Patents

Literature

53results about How to "Relieve clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

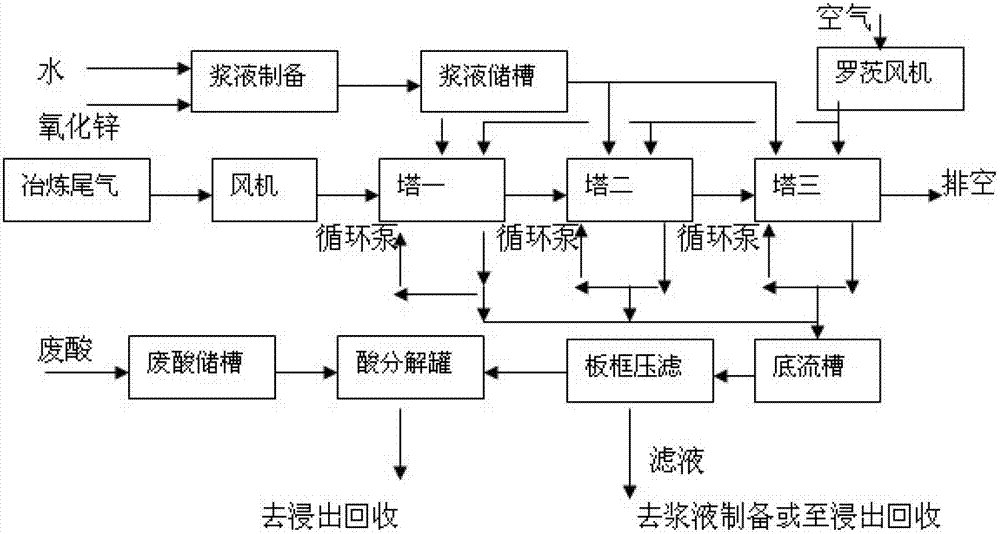

Tail gas desulfuration adopting zinc oxide method in smelting industry

ActiveCN102755826AReduce in quantityReduce wear and tearDispersed particle separationLiquid wasteDecomposition

The invention belongs to the technical filed of environmental protection, and particularly relates to tail gas desulfuration adopting a zinc oxide method in smelting industry. The tail gas desulfuration adopting a zinc oxide method in smelting industry comprises the following steps of: preparing a serous fluid-increasing smelting tail gas pressure-absorbing procedure-oxygenation procedure-plate frame pressure filtration procedure-acid decomposition procedure; the quantity of absorbing towers can be determined according to the temperature of tail gas to be processed and sulfur dioxide content, and a primary-level absorbing tower is used when the sulfur dioxide content of the tail gas is in the range of 0-6000 mg / Nm3; and a secondary-level absorbing tower is used when the sulfur dioxide content of the tail gas is in the range of 6000-12000 mg / Nm3, and a third-level absorbing tower is used when the sulfur dioxide content of the tail gas is in the range of 12000-24000 mg / Nm3. The air oxidation is realized in the absorbing tower, ZnSO3.5H2O which is easy to crystallize is oxidized to be ZnSO4, the quantity of the crystals is greatly reduced, the phenomena of sedimentation and choking are greatly relieved, and the abrasion to the circulating pump and a pipeline is relieved; and the waste acid generated by a smelting industry is utilized, part of waste fluid or waste acid is reused, and the clean production and work is promoted.

Owner:江苏恒丰伟业科技工程有限公司

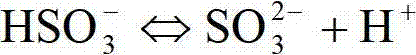

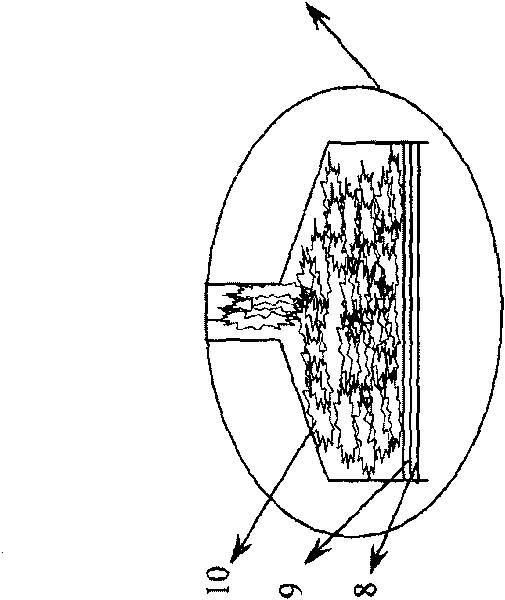

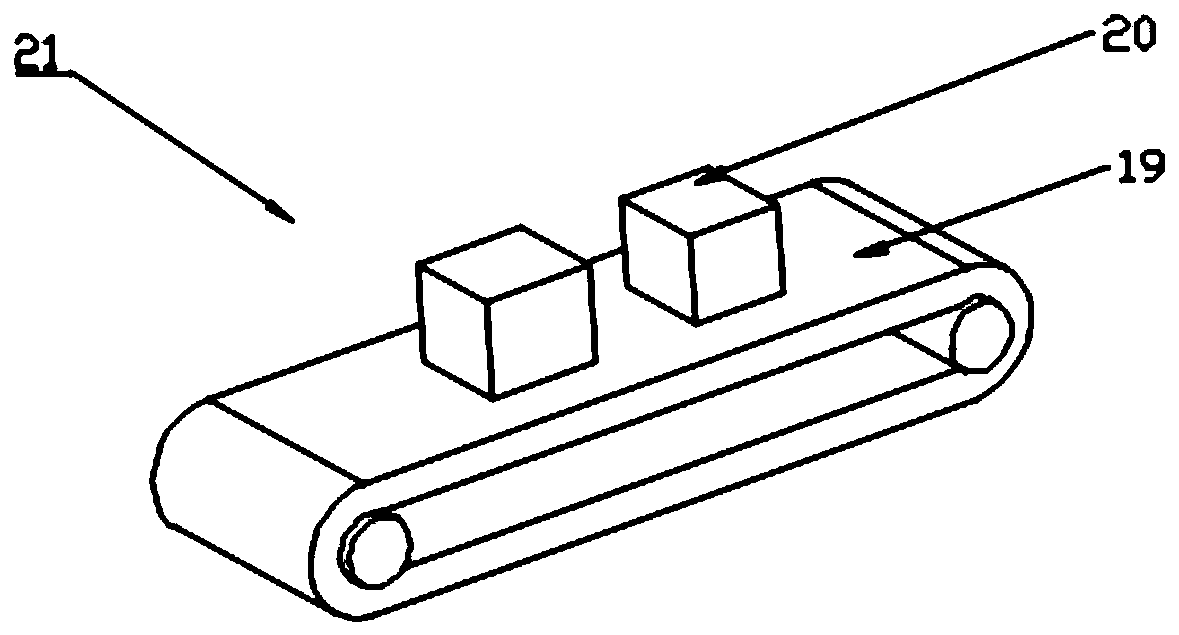

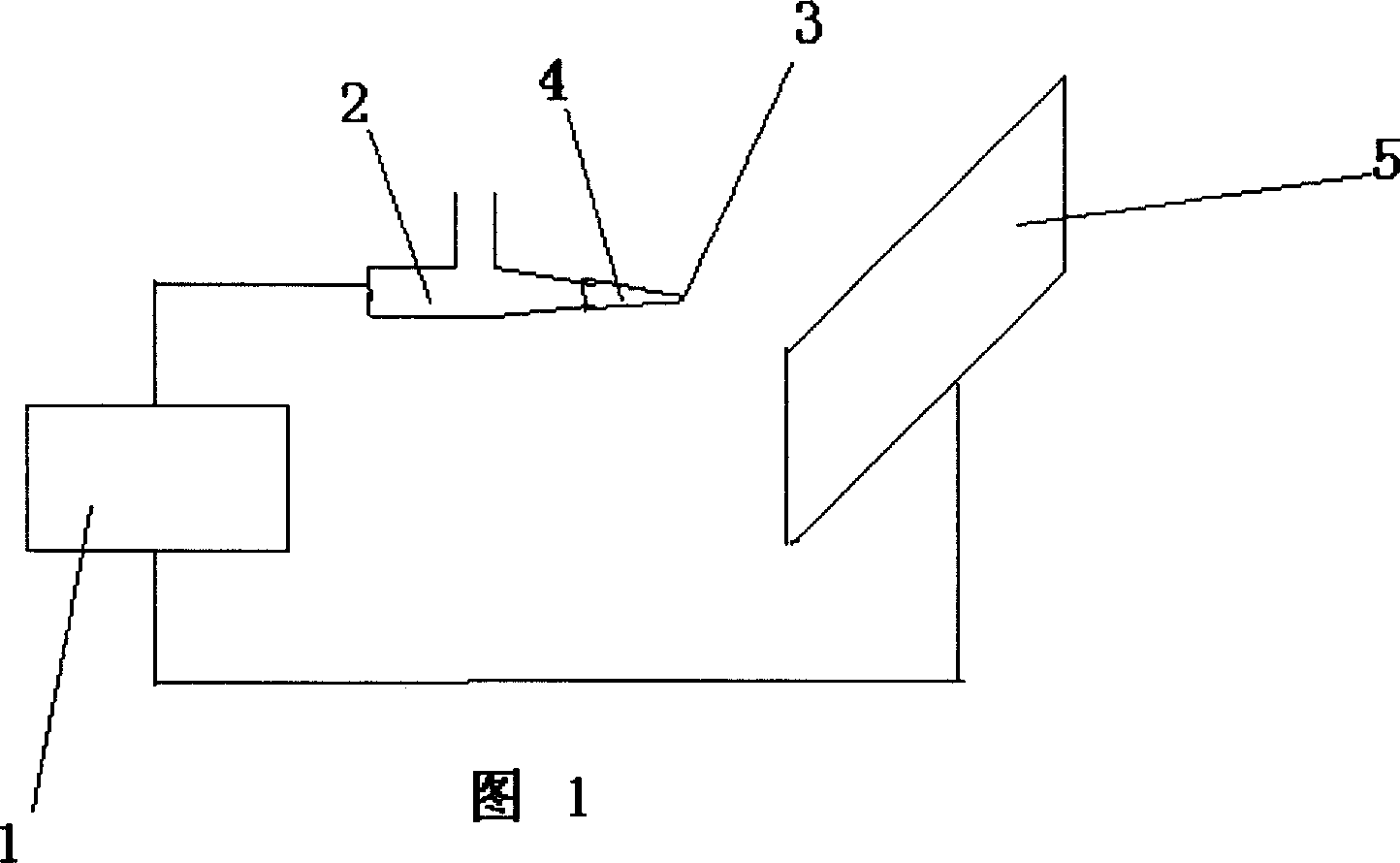

Microalgae concentrating and collecting method and device thereof

InactiveCN101693878ARelieve cloggingAchieve separationBioreactor/fermenter combinationsBiological substance pretreatmentsContinuous operationEnvironmental geology

A microalgae concentrating and collecting method can realize the separation of micoralgae and water through filtering water in microalgae liquid and exhausting and collecting water through a siphon. A microalgae concentrating and collecting device of the invention comprises a microalgae culture pool for culturing and collecting microalgae, a micro-strainer and a siphon, wherein the micro-strainer is arranged in the microalgae pool, and is provided with a micro-filter film which allows water to pass through for filtering water in the microalgae and collecting microalgae, one end of the siphon is a tee pipe, one port of the tee pipe is connected with the water outlet of the micro-strainer for self-suction of water to stop water cutoff, other port thereof is connected with a water collecting pool for discharging water in the microalgae culture pool into the water collecting pool through the siphon in the mode of self-flow, and the third port thereof is connected with an air / liquid back-flush inlet, and electromagnetic valves are respectively installed on the siphon which is connected with the water collecting pool and the air / liquid backflush inlet. The electromagnetic valves are used for controlling the back-flush, and realize the continuous operations of microalgae concentration and collection. The invention can realize the microalgae collection with ultra-low energy consumption.

