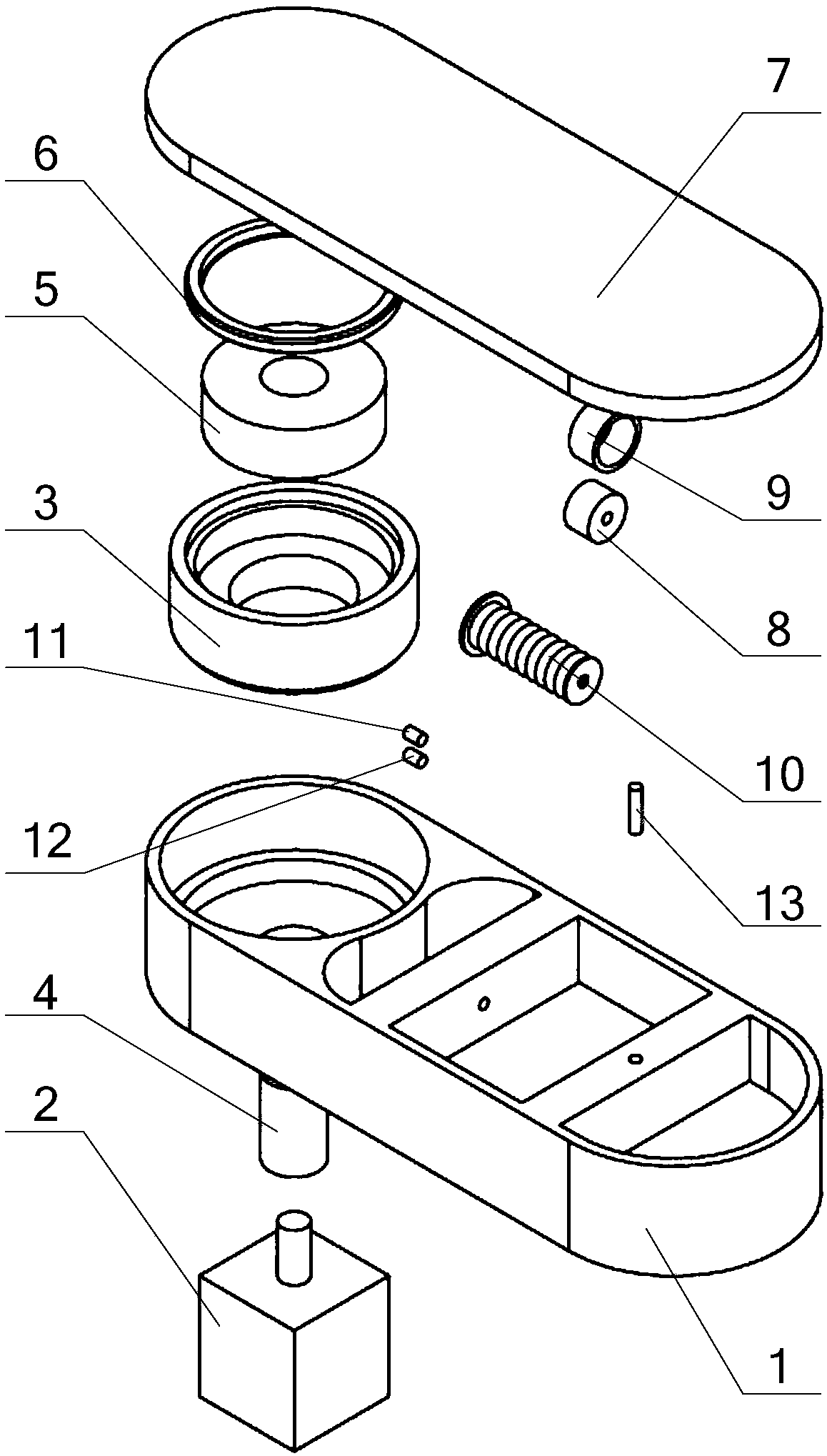

Internal circulation type lubricating self-cleaning mechanism

The invention relates to an internal circulation type lubricating self-cleaning mechanism. A motor is connected to a large arm in a static sealing manner, the output end is connected with one end of an output shaft of a speed reducer through an input gear shaft of the speed reducer, one end of a shell of the speed reducer is fixedly arranged in the large arm in a static sealing mode, the other endof the shell of the speed reducer is in sealing rotation connection with the output shaft of the speed reducer, and the other end of the output shaft of the speed reducer is in static sealing connection with a small arm; an inner cavity of the speed reducer is arranged in the large arm, the inner cavity of the speed reducer is in communication with one end of an elastic mechanism through an oil way A, the other end of the elastic mechanism is in communication with the inner cavity of the speed reducer through an oil way B, an oil outlet one-way valve which can only flow to the elastic mechanism is arranged in the oil way A, and an oil return one-way valve which can only flow to the inner cavity of the speed reducer is arranged in the oil way B; and close to the other end of the elastic mechanism, of the oil way B is provided with a filter element. According to the internal circulation type lubricating self-cleaning mechanism, the internal pressure of a robot joint can be stabilized, oil seepage is prevented, the joint rotation resistance of the robot is small, the energy efficiency is reduced, and the energy-saving and environment-friendly effects are better and remarkable.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

