Patents

Literature

85results about How to "Achieve precise delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

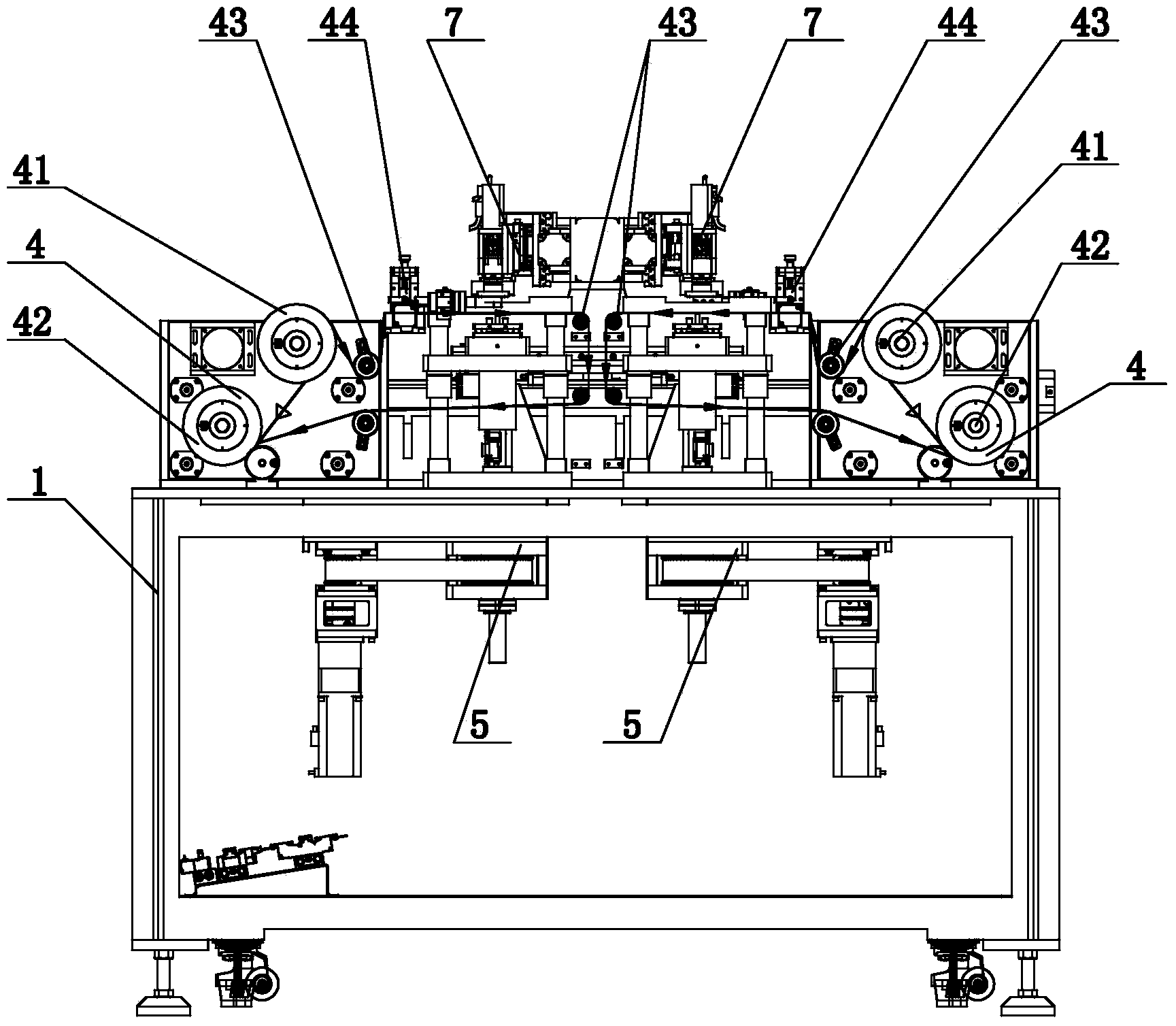

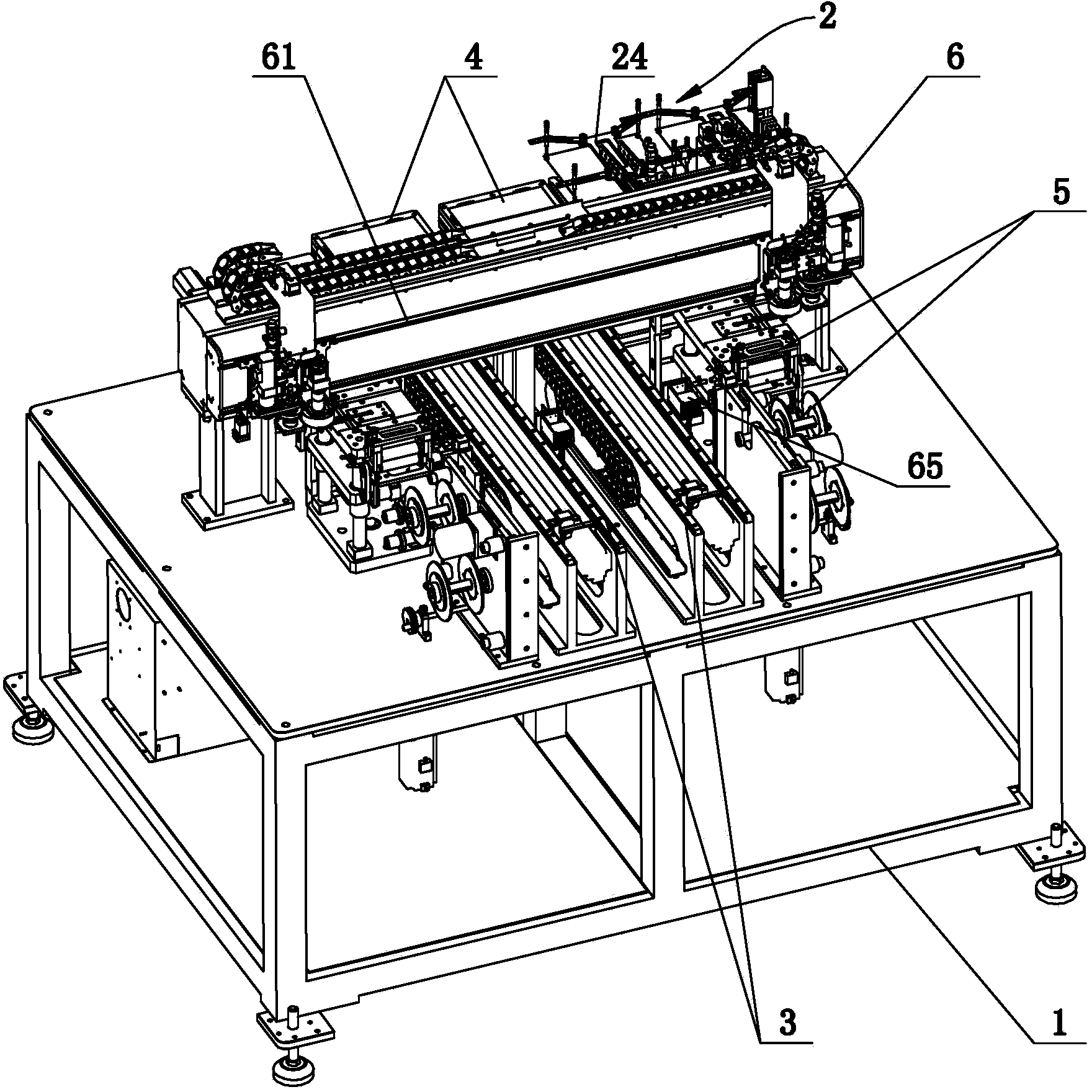

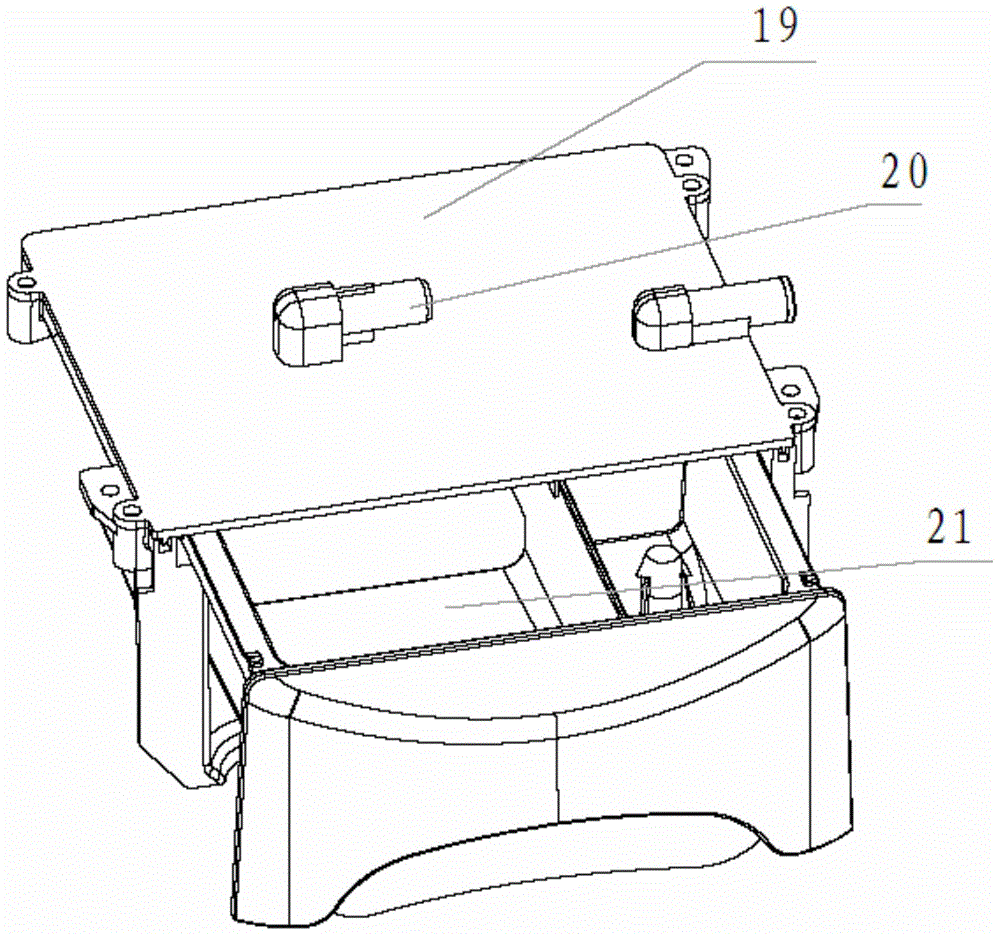

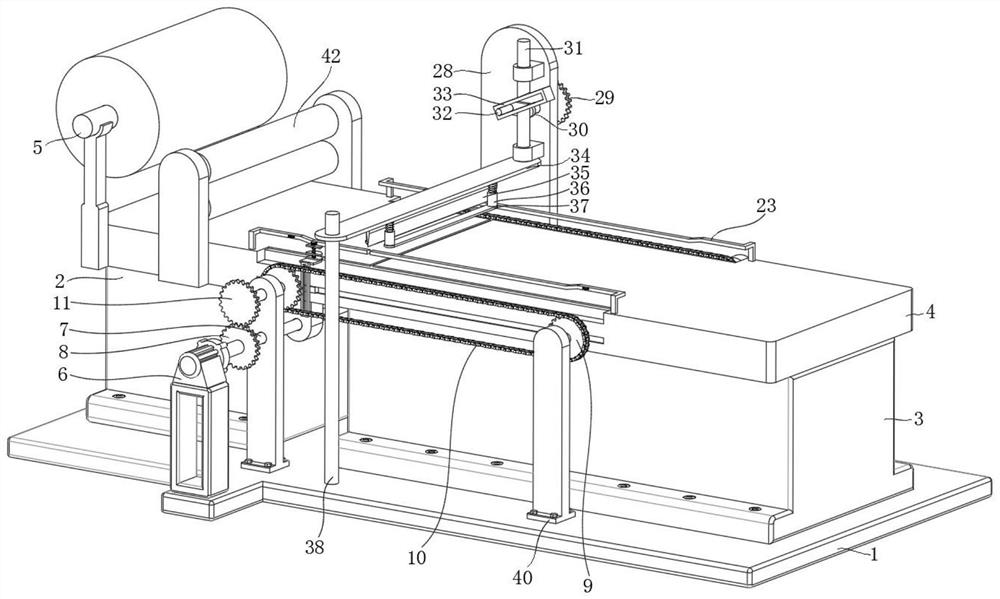

Full-automatic stiffening plate false sticking machine

ActiveCN103987199ATo achieve singleThe punching position is accuratePrinted circuit manufactureLow visionEngineering

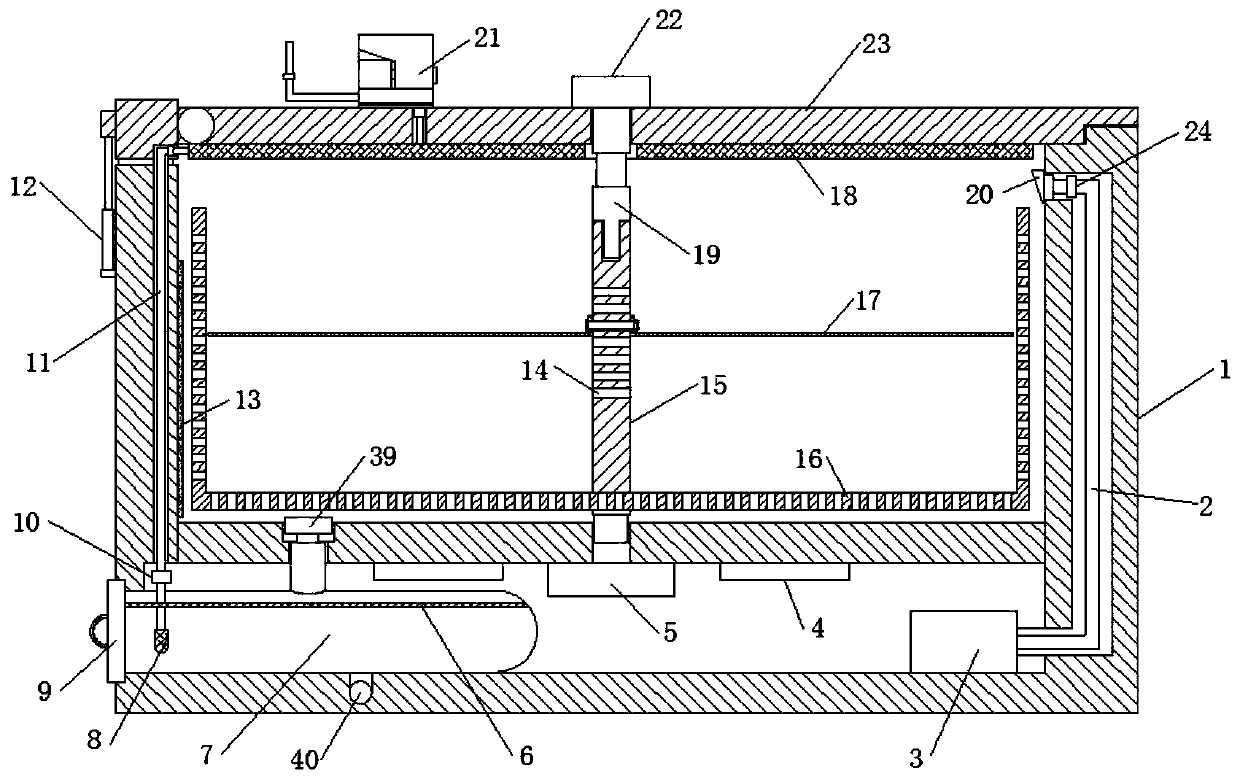

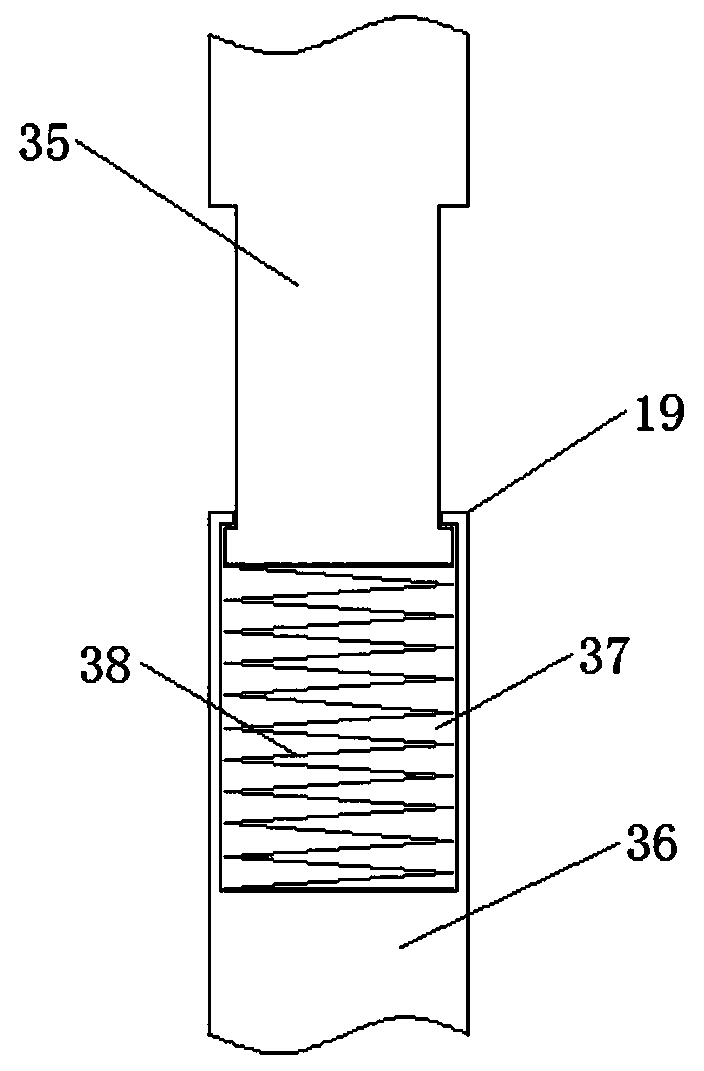

The invention discloses a full-automatic stiffening plate false sticking machine, and belongs to the technical field of flexible printed circuit processing devices. The full-automatic stiffening plate false sticking machine comprises a machine frame, an FPC positioning heating platform driven by an X-direction movement mechanism is installed on the machine frame in a sliding mode, and a feeding mechanism, a servo blanking mechanism and a sticking mounting mechanism are arranged on the machine frame. The servo blanking mechanism comprises a material overturning mechanism. The sticking mounting mechanism comprises a supporting beam, a Z-direction and angle theta rotating movement mechanism, an upper vision camera and a lower vision camera, wherein a Y-direction movement mechanism is arranged on the supporting beam, the Z-direction and angle theta rotating movement mechanism is installed on the Y-direction movement mechanism, a stiffening plate suction nozzle is installed on the Z-direction and angle theta rotating movement mechanism, the upper vision camera is installed on the Y-direction movement mechanism, and the lower vision camera is installed on the machine frame. According to the full-automatic stiffening plate false sticking machine, the stiffening plate can be accurately stuck and mounted on an FPC, production efficiency and sticking mounting precision are greatly improved, the production cost is reduced, and device stability is high and product quality is reliable during actual production.

Owner:GOERTEK INC

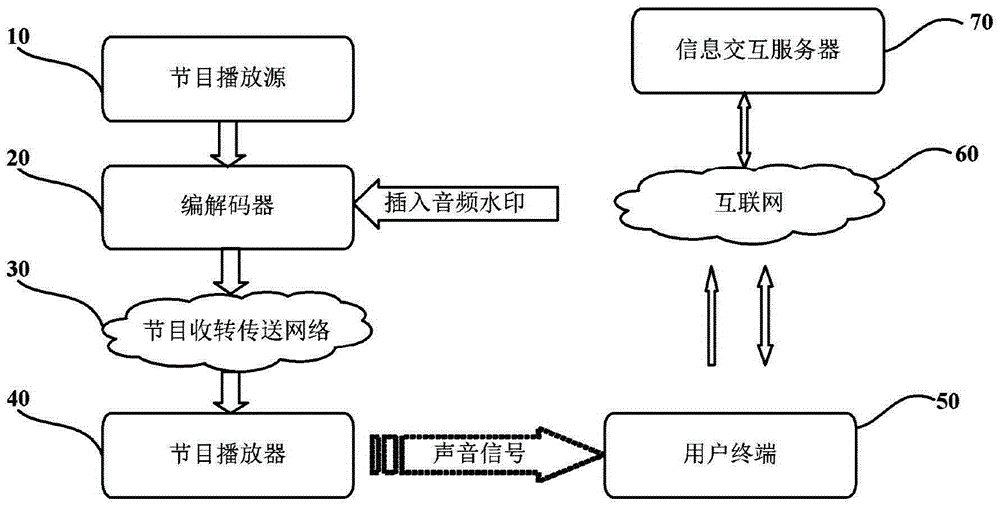

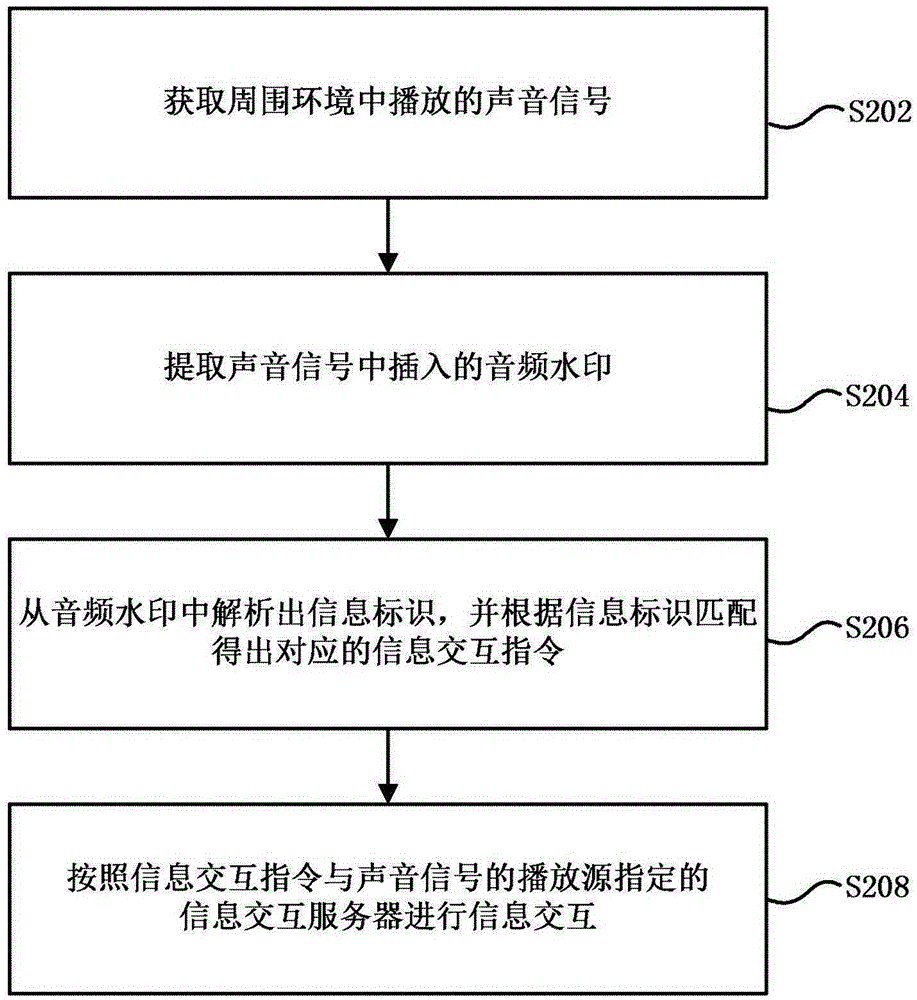

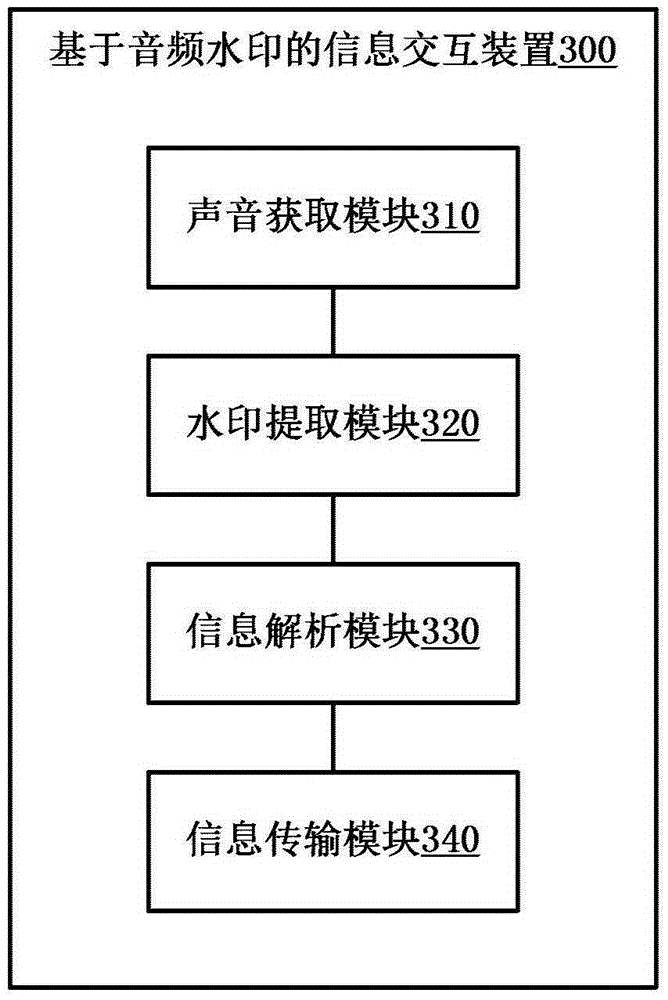

Audio watermark-based information interaction method and device

ActiveCN105392022AEasy to use in depthImprove user experienceSelective content distributionAudio watermarkTime information

The invention provides an audio watermark-based information interaction method and a device. The audio watermark-based information interaction method comprises steps: sound signals played in the surrounding environment are acquired; an audio watermark inserted in the sound signals is extracted, wherein the audio watermark is generated and embedded according to an information identifier corresponding to real-time information which needs to be provided for a user by a sound signal playing source; the information identifier is analyzed in the audio watermark, and a corresponding information interaction instruction is obtained according to information identifier matching; and according to the information interaction instruction, information interaction with an information interaction server specified by the sound signal playing source is carried out. By applying the scheme of the invention, an additional information interaction means is provided for traditional media, deep utilization can be carried out on contents of the traditional media, the business outlook is good, and more values can be provided for a media provider.