Owner:青岛生物能源与过程研究所

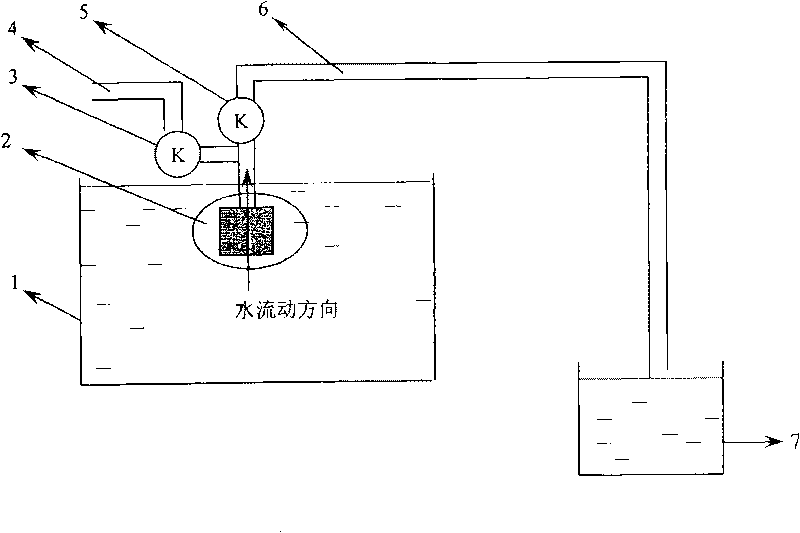

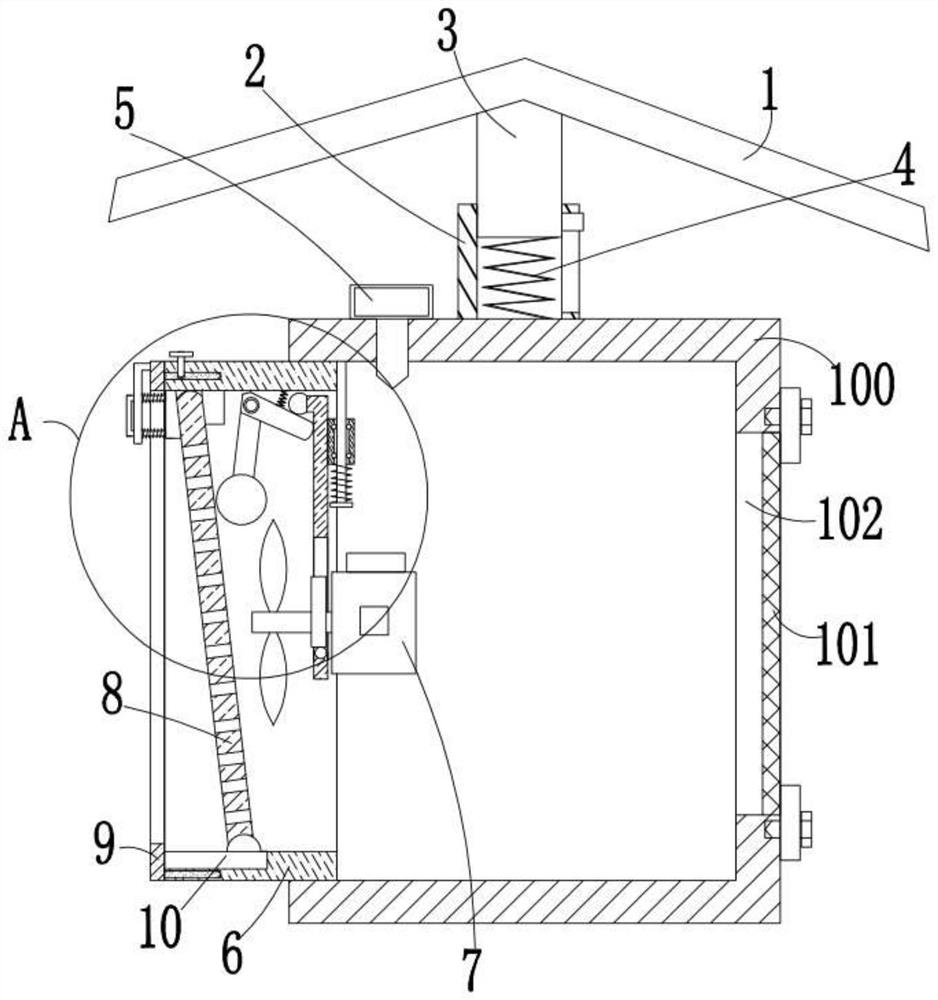

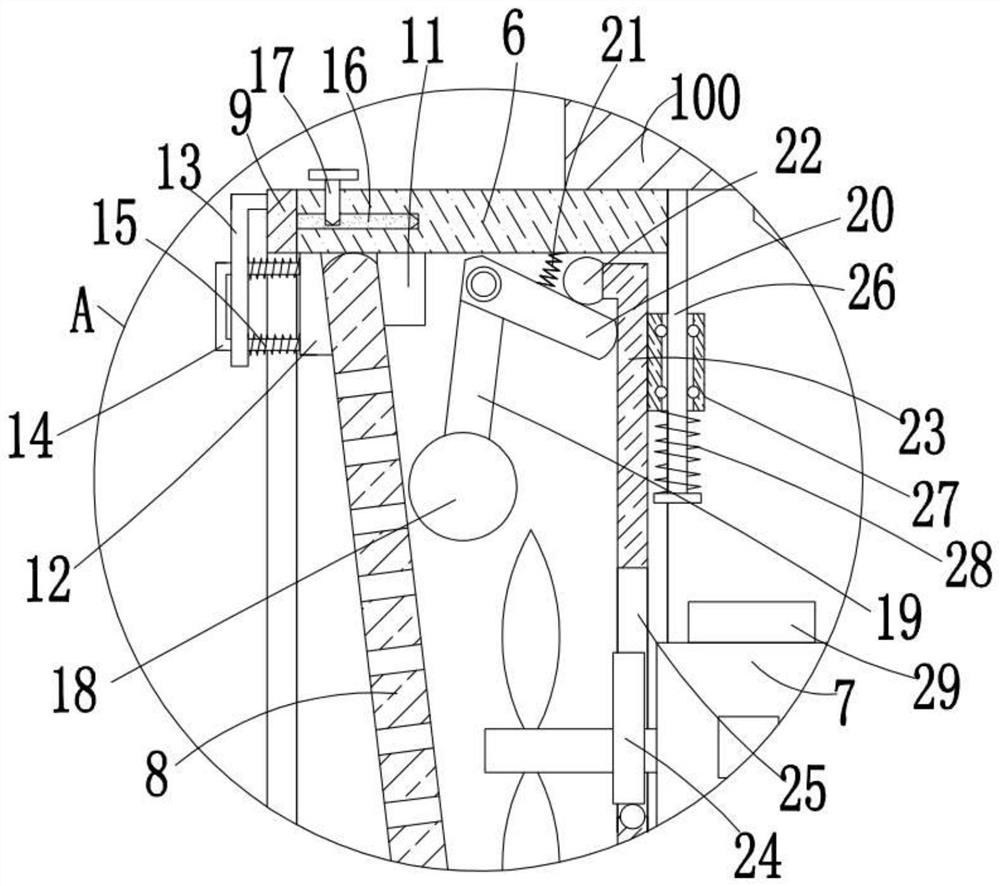

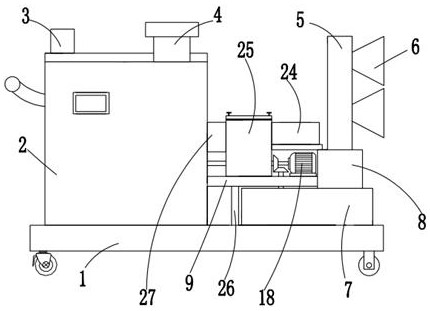

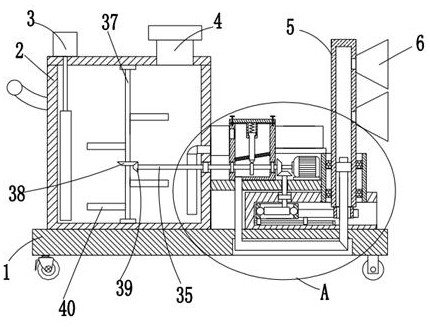

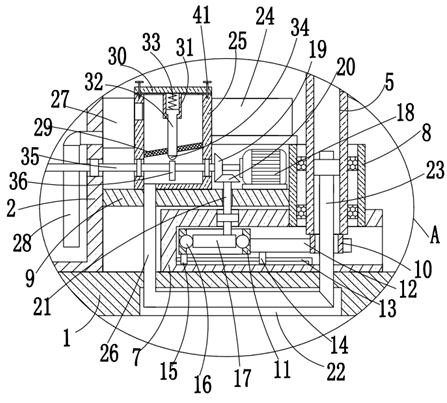

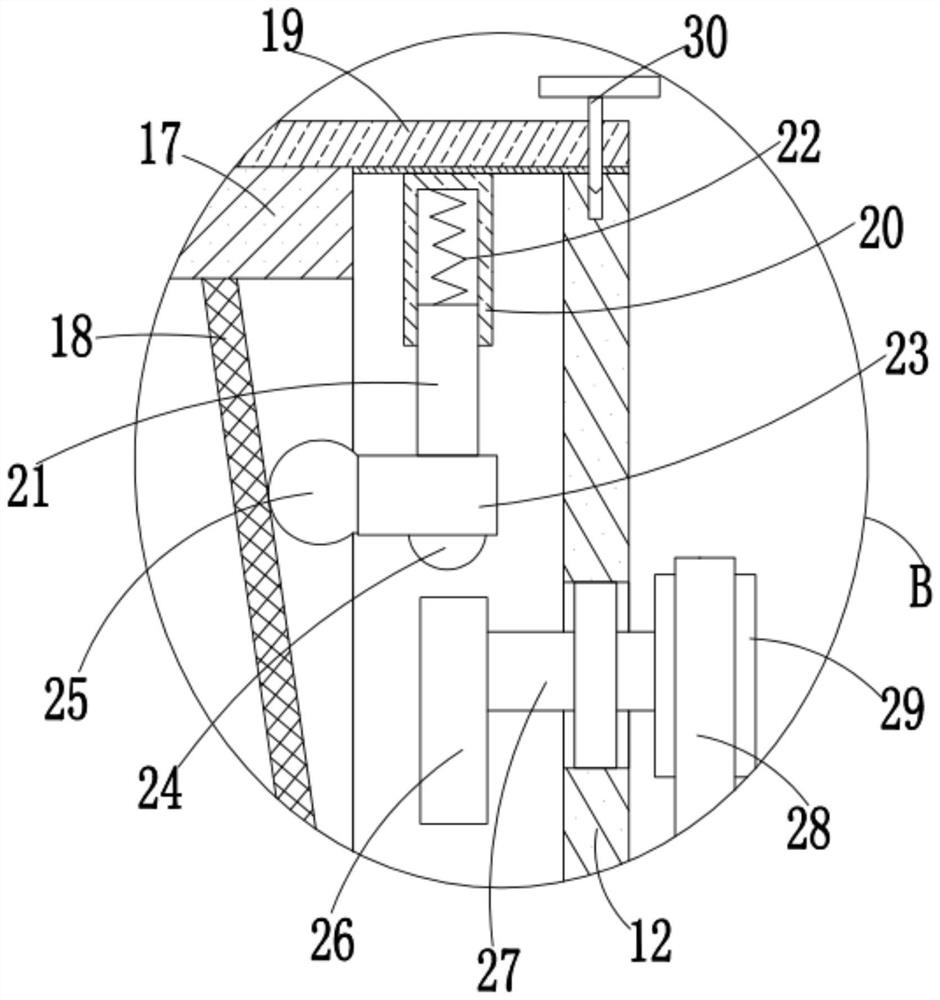

Electrical control cabinet

InactiveCN112616275AImprove vibrationEffective shake offDispersed particle filtrationTransportation and packagingElectrical controlDust particles

The invention discloses an electrical control cabinet which comprises an electrical control cabinet body. An air outlet hole is formed in the inner wall of the right side of the electrical control cabinet body, a dustproof net is movably arranged in the air outlet hole in a sleeved mode, the dustproof net is fixed to the right side of the electrical control cabinet body in a threaded mode, and a V-shaped protection plate is arranged above the electrical control cabinet body. The bottom of the V-shaped protection plate is fixedly provided with a fixed block, and the top of the electrical control cabinet body is fixedly provided with a rectangular pipe which sleeves the fixed block in a sliding manner. The electrical control cabinet is reasonable in design, the cooling fan can be automatically started to dissipate heat when the temperature in the electrical control cabinet body is higher than the preset temperature, the heat dissipation efficiency is improved, the dustproof plate can be conveniently and continuously vibrated left and right in the heat dissipation process, and dust particles attached to the right side of the dustproof plate can be effectively vibrated off in cooperation with the inclined arrangement mode of the dustproof plate; the blocking phenomenon is relieved, normal and stable entering of air is guaranteed, the dustproof plate can be taken out to be cleaned, and the use requirement is met.