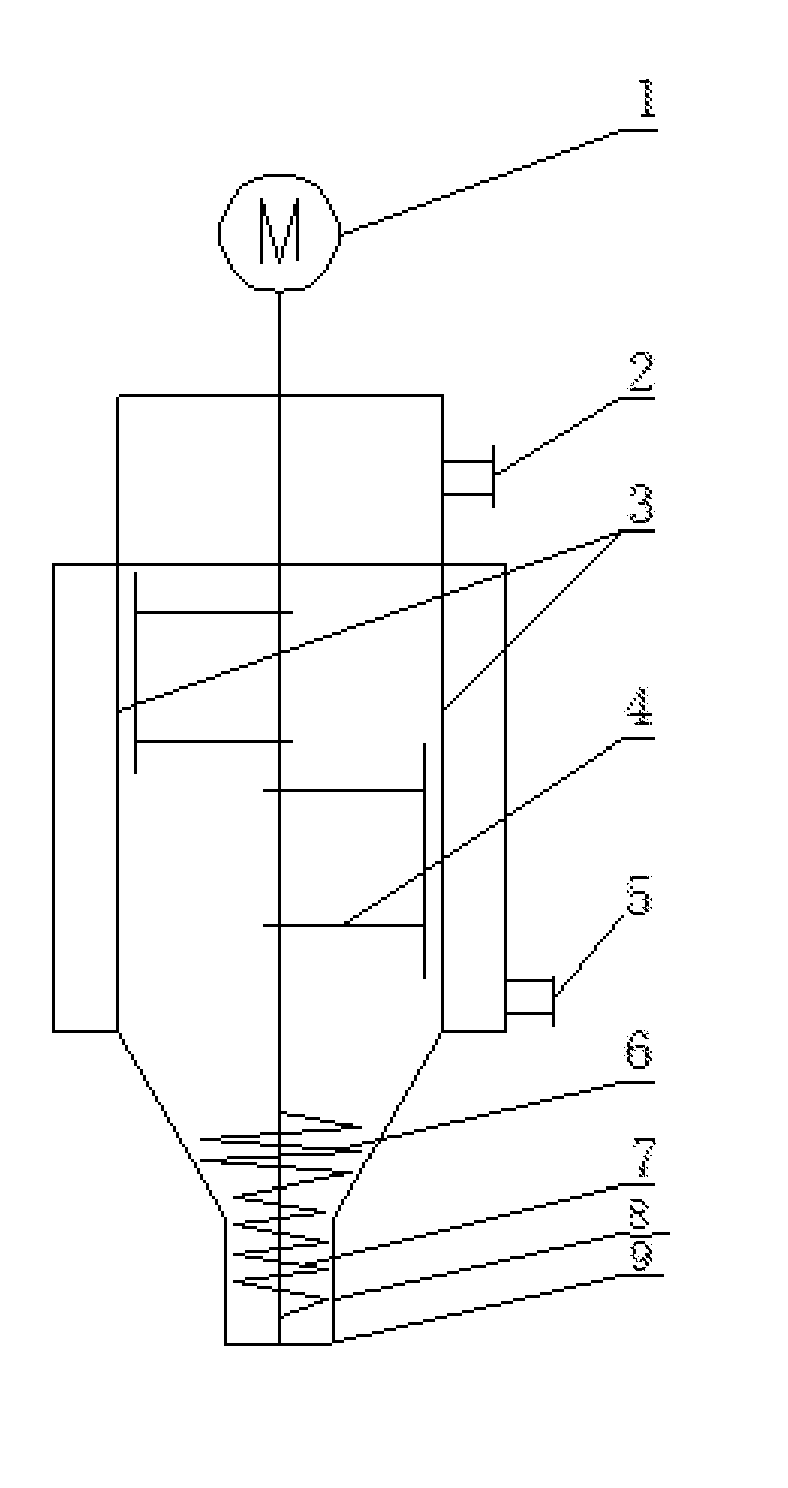

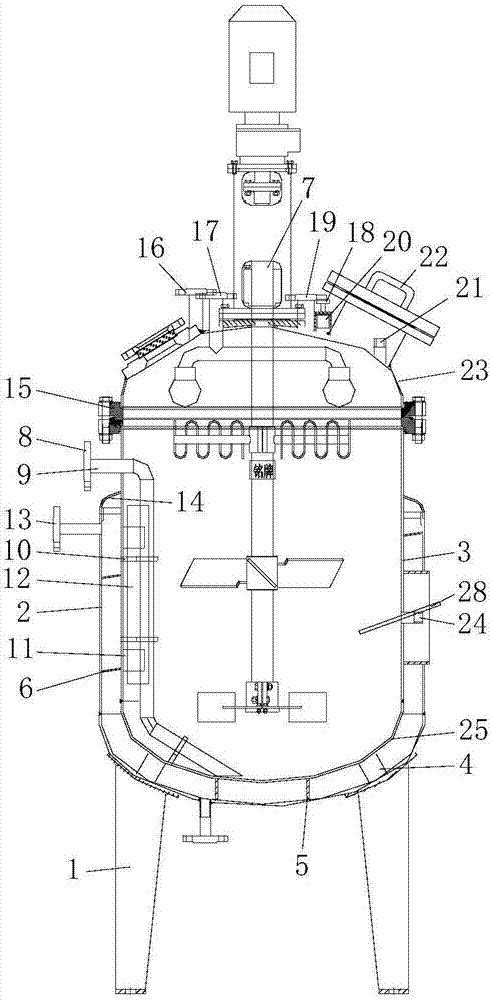

Primary seed fermentation tank

InactiveCN106967596APromote fermentationEasy to cleanBioreactor/fermenter combinationsBiological substance pretreatmentsPressure senseEngineering

The invention discloses a first-stage seed fermentation tank, which comprises a bracket, the upper end of the bracket is fixedly installed with a jacket cylinder body, the inner cavity of the jacket cylinder body is fixedly installed with an inner tank cylinder body, the upper end surface of the inner tank cylinder body and the inner tank body A stirring system is fixedly installed in the center of the inner cavity of the tank cylinder, the first compressed air connection pipe and the discharge connection pipe are arranged on the side upper end of the inner chamber cylinder body, and the steam connection pipe, the breathing pipe connection pipe and the washing pipe connection pipe are provided on the jacket cylinder body; A second compressed air connection and a material connection are installed on the other side of the upper end surface of the inner tank cylinder, and a pressure detection connection is provided below the second compressed air connection. The first-level seed fermentation tank fully ensures that the seed fermentation is in a stable environment and improves the quality of seed fermentation by setting steam connection pipes, breathing pipe connection pipes, washing pipe connection pipes, material connection pipes, pressure detection connection pipes, sampling valve connection pipes and thermometer blind pipes. , and it is easy to clean, which facilitates the fermentation of the next batch of seeds and improves the efficiency of production.

Owner:HUBEI GOLDEN EAGLE BIOTECH

Mechanical extruding machine

ActiveCN108705803AInternal pressure unchangedSteady state production processShaping pressInternal pressureLever pressing

The invention discloses a mechanical extruding machine. The mechanical extruding machine comprises a material bin, a die cavity, a pushing head and an adjusting mechanism, wherein the adjusting mechanism comprises a pressing strip, a pressing rod and an adjusting oil cylinder; the die cavity is mounted at a discharging port of the material bin, and an extruding chamber is arranged in the die cavity; the pressing strip is arranged in the extruding channel; one end of the pressing rod extends into the die cavity and is connected to the pressing strip, and the other end of the pressing rod is connected to a piston rod of the adjusting oil cylinder; and an adjusting oil cylinder body is mounted on a discharging plate. According to the mechanical extruding machine, the size of the die cavity isdynamically adjusted in order to maintain the inner pressure of the die cavity, and thus one die cavity can realize various biomass formation, and as a result, the extruding forming cost is decreased, and the extruding forming efficiency is improved; and meanwhile, when the temperature of the die cavity changes, the size of the die cavity can be dynamically adjusted to remain the inner pressure of the die cavity. Therefore, the whole biomass extruding forming production process is kept stable, and the extruding forming quality and output cannot be influenced by the change of raw materials andtemperature.

Owner:博海威玛(烟台)机械有限公司

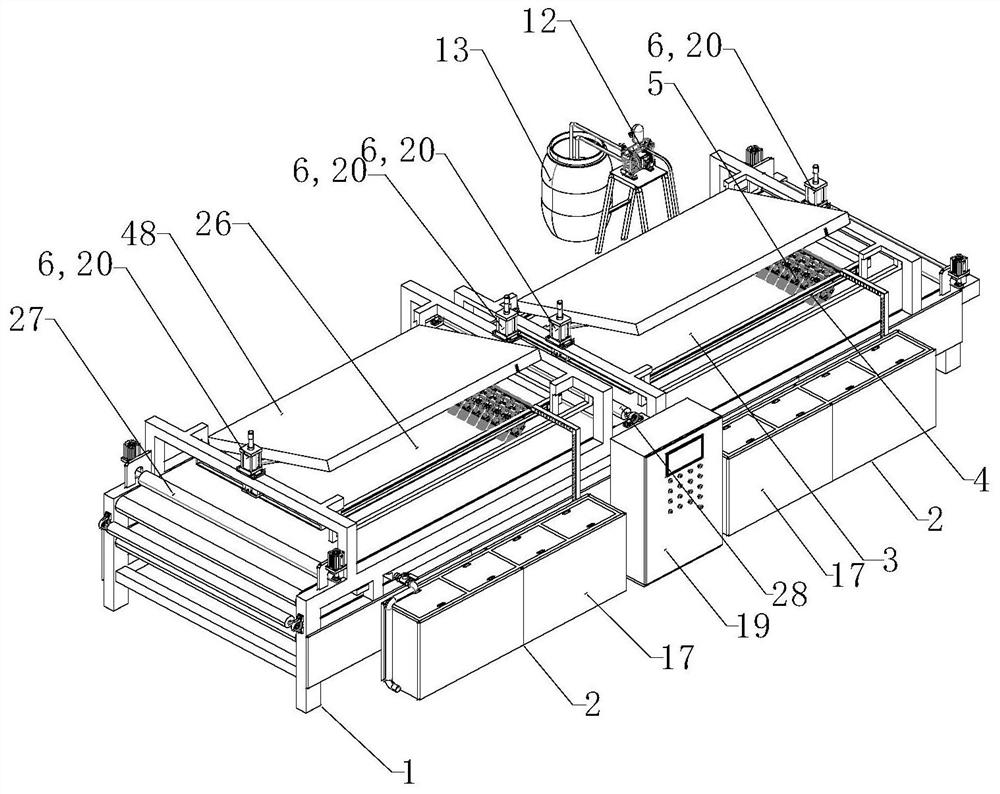

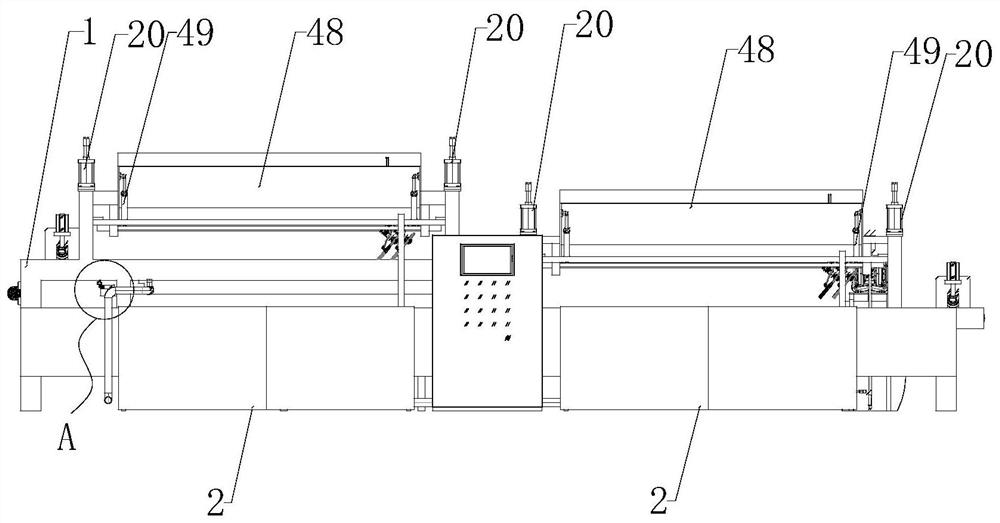

Numerical control intelligent tie-dyeing machine

PendingCN113502620AAchieve precise deliveryRealize fixed-point printing and dyeingSucessive textile treatmentsTextile treatment cleaning apparatusNumerical controlControl engineering

The invention relates to a numerical control intelligent tie-dyeing machine. The machine comprises a rack, a dye bin assembly, a first conveying belt arranged on the rack and a dyeing device located above the first conveying belt; the dyeing device comprises a mounting frame, and a plurality of brushes arranged on the mounting frame; the dye bin assembly comprises a plurality of dye bins; feeding pipes are arranged in the dye bins; the feeding pipes in the dye bins are communicated with corresponding dye barrels through respective conveying pumps; a plurality of dye output holes are formed in the bin walls of the dye bins; the dye output holes are connected with first electromagnetic valves through pipelines; and the dye output holes of the dye bins are communicated with corresponding dye output pipes after being output through the respective first electromagnetic valves. According to the numerical control intelligent tie-dyeing machine, through the arrangement of the dye bins and the first electromagnetic valves, output control over dyes of all colors is achieved, so that the dyes of specific colors can be output; and meanwhile, through the arrangement of the multiple brushes, cloth can be accurately dyed, and the dyeing effect is better.