Owner:北京子天汇科信息技术有限公司

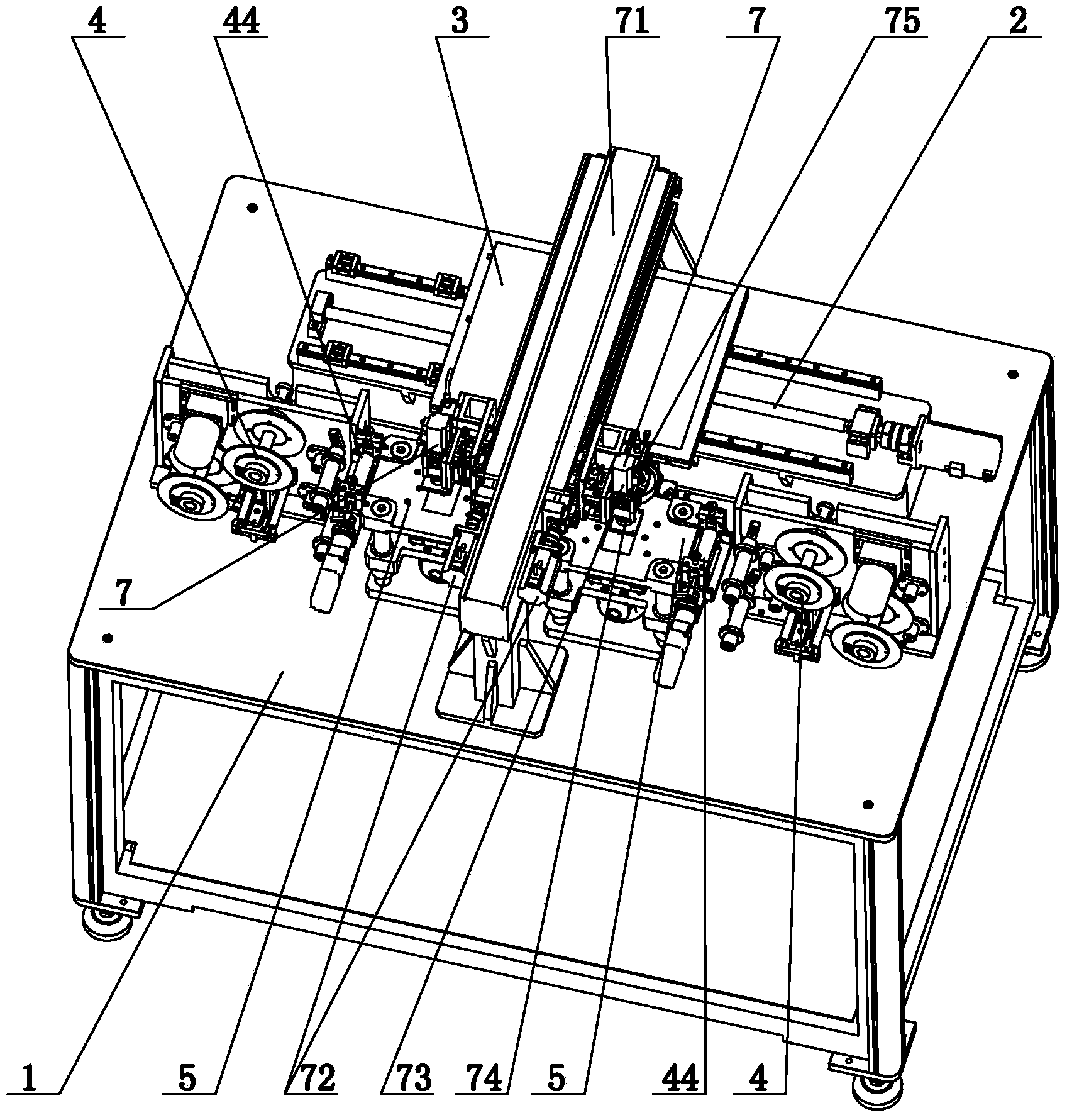

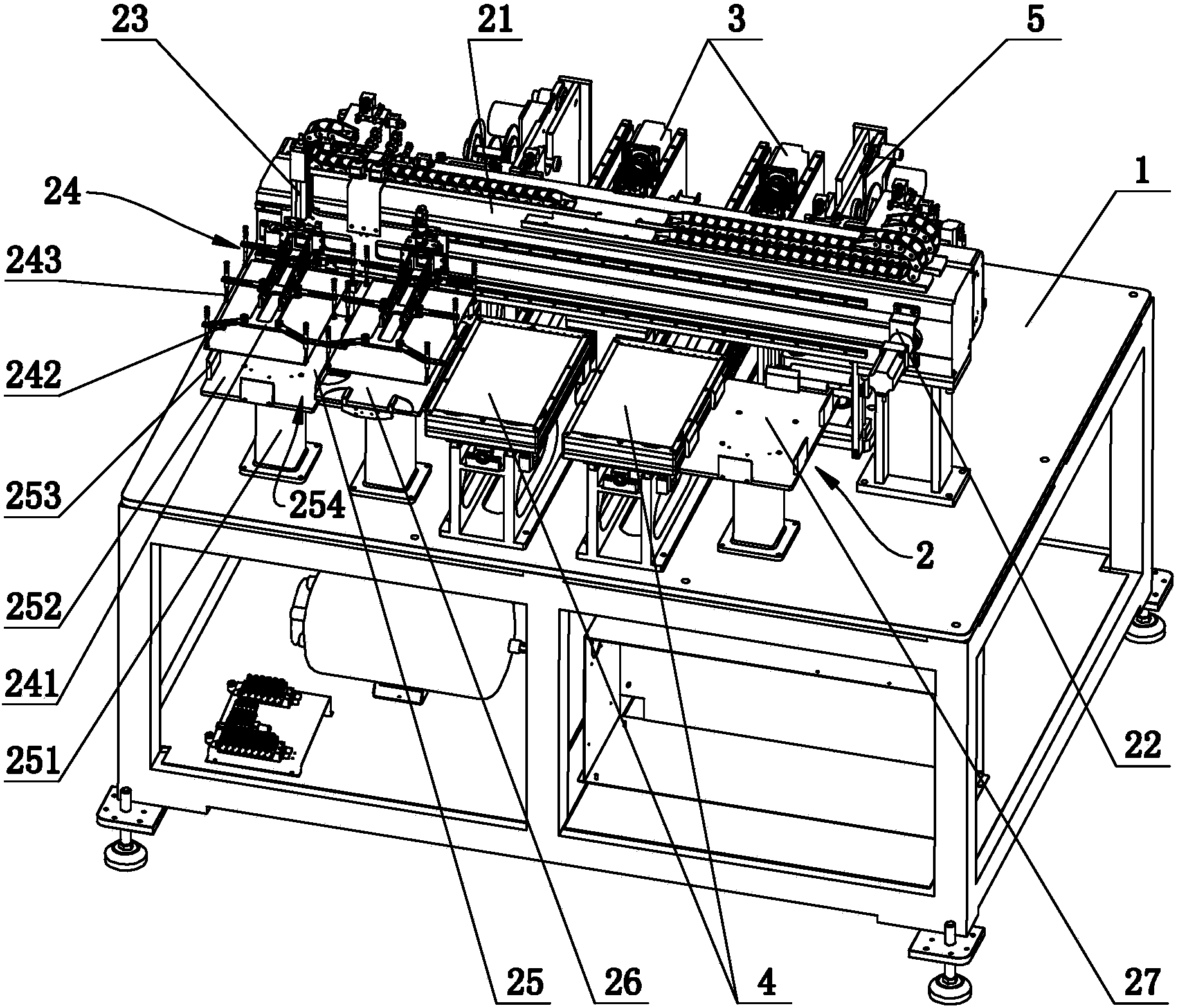

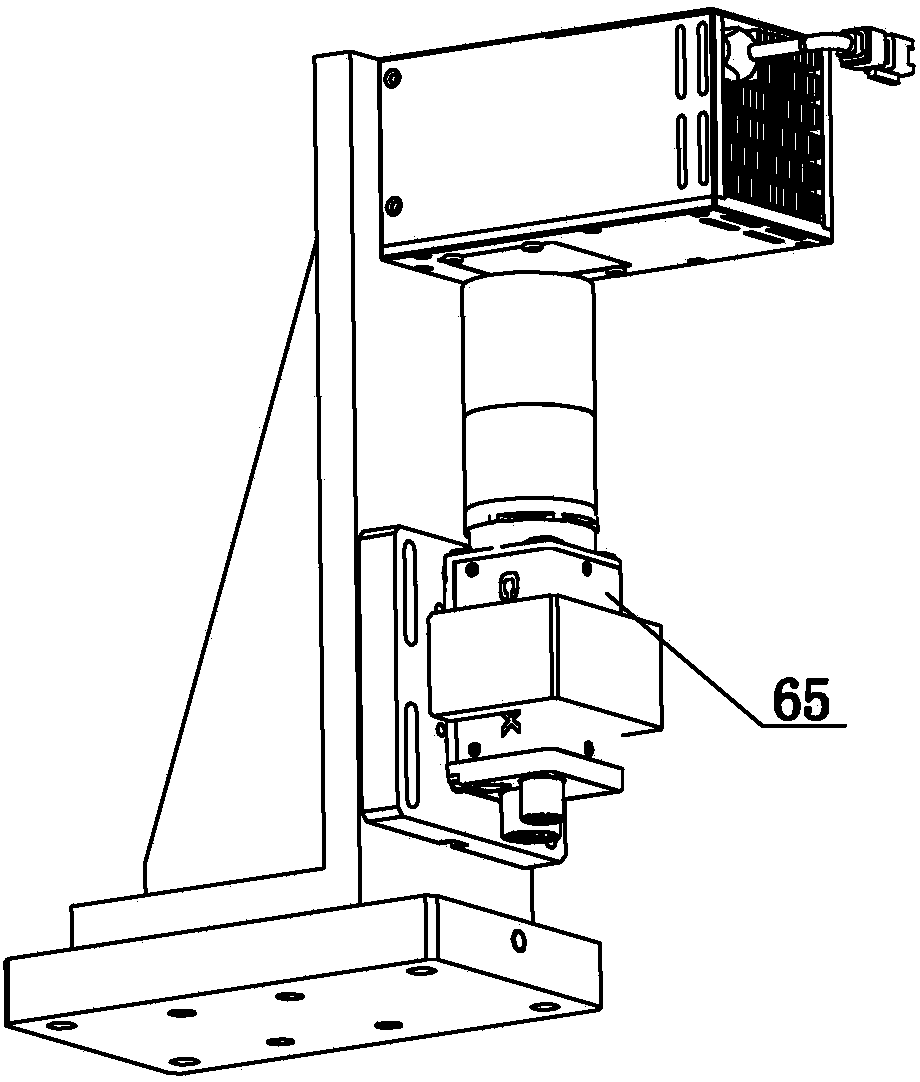

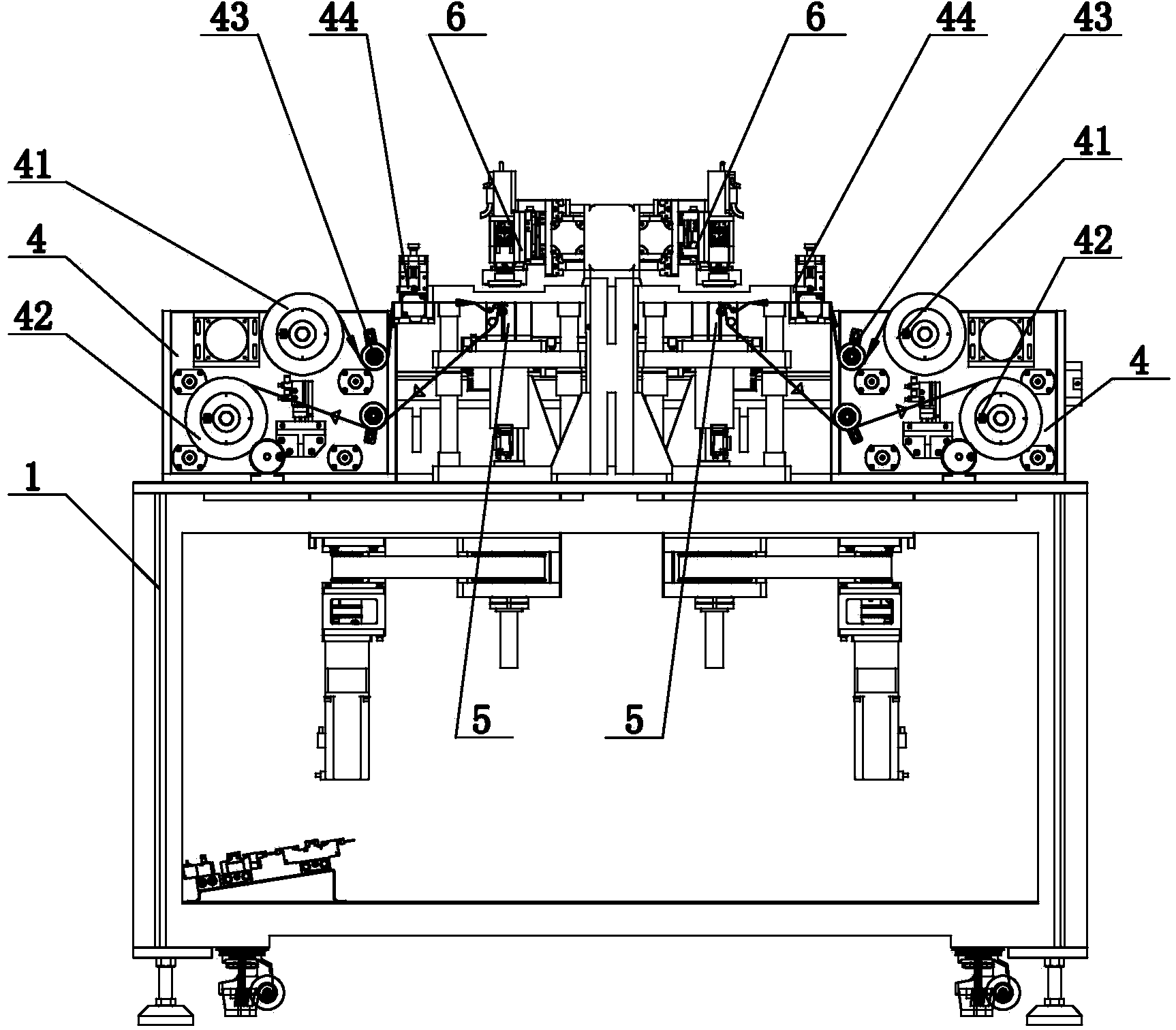

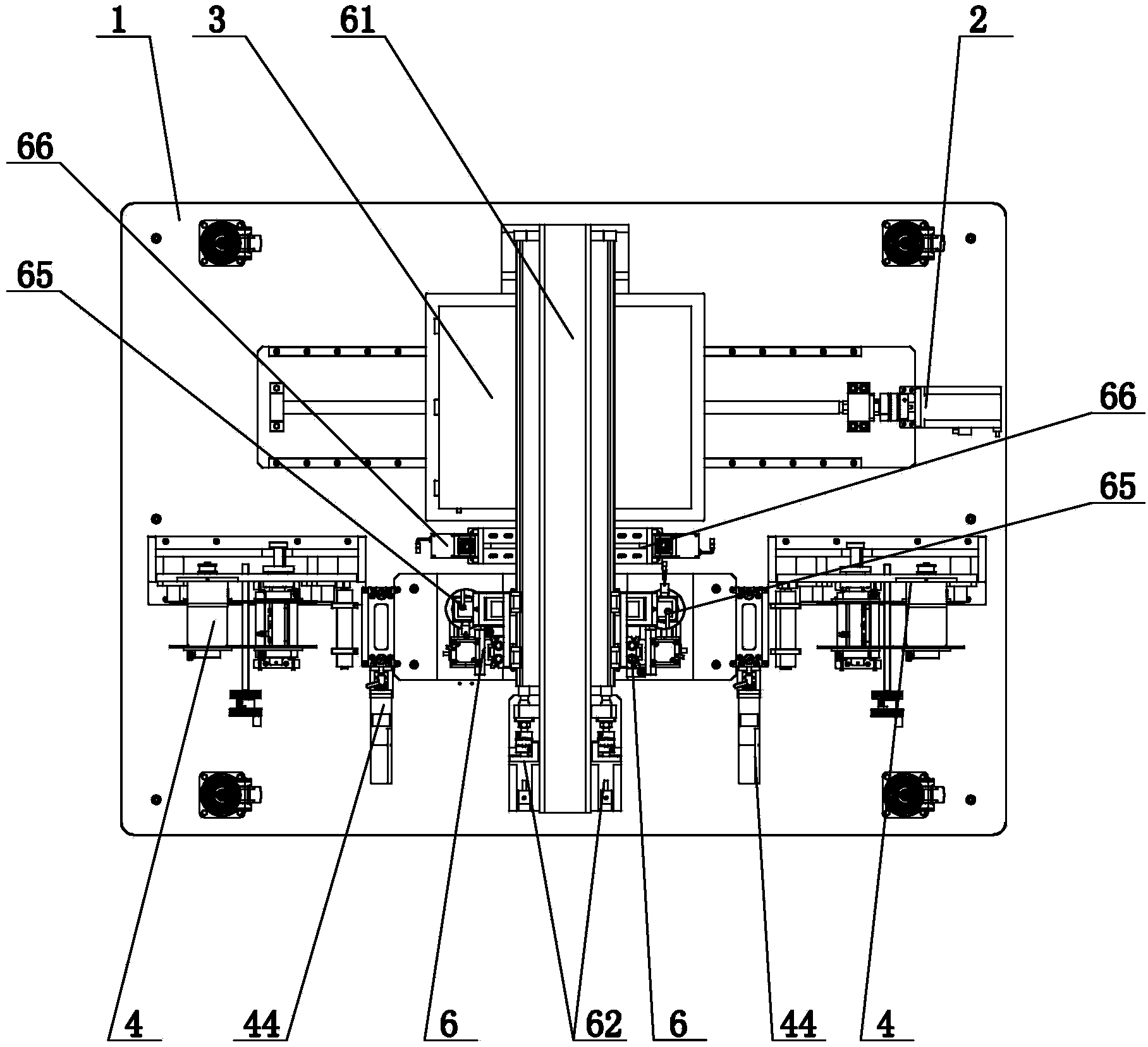

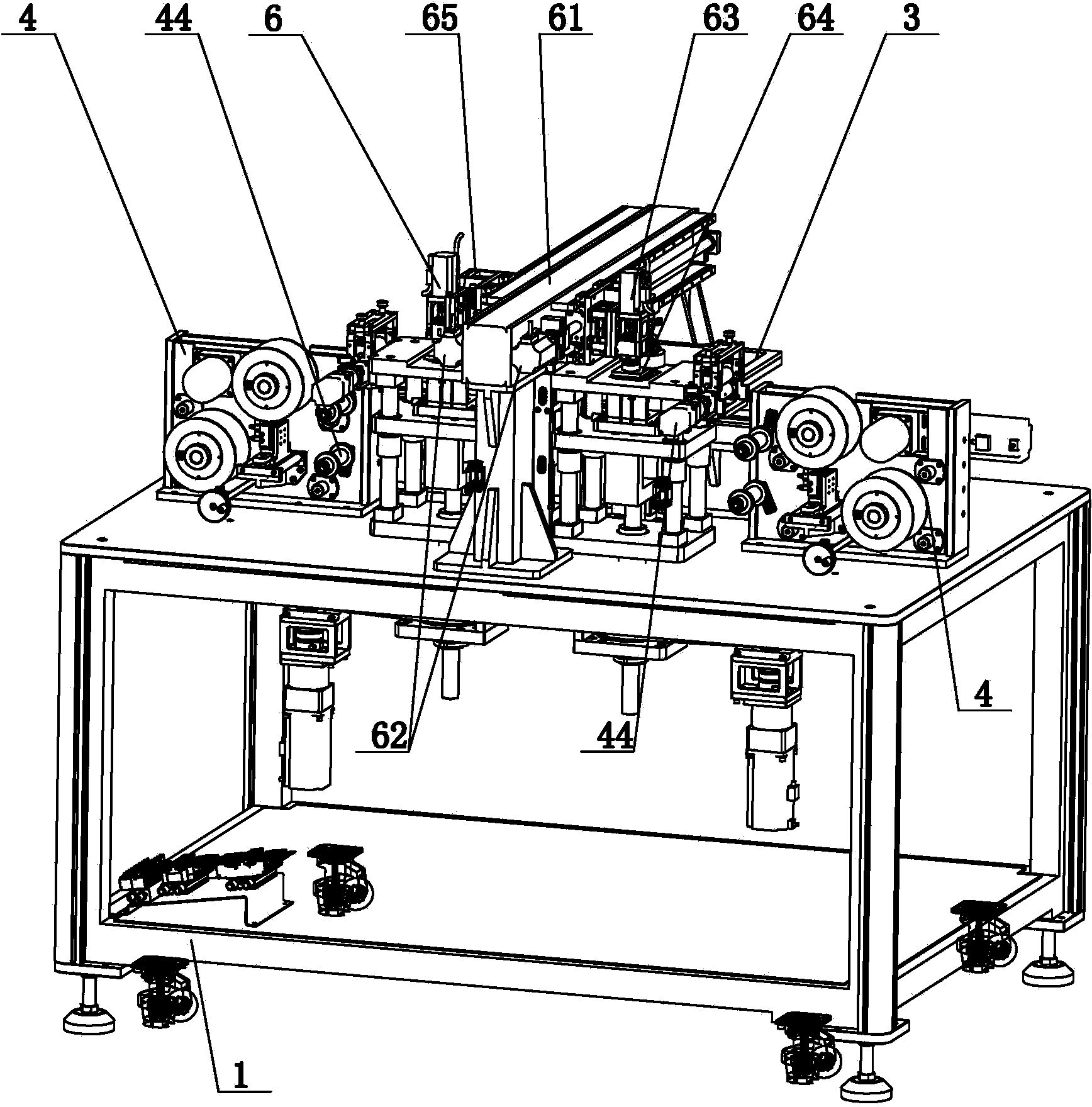

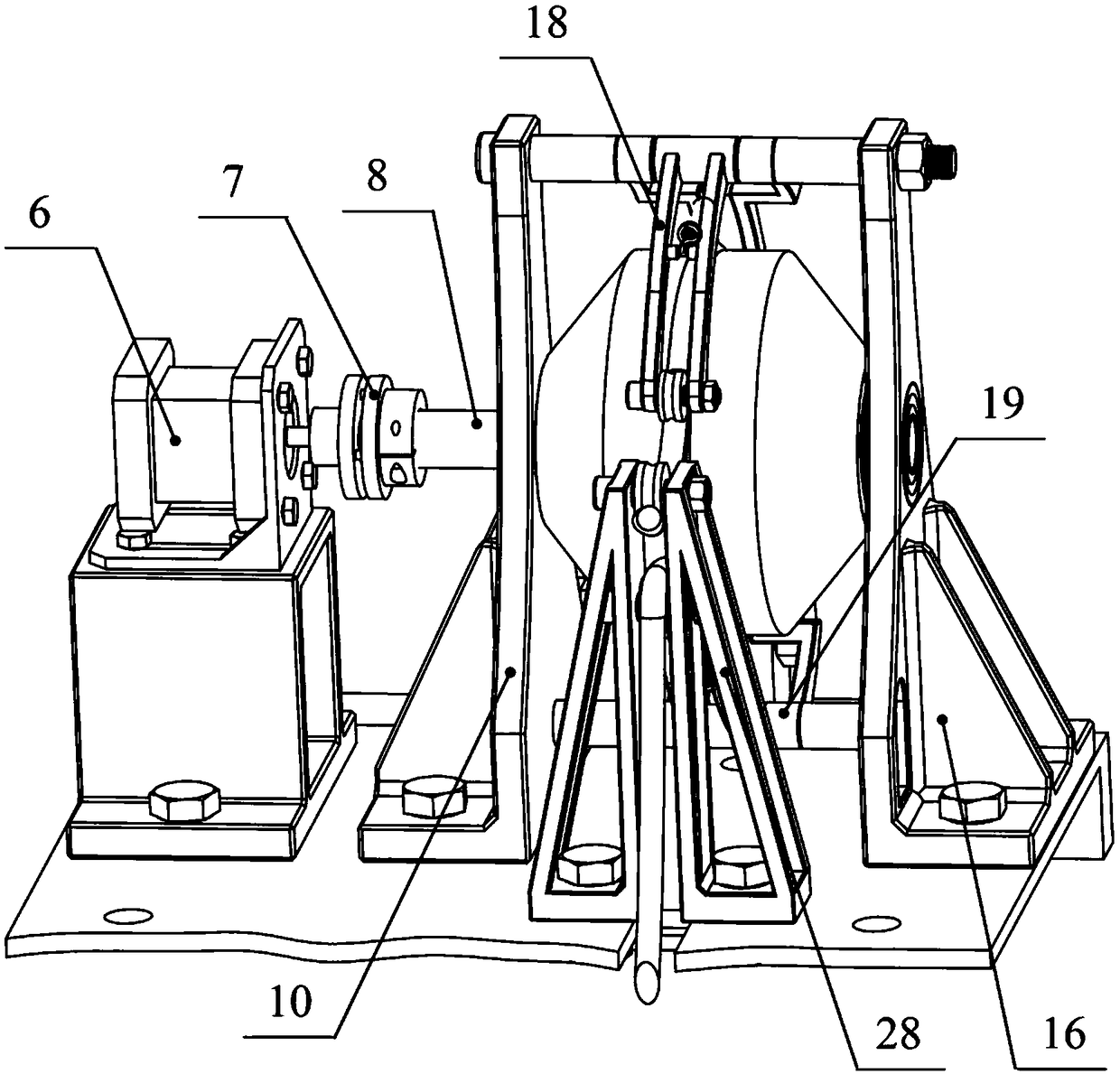

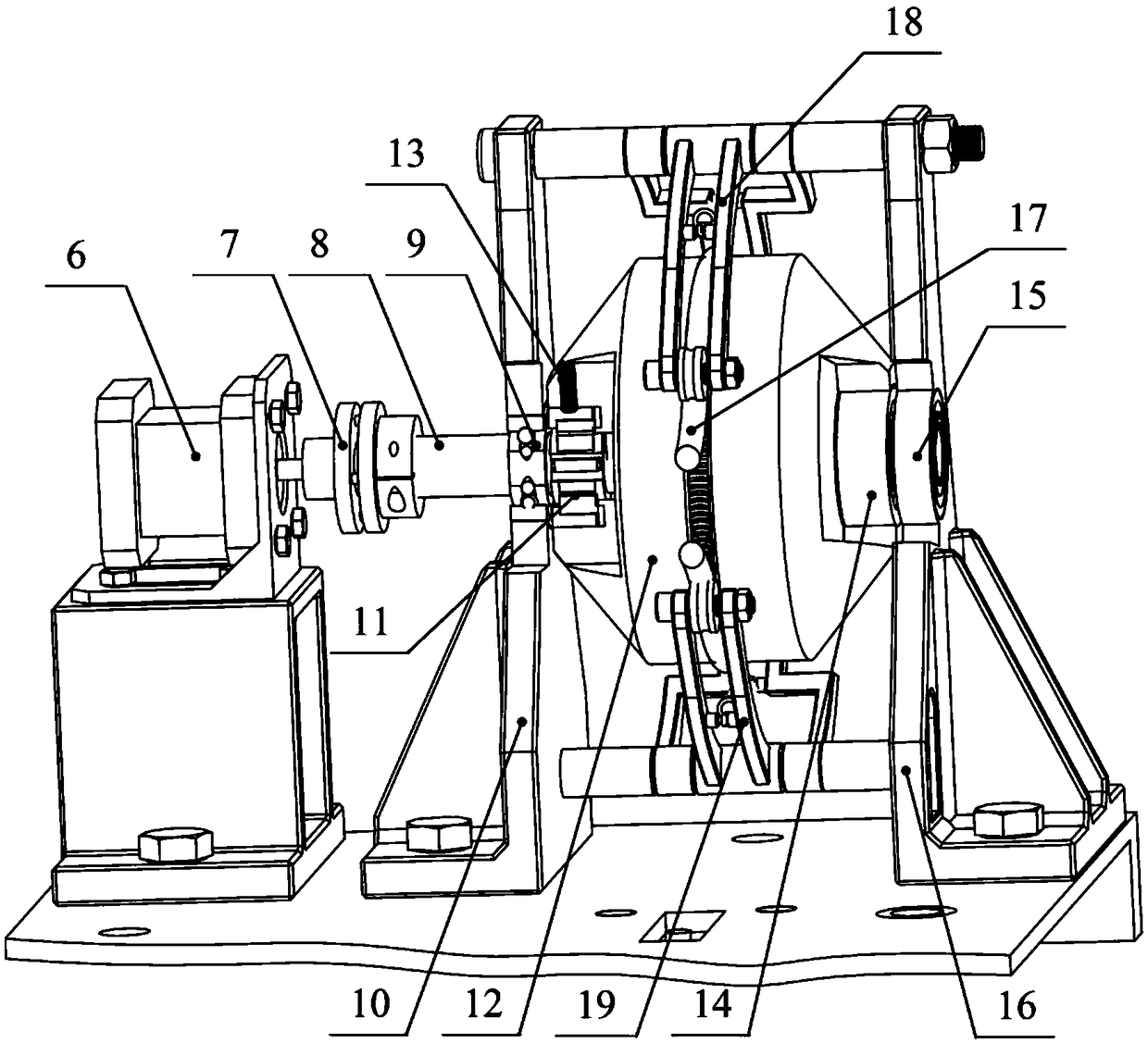

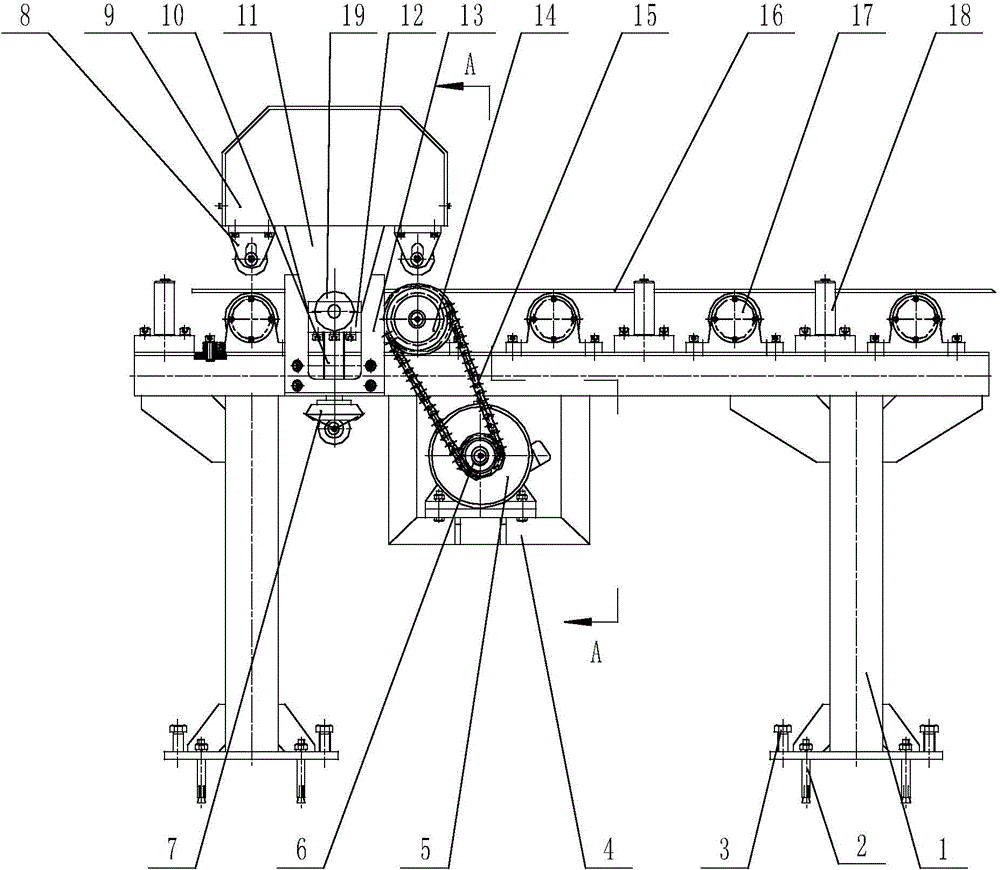

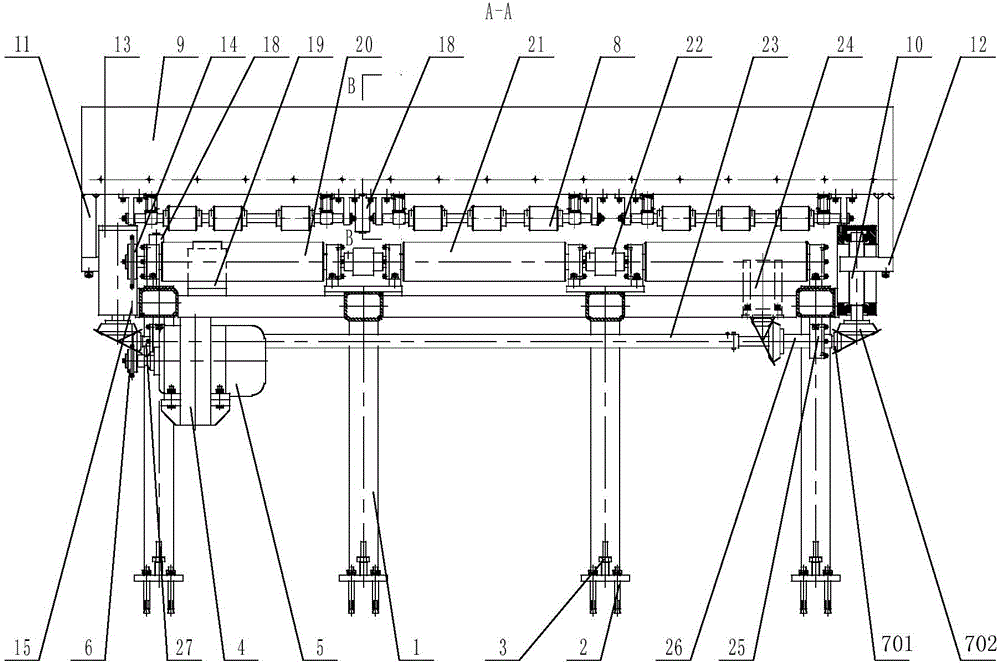

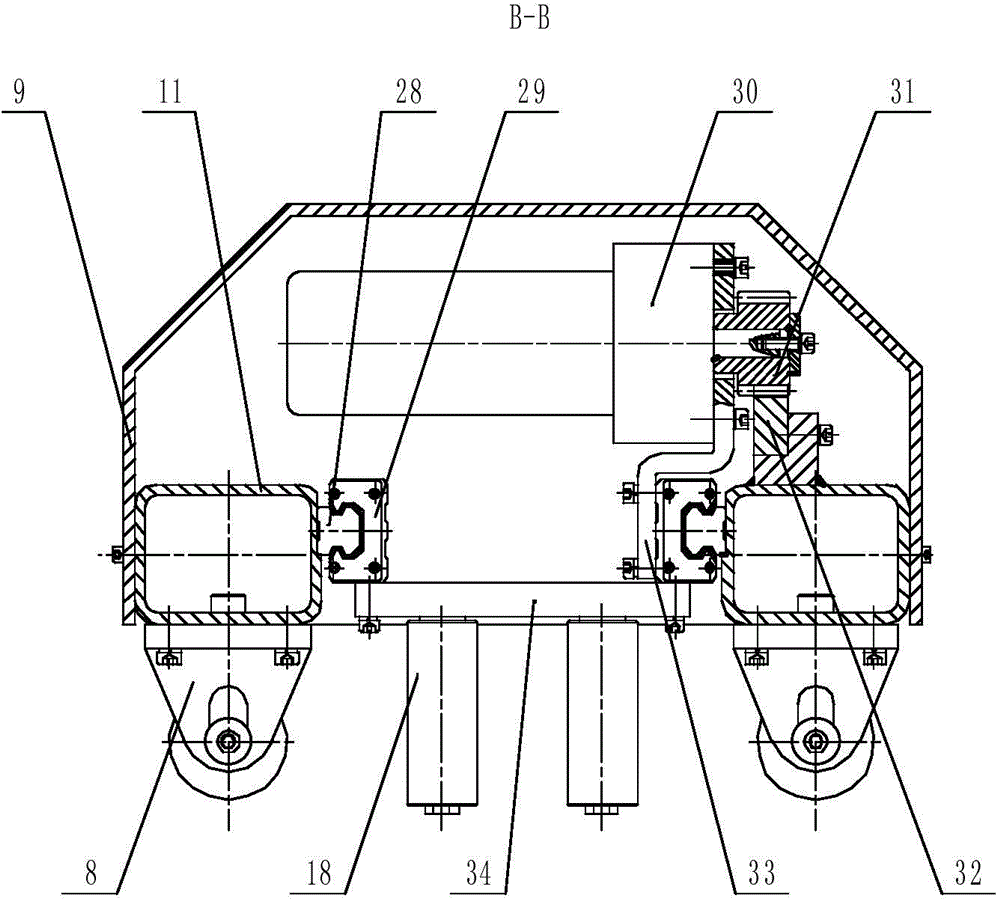

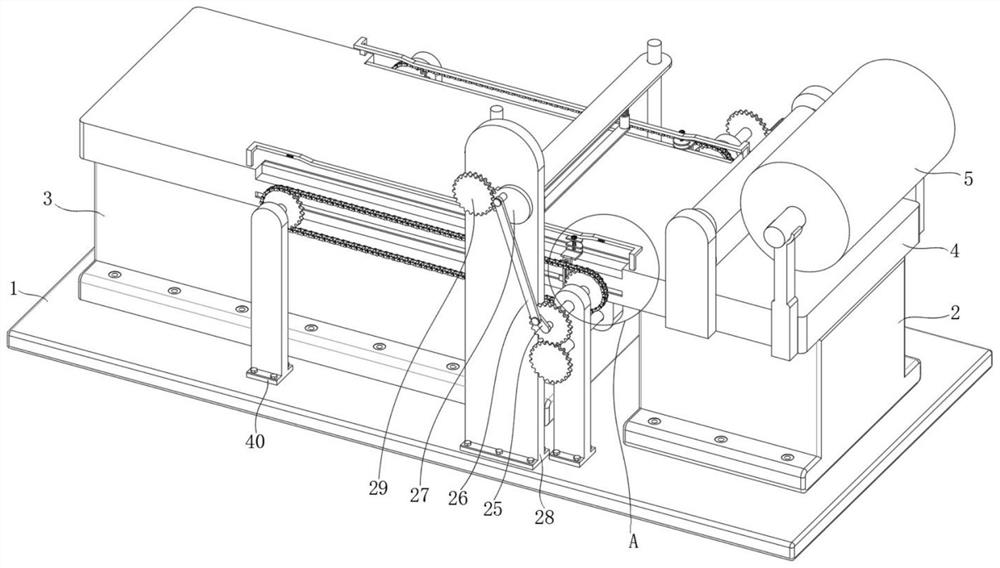

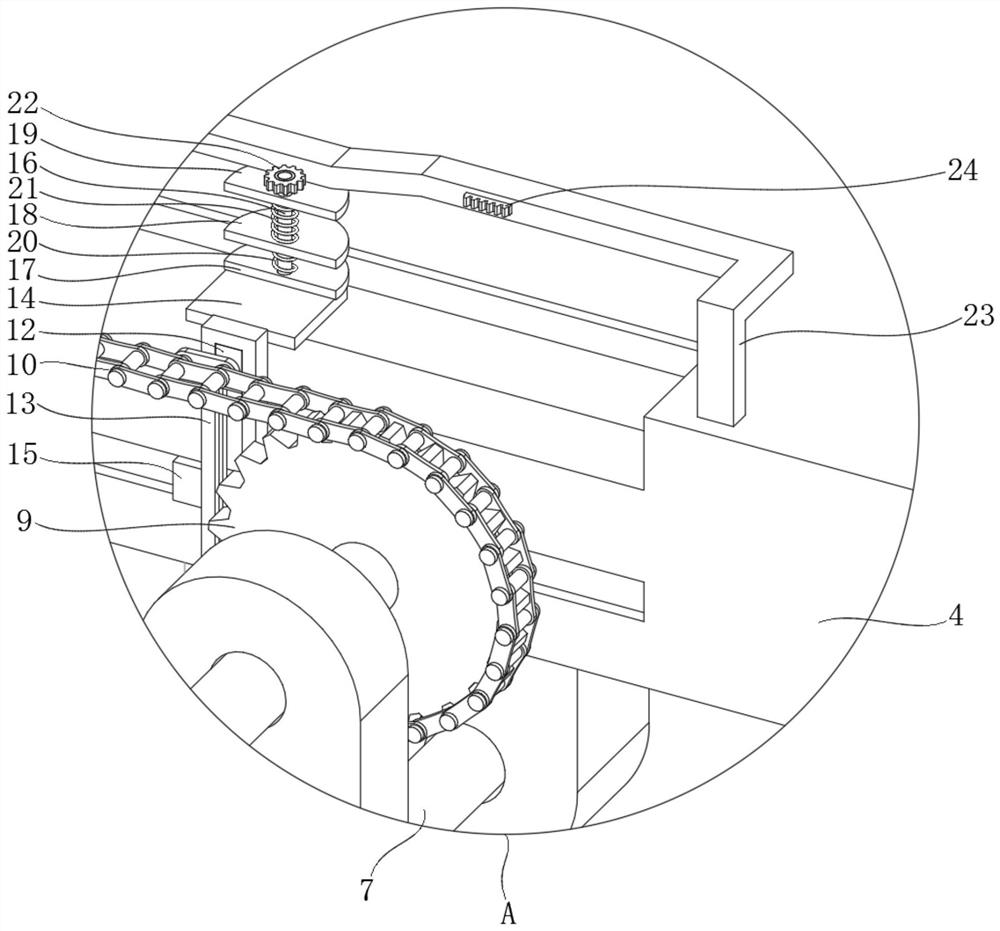

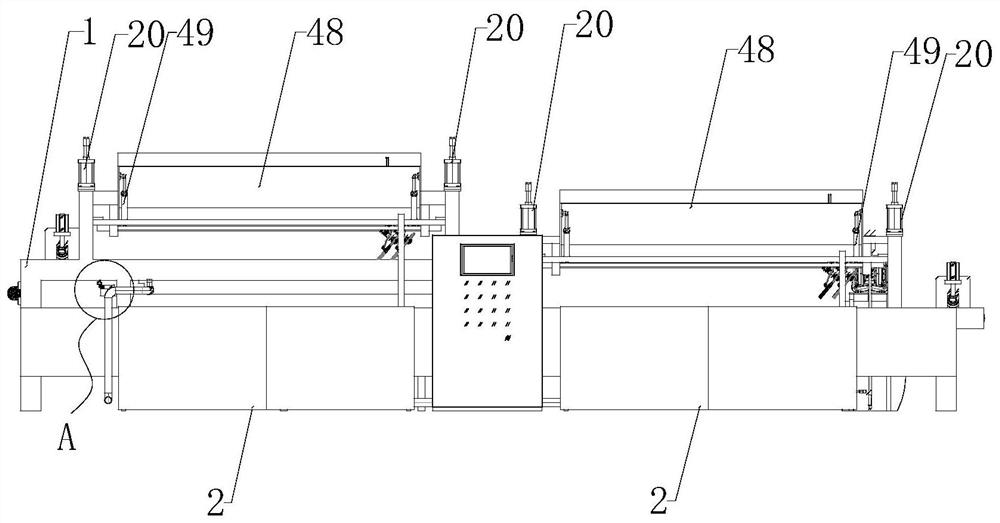

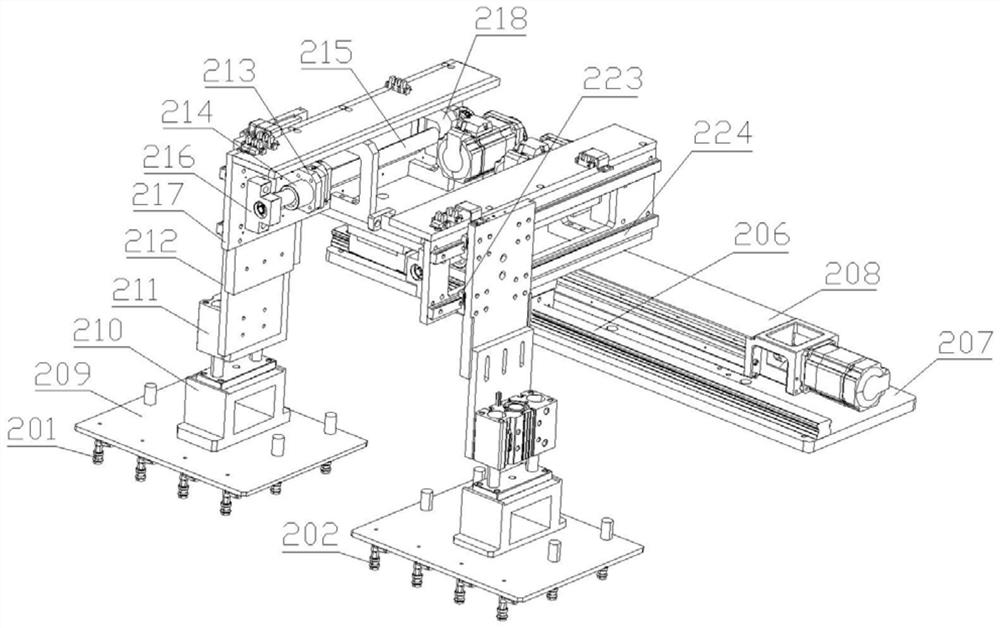

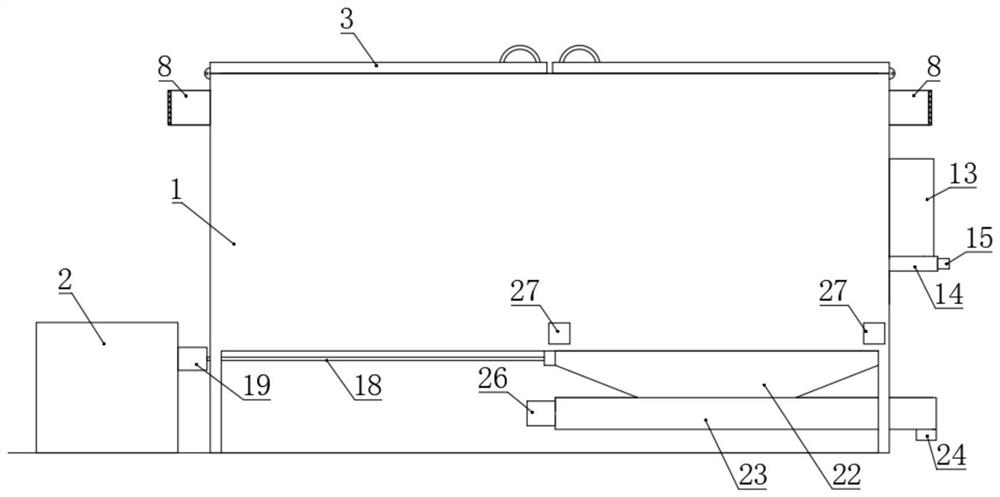

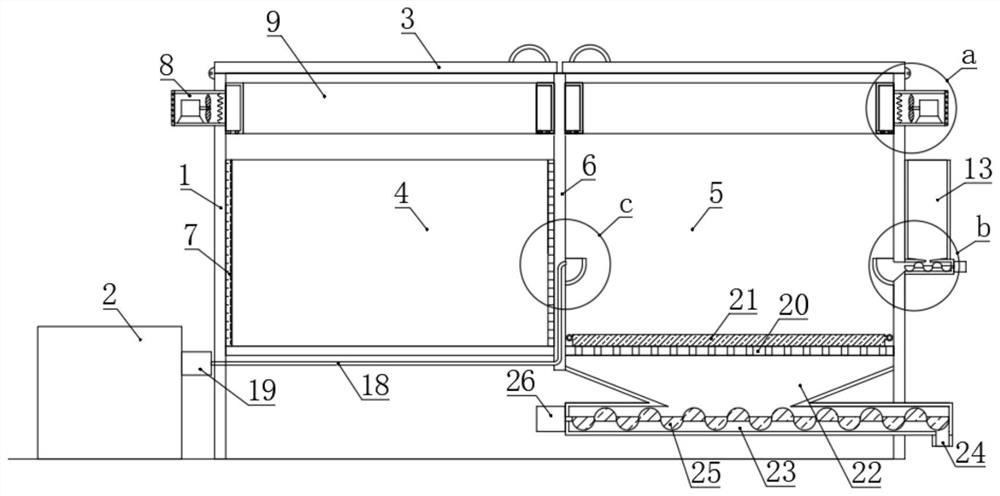

Full-automatic reinforcement plate pre-lamination machine

ActiveCN104113987ATo achieve singleRealize automatic loading and unloadingPrinted circuit manufactureEngineeringMachining

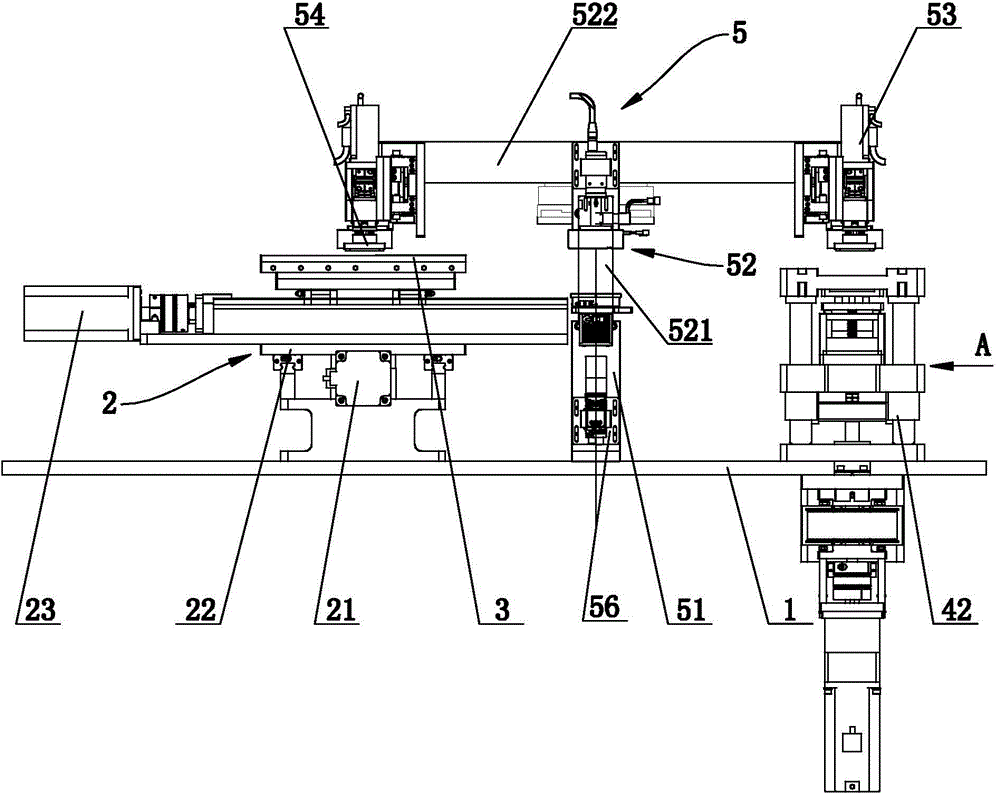

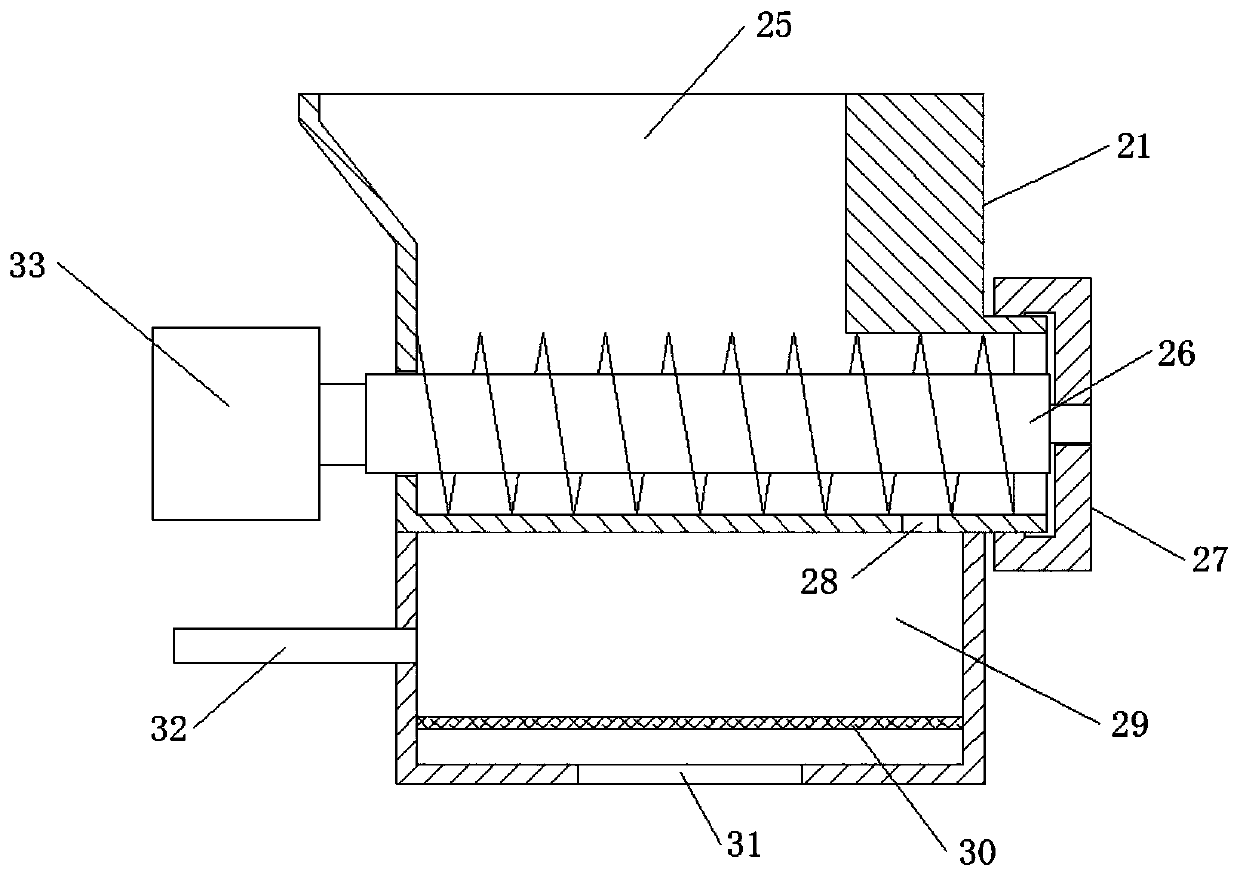

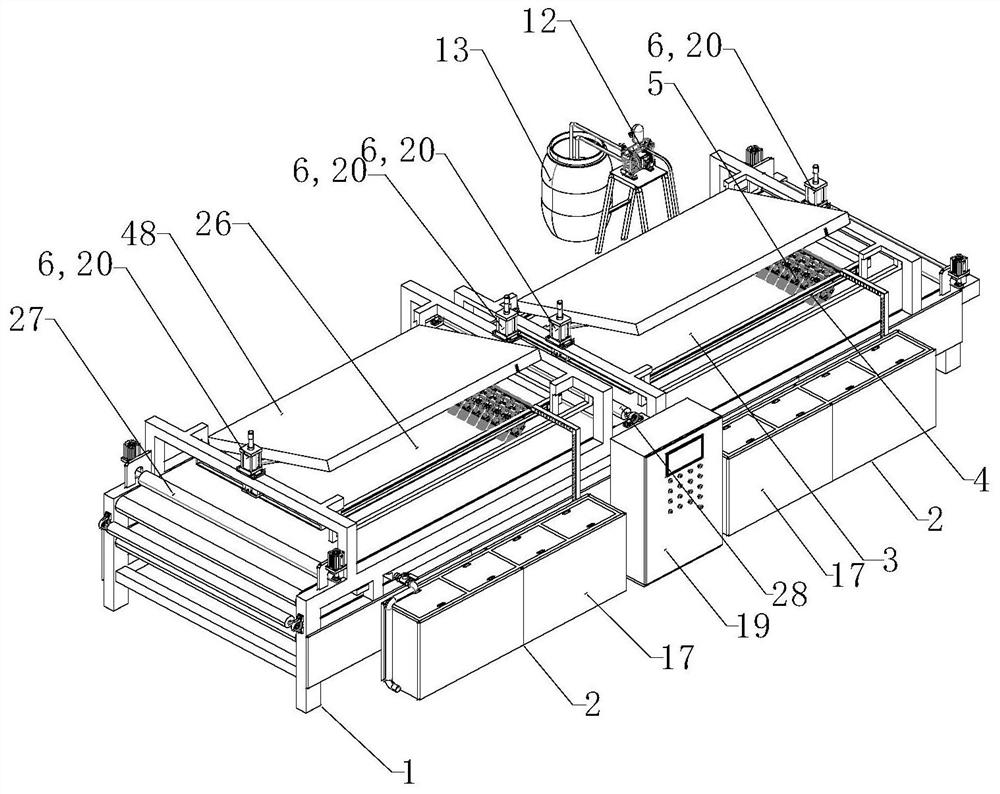

The invention discloses a full-automatic reinforcement plate pre-lamination machine and belongs to the technical field of FPC (Flexible Printed Circuit) machining equipment. The full-automatic reinforcement plate pre-lamination machine comprises a frame which is provided with a feeding and discharging mechanism; the feeding and discharging mechanism comprises a supporting beam; the first side of the supporting beam is provided with a first Z direction motion mechanism which is driven by a first X direction motion mechanism; the first Z direction motion mechanism is provided with a FPC suction nozzle; a feeding cabin, an FPC positioning mechanism and a storage cabin are arranged along the frame portion in turn, wherein the frame portion is arranged below a motion path of the FPC suction