Owner:张彦生

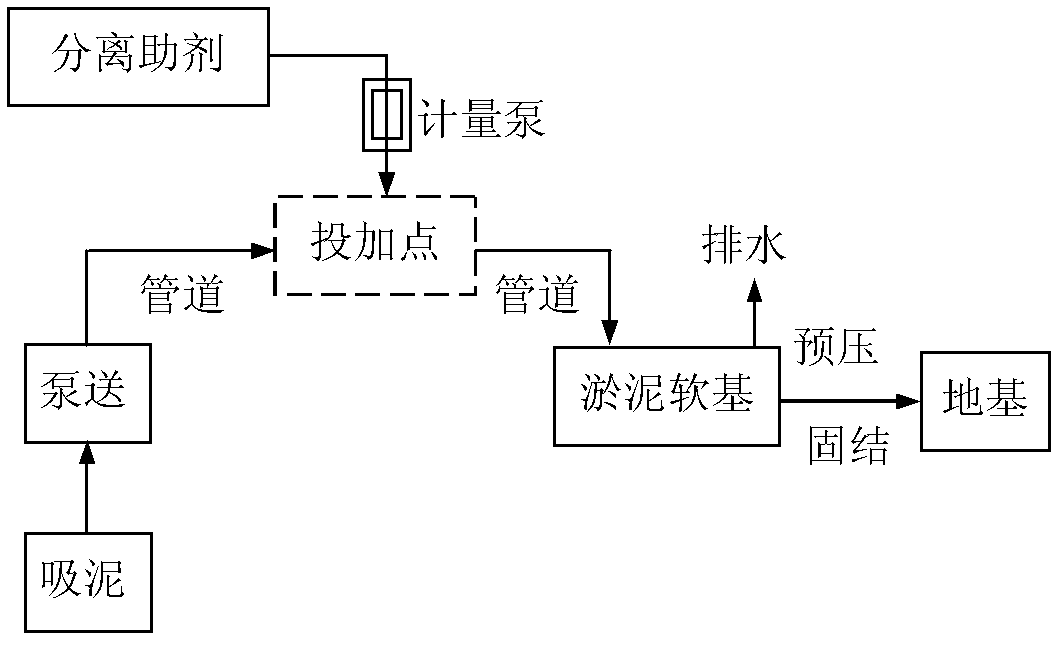

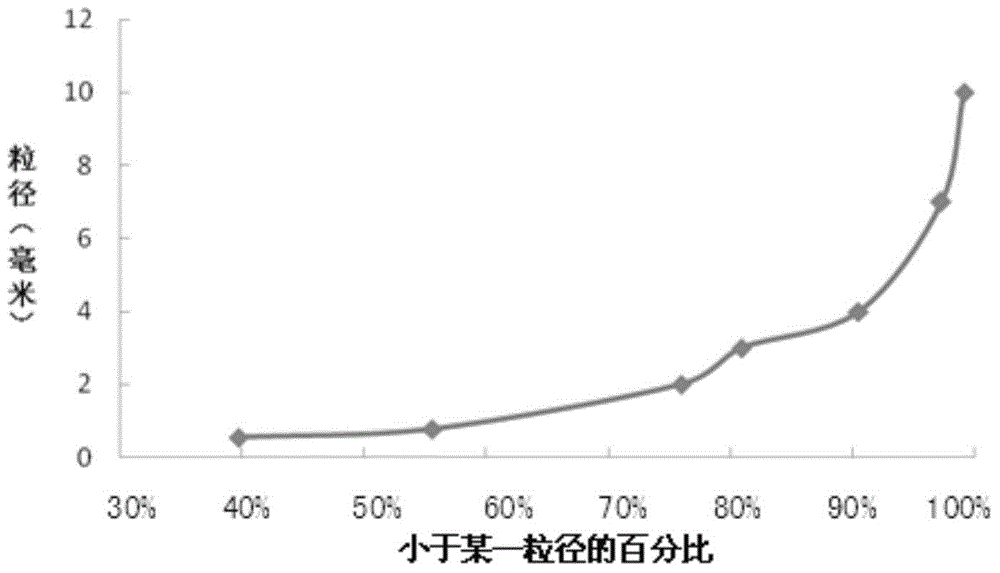

Dredger fill sludge dewatering and solidification method

InactiveCN102312416AFast separationWell mixedLand reclamationSoil preservationFlocculationHydraulic engineering

The invention discloses a dredger fill sludge dewatering and solidification method, belonging to the hydraulic dredger fill field of hydraulic engineering. The method mainly comprises the processes of sludge suction, pumping, separation adjuvant dosing, dewatering, pre-pressing solidification and separation adjuvant dosing. The implementation of the method comprises the steps of: firstly partitioning a dredger fill area, then dissolving and diluting separation adjuvant, arranging separation adjuvant dosing points on a dredger fill sludge delivery pipe, evenly mixing the separation adjuvant under the hydraulic agitation effect of delivered sludge in the pipe, spraying the mixed sludge into the dredger fill area, avoiding artificial disturbance as much as possible, finally drain supernatant clear water of the dredger fill area and using a pre-pressing method for further dewatering and solidification to form a foundation. By adopting the method, the separation adjuvant is evenly mixed with the dredger fill sludge under the hydraulic agitation effect during pipe delivery. Through the effects of collision, coagulation, flocculation, agglomeration and the like, the grain size of the dredger fill sludge is increased, the sludge-water separation speed is accelerated, the dewatering efficiency is improved, the sludge solidification effect is promoted and the engineering benefit is improved. The method has the advantages of that the method is economic, practical and environment-friendly.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