Owner:常州智源万达软件有限公司

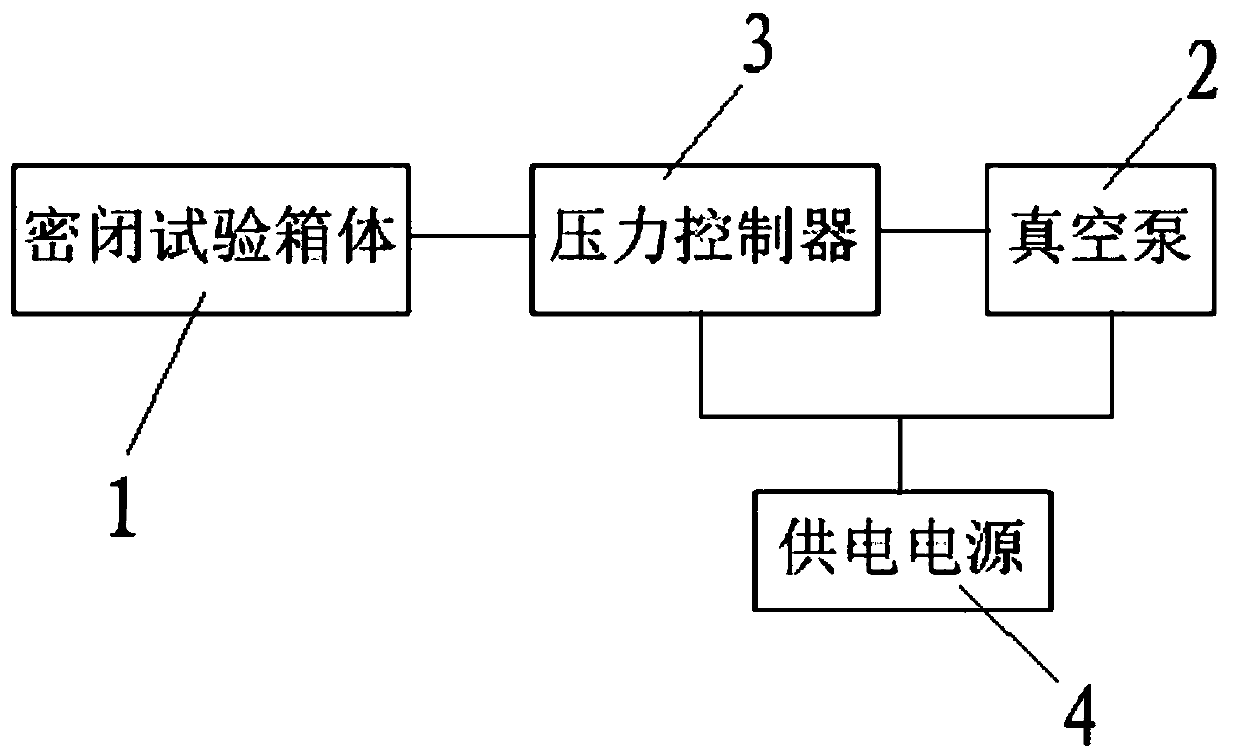

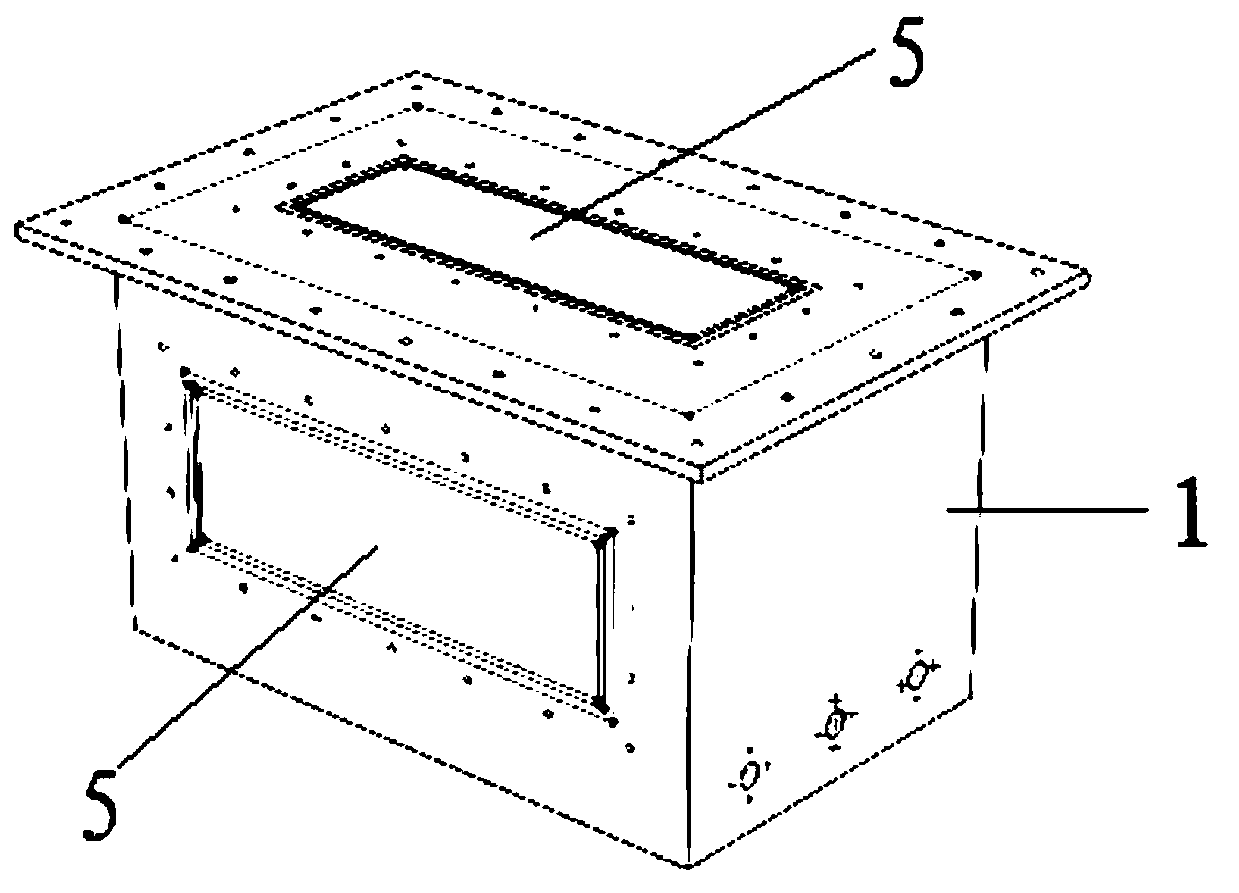

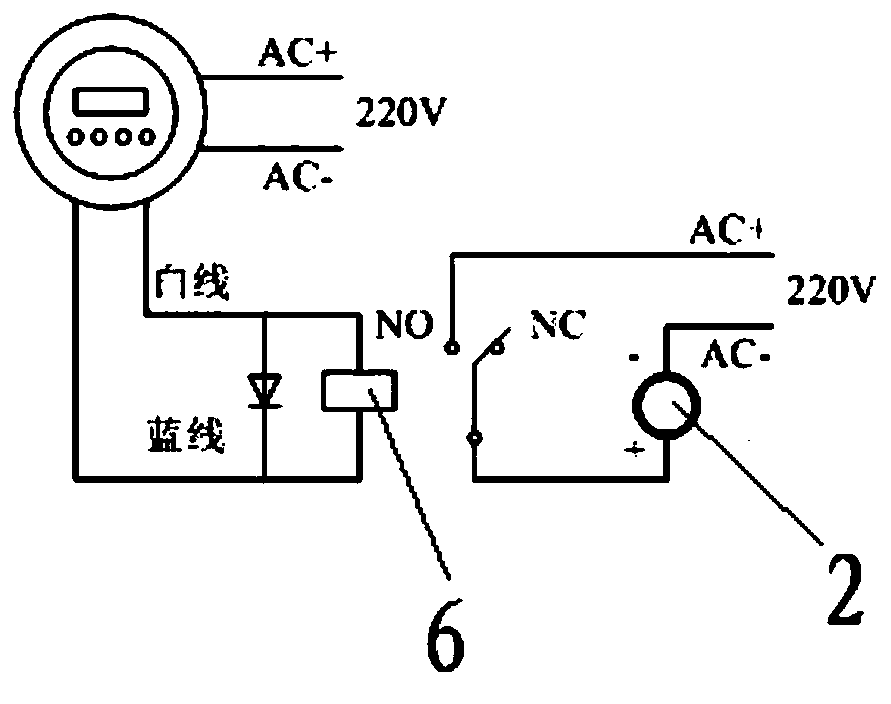

Plateau environment simulation test bed

InactiveCN110339872AReliable operationImprove toughnessTesting dielectric strengthAir-pressure/air-lock chambersPressure controllerPressure range