nozzle; the frame portion which is located between the FPC positioning mechanism and the storage cabin is provided with an FPC heating platform which is driven by a Y direction motion mechanism; the frame is provided with a feeding mechanism and a lamination mechanism. According to the full-automatic reinforcement plate pre-lamination machine, the automatic feeding and discharging of an FPC is achieved, the consistency of the mechanisms is good, and accordingly the production efficiency is improved, the production cost is reduced, and the degree of automation is high.

Owner:GOERTEK INC

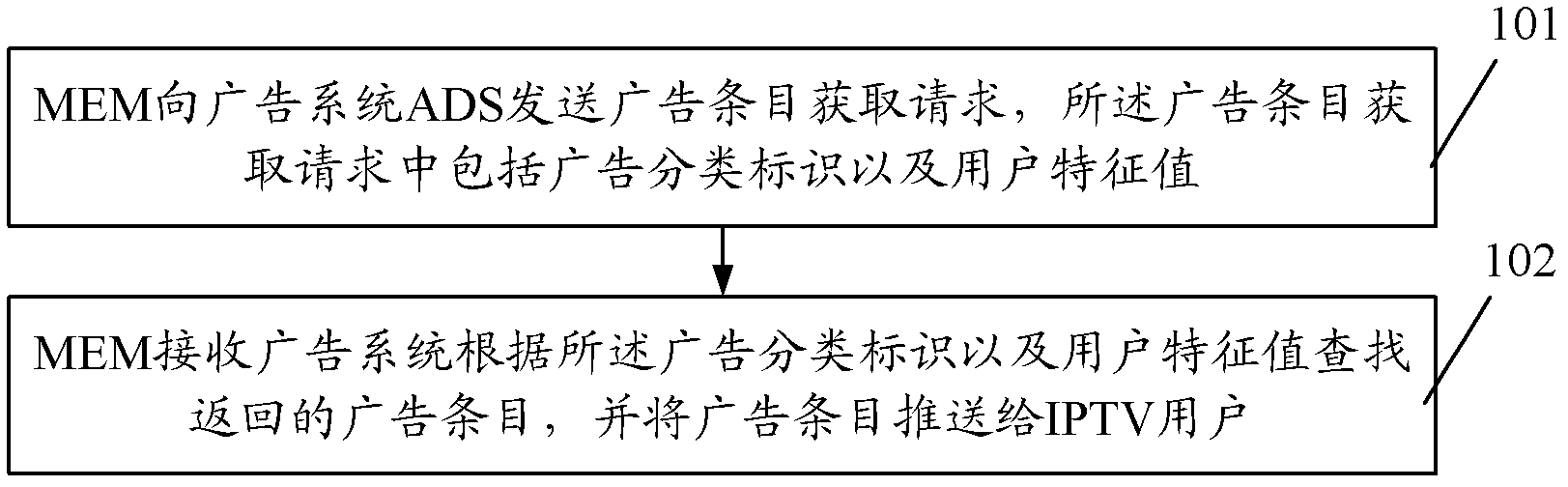

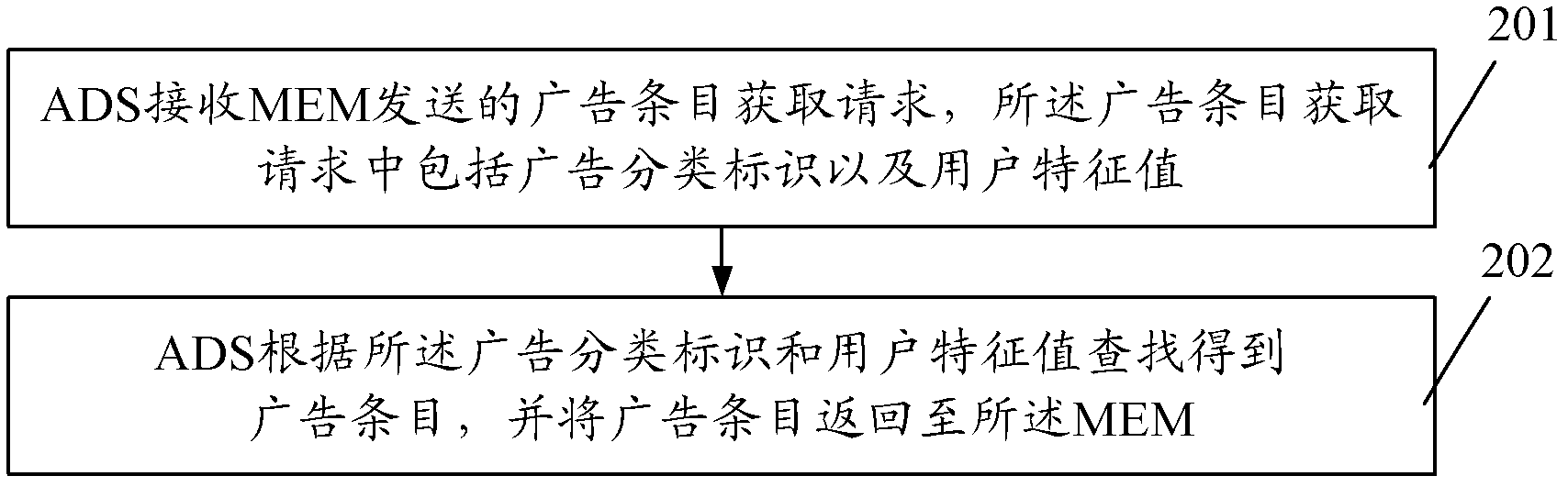

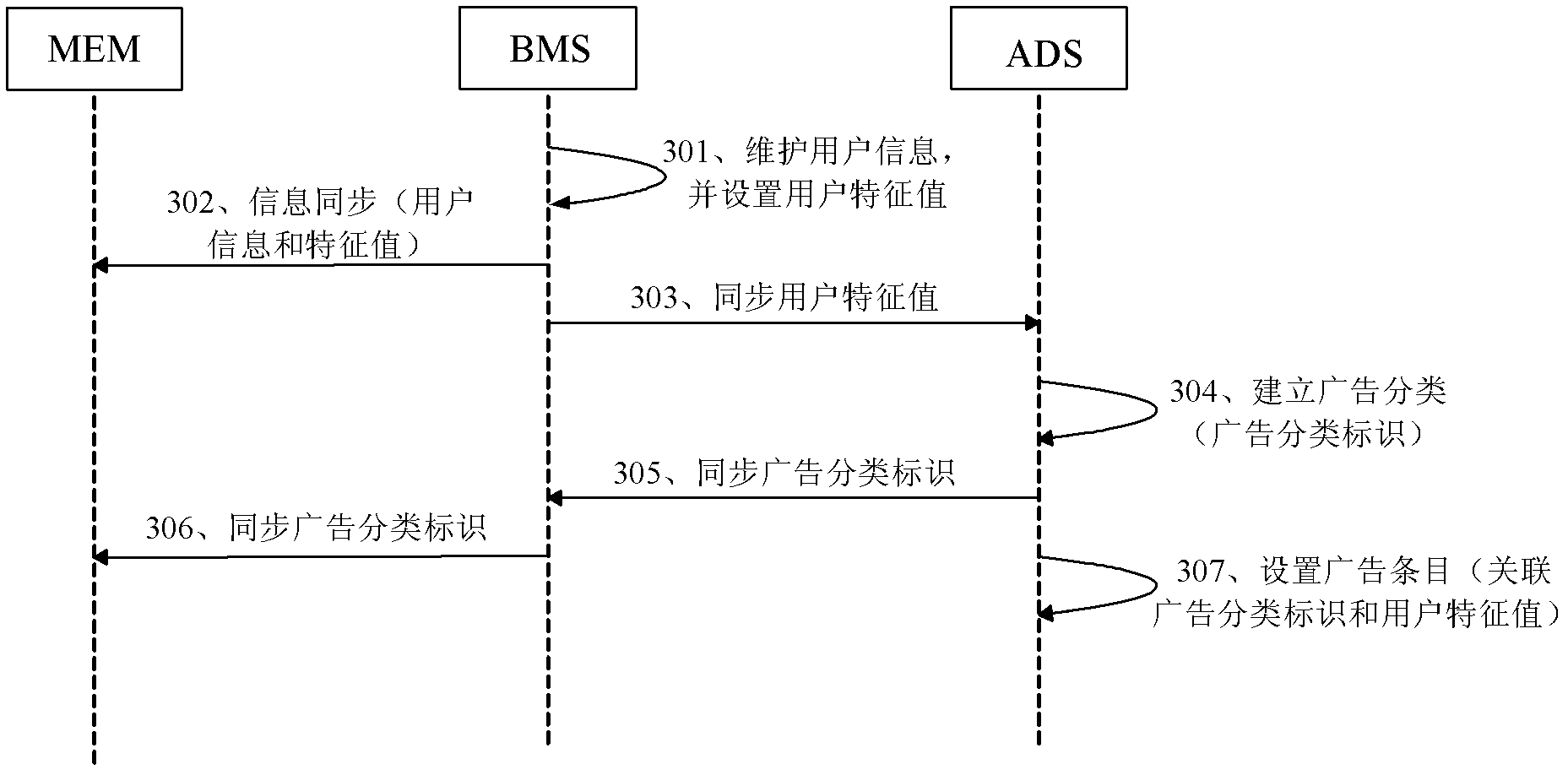

Method, apparatus and system for IPTV (internet protocol television) advertising delivery

InactiveCN102984554AActive deliveryAchieve precise deliverySelective content distributionMarketingWorld Wide WebInternet Protocol

The present invention provides a method, an apparatus and a system for IPTV (internet protocol television) advertising delivery. The method includes: sending an advertising entry acquisition request to an advertising system ADS, wherein the advertising entry acquisition request comprises an advertising catalog label corresponding to the advertising catalog an IPTV subscriber subscribes to, and a subscriber eigenvalue the IPTV subscriber corresponding to, and the advertising entry is located in the advertising category; receiving the advertising entry returned via the advertising system, attributes of advertising entry including the advertising catalog label and the subscriber eigenvalue; and pushing the advertising entry to IPTV subscribers. The method, apparatus and system of the present invention realizes pushing advertising to the subscriber actively, and precise advertising delivery.