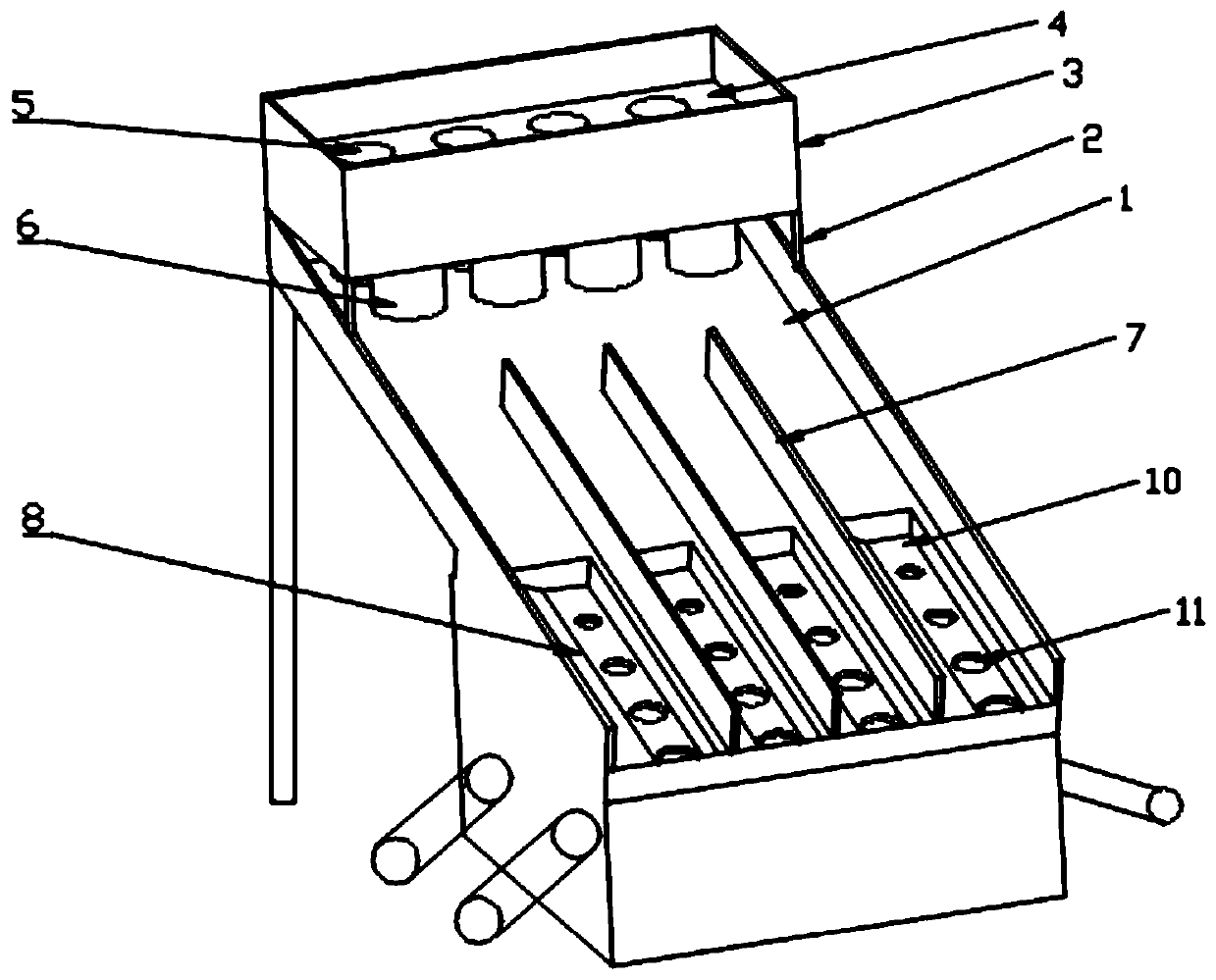

Fruit and vegetable screening machine

InactiveCN111589718ARelieve cloggingImprove flowNon-rotating vibration suppressionGradingEngineeringStructural engineering

The invention discloses a fruit and vegetable screening machine. The fruit and vegetable screening machine comprises a supporting frame, wherein a guide plate is arranged above the supporting frame; the top of the guide plate is provided with a feeding box; front and rear ends of the guide plate upwards extend to form baffle plates; a plurality of guide baffle plates are arranged between the baffle plates; a guide channel is formed between every two guide baffle plates; ends, away from the feeding box, of the guide baffle plates are provided with screening devices; each screening device comprises a screening board, a screening box, and a plurality of screening slots which are formed in the screening plate, wherein screening holes of different sizes are formed in the screening slots, the screening holes are sequentially arranged to the bottom ends of the screening slots from big to small in a longitudinal direction of the screening slots, the bottom ends of the screening slots are provided with screening baffle plates, a plurality of transfer slots are formed in the screening box, each transfer slot corresponds to multiple screening holes of the same dimension, transfer tubes are arranged between the screening holes and the transfer slots, notches are formed in side walls of joints of the transfer tubes and the screening holes, and distance adjustable devices are inserted into the notches. The fruit and vegetable screening machine disclosed by the invention is convenient for relieving a blockage phenomenon while quantity of fruits and vegetables is great.

Owner:安徽富牧通生物科技有限公司

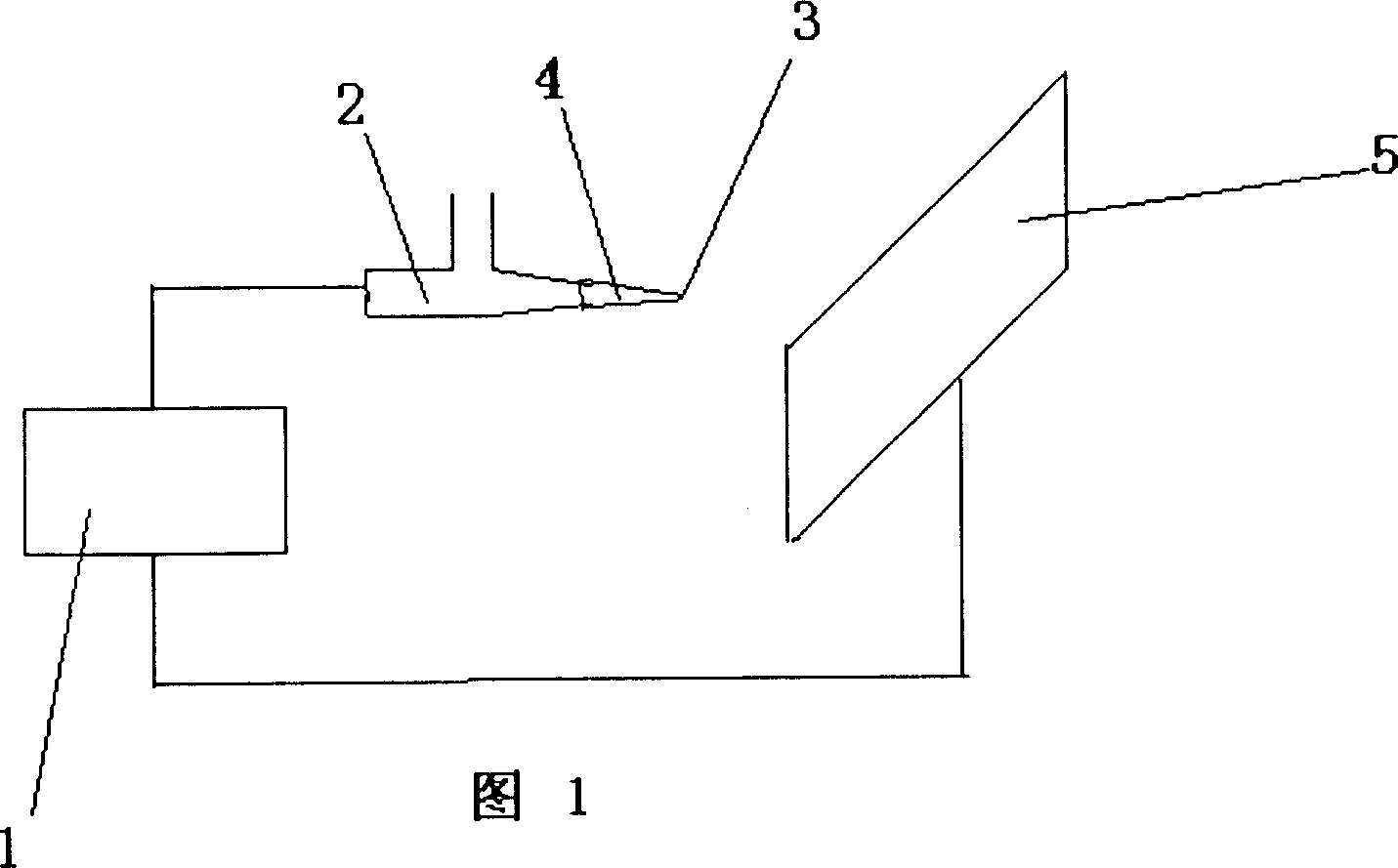

Agricultural intelligent irrigation equipment

InactiveCN112189548AAvoid idlingRealize the purpose of swing sprayingWatering devicesSpraying apparatusAgricultural scienceAgricultural engineering

The invention provides agricultural intelligent irrigation equipment, and aims to solve the problems that existing irrigation equipment can inconveniently achieve automatic swing water spraying, waterstirring and vibration filtering. According to the technical scheme, the agricultural intelligent irrigation equipment comprises a base, two universal wheels are rotatably mounted at one side of thebottom of the base, and two walking wheels are rotatably mounted at the other side of the bottom of the base; and a water tank is fixedly connected to the top of the base, a water level sensor is fixedly installed at the top of the water tank, the detection end of the water level sensor extends into the water tank, one side of the top of the water tank communicates with and is fixedly provided with a water inlet pipe, the water inlet pipe is sleeved with a pipe cover in a threaded manner, and a vertical pipe with the top provided with a plugging mechanism is arranged above the base. The agricultural intelligent irrigation equipment is reasonable in design, the functions of automatic swing spraying, vibration filtering and stirring can be conveniently and integrally formed through single driving, the spraying range is enlarged, the filtering stability is improved, the blockage risk of a spray head is reduced, the phenomenon that liquid medicines are precipitated due to long-time standing is avoided, time and labor are saved, and use is facilitated.