The invention discloses a plateau environment simulation test bed. The plateau environment simulation test bed comprises a sealed test box body, a vacuum pump, a pressure controller and a power supply; one end of the pressure controller is connected with the sealed test box body, and the other end of the pressure controller is connected with the vacuum pump; and the pressure controller and the vacuum pump are correspondingly connected with the power supply. According to the plateau environment simulation test bed, the vacuum pump is used for extracting air from the inner part of a sealed testbox, different pressure ranges are set in the pressure controller, air pressure in the sealed test box body is controlled within a certain range, and the plateau environment simulation test bed can beused for simulating the power consumption, temperature rise, efficiency and other performance parameters of a power device under high altitude environments, and it is ensured that electrical equipment produced in plain areas can be operated reliably in plateau environments.

Owner:STATE GRID CORP OF CHINA +3

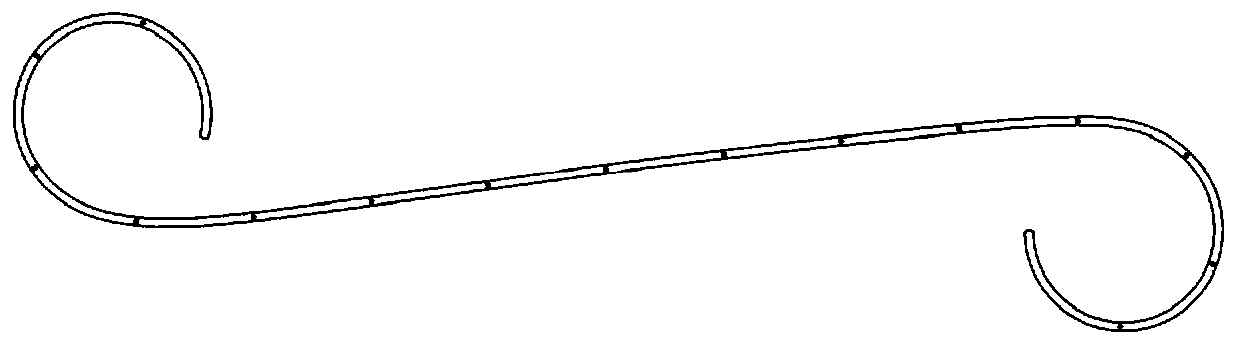

Anti-reflux method capable of conducting automatic adjustment along with changes of bladder pressure, and ureteral stent

PendingCN111035842AAchieve anti-refluxPrevent reverse accessStentsWound drainsPelvis renalisBladder pressure

The invention discloses an anti-reflux method capable of automatically adjusting along with the change of bladder pressure and a ureteral stent. According to the method, a water retaining soft sleeveis connected to an outlet of a bladder tube section of the stent; the water retaining soft sleeve in a urine storage period is in a free state, and urine in the renal pelvis enters the ureteral stentand is discharged into the bladder through the water retaining soft sleeve; and the water retaining soft sleeve covers the outlet of the bladder tube section under the pressure of the bladder during urination, and anti-reflux effect is achieved. According to the ureteral stent, the water retaining soft sleeve is arranged at the outlet of the bladder tube section, the water retaining soft sleeve inthe urine storage period is in the free state, and urine in the renal pelvis enters the ureteral stent and is discharged into the bladder through the water retaining soft sleeve; during urination, the water retaining soft sleeve covers the outlet of the bladder tube section under the action of bladder pressure; and after urination is finished, the bladder pressure is reduced, and the water retaining soft sleeve returns to a free state. Urine is prevented from reversely entering the ureteral stent by utilizing the covering and sealing effects of the soft water retaining soft sleeve on the urination opening of the ureteral stent, so the anti-reflux effect of the ureteral stent is realized.