Owner:HUAWEI SOFTWARE TECH

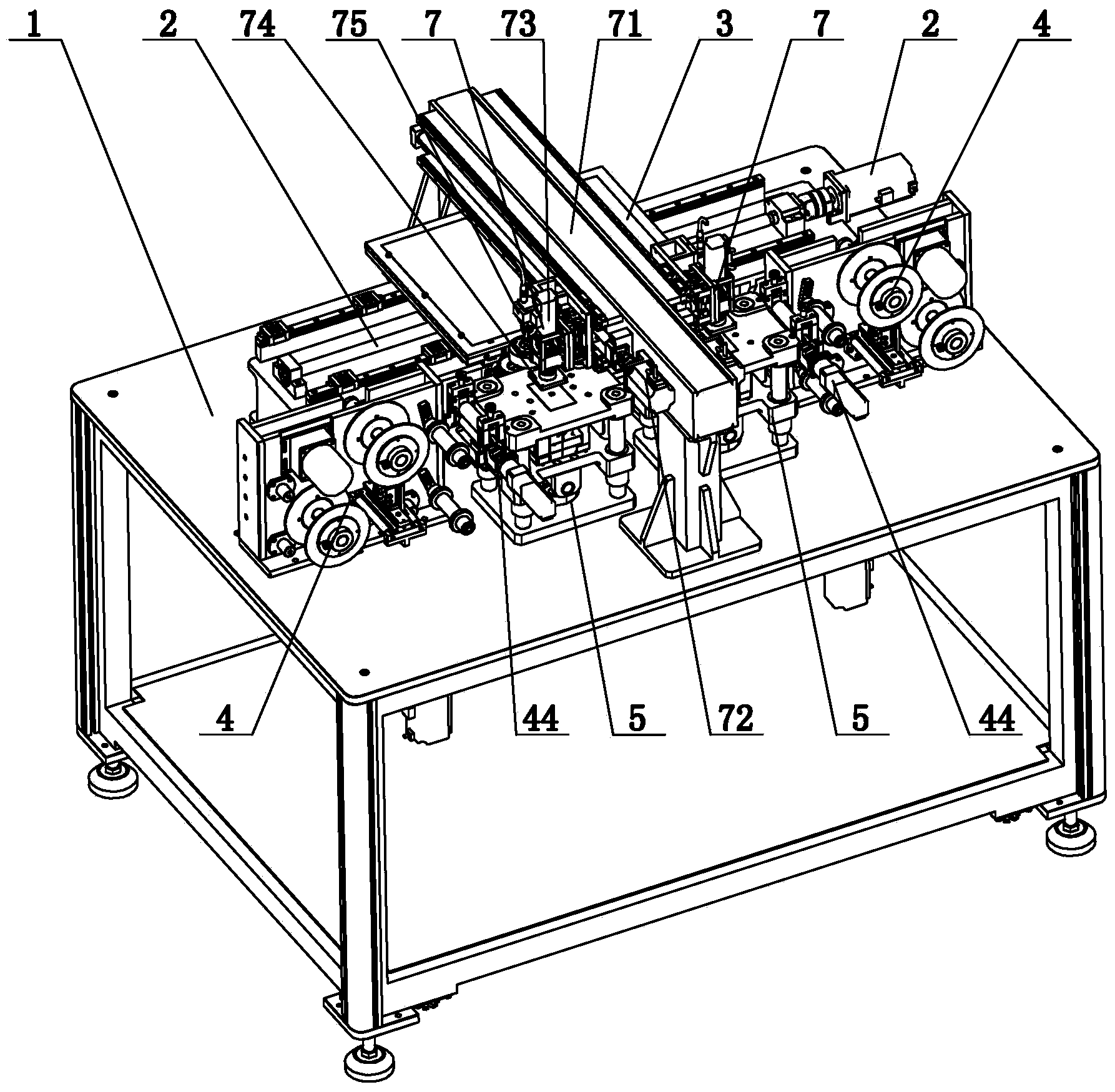

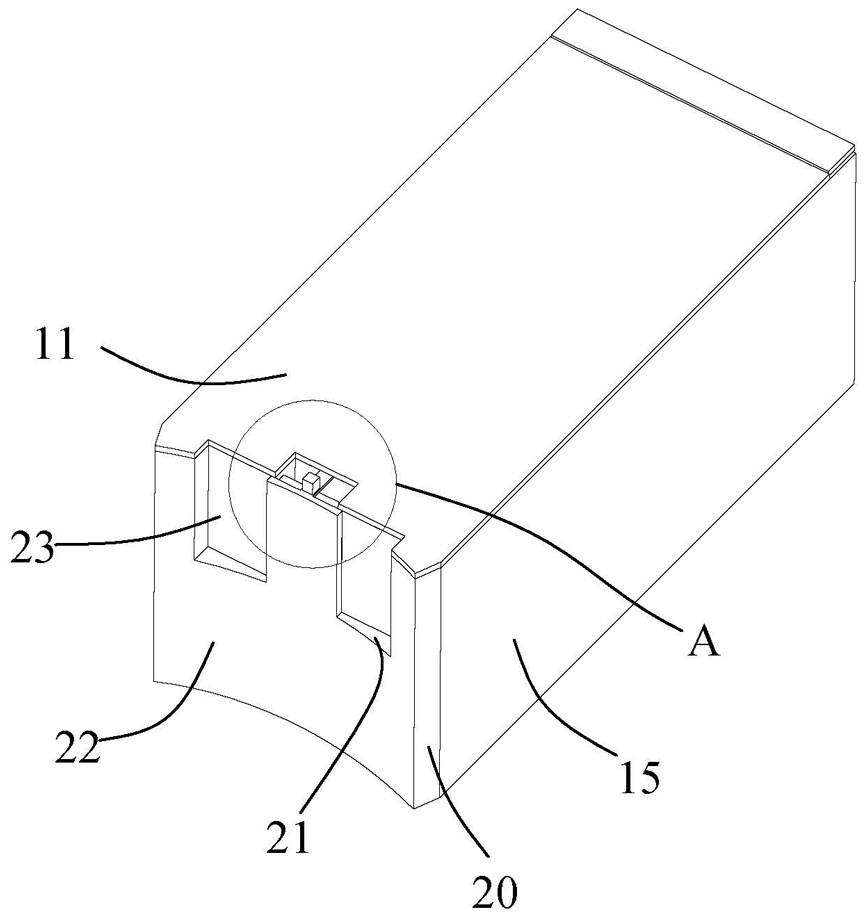

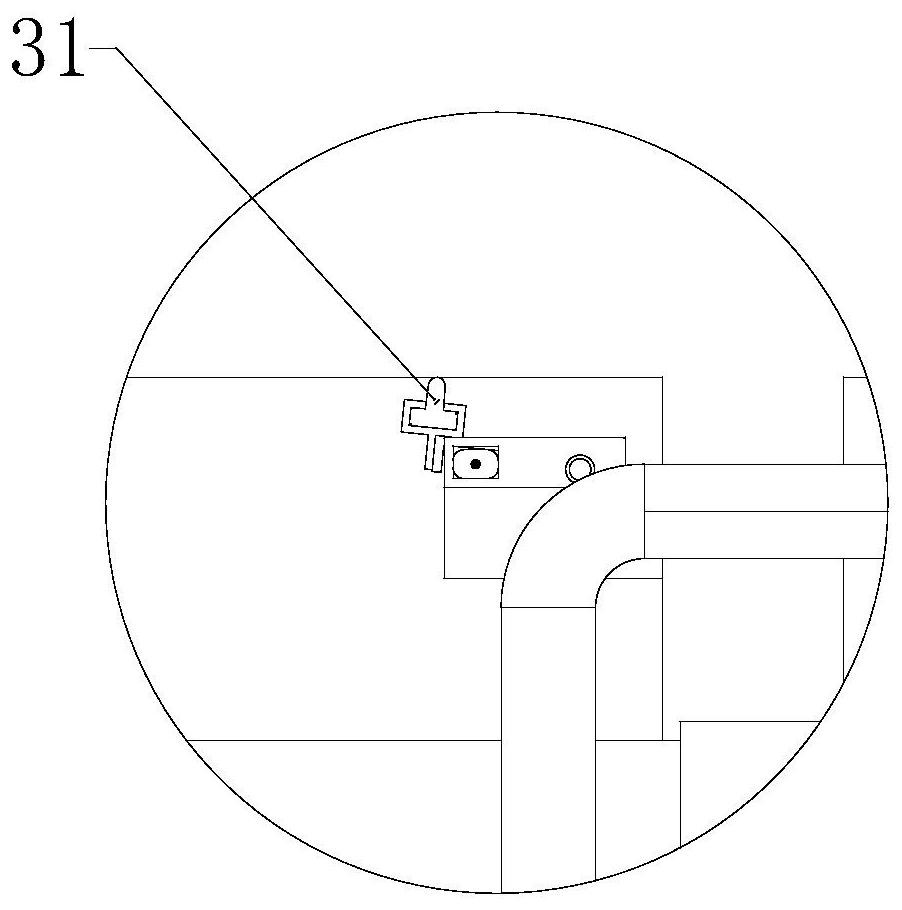

Stripping type stiffening plate false sticking machine

ActiveCN103987200AEasy to pasteAccurate placement to achievePrinted circuit manufactureEngineeringLow vision

The invention discloses a stripping type stiffening plate false sticking machine, and belongs to the technical field of flexible printed circuit processing devices. The stripping type stiffening plate false sticking machine comprises a machine frame, an FPC positioning heating platform driven by an X-direction movement mechanism is installed on the machine frame in a sliding mode, and a feeding mechanism, a stripping mechanism and a sticking mounting mechanism are arranged on the machine frame. The sticking mounting mechanism comprises a supporting beam, a Z-direction and angle theta rotating movement mechanism, an upper vision camera and a lower vision camera, wherein a Y-direction movement mechanism is arranged on the supporting beam, the Z-direction and angle theta rotating movement mechanism is installed on the Y-direction movement mechanism, a stiffening plate suction nozzle is installed on the Z-direction and angle theta rotating movement mechanism, the upper vision camera is installed on the Y-direction movement mechanism, and the lower vision camera is installed on the machine frame. According to the stripping type stiffening plate false sticking machine, the stiffening plate can be accurately stuck and mounted on an FPC, production efficiency and sticking mounting precision are greatly improved, the production cost is reduced, and device stability is high and product quality is reliable during actual production.

Owner:GOERTEK INC

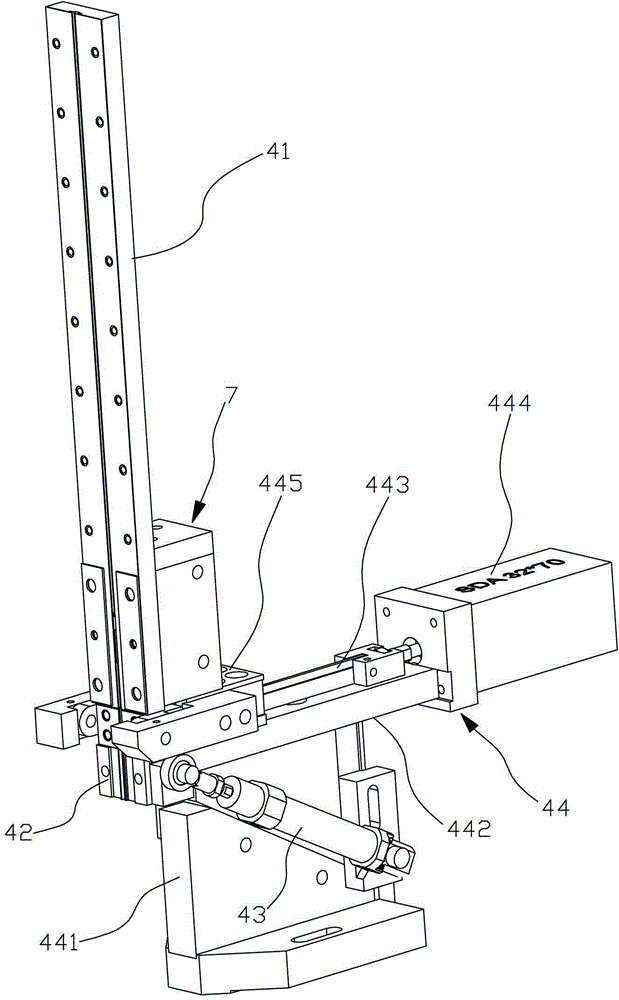

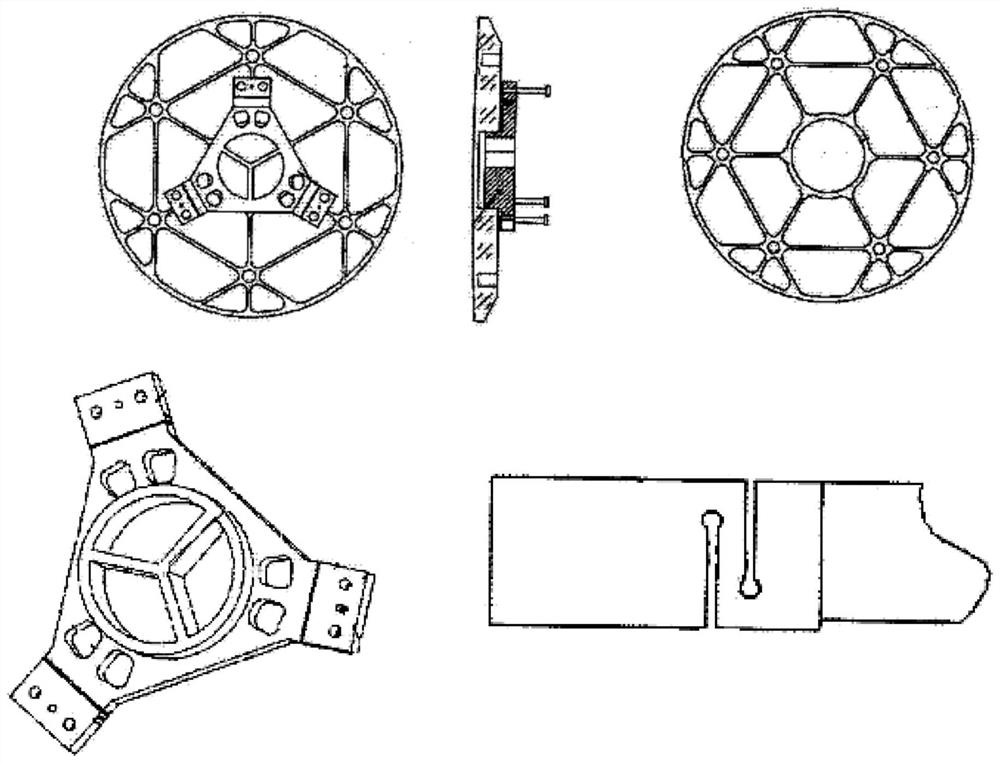

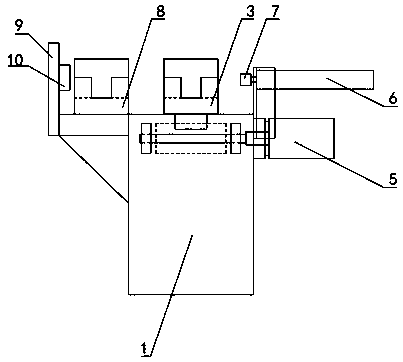

Automatic elastic sheet feeding assembling machine of alloy YG head with pull sheet

ActiveCN104858318AImprove pass rateSuitable for mass productionSlide fastenersMetal-working feeding devicesAlloyEngineering

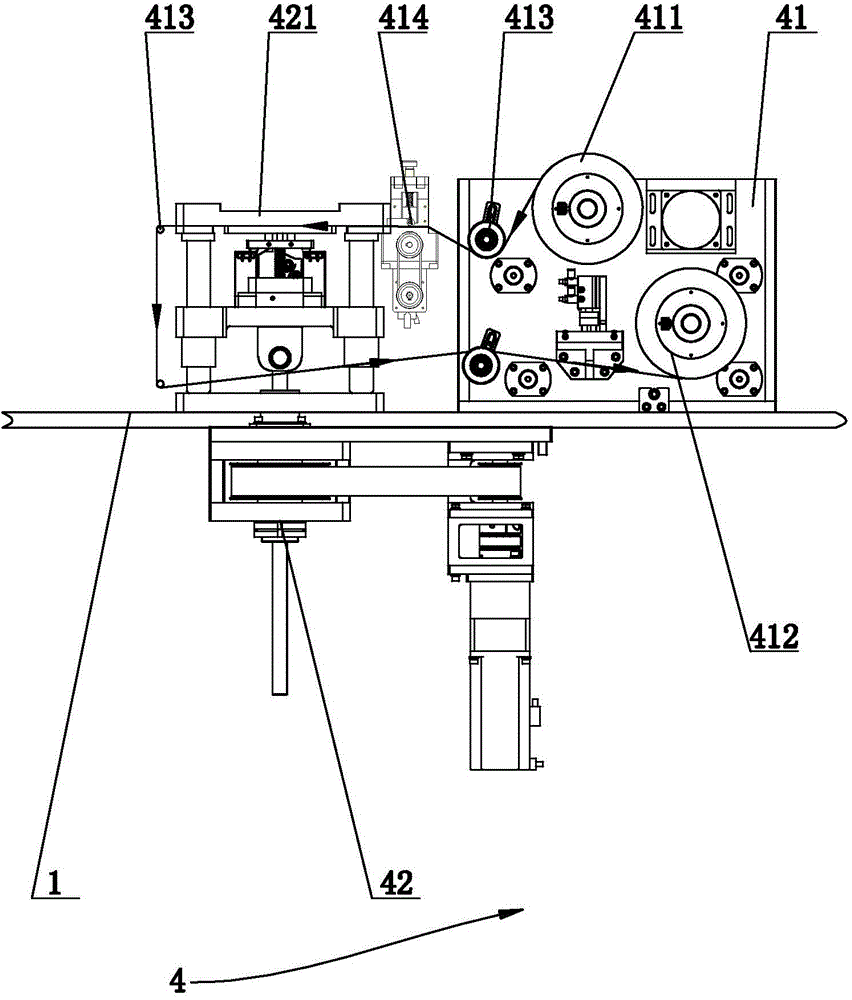

An automatic elastic sheet feeding assembling machine of an alloy YG head with a pull sheet comprises a rack and a round rotary disc, a plurality of pull head mold cores are arranged on the circumferential face of the round rotary disc at intervals, a pull head conveying device, an elastic sheet conveying device and a riveting device are arranged on the circumferential side face of the round rotary disc, the pull head conveying device comprises a pull head rail, a burr cutter and a power mechanism enabling the burr cutter to turn over are arranged at the tail end of the pull head rail, and a pull head pushing mechanism is arranged behind the burr cutter. The elastic sheet conveying device comprises an elastic sheet rail, a clamping mechanism for clamping an elastic sheet is arranged at the tail end of the elastic sheet rail, and an elastic sheet pushing mechanism is arranged above the clamping mechanism. The burr cutter capable of guiding movement of pull heads is adopted, the burr cutter is firstly vertically placed and used for bearing the pull heads discharged out of the pull head rail, and then turns over through the power mechanism to be horizontal, the pull heads are pushed into the pull head mold cores to be located through the pull head pushing mechanism, the pull heads can be precisely conveyed through the pull head pushing mechanism, and the riveting quality of the pull heads can be guaranteed.

Owner:QUANZHOU LICHENG DISTRICT ZHAN AUTOMATION EQUIP

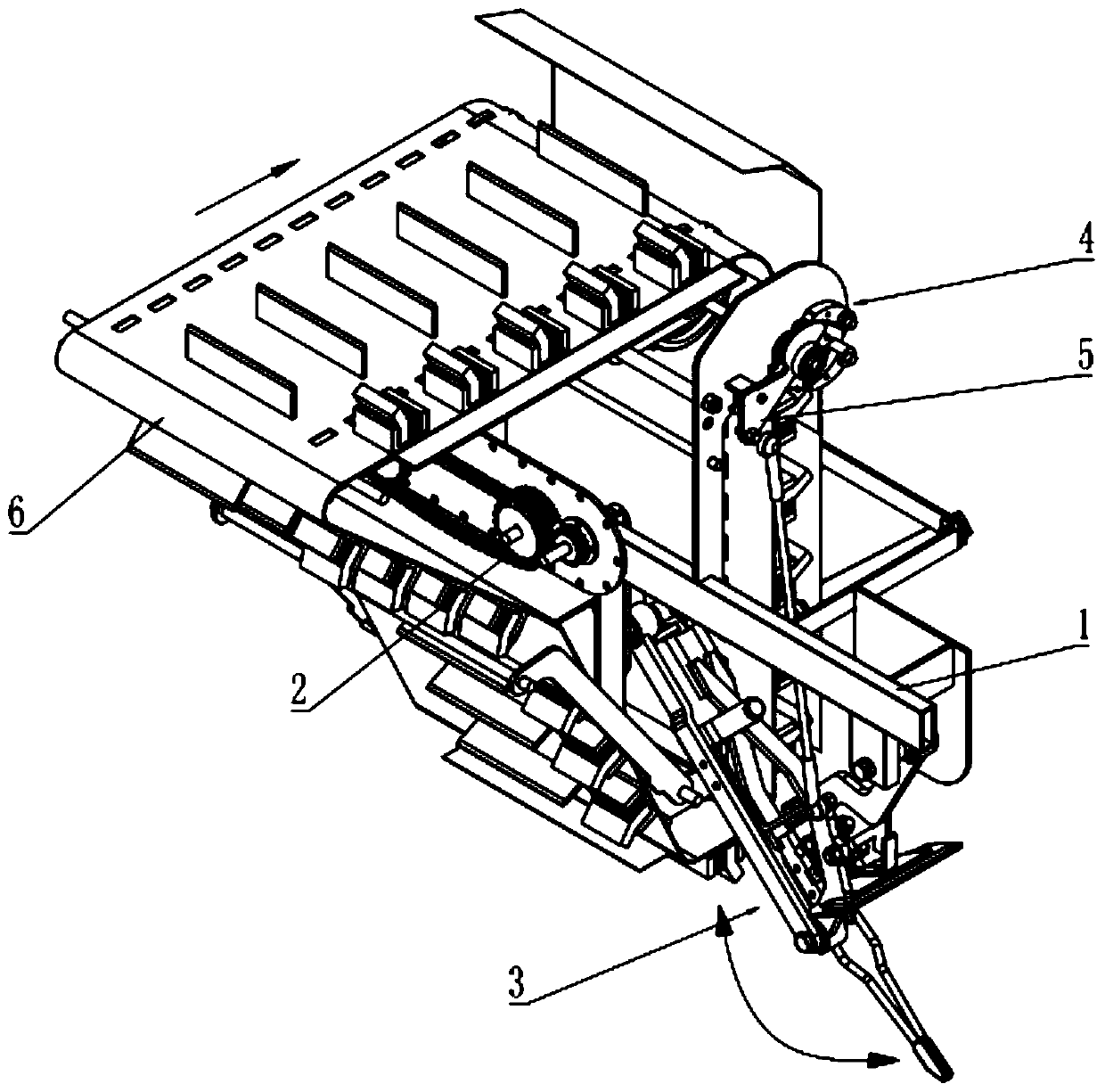

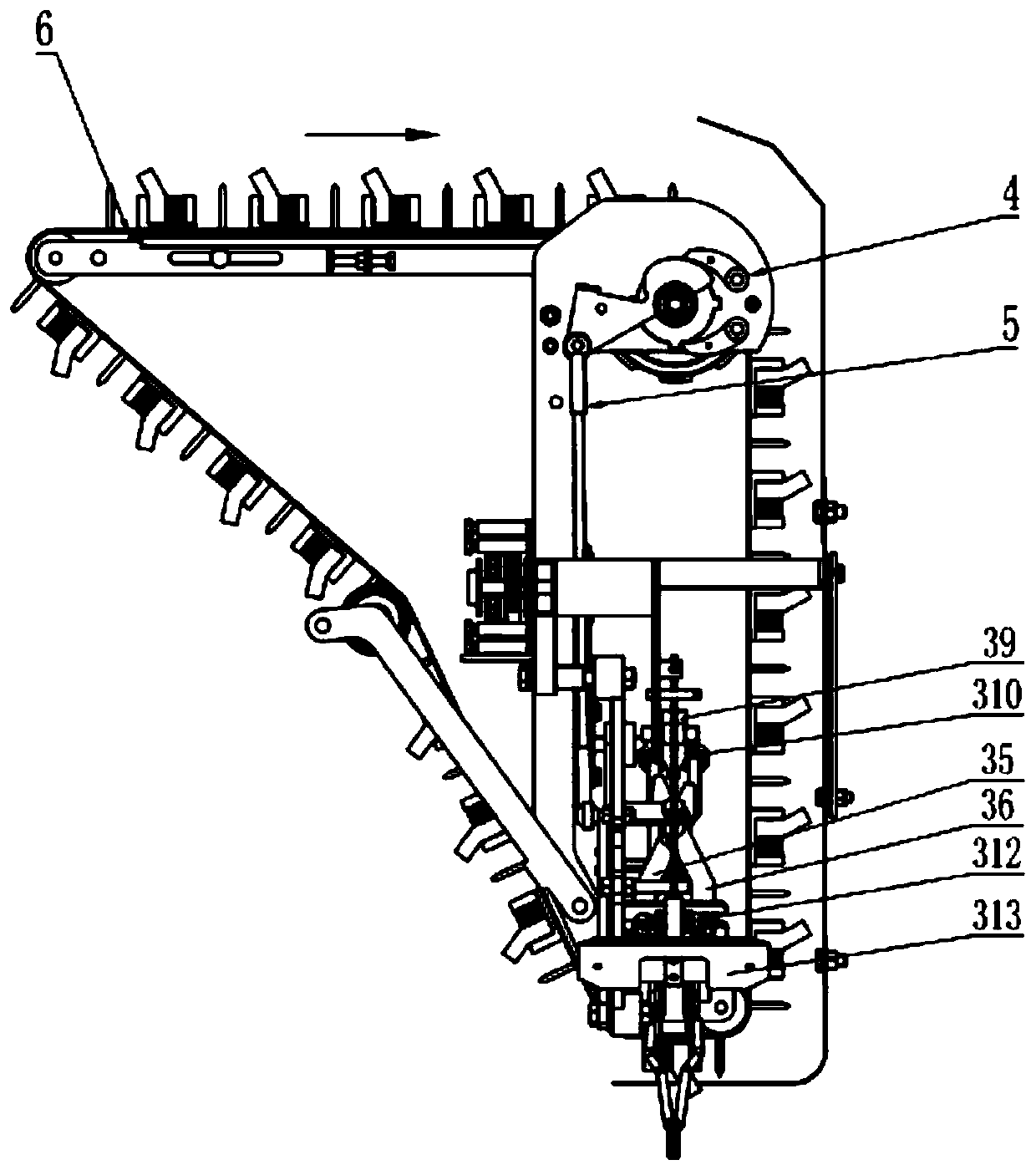

Conveyor belt-clamping type on-membrane inclined planting device for rhizome big seedling crops

PendingCN110775618ASolve the problem of leaking seedlingsAvoid errorsConveyorsTransplantingAgricultural engineeringControl theory

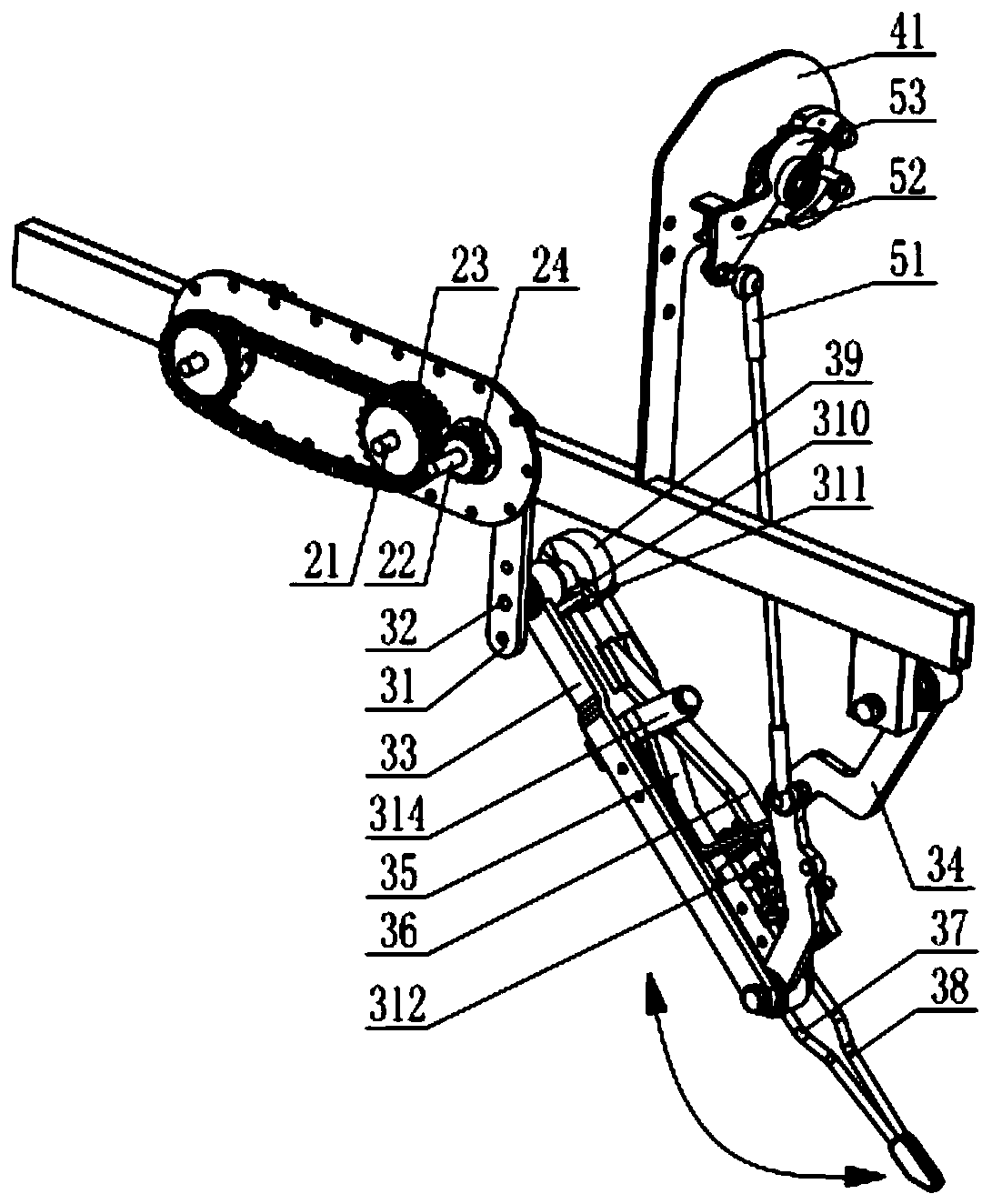

The invention discloses a conveyor belt-clamping type on-membrane inclined planting device for rhizome big seedling crops. The conveyor belt-clamping type on-membrane inclined planting device for rhizome big seedling crops comprises a main rack, wherein a planting drive mechanism is mounted on the main rack; the output end of the planting drive mechanism is connected with a clamping planting mechanism; a conveyor belt intermittent control mechanism is further mounted on a position, above the clamping planting mechanism, on the main rack; a spatial four-bar connecting mechanism is connected between the clamping planting mechanism and the conveyor belt intermittent control mechanism; and the output end of the conveyor belt intermittent control mechanism is in transmission connection with a seedling conveying device. The conveyor belt-clamping type on-membrane inclined planting device adopts an intermittent conveyor belt-clamping way to perform on-membrane inclined transplanting to solvethe seedling leaking problem as fibrous roots are easily clamped to take back the seedlings; and moreover, motion generated by the clamping planting mechanism is combined with the spatial four-bar connecting mechanism and the conveyor belt intermittent control mechanism for controlling intermittent transmission of a seedling conveyor belt, so that the purpose of precisely conveying the seedlings through the conveyor belt is realized, and therefore, errors, caused by accumulated errors of two sets of transmission devices, of seedling planting positions are avoided.