Owner:黄佳创

Smoke waste heat utilization system

ActiveCN105135468AMeet the working temperatureWorking temperature is suitableCombustion processIndirect carbon-dioxide mitigationAir preheaterPlate heat exchanger

The invention discloses a smoke waste heat utilization system. The system comprises an air preheater, wherein the air preheater is connected with a high-temperature smoke cooler, the high-temperature smoke cooler is connected with a dust removal device, the dust removal device is connected with a desulfurizing device, a low-temperature smoke cooler is further connected between the dust removal device and the desulfurizing device, a heating medium channel of the high-temperature smoke cooler and a heating medium channel of the low-temperature smoke cooler are both connected with a heat exchange device used for heating air supplied to the air preheater, and the heat exchange device is a heat-pipe type heat exchanger. The system can recover smoke waste heat between the air preheater and the dust removal device, can also recover smoke waste heat between the dust removal device and the desulfurizing device and can transfer recovered heat to the air supplied to the air preheater through the heat exchange device, then the heat is recovered to a thermal system of a boiler, and the utilization efficiency of the smoke waste heat of the boiler is greatly improved.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +3

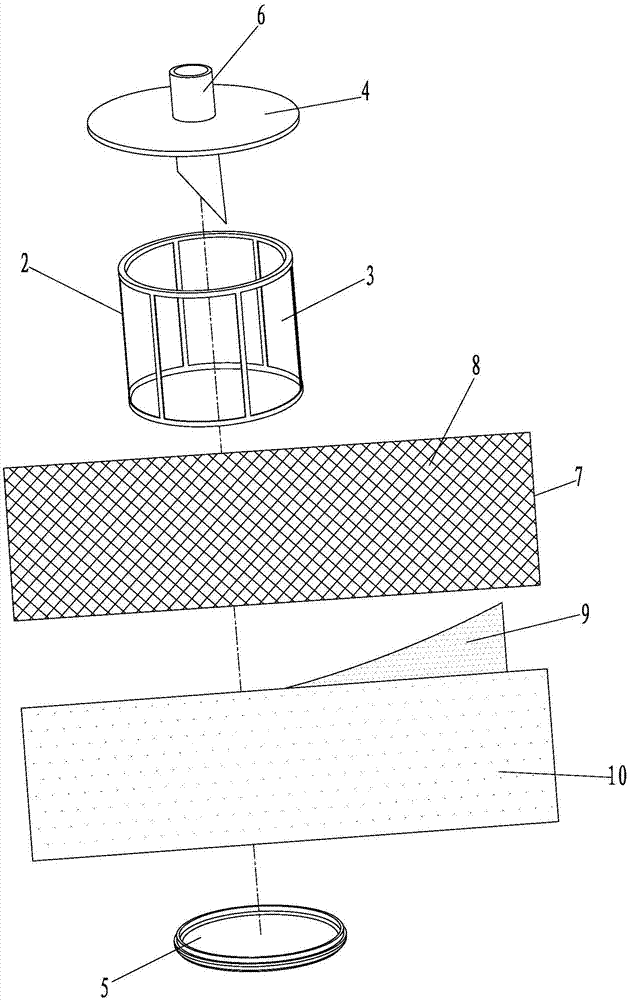

Precise liquid filtering apparatus

InactiveCN107158781AHigh hole densityUniform pore sizeMoving filtering element filtersPorous membranePollutant

The invention discloses a precise liquid filtering apparatus. The apparatus comprises a rotatable filter cylinder device, the rotatable filter cylinder device is provided with an ultrasonic wave or air explosion cleaning device, the filter cylinder device is connected with a liquid inlet tube, a liquid outlet tube and a waste discharging tube, the filter cylinder device communicates with a filter stock solution through the liquid inlet tube, the liquid inlet tube is provided with a circulating pump, the water outlet tube is provided with a vacuum pump, a filtered filtrate is pumped out by the vacuum pump, and the waste discharge tube communicates with the filter stock solution. The apparatus adopts a nuclear porous membrane or an effective compound of the nuclear porous membrane and other filter materials as a filter material reserves the filtration characteristics of a traditional filter material and the fine filtration effect of the nuclear porous membrane, and the apparatus adopting a cross flow filtration manner keeps pollutants on the surface of the filter membrane at a small level, alleviates the obstruction of filter pores, improves the filtering efficiency and prolongs the service life of the filter membrane.

Owner:上海谷奇核孔膜科技股份有限公司

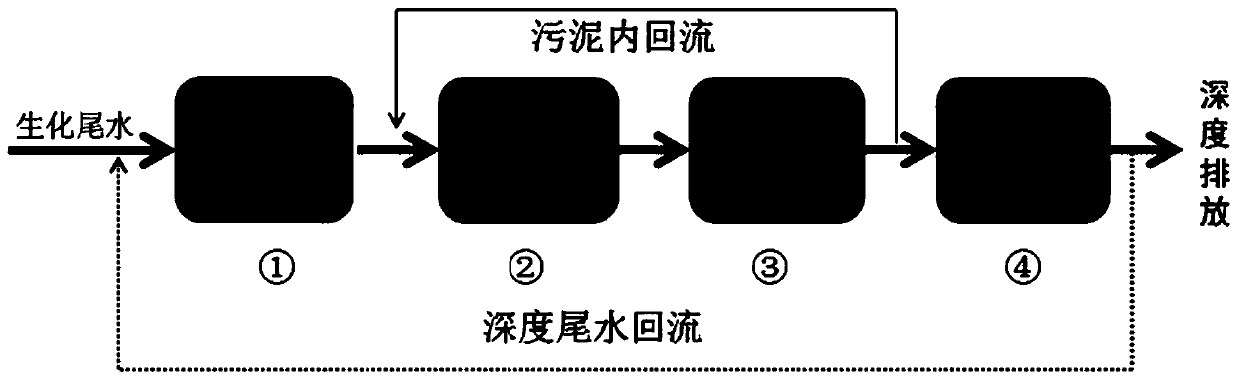

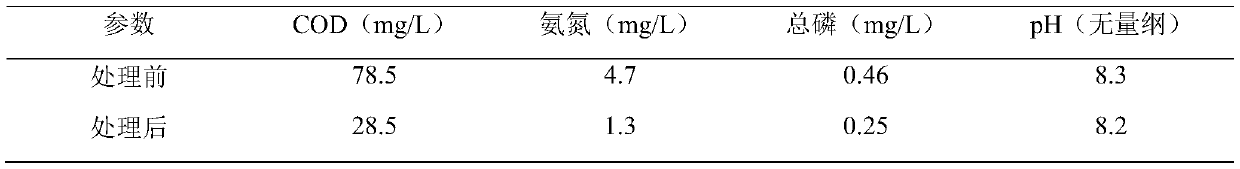

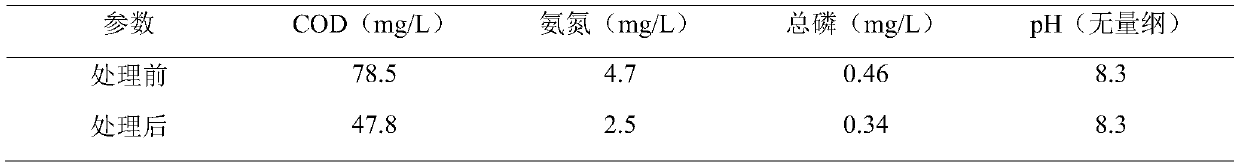

Quasi-earth-surface IV-type water standard deep treatment catalyst system, treatment method and device

InactiveCN110054363AImprove the water output indexReduce concentrationMultistage water/sewage treatmentTreatment involving sedimentationMass ratioEarth surface

The invention discloses a quasi-earth-surface IV-type water standard deep treatment catalyst system, a treatment method and device, and belongs to the field of the environmental protection. The systemcomprises serially connected front end pre-reduction catalyst and secondary deep purification catalyst containing zero-valent iron / zero-valent copper / active carbon compositions. A mass ratio of iron / carbon in the front end pre-reduction catalyst is (2.5-7):1, and a mass ratio of iron / carbon in the secondary deep purification catalyst is (0.8-1.25):1. The method for treating biochemical tail waterby using the above catalyst system is performed through the following treatment units successively: 1) a front end pre-reduction unit; 2) a biological deep oxidation unit: further reducing COD, ammonia nitrogen and phosphorus of the system; 3) a deep sedimentation unit: removing suspended solids SS; and 4) a secondary deep purification unit. The secondary sedimentation tail water treated by the method is capable of removing toxicity of toxic and harmful organic pollutants, and deeply degrading and removing organic matters. The method is an efficient feasible quasi-earth-surface IV-type waterdeep treatment method.

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST

Production method of low-carbon and medium-carbon steel

ActiveCN102962411AImproved pourability of molten steelAlleviation of nozzle clogging in continuous castingOxideSulfur content

The invention provides a production method of medium-low- carbon and medium-carbon steel. The method comprises the following steps of controlling sulfur content in molten iron to be less than 0.015 percent by weight; primarily refining the molten iron to form molten steel, and discharging the molten steel into a ladle; adding 1.5kg to 4.5kg of deoxidizing agent per ton steel with aluminum content being not greater than 2.0 percent by weight into the ladle according to the oxygen content of the molten steel at a primary refining terminal point during the process for tapping steel of 20 percent to 30 percent by weight; adding 1.0 to 3.5kg ladle slag modifier per ton steel into the ladle so as to control the sum of the ferric oxide (FneO) content and the manganese oxide (MnO) content to be less than or equal to 10 percent by weight in the process for tapping 80 to 90 percent by weight of steel; blowing argon to refine the molten steel; and adopting a continuous casting technique to pour the molten steel so as to acquire a casting blank. Due to the adoption of the method, the refining of a low-frequency (LF) ladle furnace is not needed, the calcium treatment is not needed, the castability of the molten steel is effectively improved, the water gapnozzle blockage phenomenon is alleviated, the turndish continuous casting furnace number of low-aluminum-content low-carbon and medium-carbon steel in the continuous casting process of low-aluminum-content medium-low carbon steel is more than 10, and a purpose of economical production can be realized.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM +1

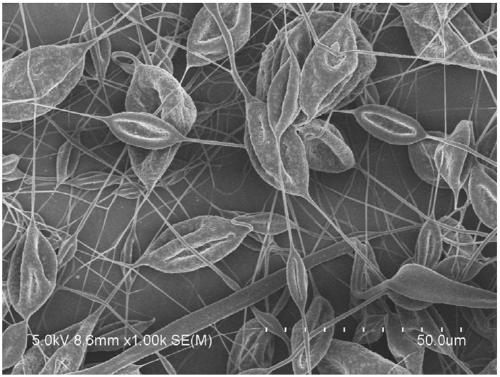

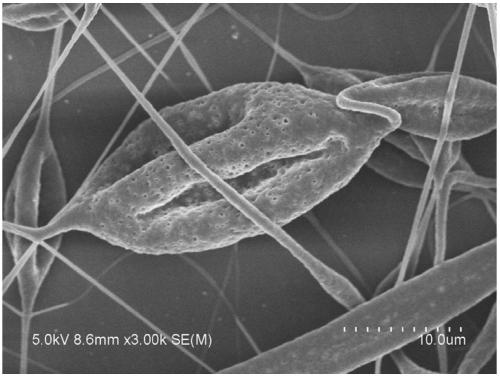

Spinning stoste of cellulose derivative and its preparation and use

InactiveCN1710158AUniform diameterQuality improvementMonocomponent cellulose artificial filamentElectrospinningSolvent

The spinning stoste is prepared using CAB, CAP, HEC and HPC as raw material, acetic acid and formic acid as solvent, adding surfactant additive through the processes of fully stirring, standing by and de-foaming. The said stoste is used for electrostatic spinning to make super-thin fiber with diameter of 200-1000nm which has not only strong adsorb-ability, filtration-ability but also good biological compatibility and biological degradability and excellent ultraviolet-resisting and cold-resisting characteristics. Advantages: released nozzle blocked situation while conducting electrostatic spinning, reduced knob generation, uniform diameter of the super-thin fiber and increased production yield.