Owner:泰州市高港中医院

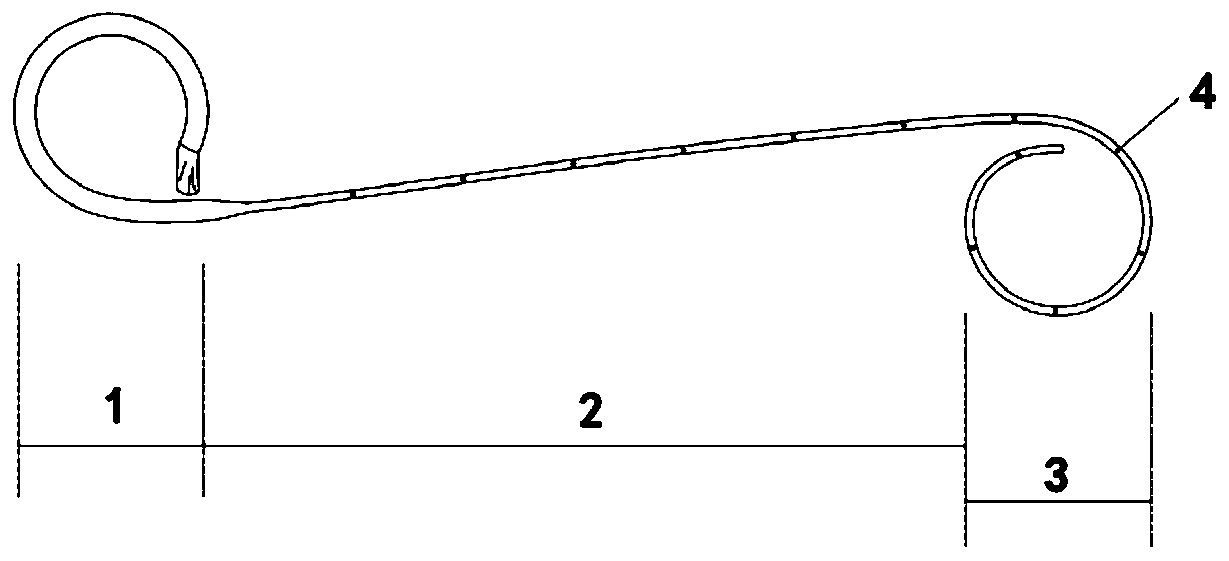

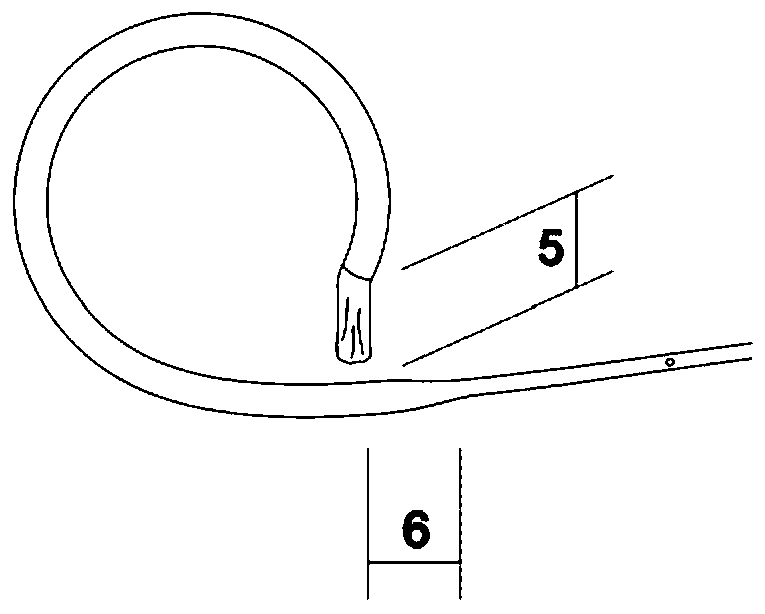

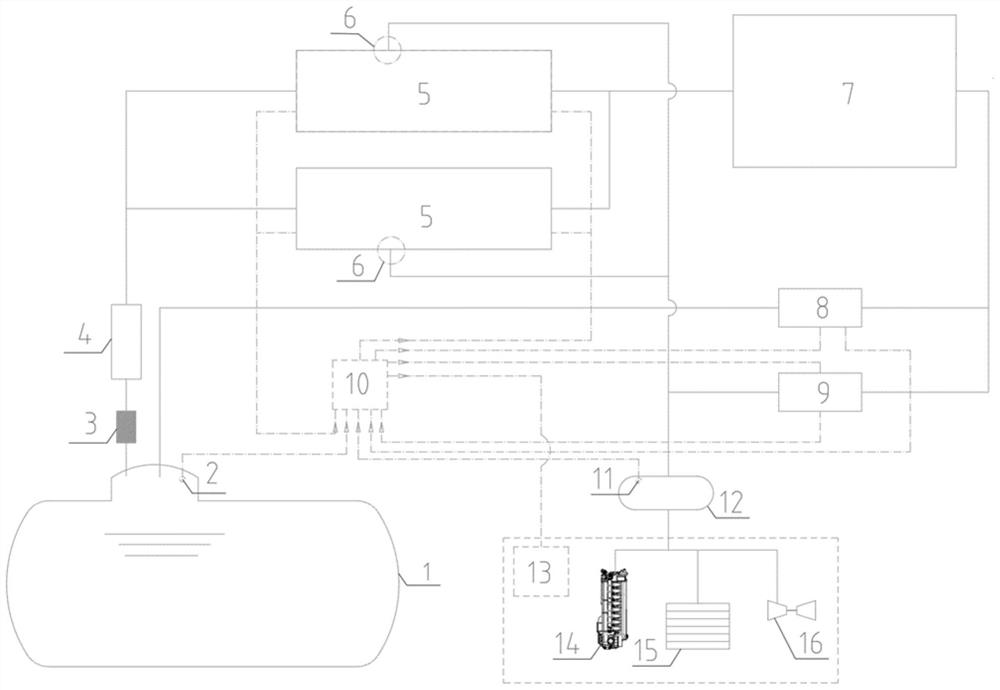

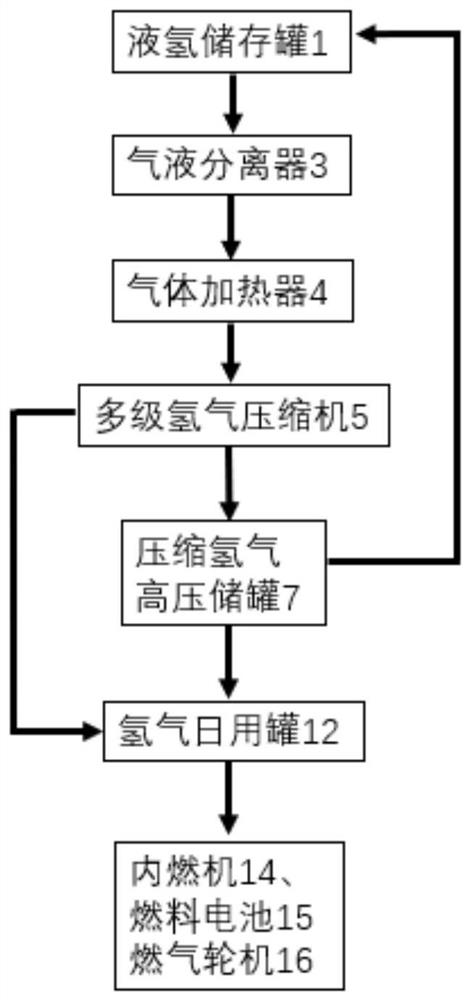

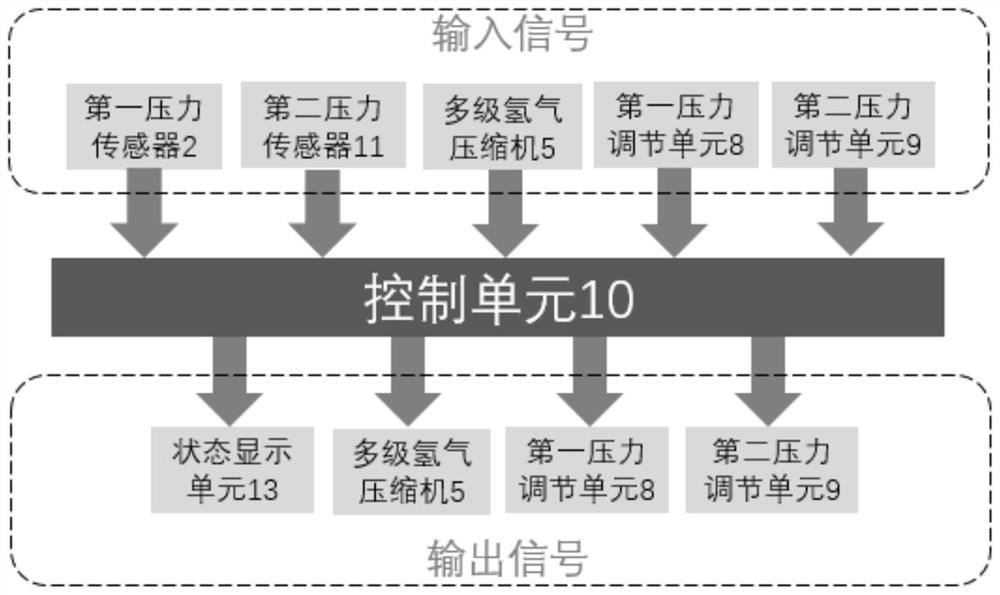

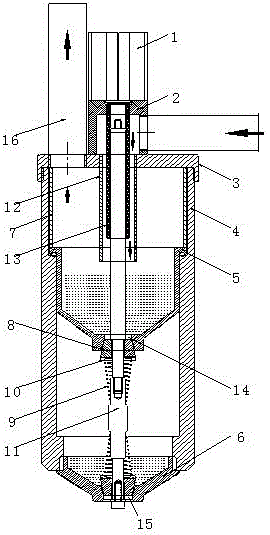

Liquid hydrogen evaporated gas treatment system and control method thereof

ActiveCN112628593AAvoid lossLow costGas handling/storage effectsPipeline systemsControl cellLiquid hydrogen

The invention provides a liquid hydrogen evaporated gas treatment system and a control method thereof. Reasonable guiding and utilization of liquid hydrogen evaporated gas in a liquid hydrogen transport ship are achieved, the evaporated gas in the liquid hydrogen storage tank can be stored in a hydrogen daily tank to be supplied to daily equipment after being compressed by a multi-stage hydrogen compressor, and can also be stored in a compressed hydrogen high-pressure storage tank, loss caused by the fact that evaporated gas is directly exhausted into the atmosphere is avoided, expensive liquefaction equipment is not needed, and the ship manufacturing cost is greatly reduced. Wherein the compressed hydrogen high-pressure storage tank simultaneously has storage and supply buffer functions, evaporated gas stored in the compressed hydrogen high-pressure storage tank can be supplied to the hydrogen daily tank and can also be supplied to the liquid hydrogen storage tank, and a key effect on maintaining the stability of the whole system is achieved. A control unit realizes real-time regulation and control of the whole system, and cooperates with the compressed hydrogen high-pressure storage tank to always keep the internal pressure of the liquid hydrogen storage tank and the hydrogen daily tank stable, so that the safety and stability in ship transportation are greatly improved, and extremely high practical value is achieved.