Owner:SHANDONG JIAOTONG UNIV

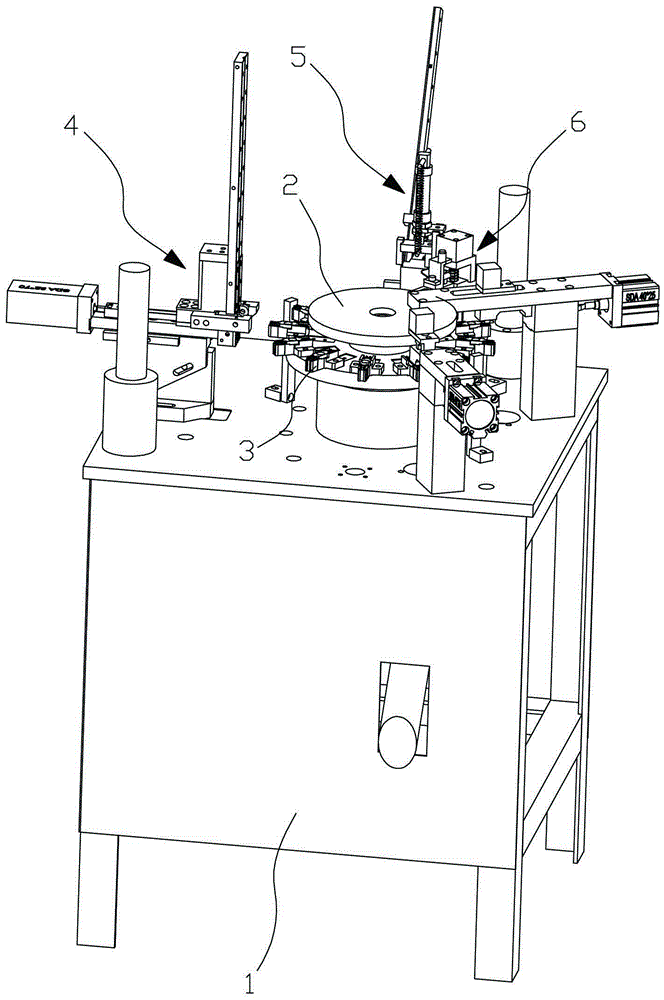

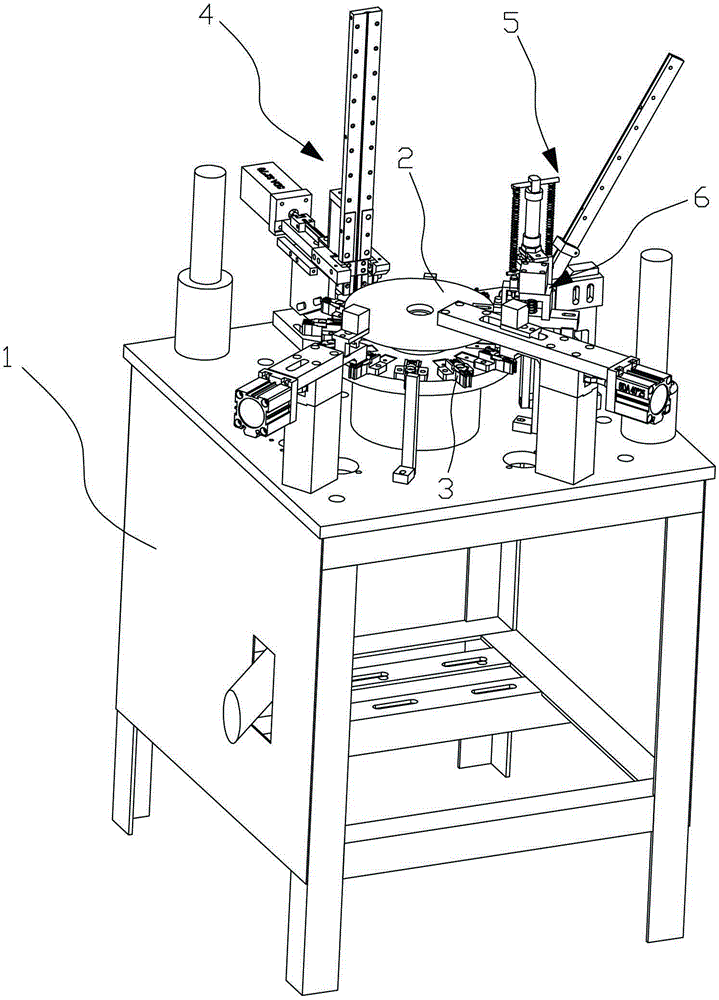

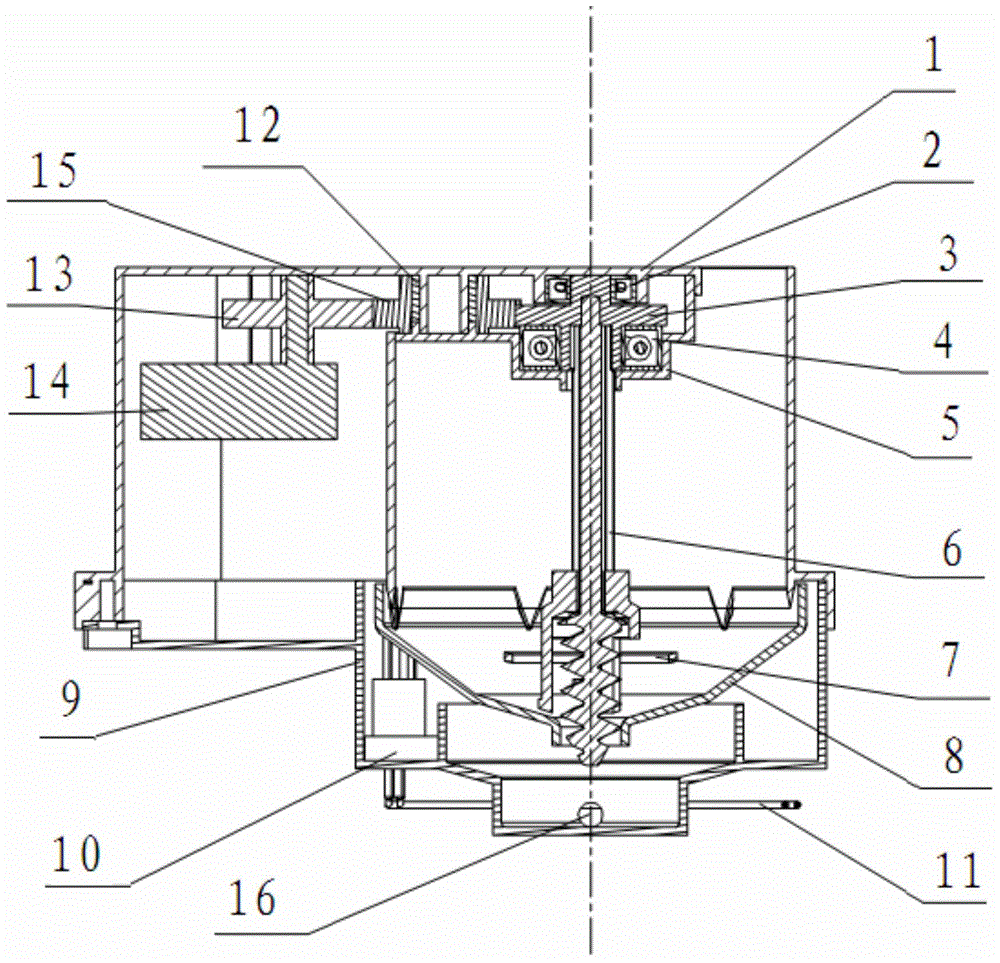

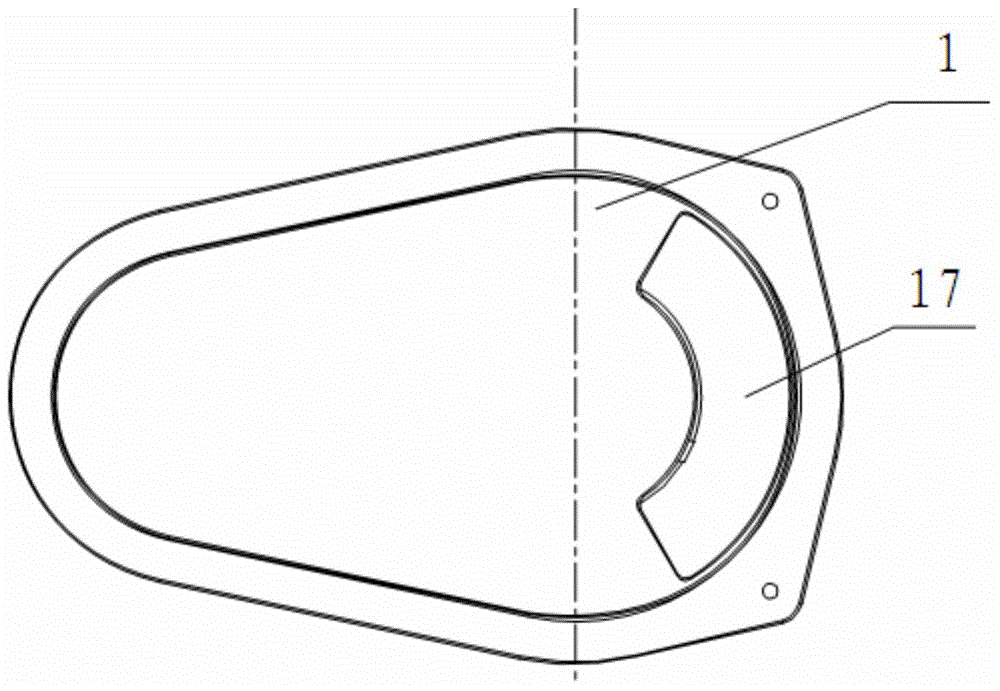

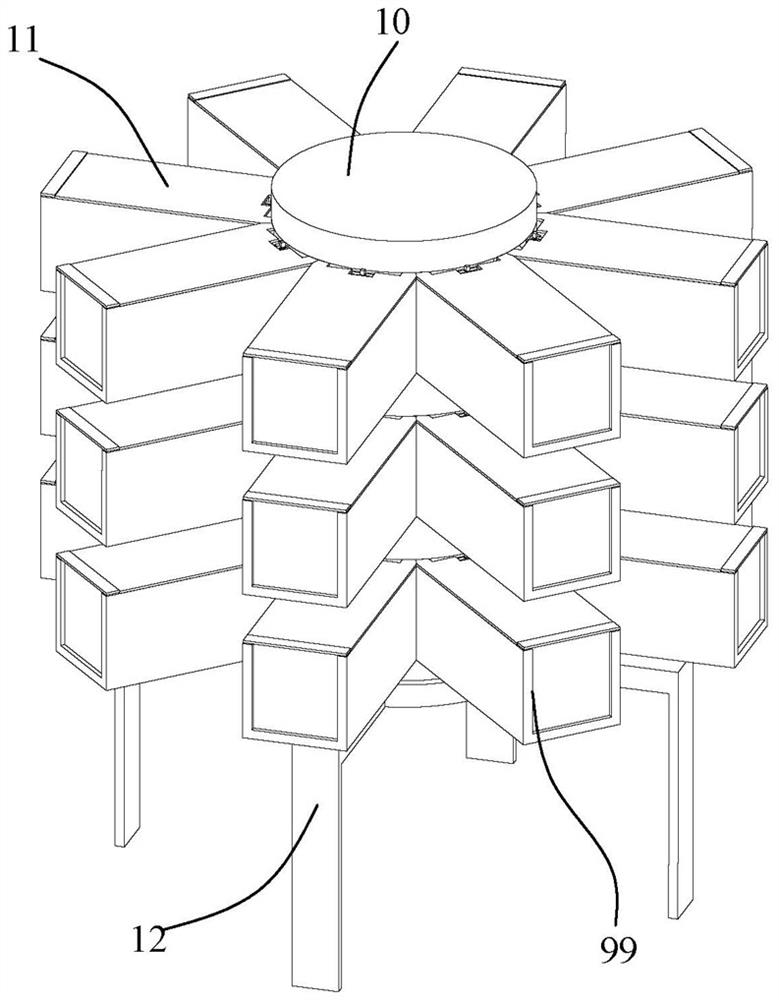

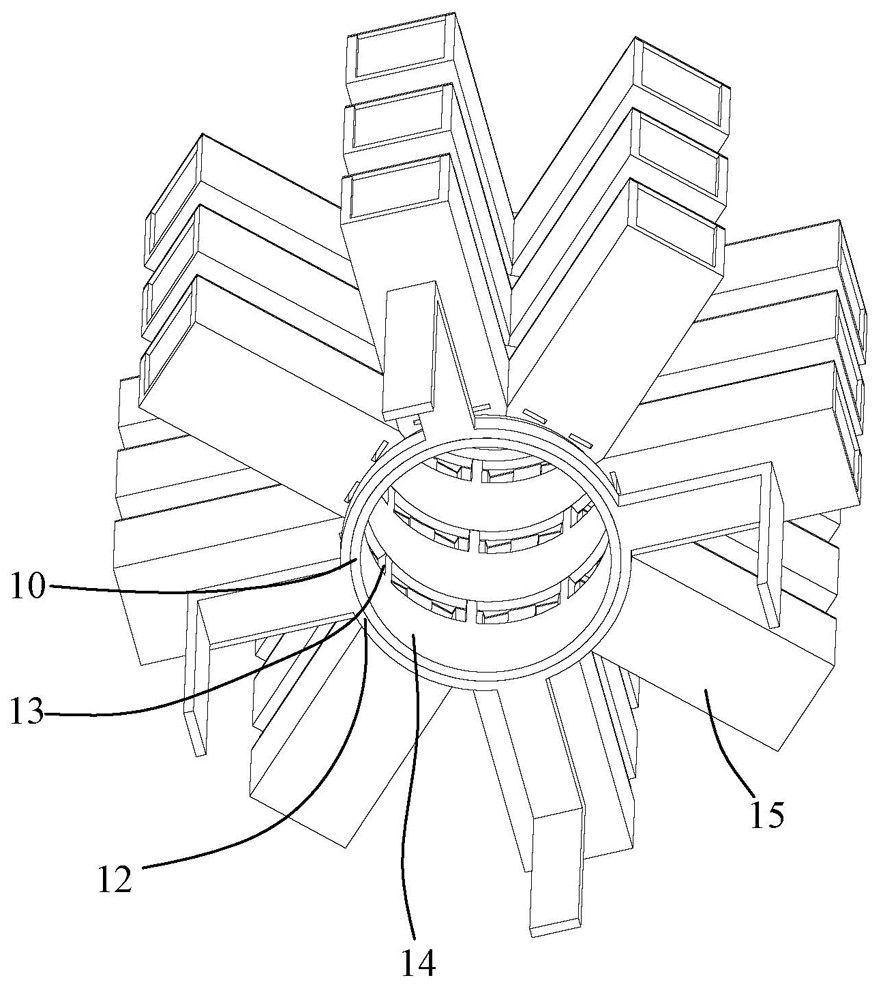

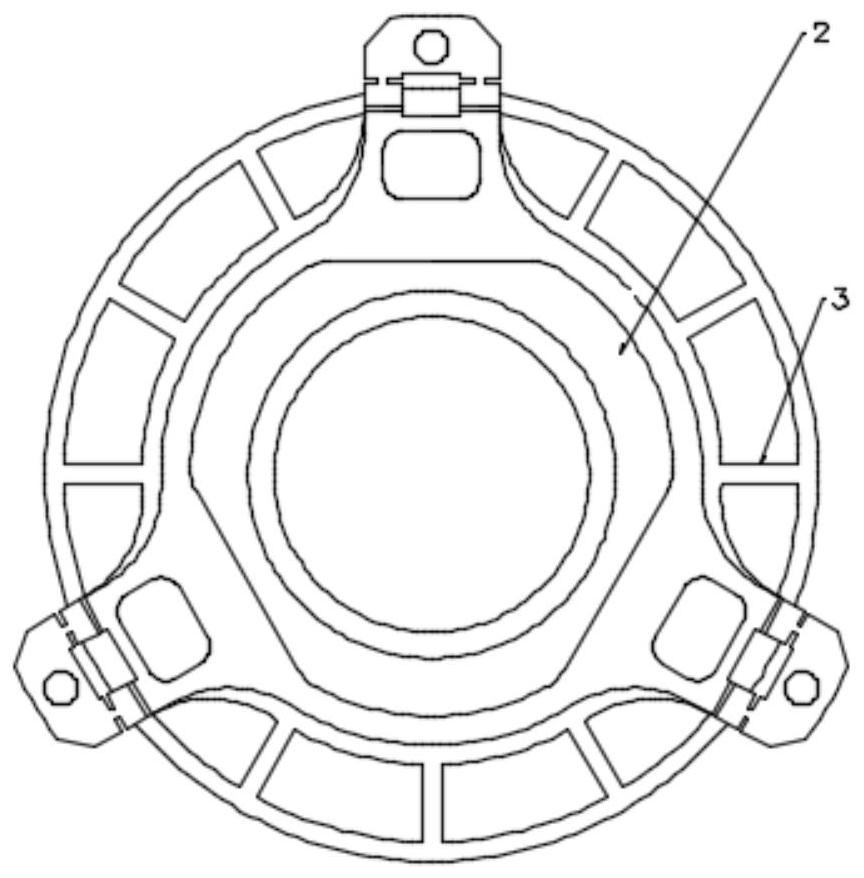

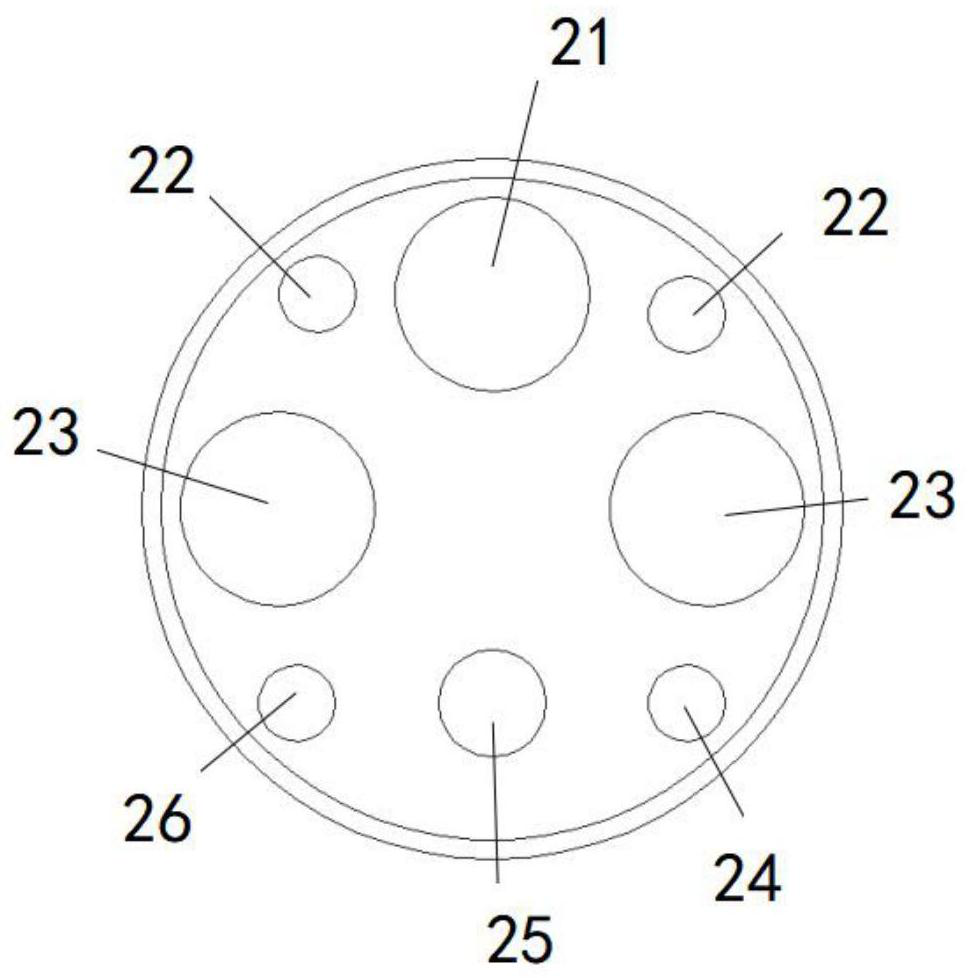

Reinforcement plate disc type full-automatic false mounting machine

ActiveCN104066276AEasy to pasteIncrease productivityPrinted circuit manufactureFlexible circuitsEngineering

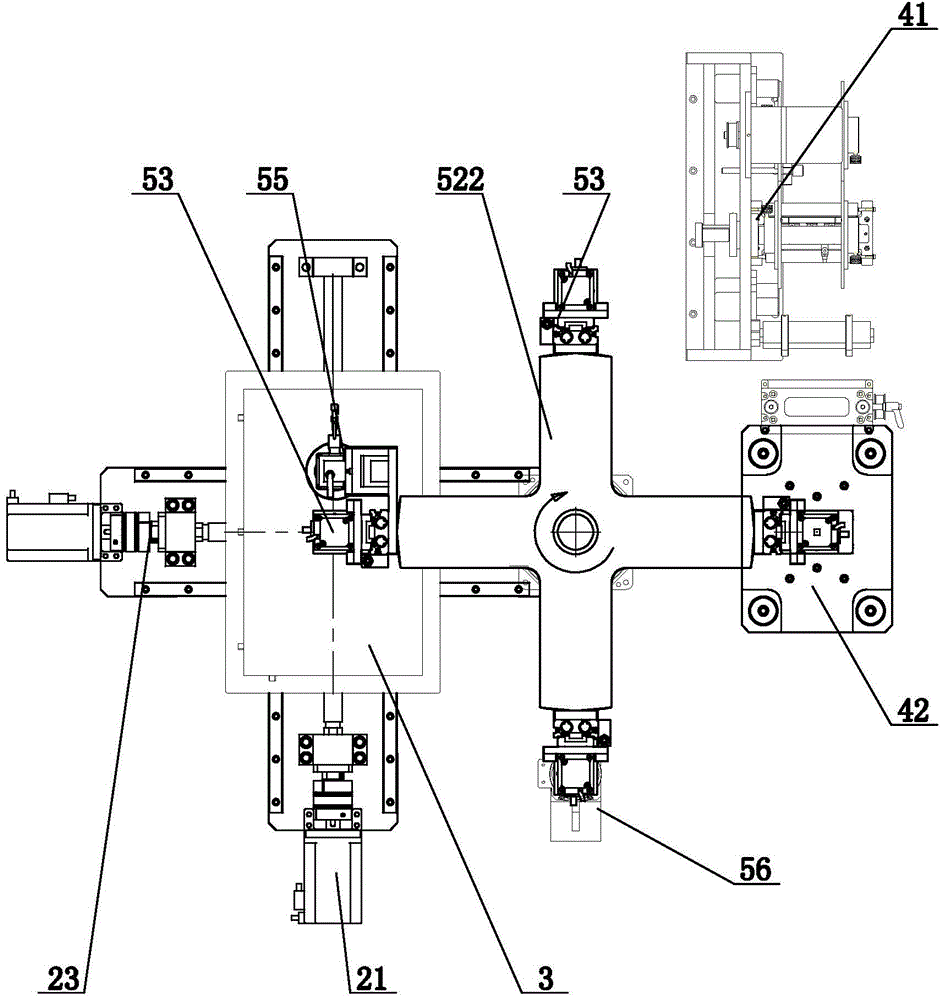

The invention discloses a reinforcement plate disc type full-automatic false mounting machine, and pertains to the technical field of flexible circuit board machining equipment. The reinforcement plate disc type full-automatic false mounting machine comprises a rack. The rack is provided with an X and Y direction movement mechanism. The X and Y direction movement mechanism is provided with a FPC locating heating platform. The rack is provided with a material supply mechanism and a mounting mechanism. The mounting mechanism comprises: a Z direction rotary mechanism which is driven by a first power device; at least one Z direction and theta-angle rotary movement mechanism which is installed on the Z direction rotary mechanism, wherein the direction and theta-angle rotary movement mechanism is provided with reinforcement plate suction nozzles; an upper vision camera which is installed on the Z direction rotary mechanism; and a lower vision camera which is installed on the rack, wherein the lower vision camera is located in the rotary trajectory range of the reinforcement plate suction nozzles. The reinforcement plate disc type full-automatic false mounting machine of the invention can be used to replace the traditional manual mounting method, so the production efficiency can be significantly improved, and the production cost can be reduced; and through the rotary mechanisms, monomer reinforcement plate can be transported continuously, so the production efficiency is higher.

Owner:GOERTEK INC

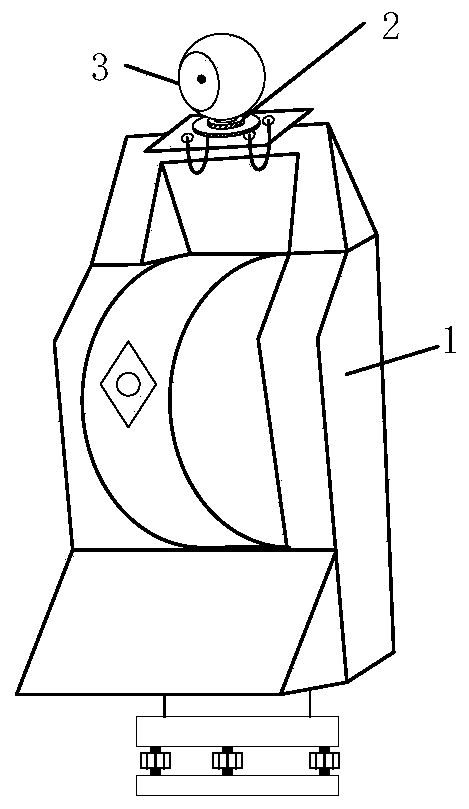

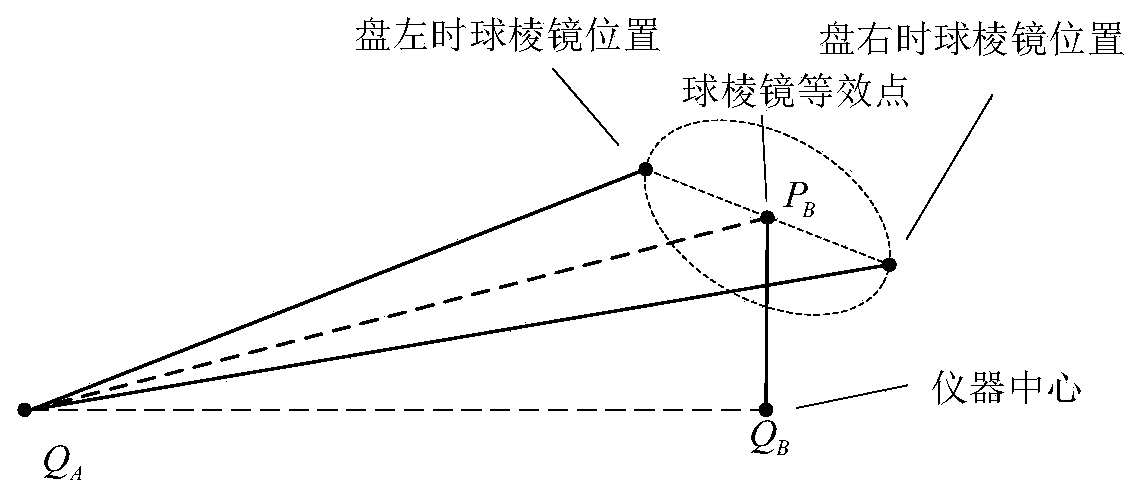

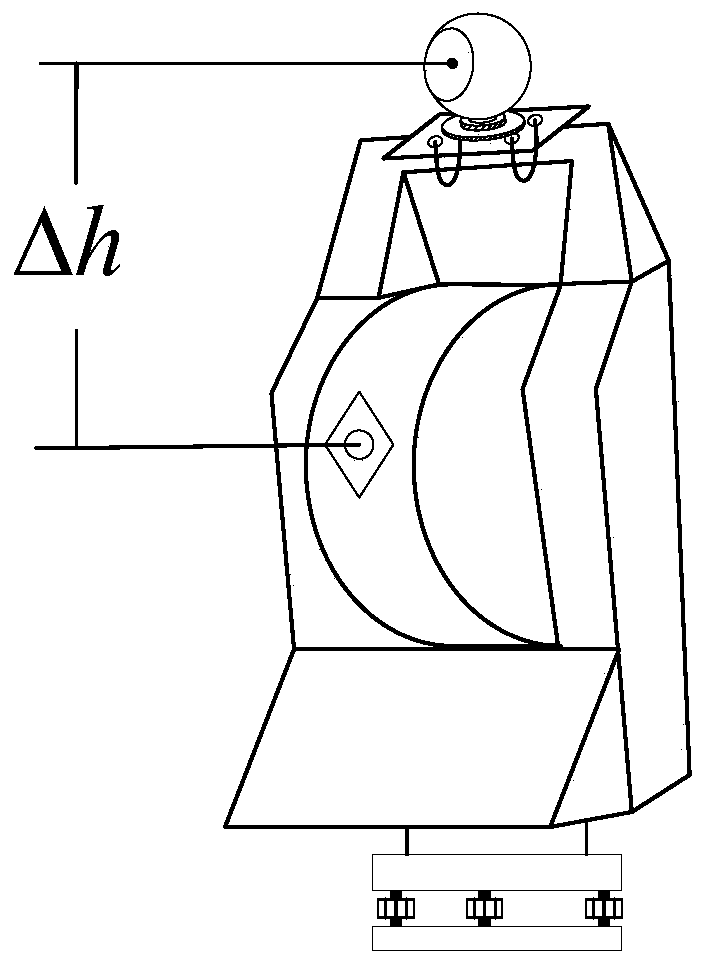

Space three-dimensional coordinate measuring instrument system and three-dimensional control network measuring method thereof

ActiveCN111238454AAchieve precise deliveryActive open surveying meansUsing optical meansComputer visionTotal station

The invention relates to a space three-dimensional coordinate measuring instrument system and a three-dimensional control network measuring method thereof, and belongs to the field of precision industry and engineering measurement. The system comprises two three-dimensional coordinate measuring instruments, a spherical prism is fixed at the top of each three-dimensional coordinate measuring instrument; when the two three-dimensional coordinate measuring instruments are used for measuring the three-dimensional control network, the two three-dimensional coordinate measuring instruments are controlled to mutually aim at and measure the spherical prism at the top of the three-dimensional coordinate measuring instruments so as to obtain a mutual aiming observation value between the three-dimensional coordinate measuring instruments, establish a parameter balancing model according to the mutual aiming observation value in combination with the observation value of each control network point in the three-dimensional control network, and carry out solving to obtain the coordinate of the control point under the condition of taking a certain observation station as a reference observation station and the translation and rotation parameters of other observation stations in the reference observation station, thereby realizing control network point coordinate transfer between the three-dimensional coordinate measuring instruments. The system is especially suitable for precise coordinate transmission scenes with poor intervisibility conditions, and can be popularized and applied to polar coordinate measurement systems such as a laser tracker and a total station.