Owner:SUZHOU UNIV

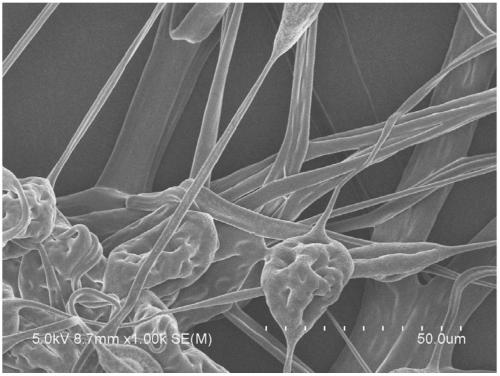

High-molecular nano-fiber net structure binding material and preparation method thereof

ActiveCN109135592AImprove conductivityFully stretchedElectro-spinningFilm/foil adhesives without carriersFiberPolymer science

The invention discloses a high-molecular nano-fiber net structure binding material and preparation method thereof. The method includes the steps: firstly, dissolving EVA (ethylene-vinyl acetate copolymer) resin in solvents in a stirring manner to prepare 4-10% of EVA electrostatic spinning fluid; secondly, performing electrostatic spinning by the electrostatic spinning fluid to prepare an EVA nano-fiber membrane which can serve as a binding material. According to the binding material, bonded materials can be effectively and uniformly bound, the diameter of a nano-fiber is small, specific surface area is large, distribution is uniform, so that bonding sites of the material are small, and bonding areas are uniformly distributed, so that uniform compactness and strong performance of the material are greatly improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