Owner:JIANGNAN SHIPYARD GRP CO LTD

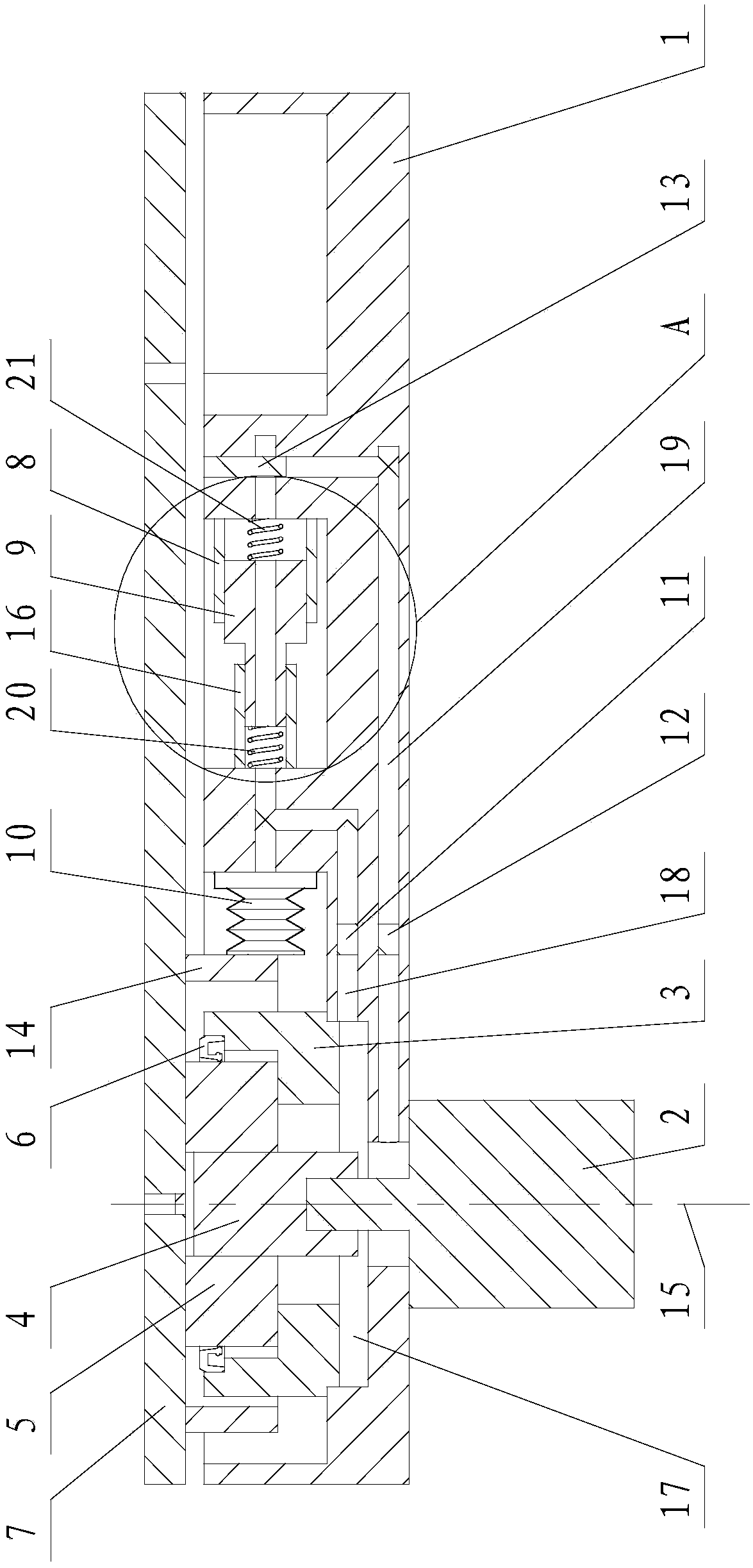

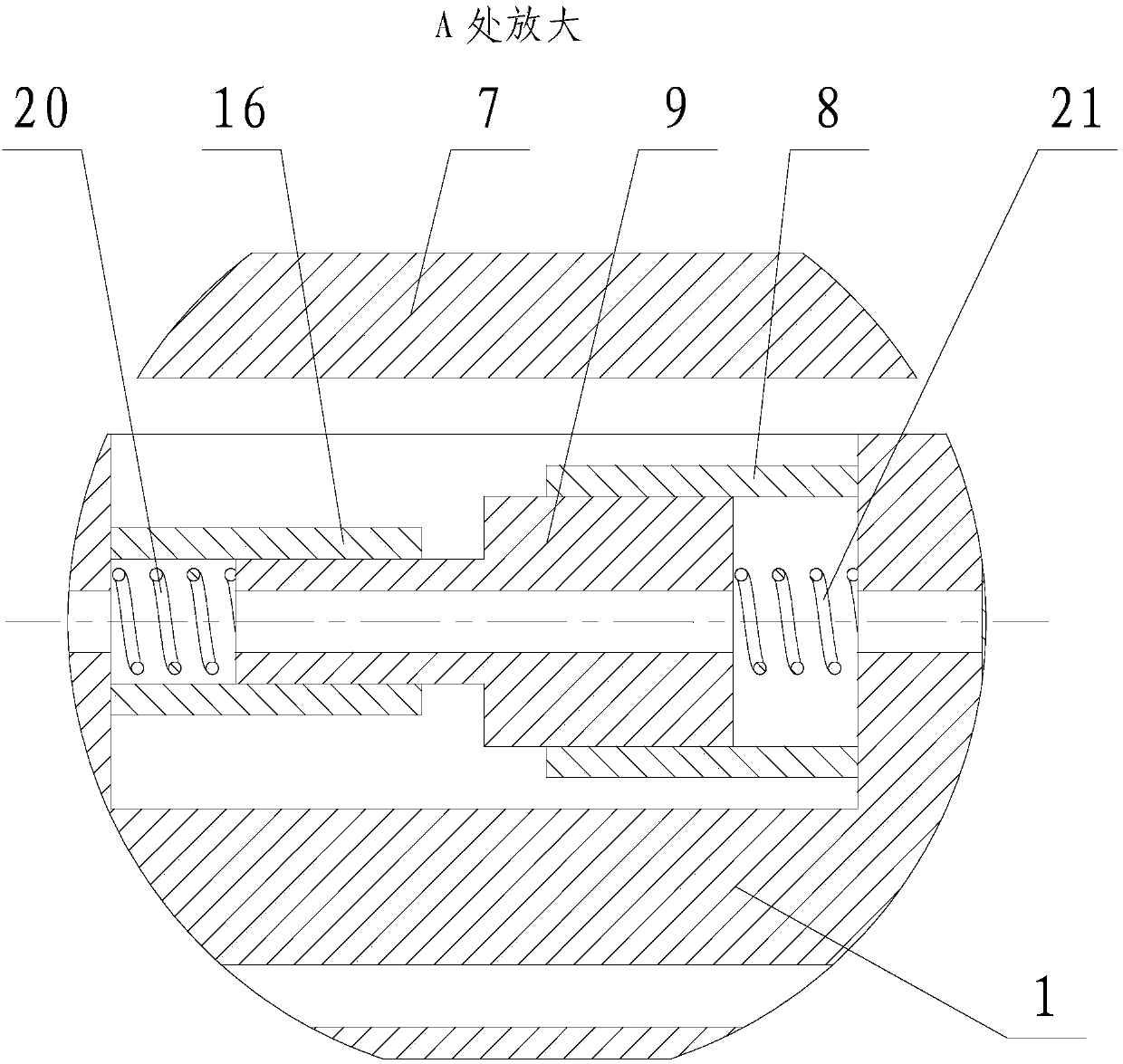

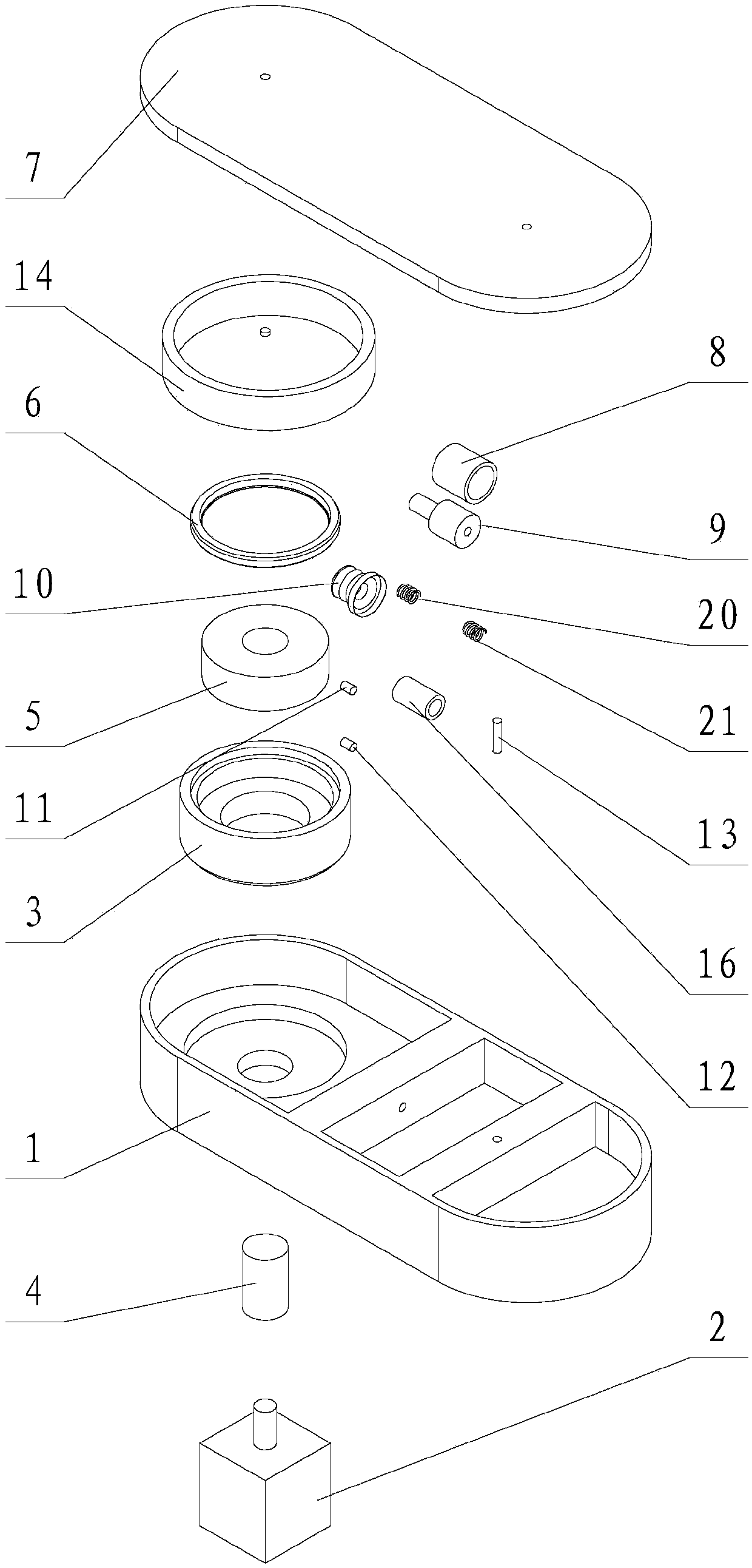

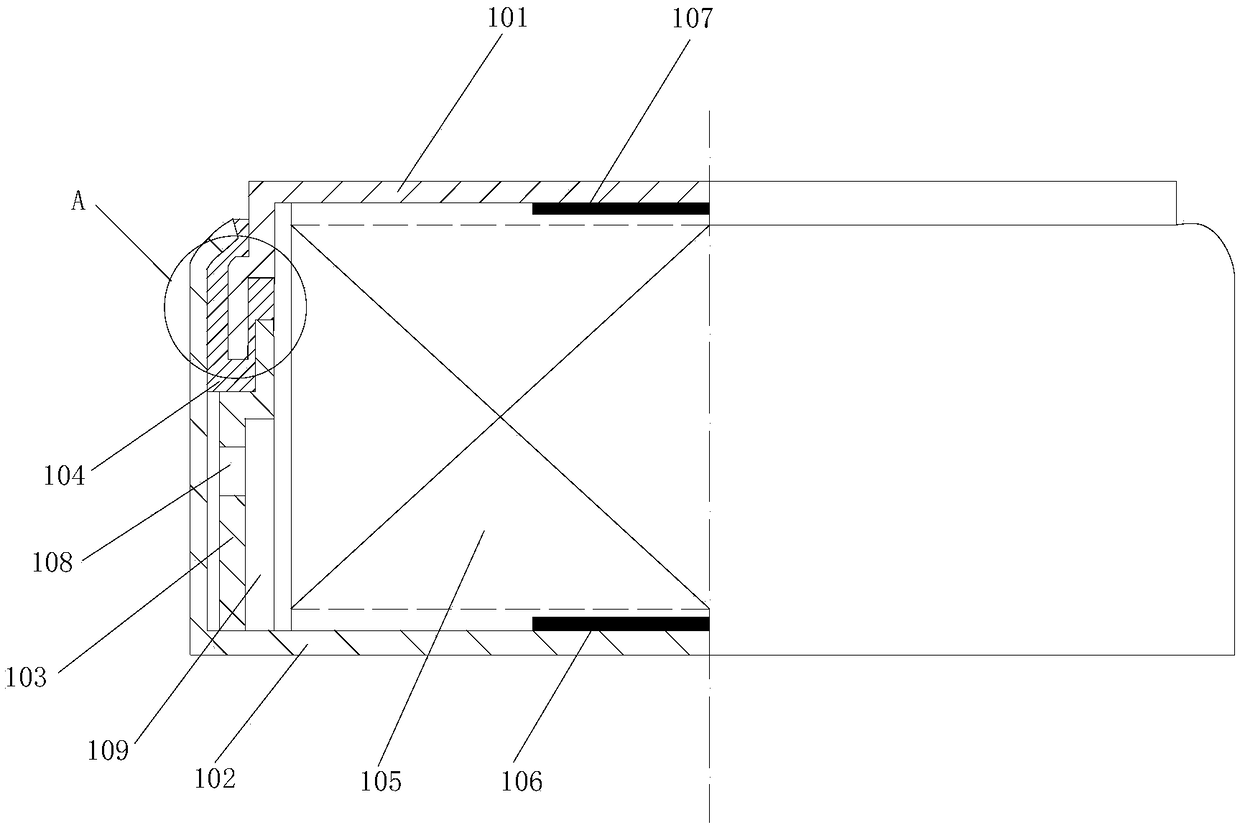

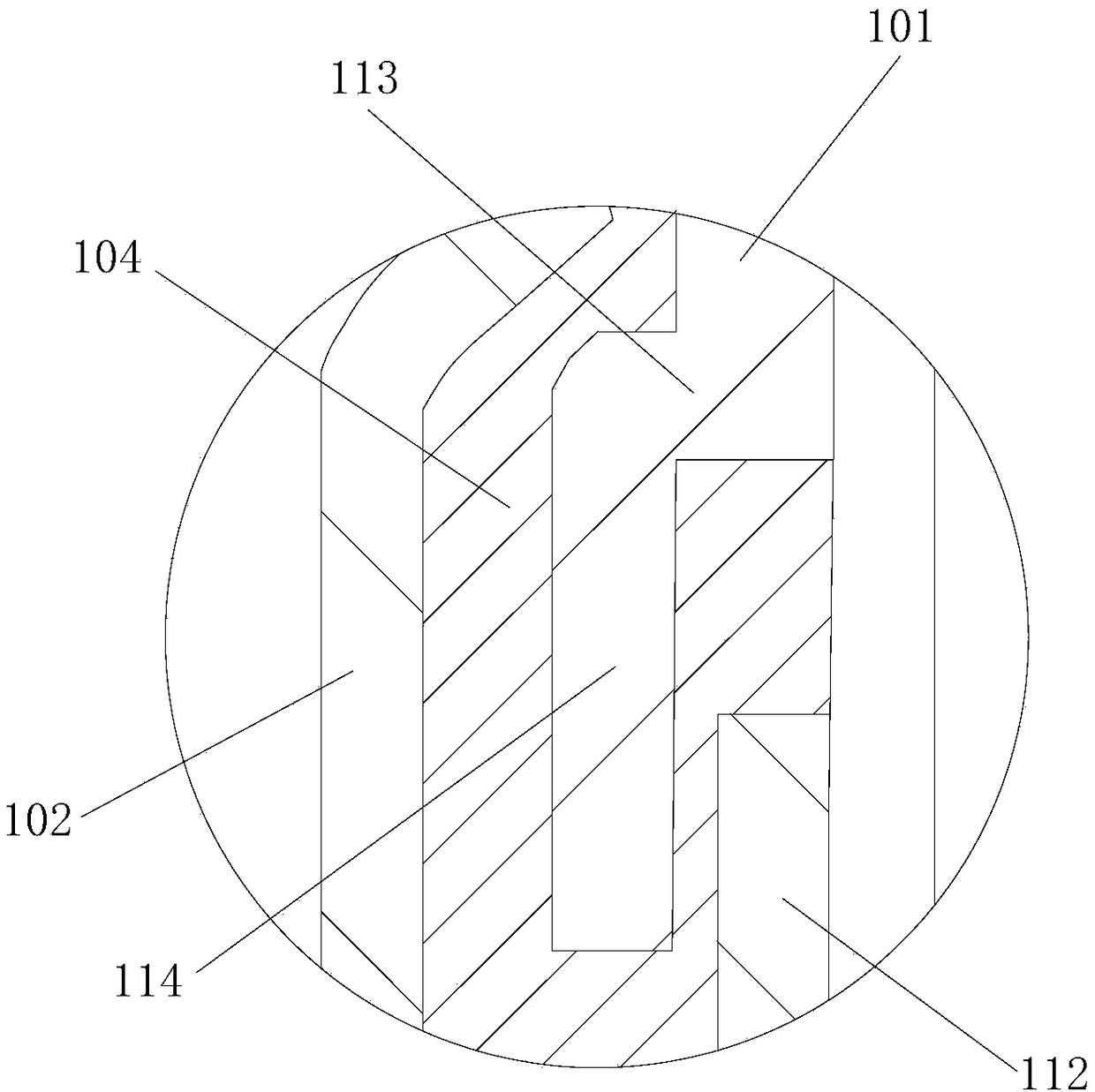

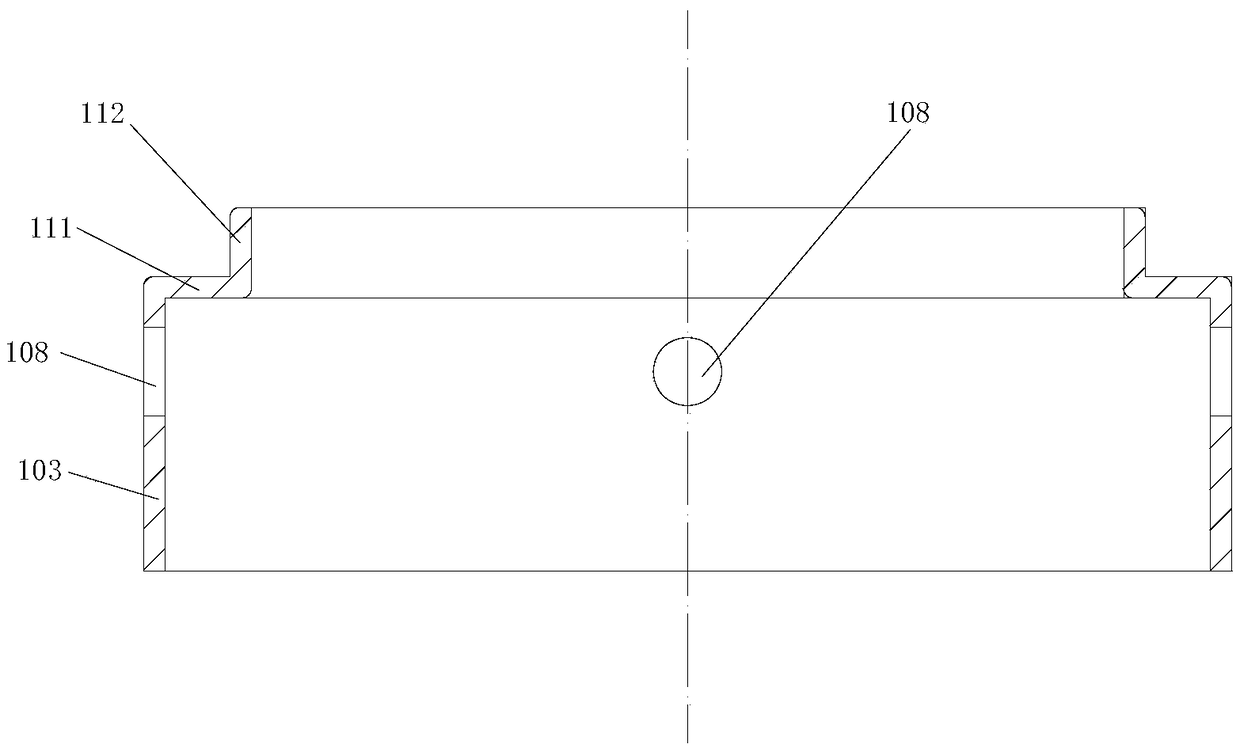

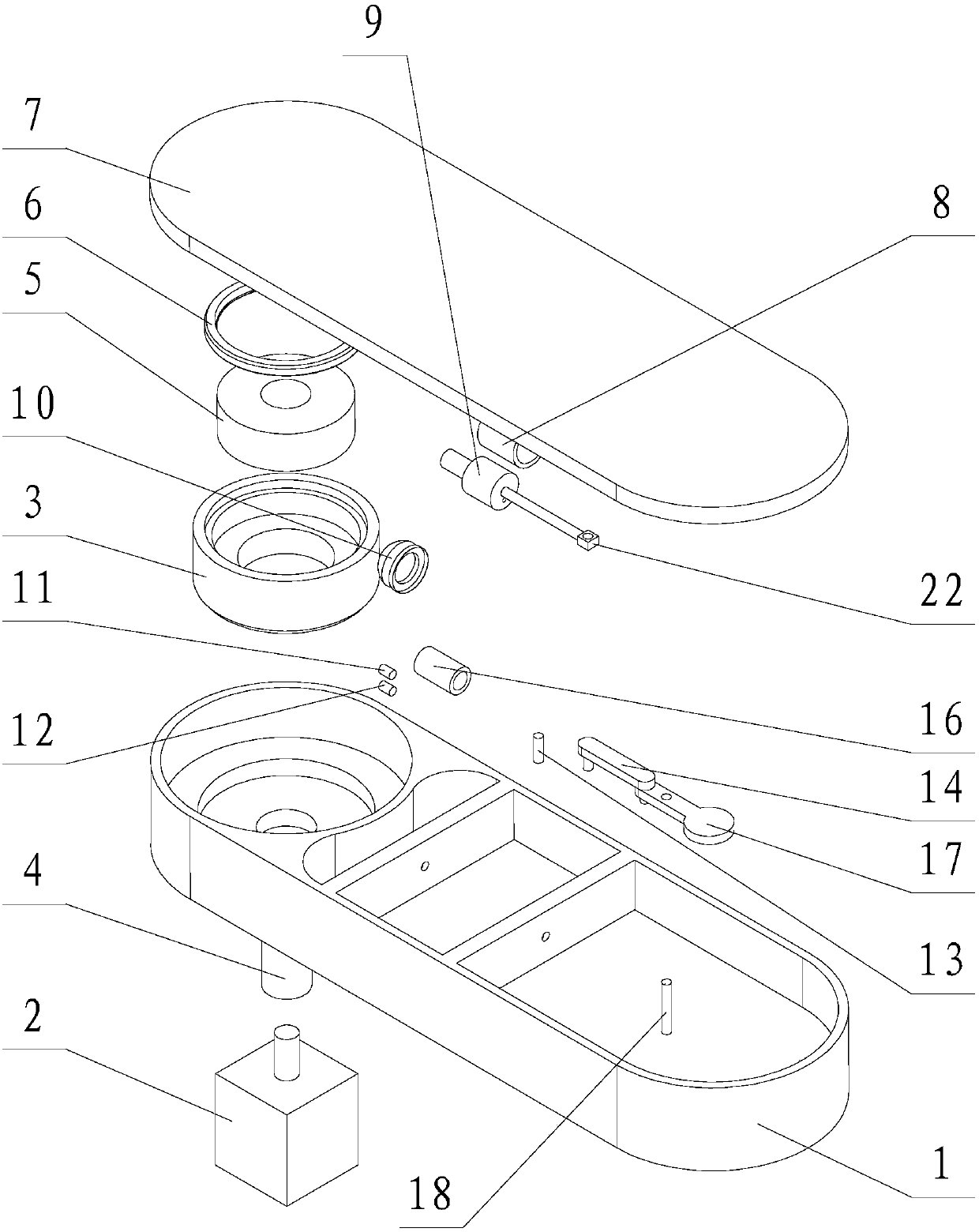

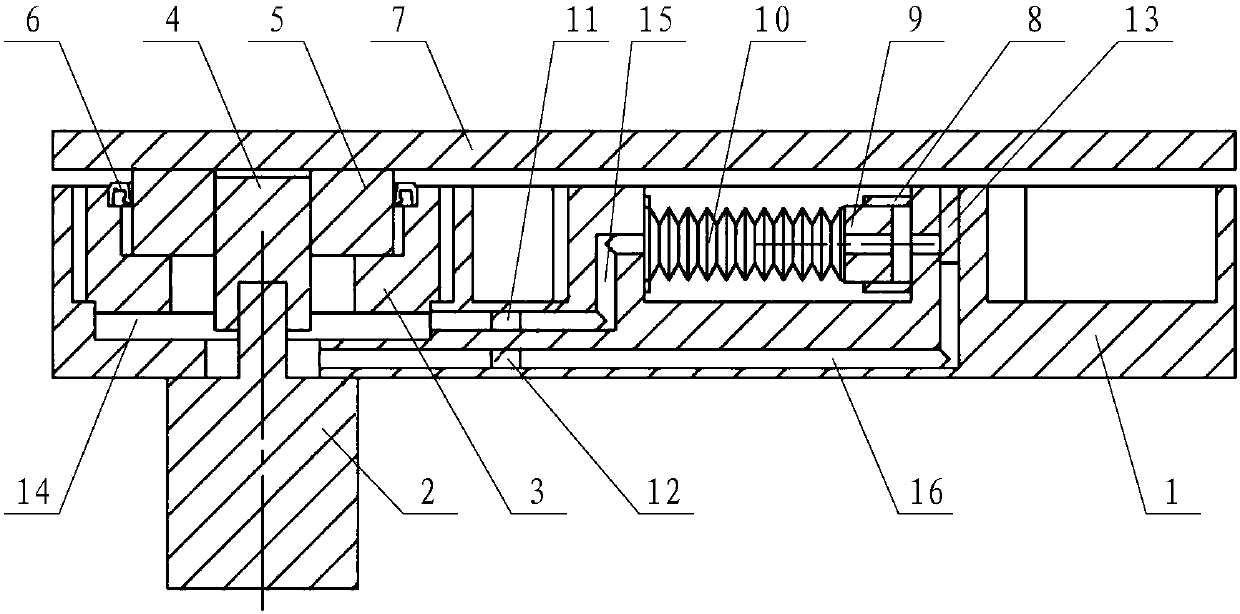

Coolant separation device for vacuum processing environment

ActiveCN106079995AAchieve replacementGuaranteed recyclingOther artistic work equipmentsModel makingInternal pressureEngineering

The invention discloses a coolant separation device for a vacuum processing environment. The coolant separation device comprises a cylinder, a cylinder mounting seat, a tank cover, a tank body, an interlayer, a conical sealing bottom, spacer bushes, sealing plugs, springs, a two-way piston rod, a water return guide pipe, a cylinder protecting pipe, a first water outlet, a second water outlet and a vacuum pipe. The top and the bottom of the tank body are respectively and hermetically connected with the tank cover and the conical sealing bottom. The interlayer is hermetically connected to the interior of the tank body, and divides the interior of the tank body into an upper sustaining pressure cavity and a lower buffering cavity. The tank cover presses the interlayer through the spacer bushes. The first water outlet and the second water outlet are controlled by the two-way piston rod to be opened or closed, the replacement of a coolant between the upper sustaining pressure cavity and the lower buffering cavity is realized, the internal pressure can be kept stable, the sealing performance can be ensured through the sealing structures that the water outlets are sealed by the sealing plugs, and scaling is avoided. The coolant separation device can ensure recycling of the coolant, and the operating efficiency of the coolant separation device is improved.

Owner:SHENZHEN SHENGLIDA CNC EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com