Owner:PLA STRATEGIC SUPPORT FORCE INFORMATION ENG UNIV PLA SSF IEU

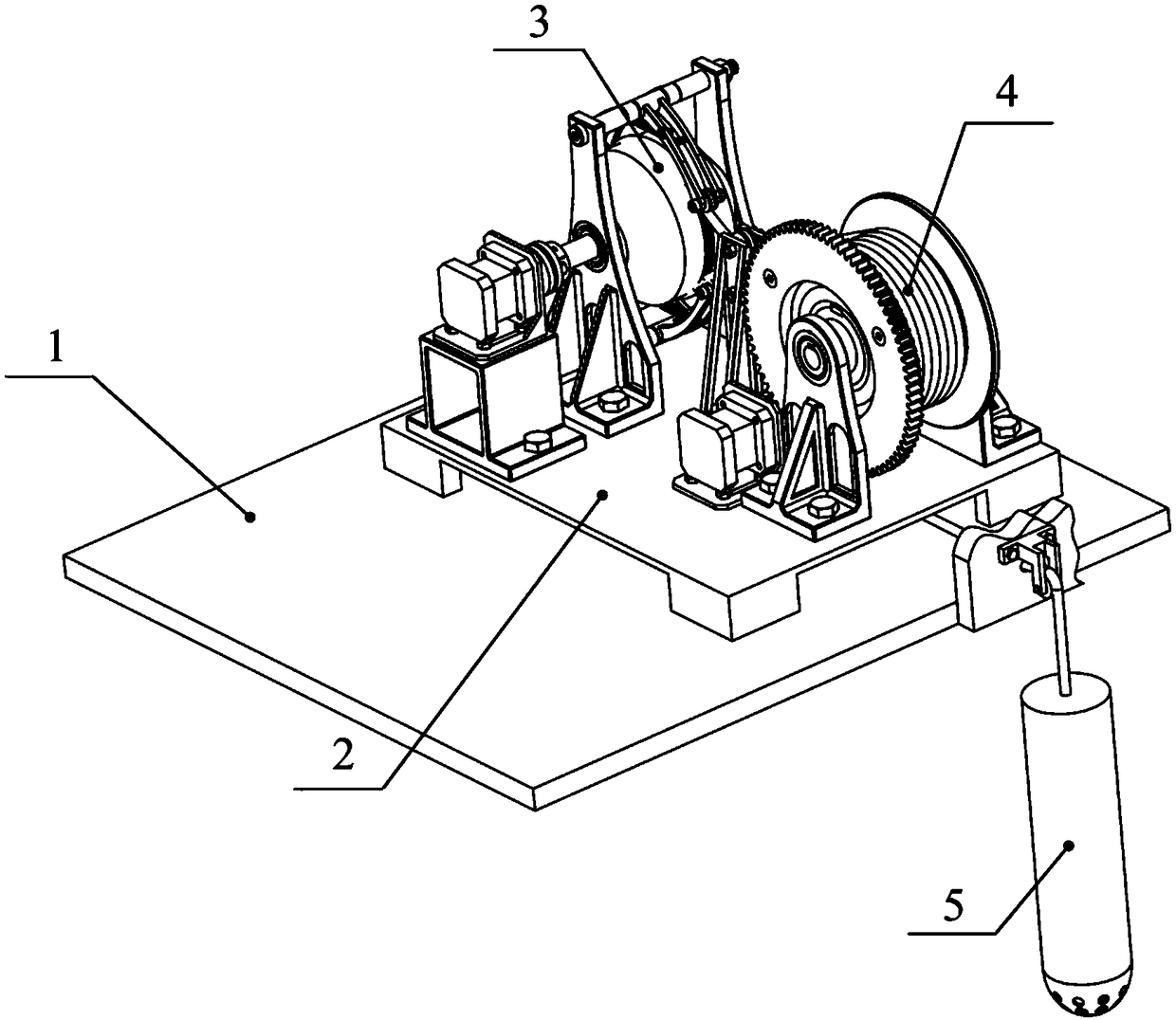

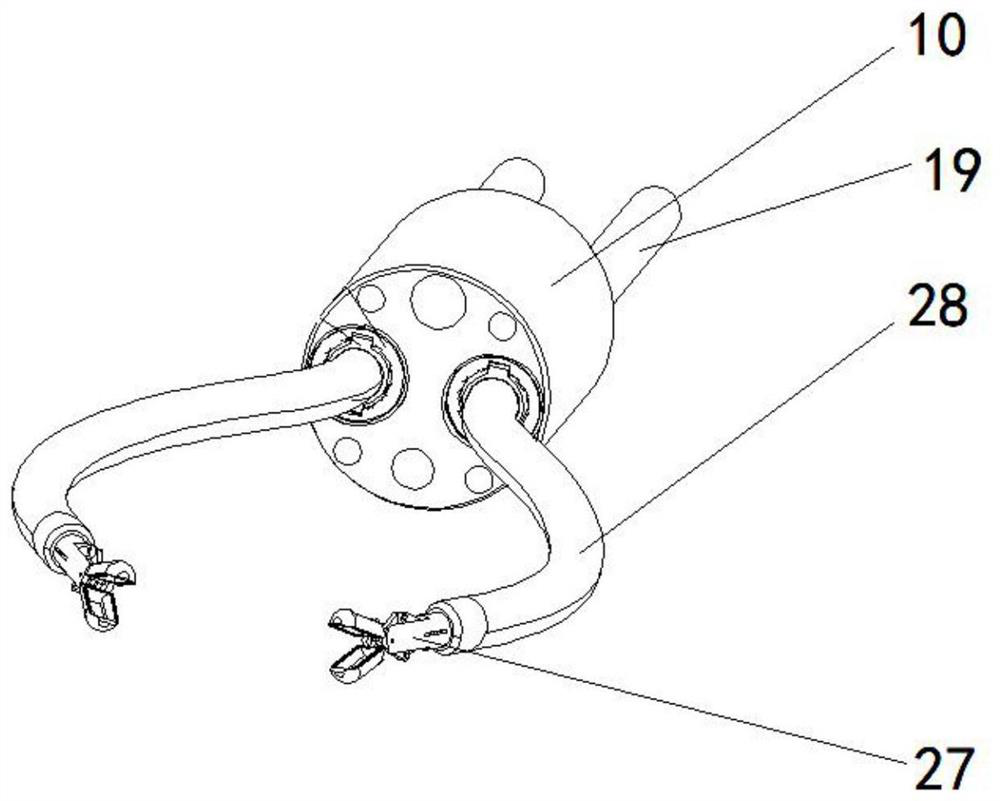

Underwater depthkeeping automatic retracting and launching device for detecting instrument

The invention provides an underwater depthkeeping automatic retracting and launching device for a detecting instrument. A cable winds on a roller; the end part of the cable bypasses a rolling wheel and is connected with the detecting instrument; when a first stepping motor drives the rolling wheel to rotate along the first direction, a first one-way bearing and a second one-way bearing are locked,a third one-way bearing is released, and the roller rotates around the third one-way bearing so as to release the detecting instrument; when a second stepping motor drives the roller to rotate alongthe second direction, the first one-way bearing and the second one-way bearing are released, the third one-way bearing is locked, and the rolling wheel rotates around the first one-way bearing so as to retract the detecting instrument; and only one circle of cable exists on the rolling wheel, and winding and unwinding are carried out by adopting the different stepping motors, so that during unwinding, the launching depth of the detecting instrument can be set through fixing the rotation circle numbers of the first stepping motor, and accurate launching in different depths underwater is realized.

Owner:JIANGSU UNIV OF SCI & TECH IND TECH RES INST OF ZHANGJIAGANG

Novel board transport device

InactiveCN104525766AWide range of applicationsHigh precisionMetal-working feeding devicesPositioning devicesEngineeringMotor drive

The invention discloses a novel board transport device. A transport rack is fixed on the ground, a gear is driven by the rotation of a translation motor on a swaging rack to transplant along a rack, to achieve the translation of a material stop idler wheel and prevent a board from shifting in a transport process; when the translation motor is adjusted to the same width with the board, the rotation motion of a compressing servo motor is converted into the up-and-down motion of the swaging rack in a lead screw seat guide block by a bevel gear pair to compress the board and supply enough contact surface; when in a chain transmission manner, a transport servo motor drives a driving transport idler wheel and a driven wheel to rotate, so as to achieve the transport of the board; meanwhile, a rolling converting device is arranged between a driving transport idler wheel and a rolling support wheel, for converting a rolling signal of the idler wheel on the rolling converting device into the transport displacement of the board, and feeding the signal back to the transport servo motor to achieve the accurate control of the board transport. The novel board transport device achieves the automatic transport of the board, and is wide in application range, improved in transport accuracy and reduced in errors.

Owner:SHANGHAI XINLI MACHINE PLANT

Device for automatically adding washing powder, and washing machine including the device

ActiveCN105155224ARealize precise quantitative deliveryAchieve precise deliveryOther washing machinesTextiles and paperBiomedical engineering

The invention provides a device for automatically adding washing powder. The device comprises a powder storage device, a powder conveying device, a diluting device and a driving device. The driving device is connected with the powder conveying device. The powder conveying device comprises a spiral rod and is arranged in the powder storage device. An outlet at the bottom of the powder storage device is connected with the second accommodating chamber of the diluting device. The diluting device is fixedly connected with the powder storage device. The device for automatically adding the washing powder according to the invention realize accurate washing powder input through matching among a spiral rod rotation time, a rotating speed and a thread pitch. The invention further provides a washing machine including the device for automatically adding the washing powder. The washing machine can accurately and automatically input the washing powder, and furthermore can remind a user to add the washing powder when a small amount of washing powder exists in the device.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

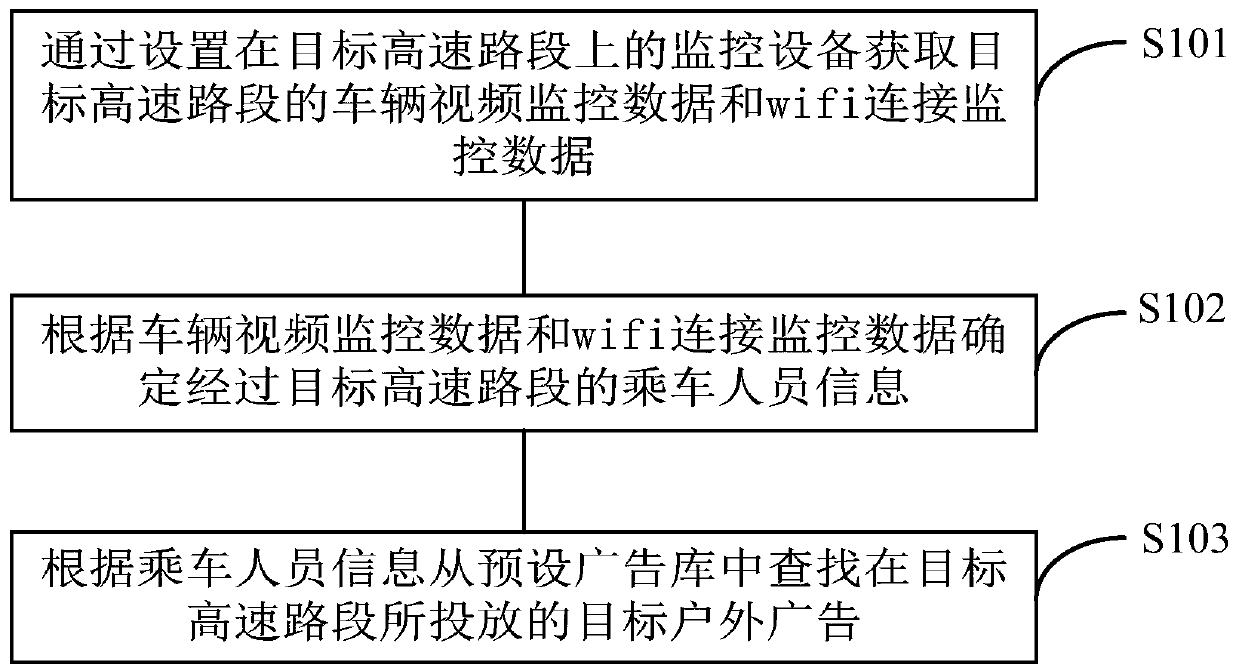

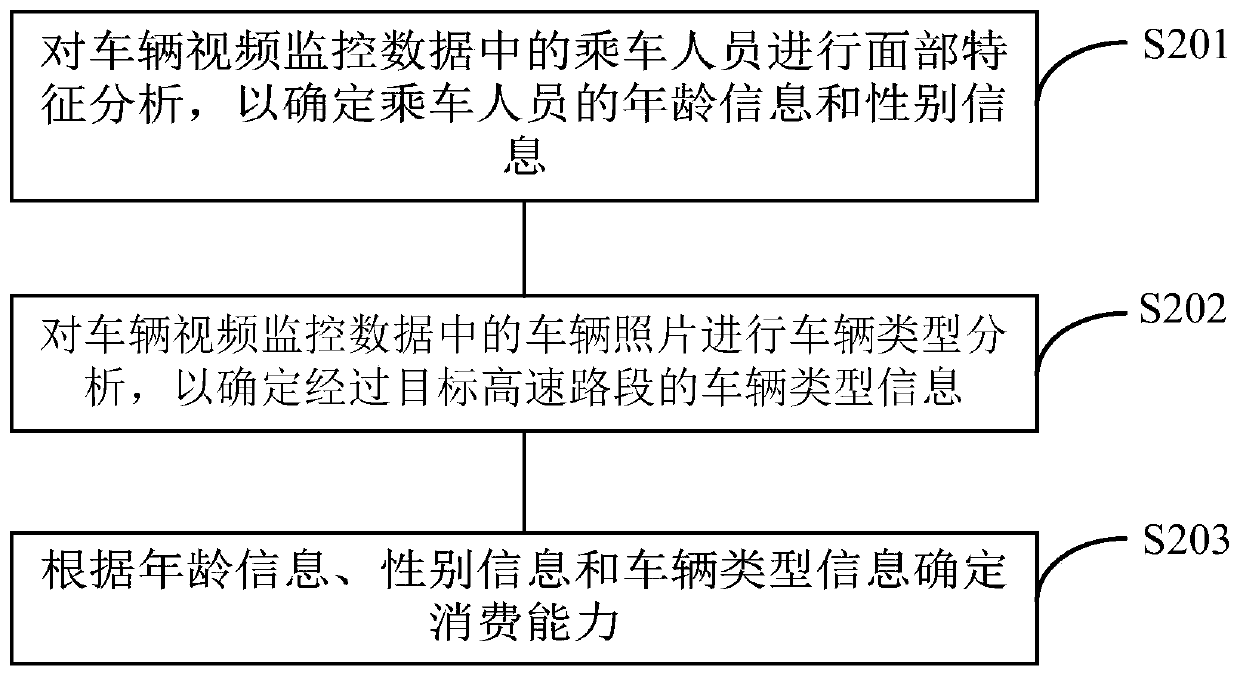

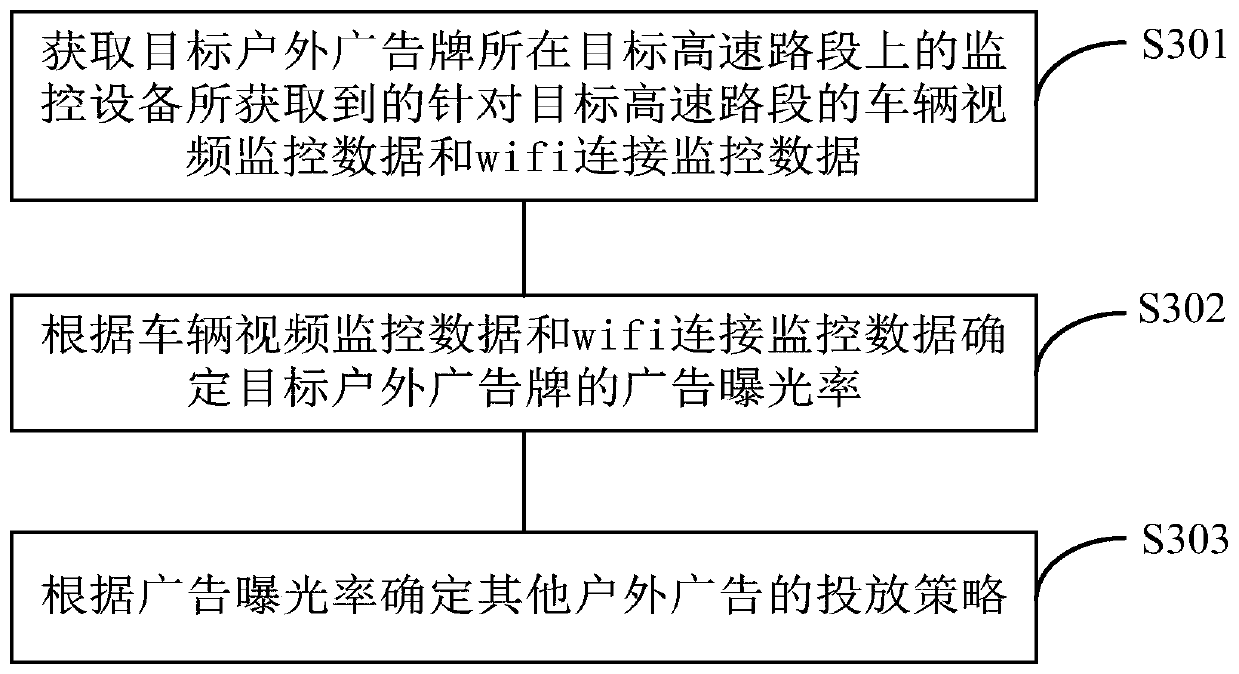

Advertisement putting method and advertisement putting strategy determination method

InactiveCN110473017AAvoid wastingImprove accuracySelective content distributionMarketingVideo monitoringMonitor equipment

The invention provides an advertisement putting method and an advertisement putting strategy determination method. The advertisement putting method comprises the steps of acquiring vehicle video monitoring data and wifi connection monitoring data of a target expressway section through monitoring equipment arranged on the target expressway section; determining passenger information passing throughthe target expressway section according to the vehicle video monitoring data and the wifi connection monitoring data; and according to the passenger information, searching a preset advertisement library for a target outdoor advertisement delivered on the target expressway section. Based on the advertisement putting method, the vehicle video monitoring data and the wifi connection monitoring data are analyzed together to obtain the passenger information; wherein the passenger information comprises the total number of passengers, the number of passengers leaning against a window and passenger identity information, and accurate delivery of the target outdoor advertising board can be achieved according to the passenger information, that is, the target outdoor advertising board delivered on thetarget outdoor advertising board is screened out according to the passenger information.

Owner:恩亿科(北京)数据科技有限公司

Leather feeding and cutting all-in-one machine for manufacturing leather carvings

ActiveCN111647696AAchieve precise deliveryNo creasesLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusWorkbenchIndustrial engineering

The invention discloses a leather feeding and cutting all-in-one machine for manufacturing leather carvings, and relates to the technical field of feeding and cutting. The leather feeding and cuttingall-in-one machine for manufacturing the leather carvings comprises a base, a first pedestal, a second pedestal, a workbench, a leather roller, a driving mechanism, a gear mechanism, a reciprocating mechanism, a clamping mechanism, an intermittent mechanism and a cutting device. The clamping mechanism clamps leather when the reciprocating mechanism advances and releases and avoids the leather whenthe reciprocating mechanism returns. According to the leather feeding and cutting all-in-one machine for manufacturing the leather carvings, through the cooperation of the reciprocating mechanism andthe clamping mechanism, the clamping mechanism clamps the leather when the reciprocating mechanism advances and releases and avoids the leather when the reciprocating mechanism returns, so that accurate conveying of leather with different thicknesses is avoided; and the cutting device can press the leather with different thicknesses and then cut the leather, so that wrinkles of the leather are avoided, and cut openings of the leather are uniform.

Owner:山东众兴泽辉新材料股份有限公司

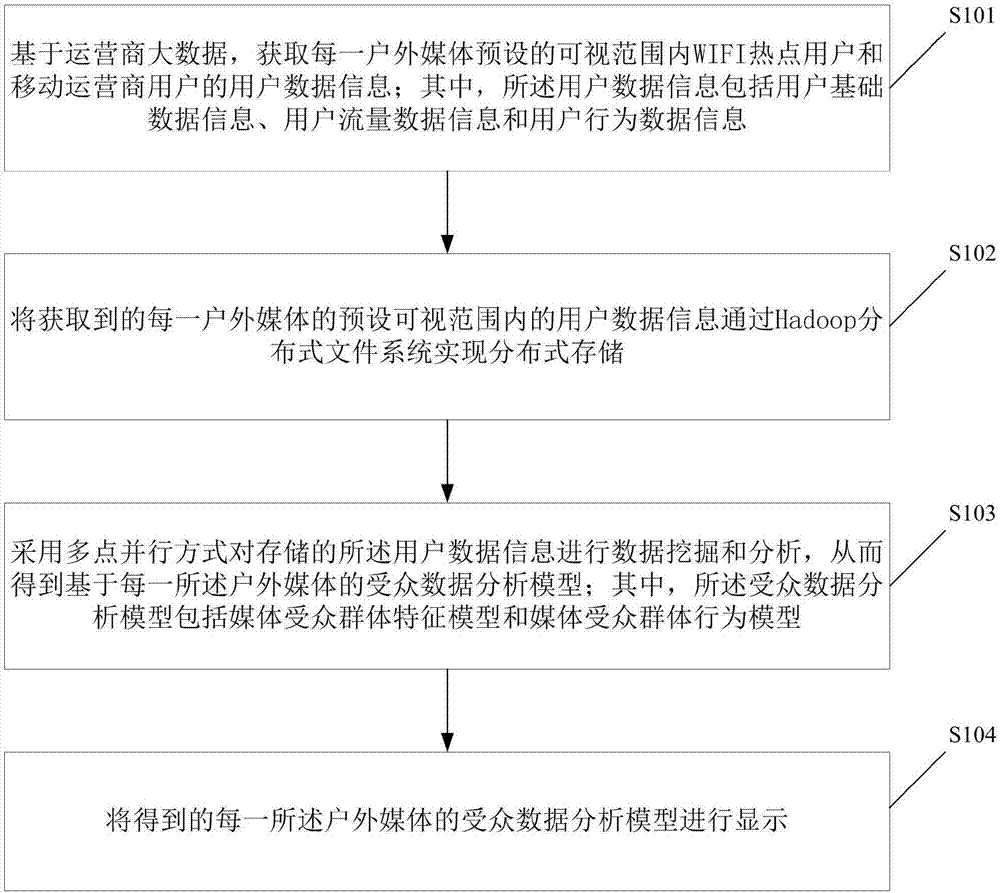

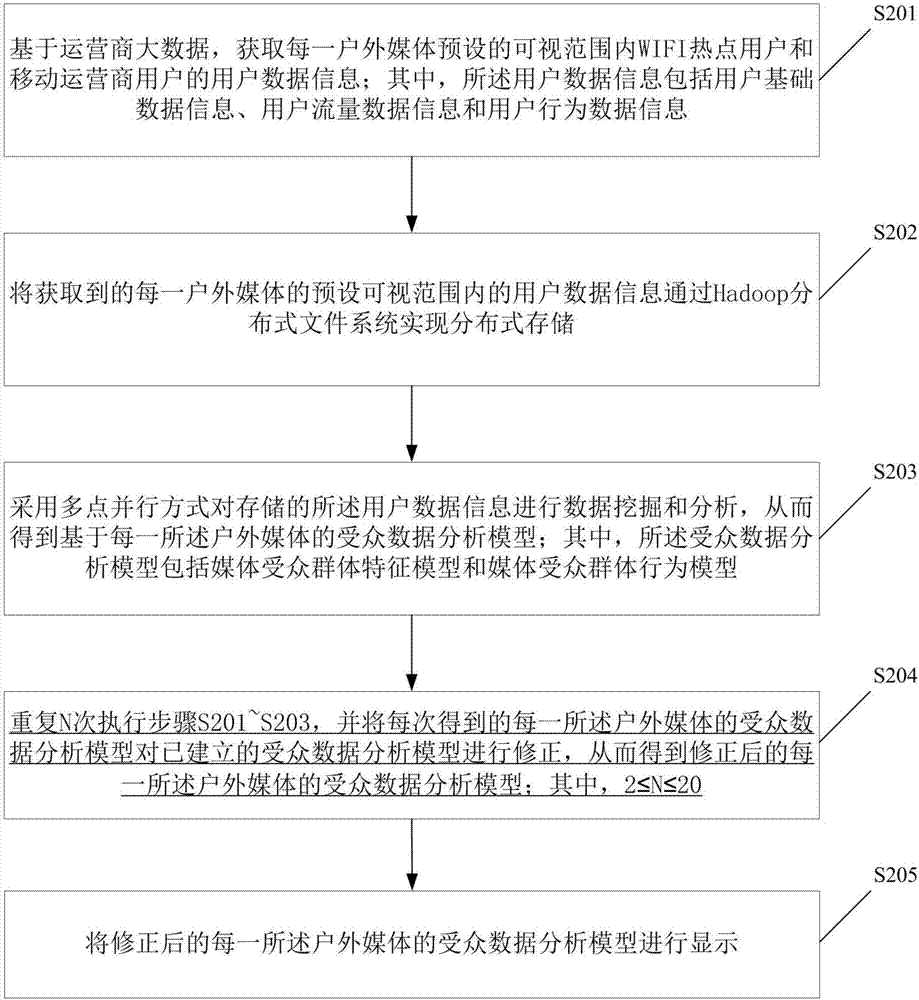

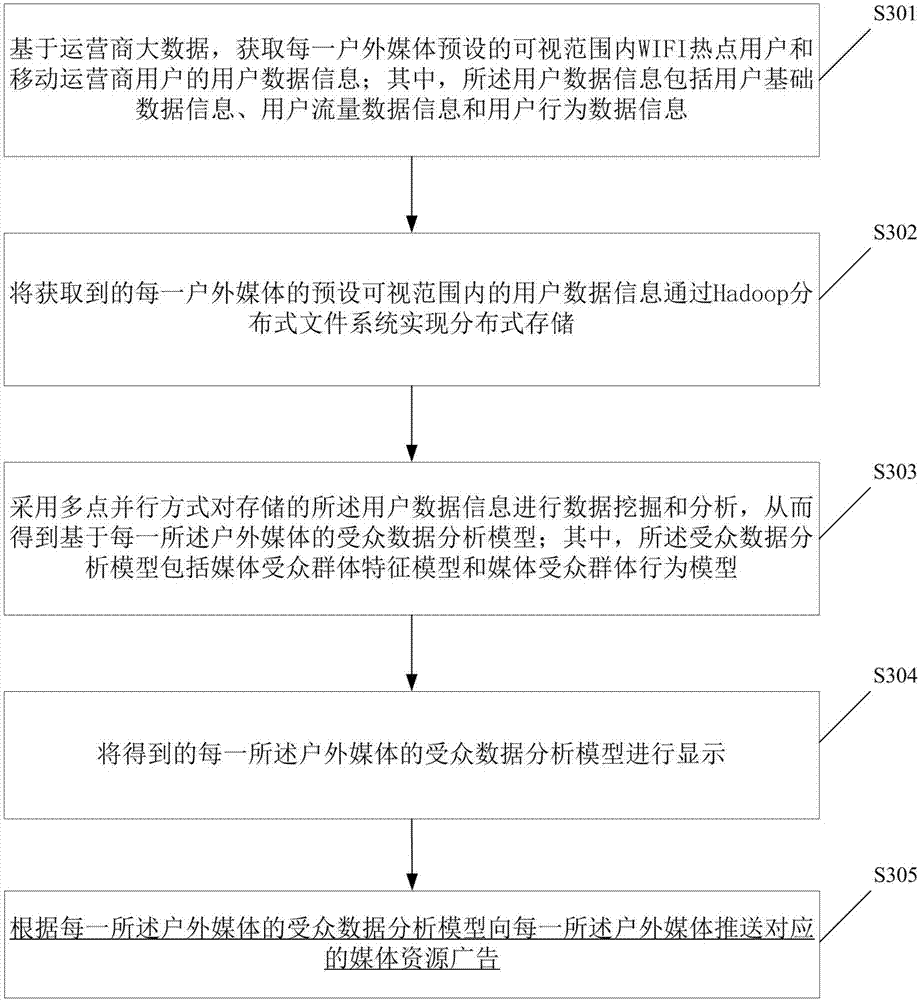

Mining and processing method and system for outdoor media resource data

ActiveCN107423315AAchieve precise deliveryRealize personalized customized deliverySpecial data processing applicationsMarket data gatheringTraffic volumeDistributed File System

The invention discloses a mining and processing method for outdoor media resource data. The method comprises the steps that S1, user data information of WIFI hotspot users and mobile operator users within a preset visible range of each part of outdoor media is acquired based on operator big data, wherein the user data information comprises user basic data information, user traffic data information and user behavior data information; S2, the acquired user data information within the preset visible range of each part of outdoor media is stored in a distributed mode through a Hadoop distributed file system; S3, a multipoint parallel mode is adopted to perform data mining and analysis on the stored user data information, so that an audience data analysis model based on each part of outdoor media is obtained, wherein the media audience data analysis model comprises a media audience group characteristic model and a media audience group behavior model; and S4, the obtained audience data analysis model of each part of outdoor media is displayed.