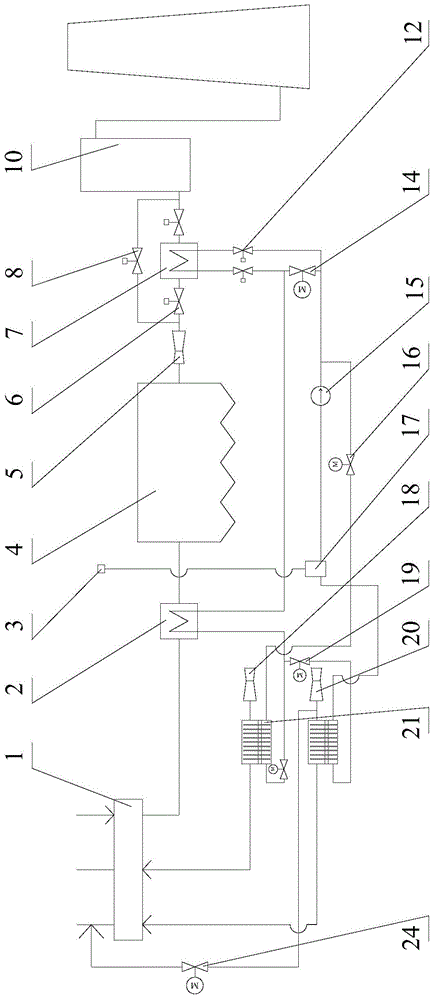

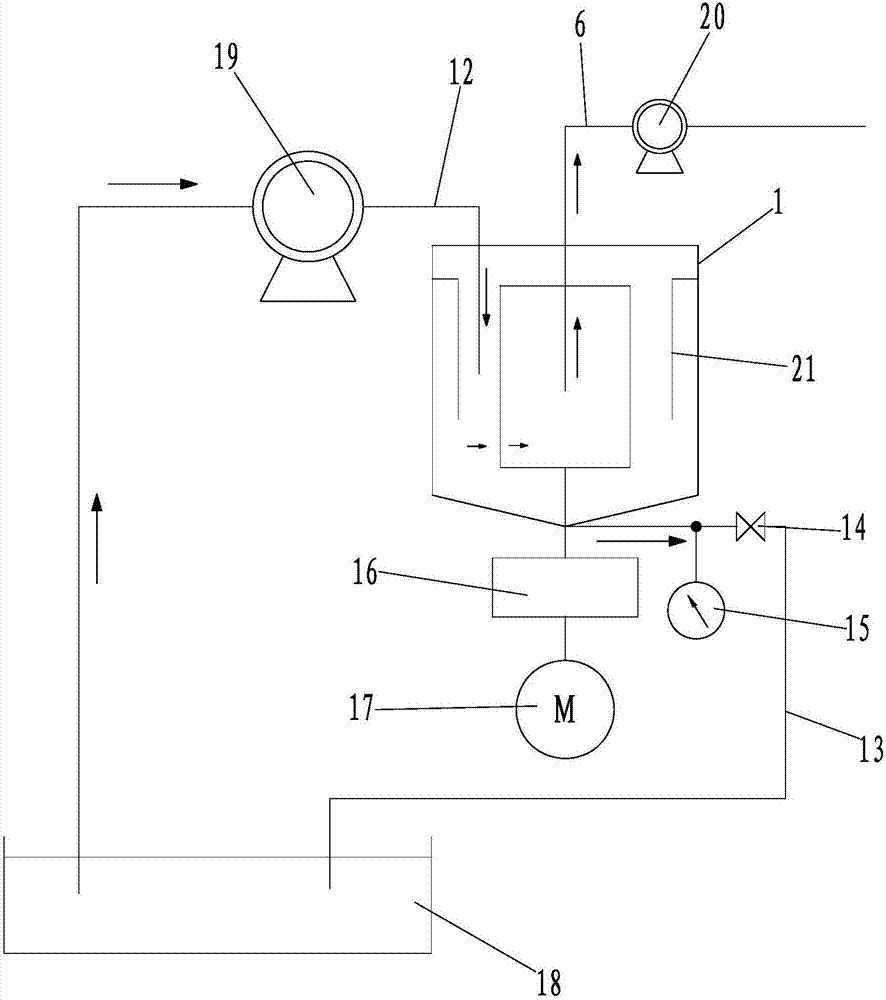

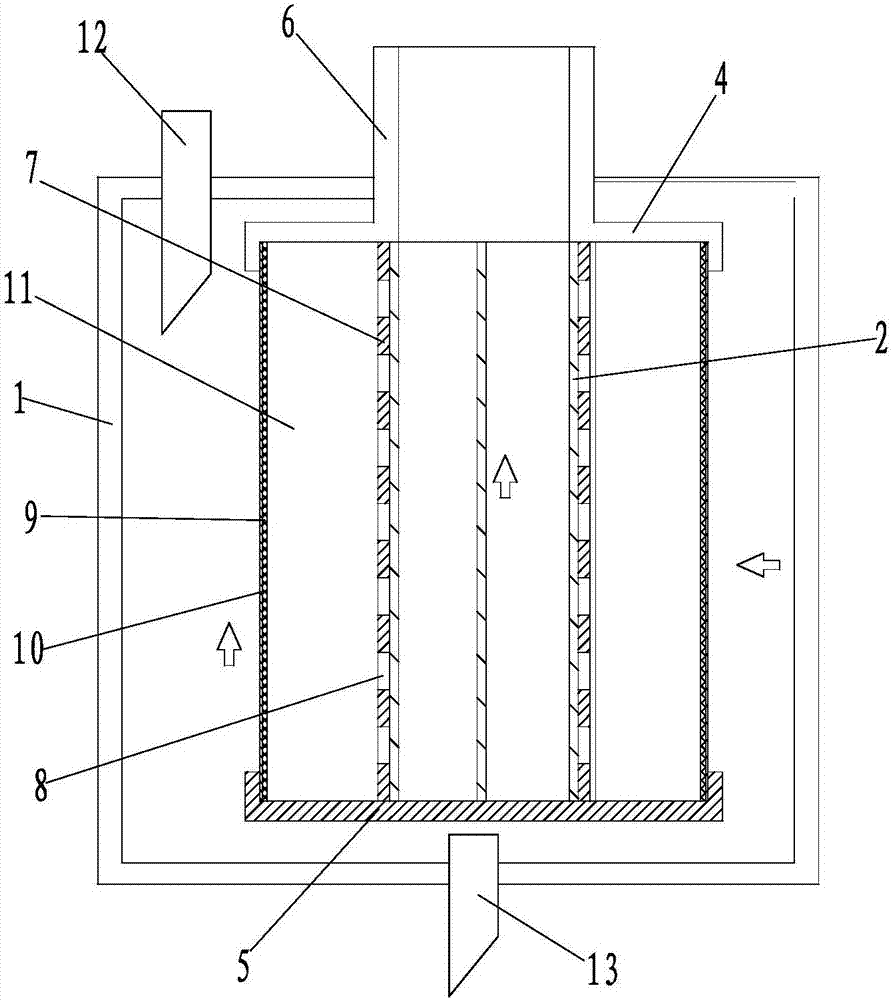

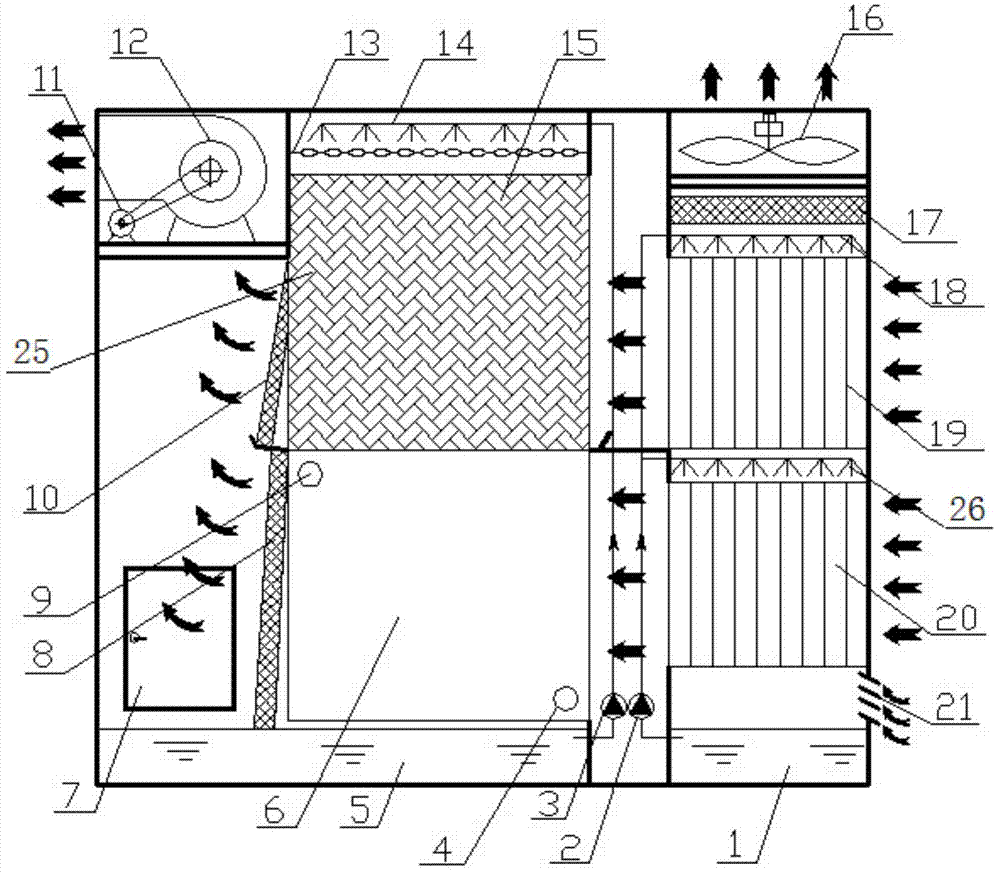

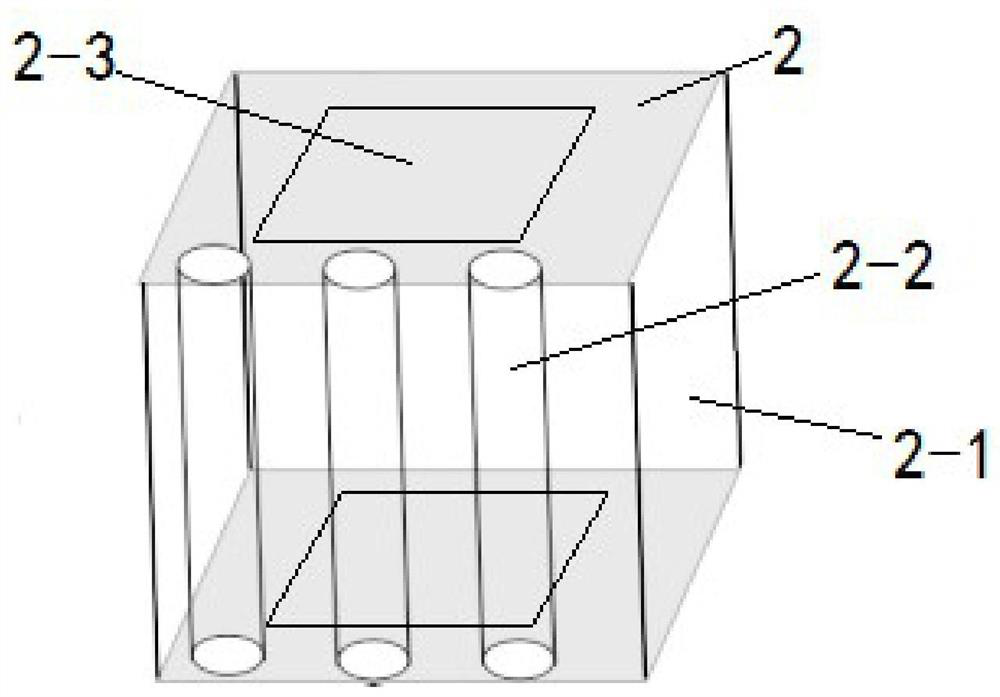

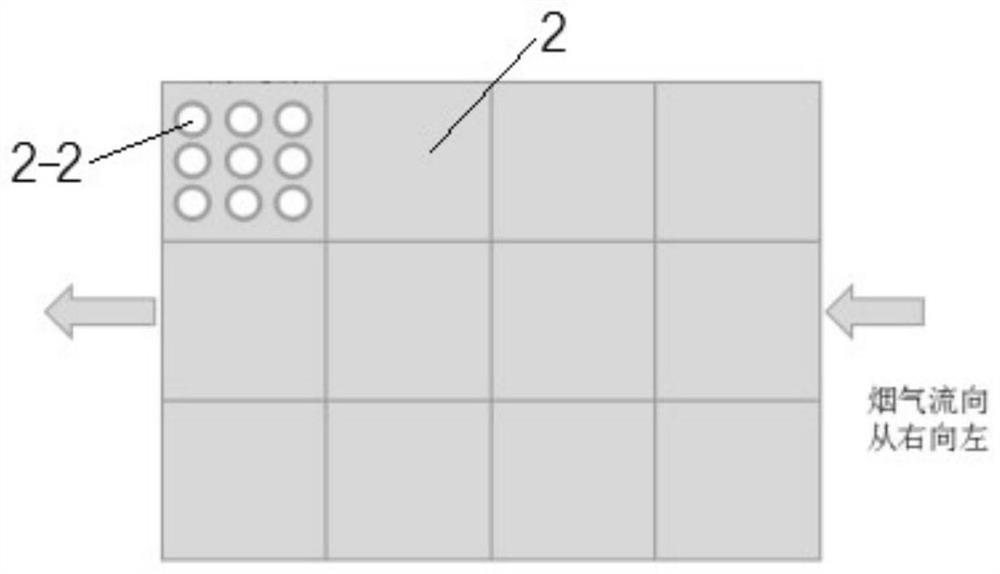

Closed type vertical tube indirect evaporation cooling high-temperature cool water unit

ActiveCN103574996ASmall sizeRelieve cloggingMechanical apparatusEvaporators/condensersVertical tubeEvaporative cooler

The invention discloses a closed type vertical tube indirect evaporation cooling high-temperature cool water unit which comprises a vertical tube type indirect evaporation cooler a and a vertical tube type indirect evaporation cooler b. The vertical tube type indirect evaporation cooler a and the vertical tube type indirect evaporation cooler b are arranged in a unit shell body from top to bottom. The lower portion of the vertical tube indirect evaporation cooler is provided with a secondary air inlet. A direct evaporation cooler, a water baffle b and a centrifugal fan are sequentially arranged behind the vertical tube type indirect evaporation cooler a in the air inlet direction. A closed heat exchanger and a water baffle a are sequentially arranged behind the vertical tube type indirect evaporation cooler in the air inlet direction. A water baffle c and an axial flow fan are sequentially arranged on the upper portion of the vertical type indirect evaporation cooler a from bottom to top. According to the closed type vertical tube indirect evaporation cooling high-temperature cool water unit, the vertical tube type indirect evaporation coolers are arranged from top to bottom, the direct evaporation cooler and the closed type heat exchanger are arranged from top to bottom, the centrifugal fan and the axial flow fan are used for respectively controlling primary air and secondary air, and the cool water unit is jointly composed, so that water quality of the cool water unit and water outlet temperature are ensured, and the heat exchange efficiency of the unit is improved to a certain degree.