Owner:广东南方新视界传媒科技有限公司

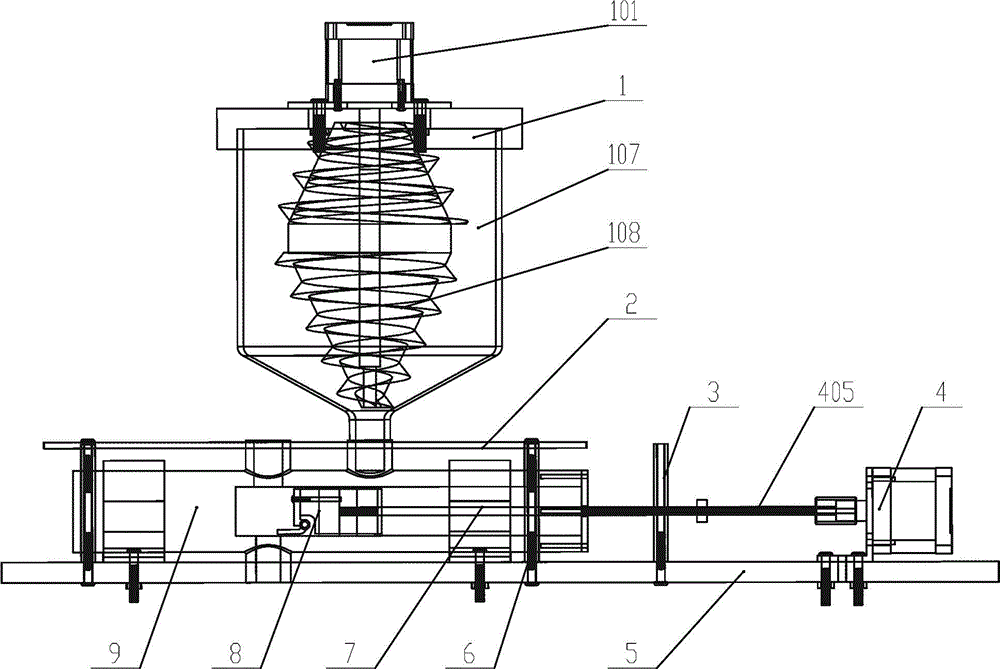

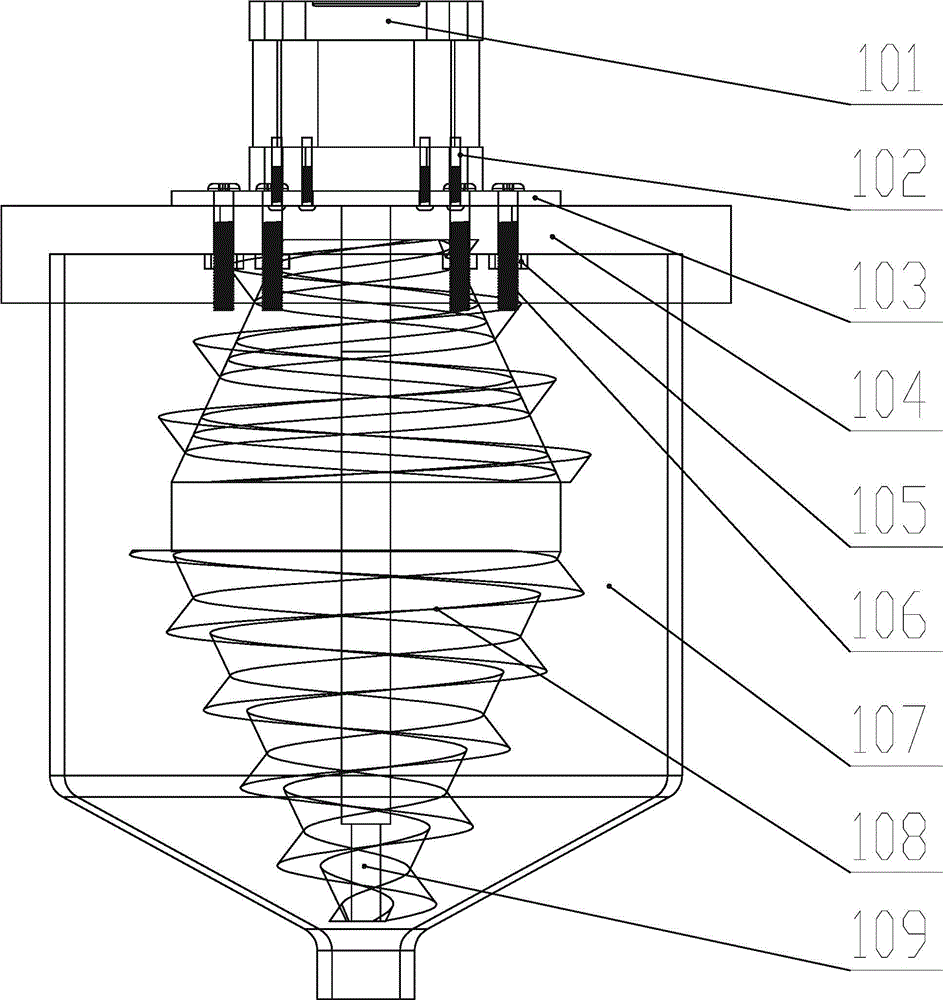

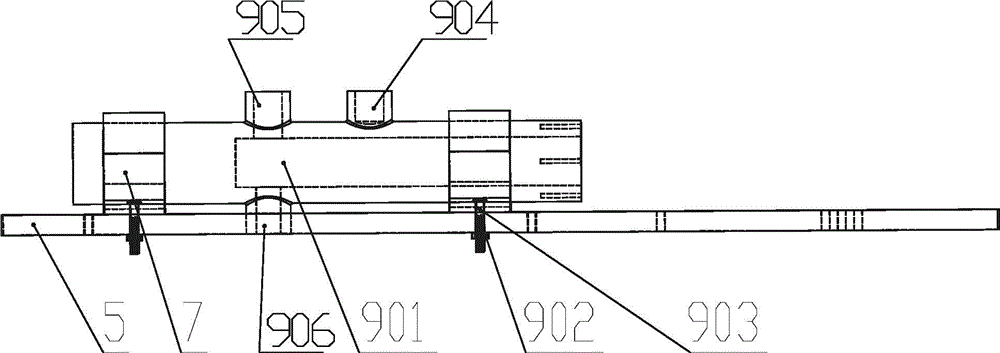

Functional gradient powder material feeding mechanism and operation method

ActiveCN105347042AMeet the requirements of conveying accuracyRelieve cloggingBulk conveyorsInterference fitAir pump

The invention discloses a functional gradient powder material feeding mechanism and an operation method. Two cylinder body fixing pieces are fixedly connected with the left side of a bottom board device of the mechanism through bolts; the cylinder body fixing pieces are used for fixing a cylinder body assembly to the bottom board device of the mechanism in an interference fit manner; a left limiting copper post is fixedly connected with the middle of the bottom board device of the mechanism; a transmission mechanism is fixedly connected with the right side of the bottom board device of the mechanism through a bolt; the transmission mechanism is connected with a sliding block in a cylinder through a threaded rod; the upper portion of the cylinder body assembly is connected with an upper supporting board in a clearance fit manner; the cylinder body assembly is fixedly connected between a supporting board and the bottom board device through four copper posts; a powder material storage bin is mounted at the upper portion of the supporting board; and the powder material storage bin is composed of a first stepping motor, a powder material barrel and a stirrer. The powder feeding mechanism can convey functional gradient powder materials accurately through back and forth movement of the transmission mechanism, intermittent rotation of the stirrer and air injection of an air pump.

Owner:CHINA THREE GORGES UNIV

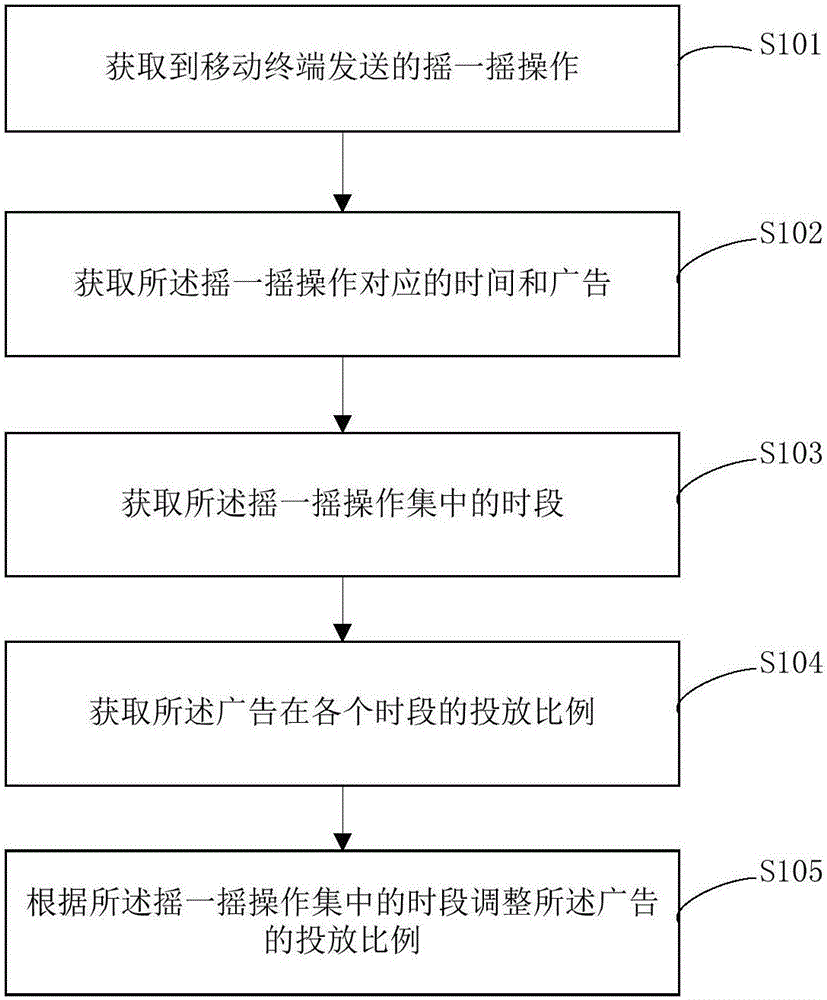

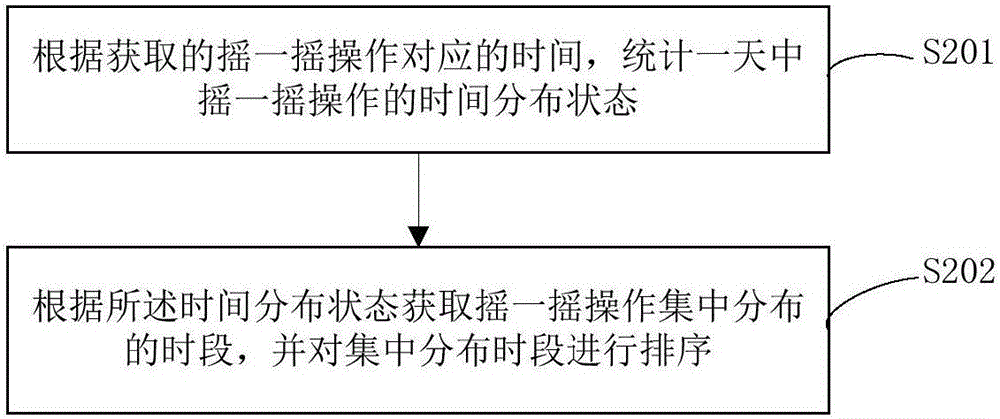

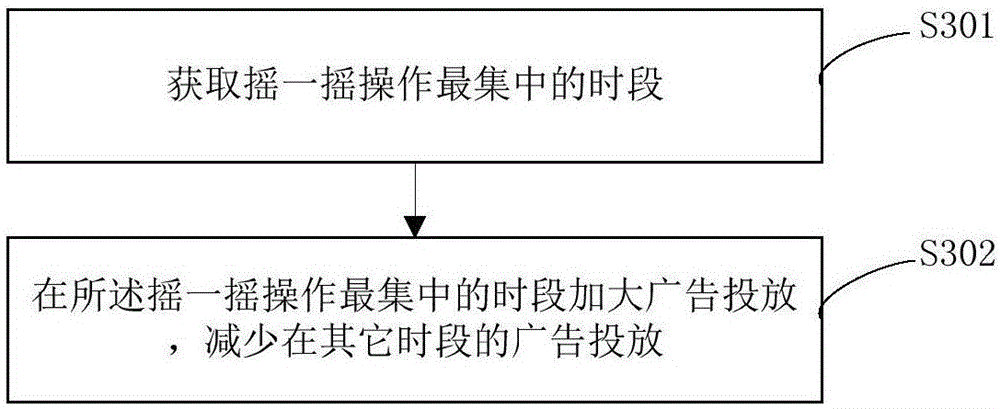

Centralized advertisement launching method and launching device

The invention discloses a centralized advertisement launching method and launching device and aims to realize advertisement resource optimization configuration according to attention of users. The method comprises steps that shake-if-off operation sent by a mobile terminal is acquired; the time and an advertisement corresponding to the shake-if-off operation are acquired; a centralized time segment of the shake-if-off operation is acquired; a launching proportion of the advertisement at each time segment is acquired; and an advertisement launching proportion is adjusted according to the centralized time segment of the shake-if-off operation. The method is advantaged in that the advertisement launching volume is associated with attention of the users, and advertisement launching strategies are adjusted according to the centralized shake-if-off time so as to realize optimal advertisement launching effects.

Owner:TVM BEIJING TECH

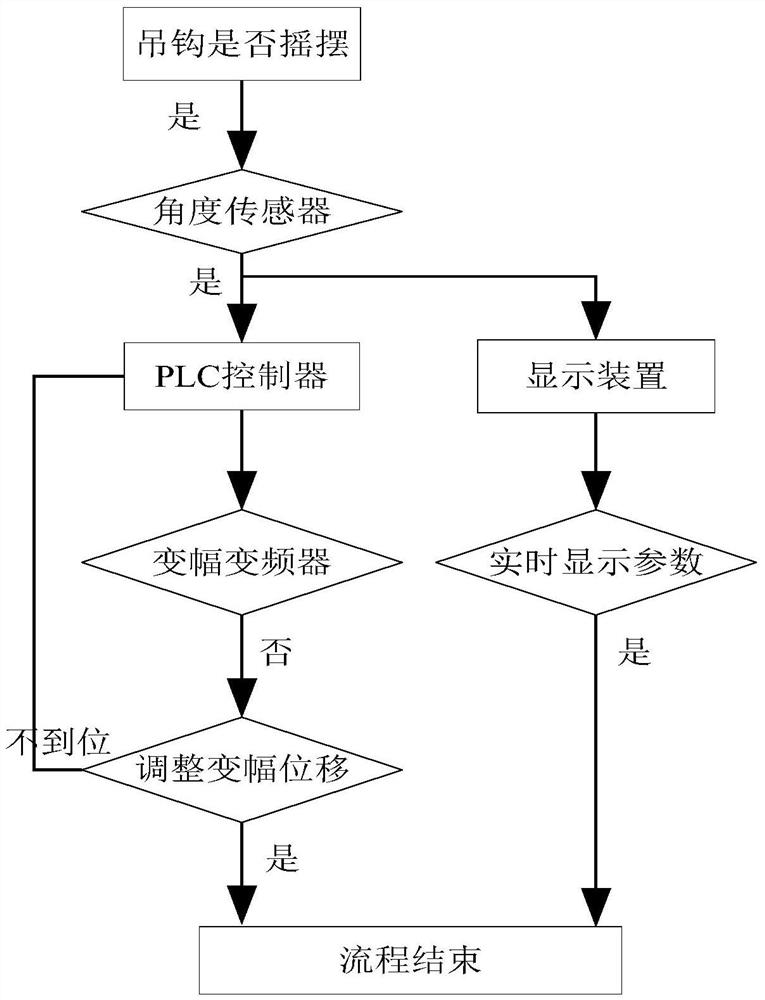

Tower crane lifting hook anti-swing control system

InactiveCN112340603AReal time monitoringAchieve precise deliveryLoad-engaging elementsControl systemControl signal

The invention discloses a tower crane lifting hook anti-swing control system which comprises a control device and a detection device, wherein the control device and the detection device are connectedthrough a CAN bus; the control device comprises a linkage table and a PLC, the linkage table is used for giving an anti-swing starting operation signal, and the PLC is used for receiving a control signal and sending an operation control command; the detection device comprises a variable-amplitude encoder installed on a variable-amplitude trolley and an angle sensor installed on a lifting hook, thevariable-amplitude encoder is used for detecting the displacement of the variable-amplitude trolley in real time, and the angle sensor is used for detecting the dangling angle of the lifting hook inreal time; and data detected by the variable-amplitude encoder and the angle sensor in real time are sent to the PLC through the CAN bus, the PLC calculates the corresponding variation through a corresponding relation model algorithm, then outputs a corresponding control signal to control the operating speed of a variable-amplitude motor, and therefore, swing of the lifting hook is reduced in realtime. According to the tower crane lifting hook anti-swing control system, swinging of the lifting hook in the operation process can be effectively eliminated, and the automation degree is high.

Owner:XUZHOU CONSTR MACHINERY

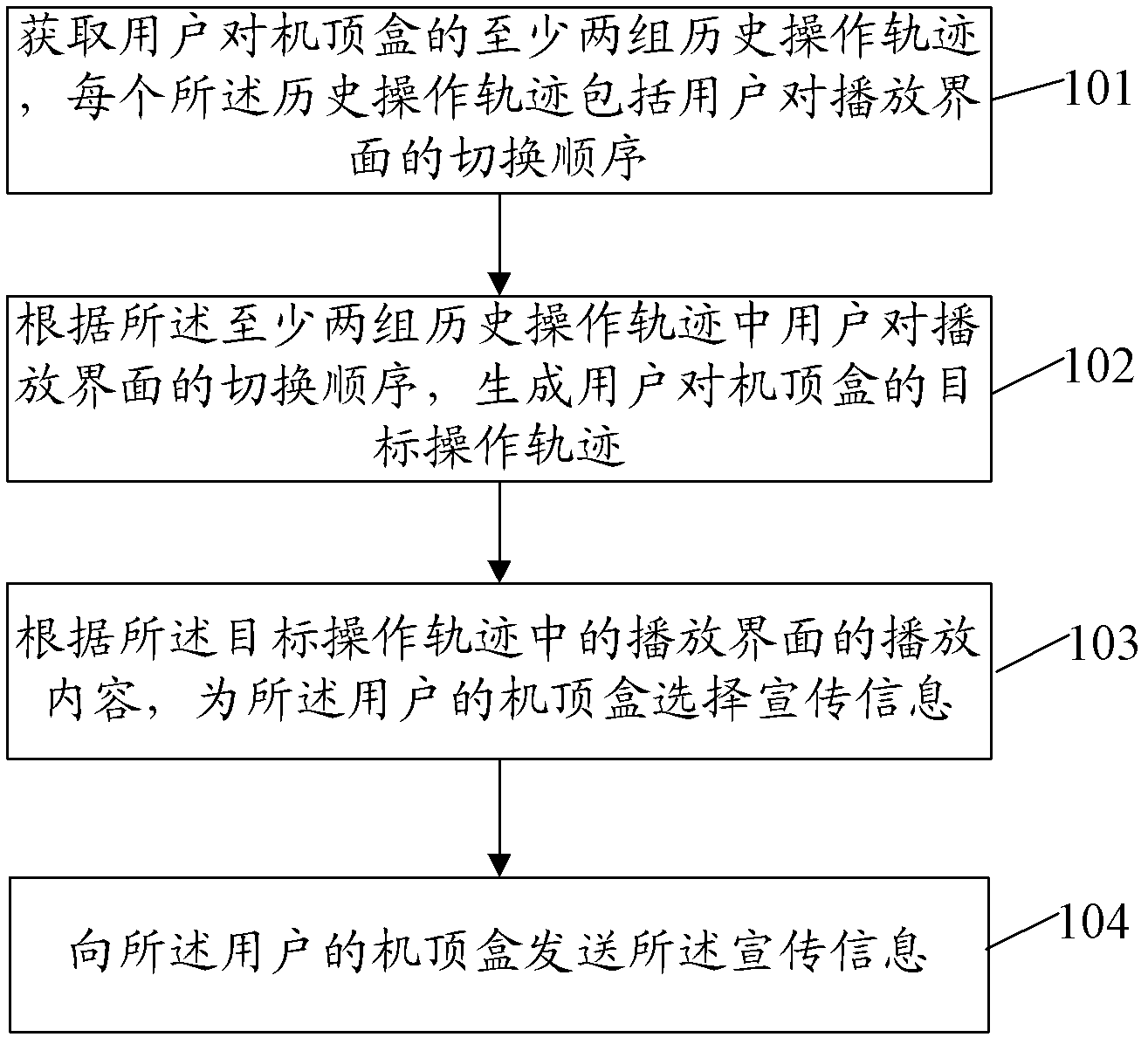

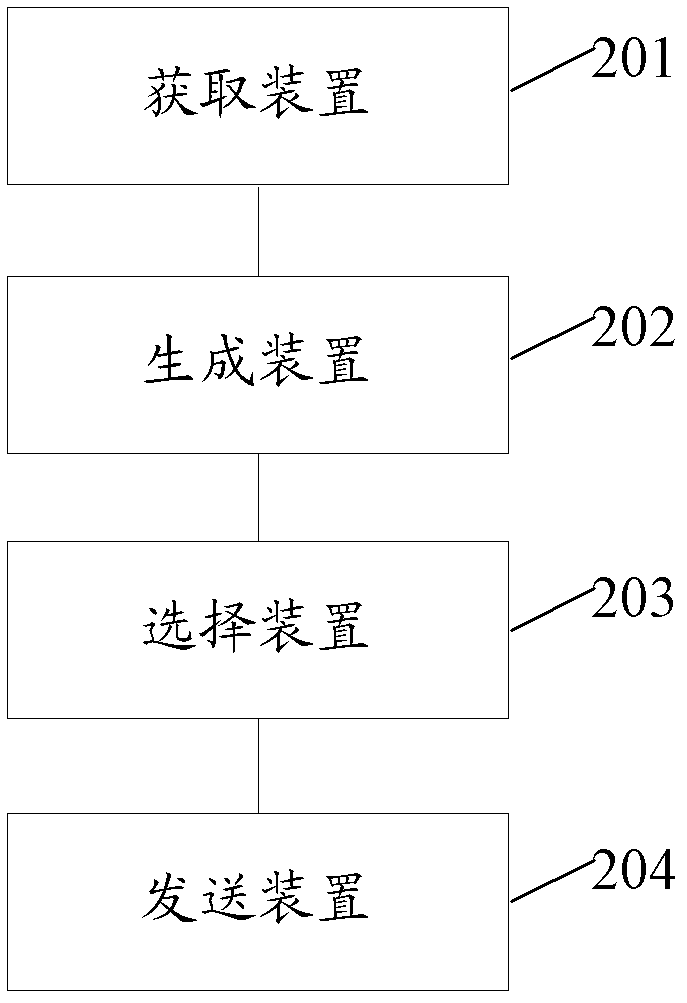

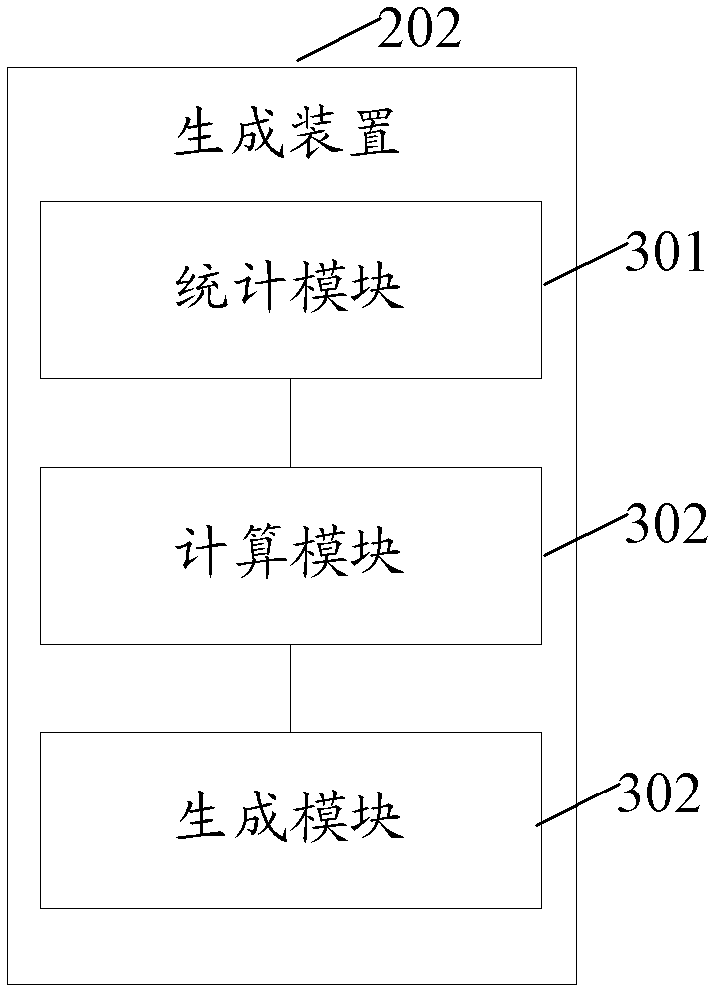

Method and system for sending propaganda information in digital TV (Television), and digital TV system

InactiveCN102843613AAchieve precise deliverySelective content distributionHuman–computer interactionDigital television

The invention provides a method and a system for sending propaganda information in a digital TV (Television). The method comprises the following steps of obtaining at least two groups of historical operation tracks on an STB (Set Top Box) by a user, wherein each group of the historical operation tracks comprises a switching order for a play interface by the user; generating a target operation track on the STB by the user according to the switching order for the play interface in the at least two groups of the historical operation tracks by the user; selecting the propaganda information for the STB of the user according to play content of the play interface in the target operation track; and sending the propaganda information to the STB of the user.

Owner:MIAOZHEN INFORMATION TECH CO LTD

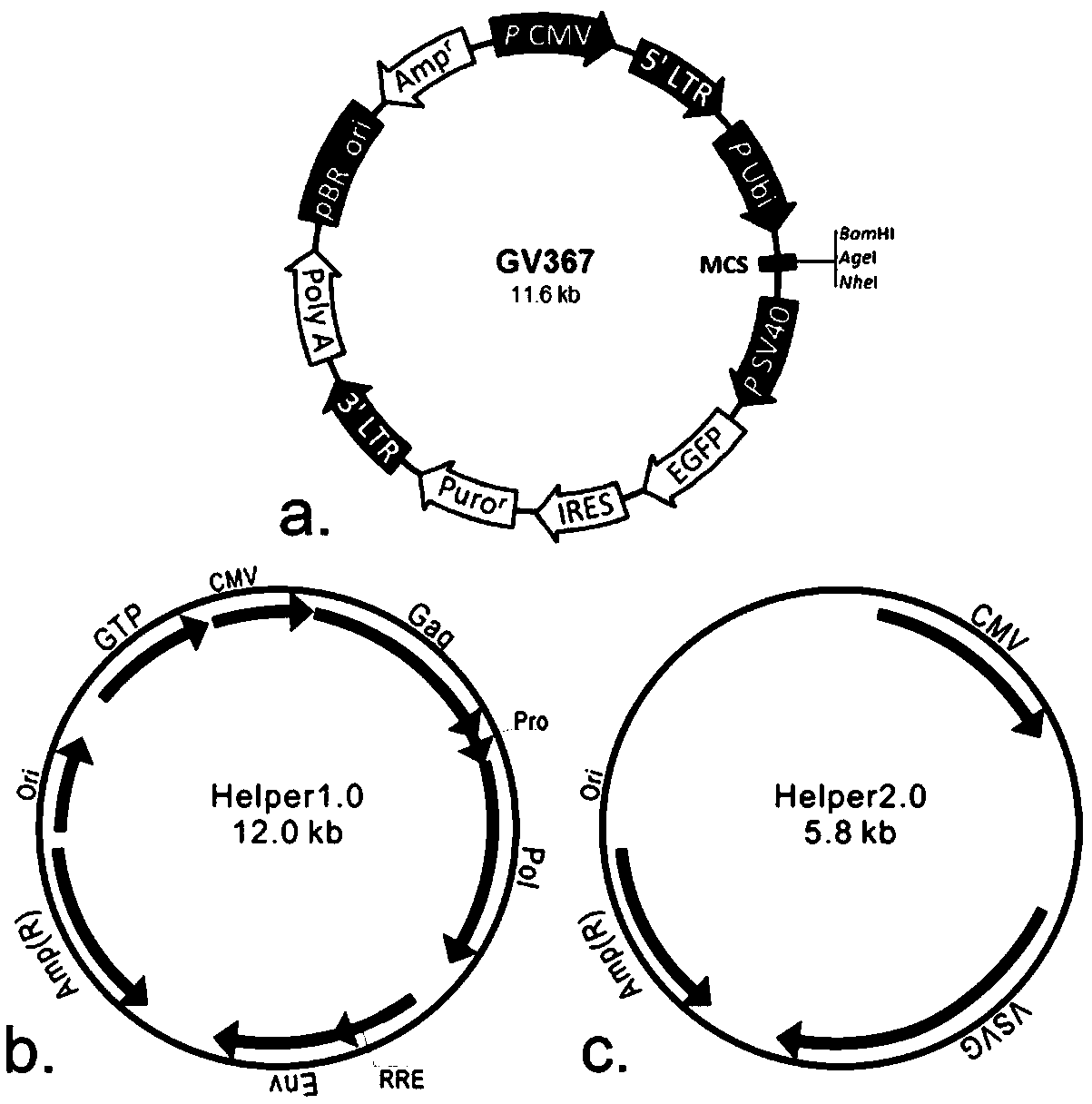

Mesenchymal stem cell preparation used for glioma immunotherapy and meanwhile capable of realizing magnetic resonance tracing

InactiveCN110522767APromote secretionAchieve precise deliveryGenetically modified cellsUnknown materialsGenetic engineeringInterferon beta

The invention belongs to the technical field of genetic engineering and biomedical engineering, and particularly discloses a mesenchymal stem cell preparation used for glioma immunotherapy and meanwhile capable of realizing magnetic resonance tracing. The mesenchymal stem cell preparation comprises mesenchymal stem cells capable of simultaneously secreting interferon-beta (IFN beta) and realizingmagnetic resonance (MR) imaging. The mesenchymal stem cells are jointly modified with IFN beta and FerritinH genes, can adjust the tumor immune microenvironment by secreting an immunomodulatory factorIFN beta, and exerts an inhibition effect on glioma growth; and meanwhile, through FerritinH reporter gene magnetic resonance (MR) imaging, the stem cells after transplanting are monitored dynamically, non-invasively and systematically in real time at the living body level, the experimental basis is provided for promoting stem cell therapy clinical transformation, a new means is provided for deeply illuminating the stem cell action mechanism, and the important scientific significance and clinical application prospects are achieved in aspects of stem cell therapy and transgenic therapy of glioma.

Owner:SUN YAT SEN UNIV

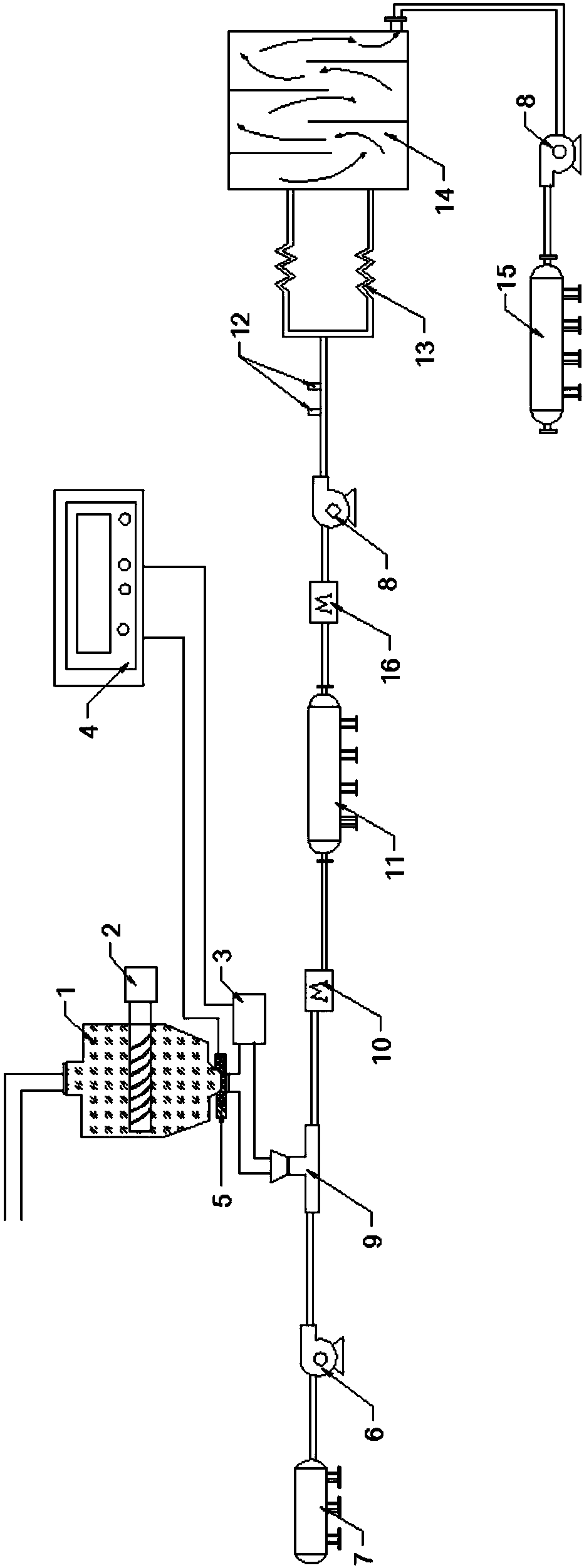

Powder fracturing fluid continuous blending method

InactiveCN108339423APrecise deliveryHigh precisionTransportation and packagingMixing methodsElectricitySuction force

The invention provides a powder fracturing fluid continuous blending method. The method comprises conveying powder into a material hopper, installing a spiral powder relaxer in the material hopper sothat materials are easy to discharge, installing a weight loss compensation sensor at a discharge port of the material hopper, accurately measuring the total amount of powder in the material hopper inreal time, feeding the powder into a spiral feeder through a pipe, electrically connecting the spiral feeder and the weight loss compensation sensor, feeding back to a control system so that precisefeeding is realized, connecting a discharge port of the spiral feeder to a side port of an ejector, respectively connecting an inlet and an outlet of the ejector to a first water inlet main pipe and asecond water inlet main pipe, sucking the powder into the ejector under a vacuum suction force produced by a high-rate water flow, mixing the powder and clear water, diluting the solution through thesecond water inlet main pipe until an appropriate concentration, conveying the solution into a blending system, carrying out uniform stirring, carrying out viscosity adjustment, and conveying the solution to the next process section. The method greatly improves the accuracy of powder weighing, improves the automation degree and reduces a production cost.

Owner:温康

a dispensing device

ActiveCN111332505BEfficient deliveryAvoid the process of repeatedly opening medicine tanks for dispensing operationsSolid materialPharmaceutical drugDispensing medications

Owner:ZHEJIANG COLLEGE OF CONSTR

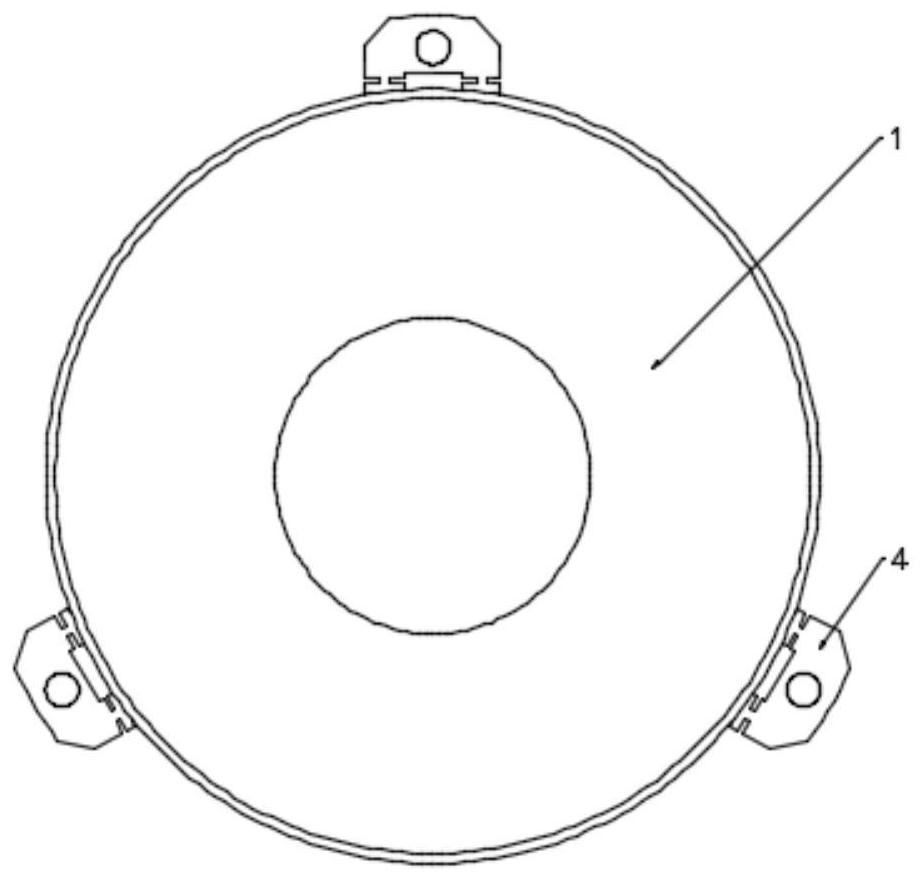

Flexible supporting structure of metal reflector

PendingCN112462484AAddressing Thermal Stability IssuesAchieve precise deliveryMirrorsMountingsEngineeringIntegrated design

The invention provides a metal reflector integrated design and low-stress installation flexible supporting structure suitable for a powerful environment. The structure comprises a reflector, a supporting back plate and a fan-shaped lightweight structure; the reflector and the supporting back plate adopt an integrated structure design, and a flexible supporting lug, a stress isolation groove and aweight reduction rectangular groove are processed on the supporting back plate. By means of the fact that the metal reflector has good machinability, the reflector base body and the supporting back plate can be subjected to integrated structural design, a flexible structure is directly machined on the back of the metal reflector, force and heat unloading of the installation environment is achieved, and therefore stress-free installation of the reflector is achieved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

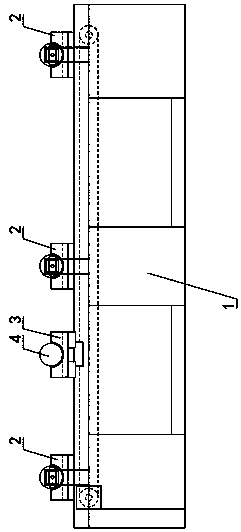

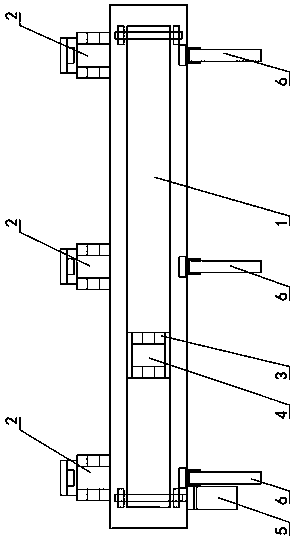

Workpiece distributing device

The invention discloses a workpiece distributing device, and belongs to the technical field of column head machining devices. The distributing device is characterized by comprising positioning devices(2) and a conveying device, wherein at least two positioning devices (2) are arranged along the conveying device, the conveying device is provided with a containing part used for containing workpieces (4), and the positioning devices (2) are provided with positioning parts used for positioning the workpieces (4). According to the distributing device, at least two positioning devices are arrangedalong the conveying device so that the workpieces can be distributed for at least two production lines at the same time; the positioning devices position the conveyed workpieces through the positioning parts so that manipulators can accurately clamp the workpieces, and then accurate feeding of the manipulators is achieved; and the manipulators only need to transfer the workpieces on the corresponding positioning devices to corresponding machine tools, so that the actions of the manipulators are reduced, the mutual interference among the manipulators is avoided, and accurate and stable feedingof the manipulators is ensured.

Owner:SHANDONG HANYE MACHINERY CO LTD +1

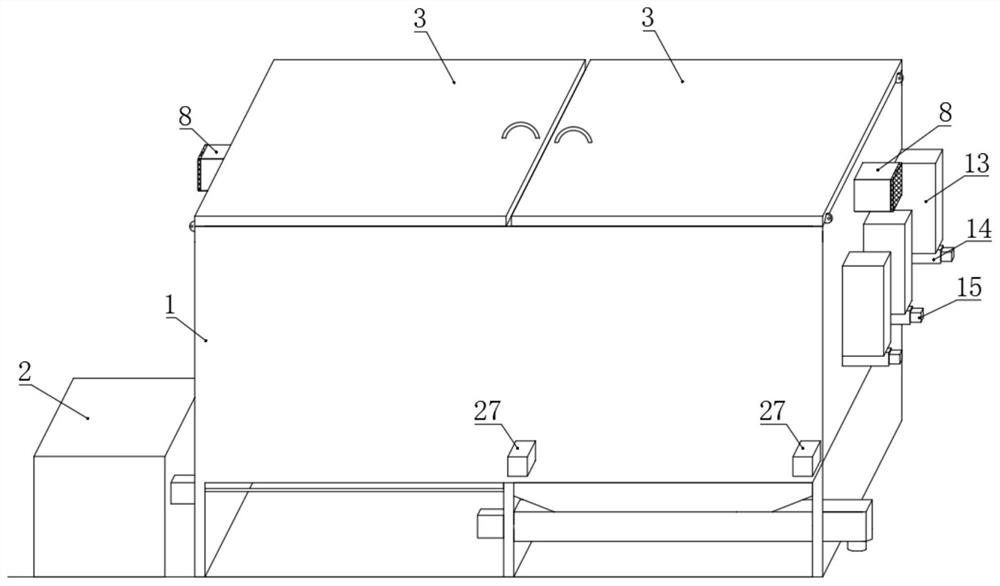

Fruit and vegetable cleaning machine

InactiveCN109875427AAchieve precise deliveryEasy to cleanKitchen equipmentWater filterAgricultural engineering

The invention discloses a fruit and vegetable cleaning machine. The cleaning machine comprises a shell body, a cover plate is arranged at the upper end of the shell body and hinged to the shell body,and an automatic salt adding device is arranged at the upper end of the cover plate; a motor B is further arranged at the upper end of the cover plate, an output shaft of the motor B penetrates through the cover plate and is fixedly connected with a rotary shaft, and a cleaning basket is detachably arranged in the shell body; the end, away from the motor B, of the rotary shaft extends to the bottom of the cleaning basket, the rotary shaft can drive the cleaning basket to rotate, and a water filtering groove is formed in a base at the lower end of the shell body; the water filtering groove is communicated with a cavity of the shell body through a tube line, a water filtering groove cover is detachably arranged on one side of the water filtering groove, and the inside of the water filteringgroove is further connected with a return pipe; the other end of the return pipe is connected with a water inlet of a sprinkler, and the return pipe is provided with a booster pump. The device effectively improves the effect of cleaning fruits and vegetables, greatly reduces pesticides remaining on the cleaned fruits and vegetables and achieves a certain freshness keeping effect.

Owner:合肥航亿科技有限公司

Numerical control intelligent tie-dyeing machine

PendingCN113502620AAchieve precise deliveryRealize fixed-point printing and dyeingSucessive textile treatmentsTextile treatment cleaning apparatusNumerical controlControl engineering

The invention relates to a numerical control intelligent tie-dyeing machine. The machine comprises a rack, a dye bin assembly, a first conveying belt arranged on the rack and a dyeing device located above the first conveying belt; the dyeing device comprises a mounting frame, and a plurality of brushes arranged on the mounting frame; the dye bin assembly comprises a plurality of dye bins; feeding pipes are arranged in the dye bins; the feeding pipes in the dye bins are communicated with corresponding dye barrels through respective conveying pumps; a plurality of dye output holes are formed in the bin walls of the dye bins; the dye output holes are connected with first electromagnetic valves through pipelines; and the dye output holes of the dye bins are communicated with corresponding dye output pipes after being output through the respective first electromagnetic valves. According to the numerical control intelligent tie-dyeing machine, through the arrangement of the dye bins and the first electromagnetic valves, output control over dyes of all colors is achieved, so that the dyes of specific colors can be output; and meanwhile, through the arrangement of the multiple brushes, cloth can be accurately dyed, and the dyeing effect is better.

Owner:常州智源万达软件有限公司

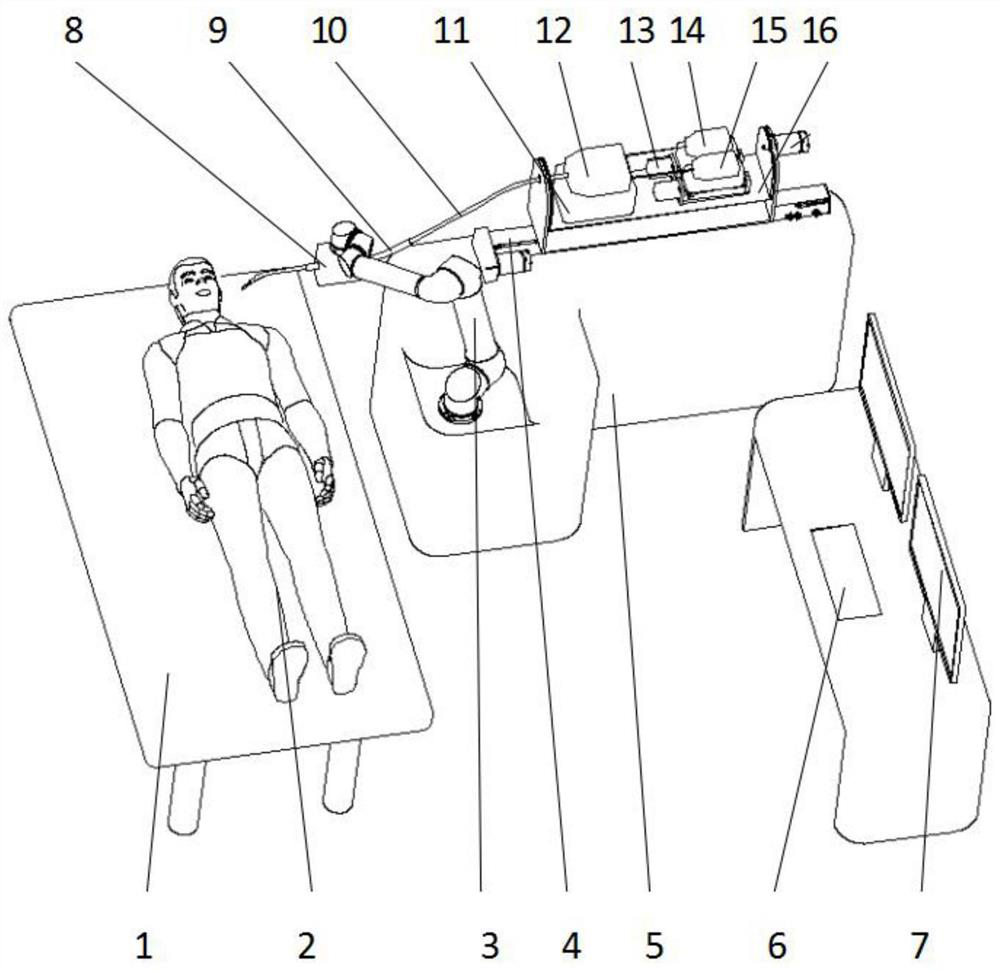

Endoscopic surgical instrument conveying device, control method and robot system

ActiveCN114010318AEasy to movePrecise positioningDiagnosticsSurgical manipulatorsRobotic systemsPhysical medicine and rehabilitation

The invention discloses an endoscopic surgical instrument conveying device, a control method and a robot system. The endoscopic surgical instrument conveying device comprises a robot base, a multi-degree-of-freedom mechanical arm, a first driving platform, a second driving platform and a control module. In an adjusting and aligning stage, the control module calculates the sliding distance of the first driving platform according to movement position conversion of a pipe conveying assembly of the multi-degree-of-freedom mechanical arm, and controls the first driving assembly to drive the first driving platform to move along with the multi-degree-of-freedom mechanical arm; and in a tube body insertion stage, the control module controls the first driving assembly to drive the first driving platform to slide, so that the endoscope body insertion tube is inserted towards the far end. By means of the control module, in the alignment process, when the multi-degree-of-freedom mechanical arm is moved, the first driving platform slides synchronously, the overall follow-up effect of the endoscope body insertion tube is kept, the situation that the endoscope body insertion tube is straightened, tightened and stressed due to distance changes is avoided, and the stable positioning process is achieved.

Owner:SUZHOU ZHONGKE HUAYING HEALTH TECH CO LTD

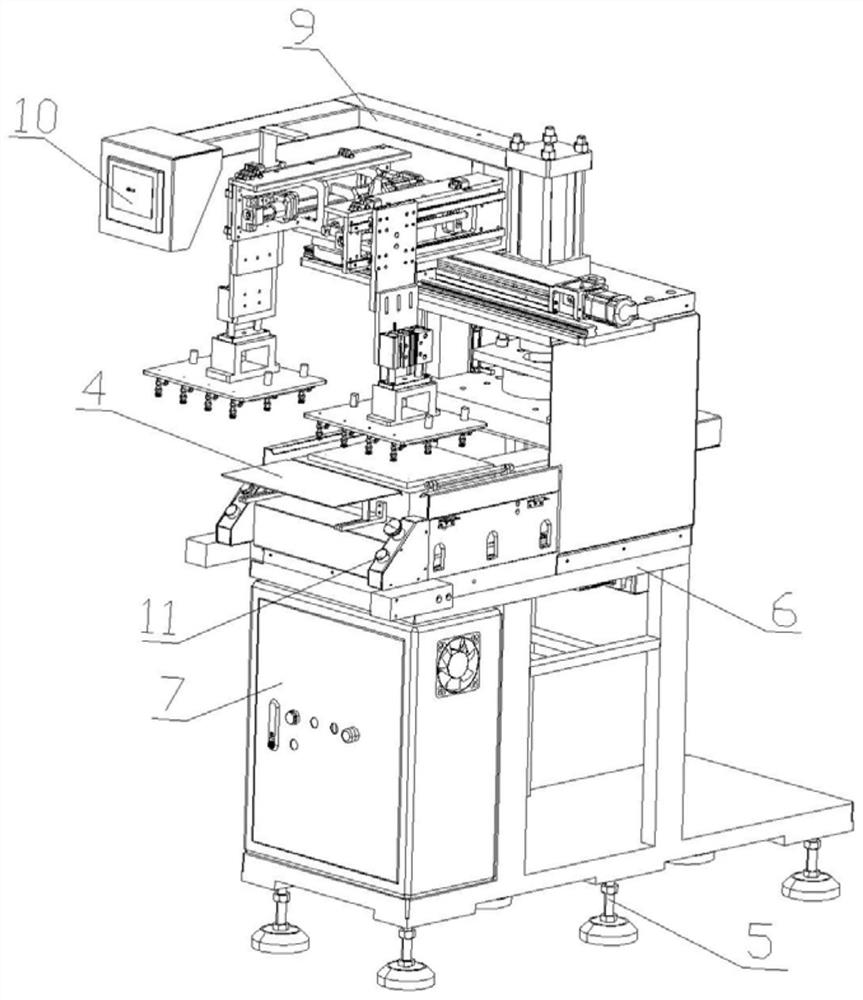

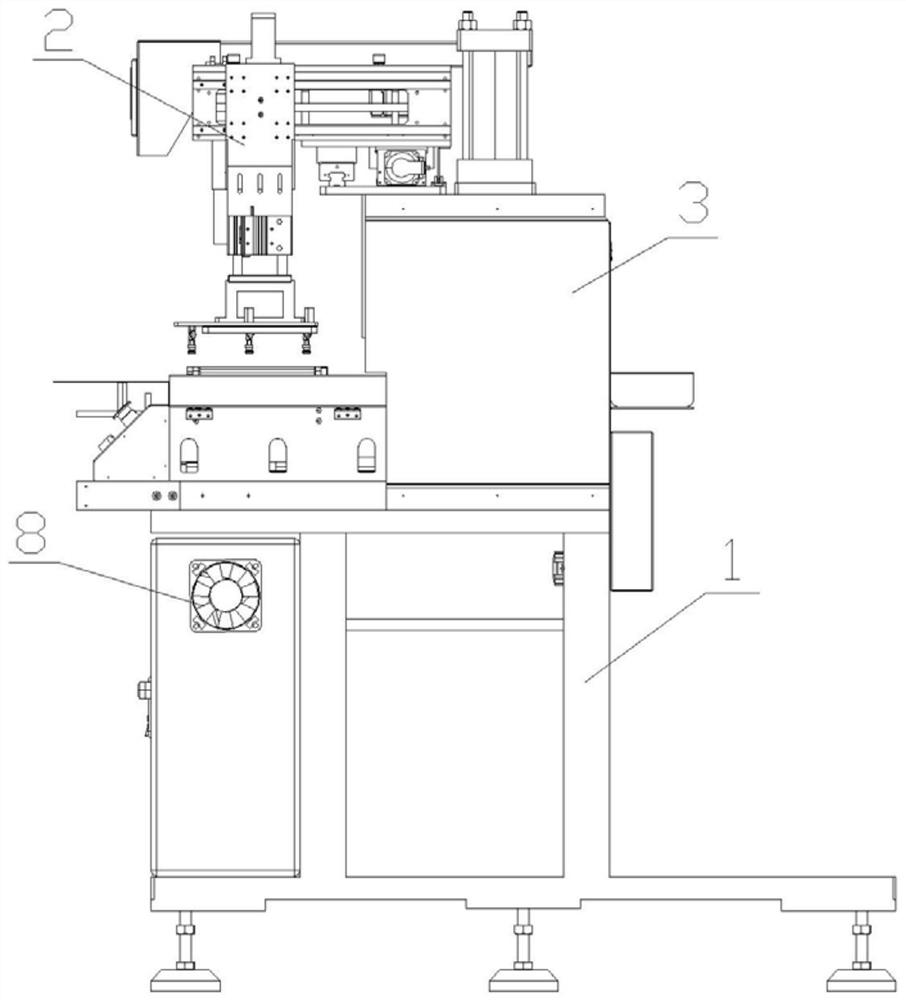

Stamping device for precious metal foil

InactiveCN113000685APrecise deliveryAchieve precise deliveryMetal-working feeding devicesStripping-off devicesCircular discMetallurgy

The invention relates to a stamping device for a precious metal foil. The stamping device comprises a machine frame, a feeding and discharging mechanism, a forming mechanism and a metal foil conveying mechanism, wherein disc supporting legs are fixed to the bottom of the machine frame, a workbench is arranged on the top of the machine frame, an electric control box used for placing electric appliance elements is arranged on the machine frame, a cooling fan is arranged on the electric control box, the metal foil conveying mechanism is arranged on the workbench, a forming mechanism is arranged on one side of the metal foil conveying mechanism, the feeding and discharging mechanism is arranged on the forming mechanism and located above the metal foil conveying mechanism, a display screen support is further arranged on the forming mechanism, and a display screen is arranged on the display screen support. According to the stamping device for the precious metal foil, the distance between an extension supporting plate and a metal foil placing plate can be adjusted according to the length of the metal foil so that the stamping device for the precious metal foil can simultaneously meet stamping machining of the metal foils with different lengths, and the practicability of the device is improved.

Owner:SUZHOU INST OF INDAL TECH

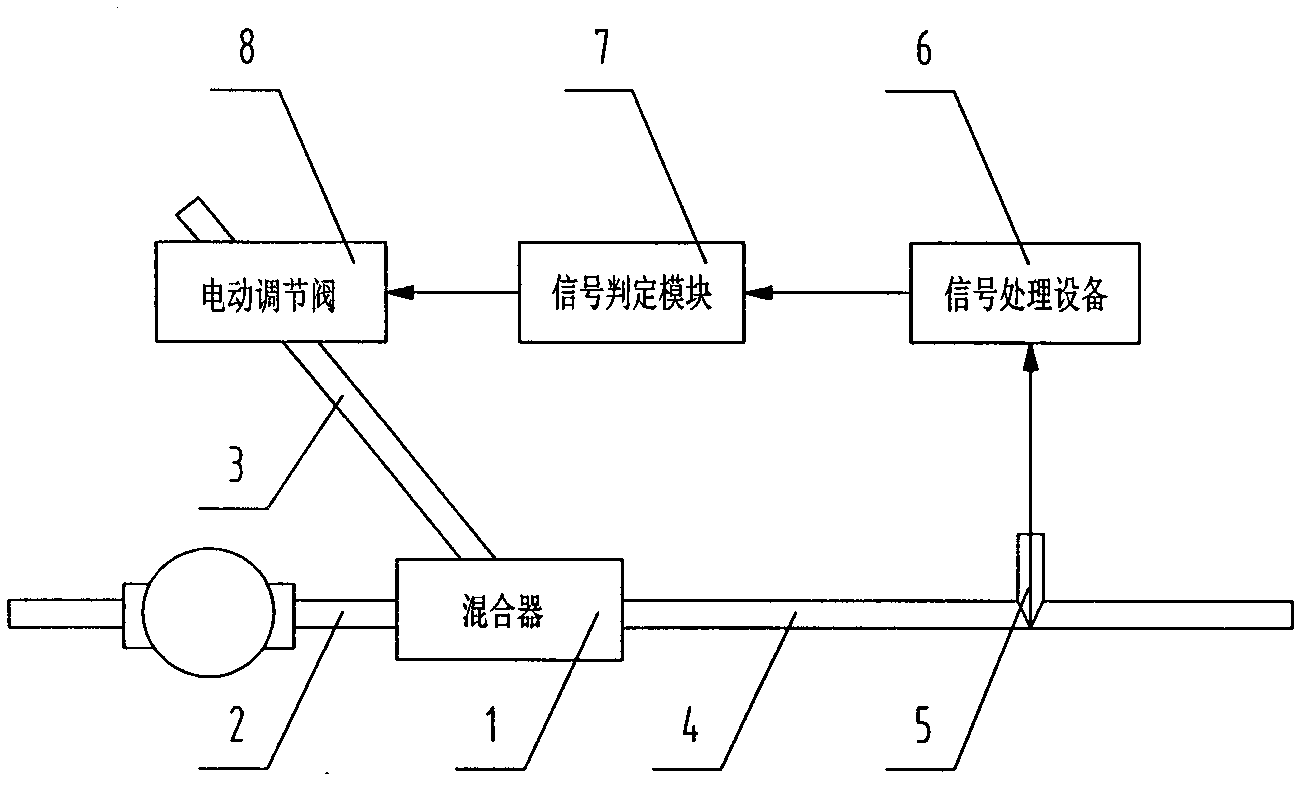

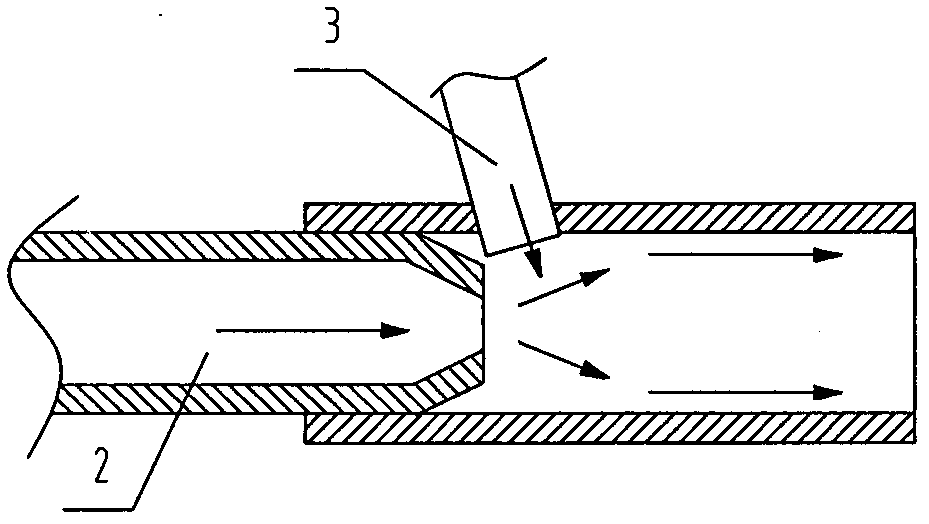

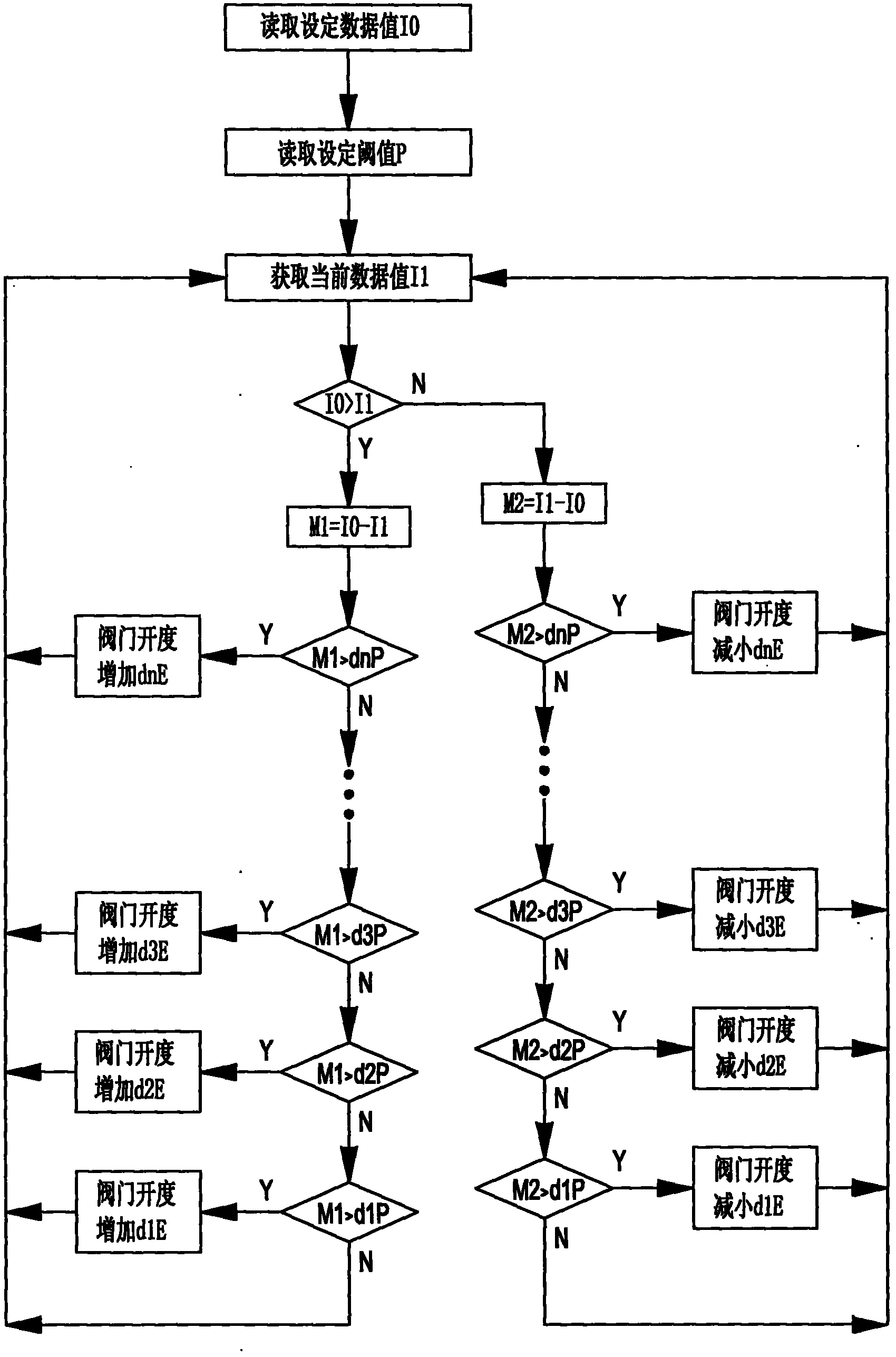

Adaptive feeding system and control method thereof

InactiveCN101927140AAchieve precise deliverySimple structureMixer accessoriesFeed devicesWater sourceClosed loop

The invention discloses an adaptive feeding system and a control method thereof. The adaptive feeding system comprises a mixer, wherein a water source end of the mixer is communicated with a water source through a water pipe; a feed opening of the mixer is communicated with a material source through a feeding pipe; and an output end of the mixer is connected with a discharging pipe. The adaptive feeding system is characterized in that: a sensor is arranged in the discharging pipe; an output end of the sensor is connected with a signal processing device; an output end of the signal processing device is connected with a signal determinant module; an output end of the signal determinant module is connected with an electric adjusting valve; and the electric adjusting valve is arranged in the feeding pipe. The adoptive feeding system has the significant advantages of simple structure, stability, reliability, quick response and the realization of accurate feeding of a plurality of types of raw materials, and can be used for performing closed-loop control according to a reaction result and can quickly adjust and correct the feeding amount so as to meet technological requirements.

Owner:重庆汉能环保工程技术有限公司

Young ostrich breeding device

InactiveCN113100112AEnsure hygienePromote healthy growthAnimal housingBird housingsAnimal scienceGreenhouse

The invention discloses a young ostrich breeding device, and belongs to the field of ostrich breeding. The young ostrich breeding device comprises a breeding box, wherein a water tank is arranged on the outer side of the breeding box, a box cover is mounted at the upper part of the breeding box through a hinge, a partition plate is vertically mounted in the breeding box, the breeding box comprises a greenhouse and a feeding chamber, the greenhouse and the feeding chamber are located on the two sides of the left side of the partition plate respectively, heat preservation cotton is mounted in the greenhouse, concentric-square-shaped pipes are mounted on the upper sides in the greenhouse and the feeding chamber and communicate with heating pipes, and the two heating pipes are both located on the outer side of the breeding box. The breeding box provides a more comfortable breeding environment for young ostriches, feed throwing is more accurate, so that the food intake is convenient to control, meanwhile, the diet space and the rest space of the young ostriches are separated, generated excrement is efficiently cleaned in time, sanitation of the whole breeding box is guaranteed, and the healthy growth of the young ostriches is greatly promoted.

Owner:新疆泉都动物管理有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com