Owner:新疆华奕新能源科技有限公司

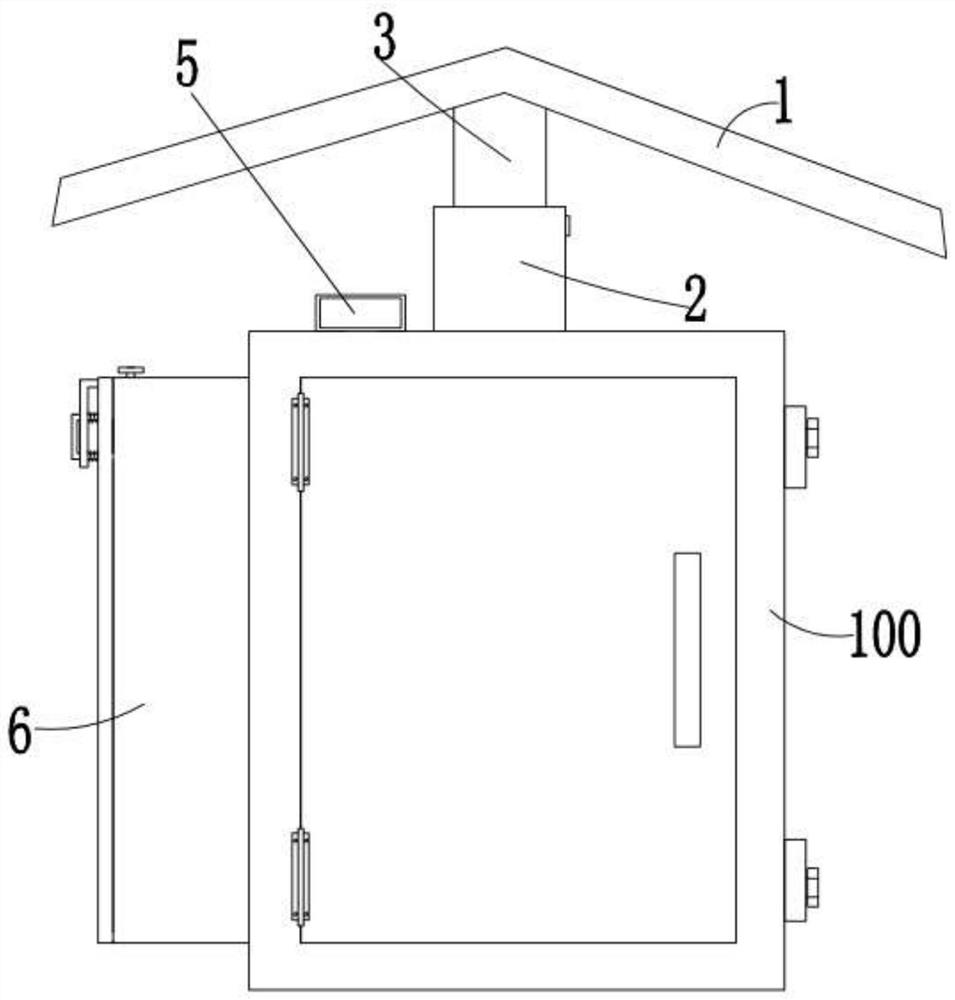

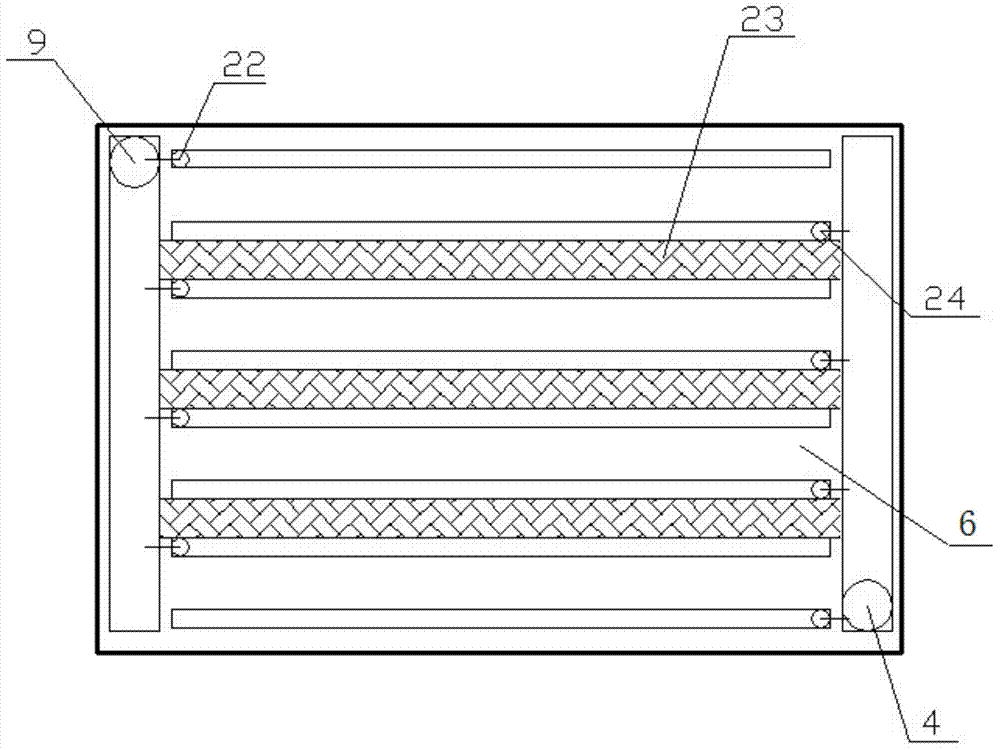

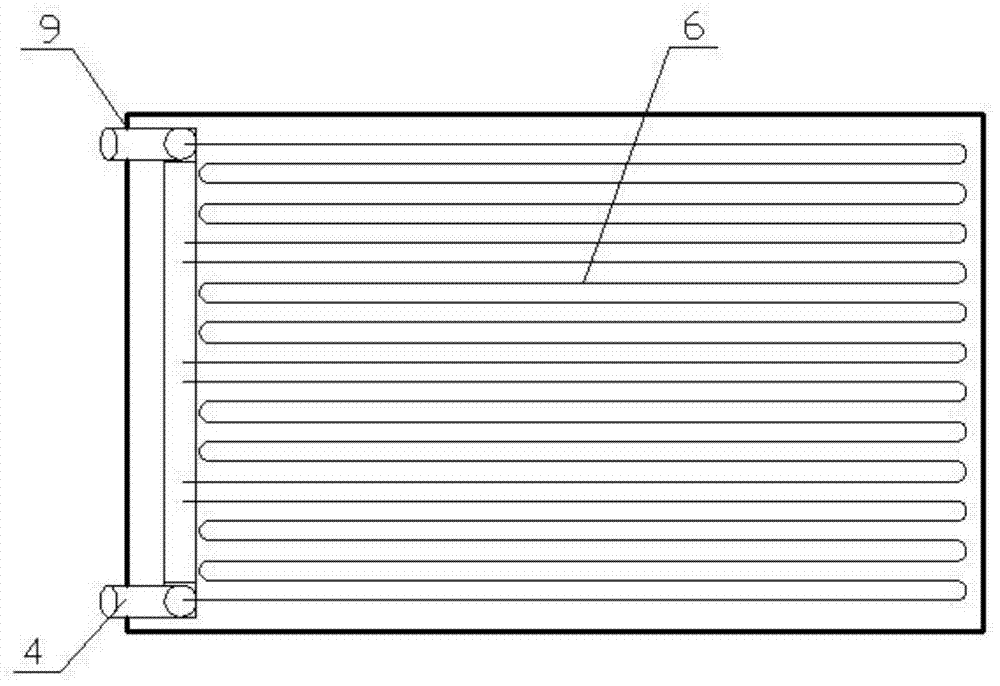

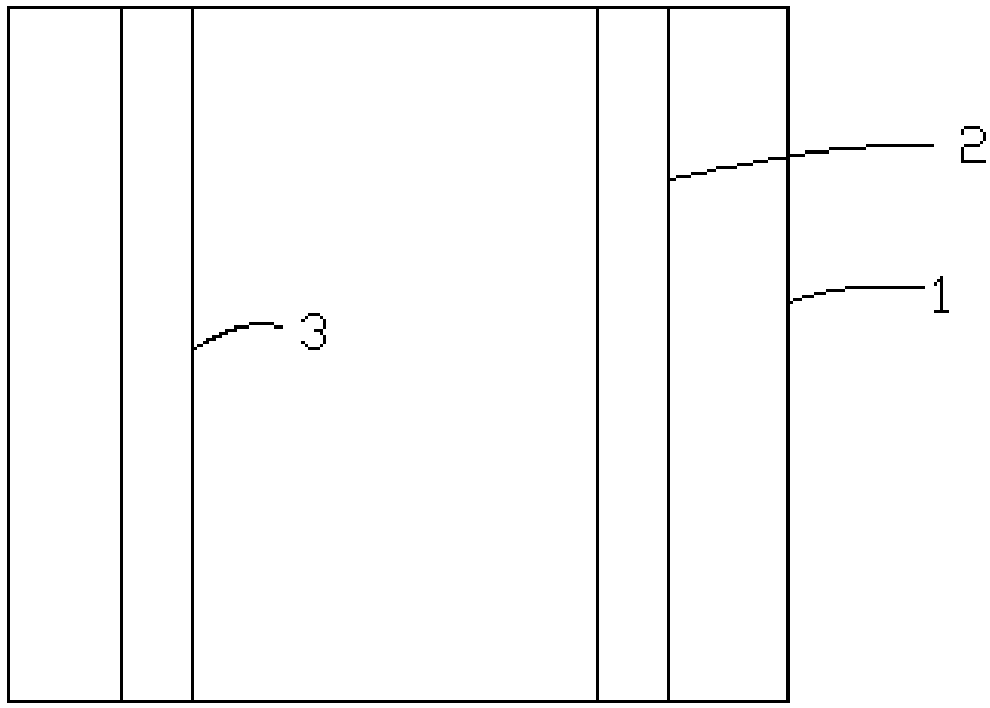

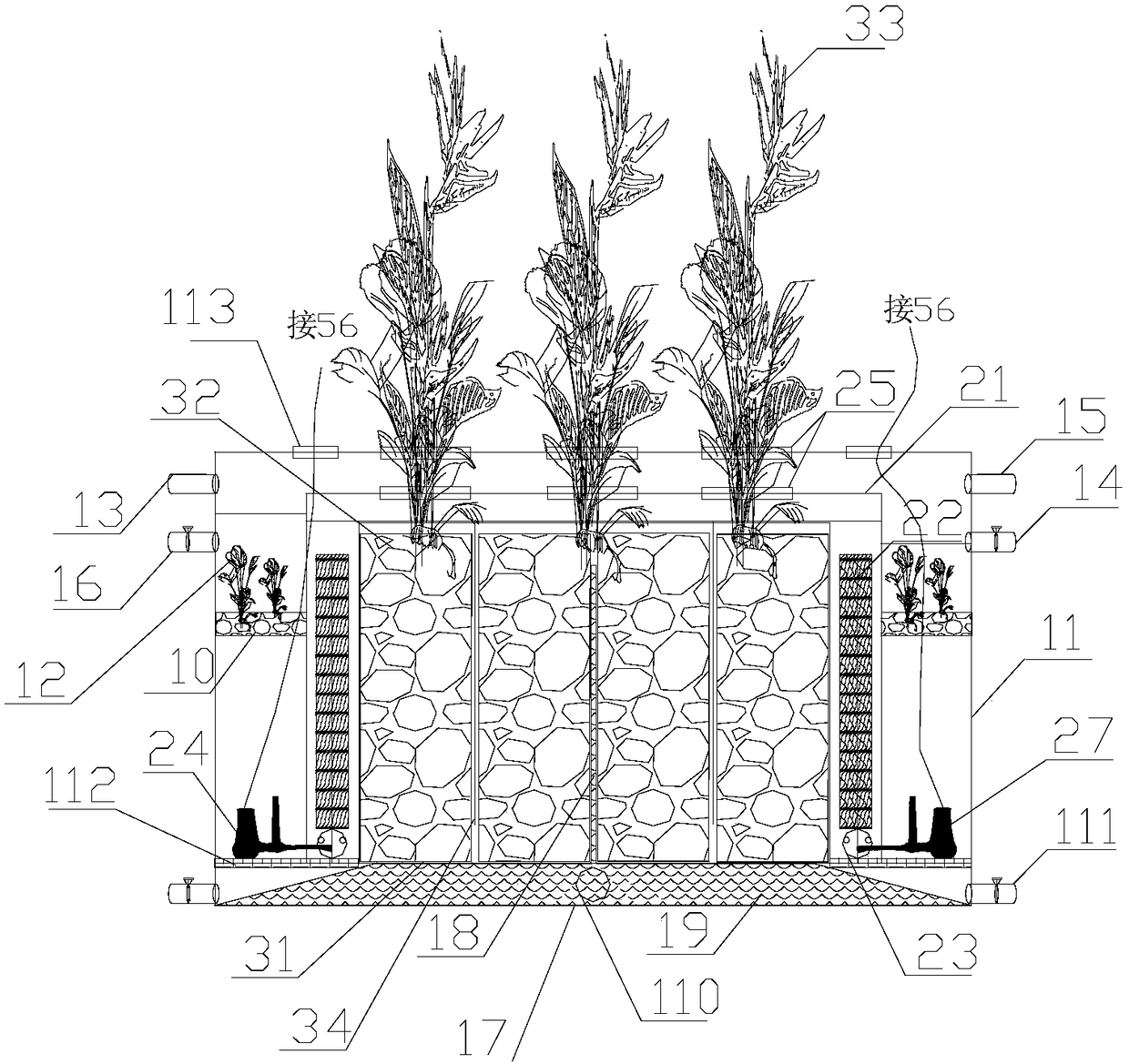

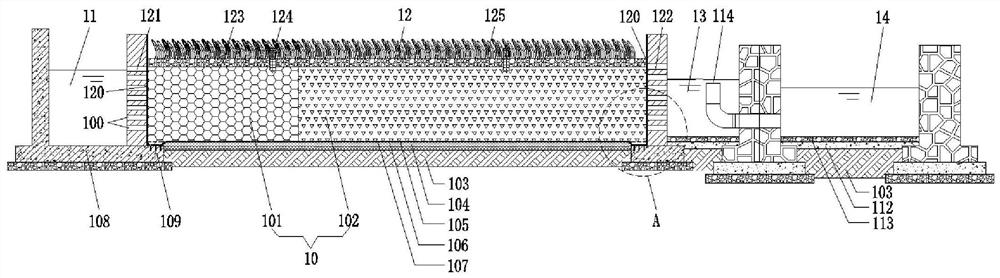

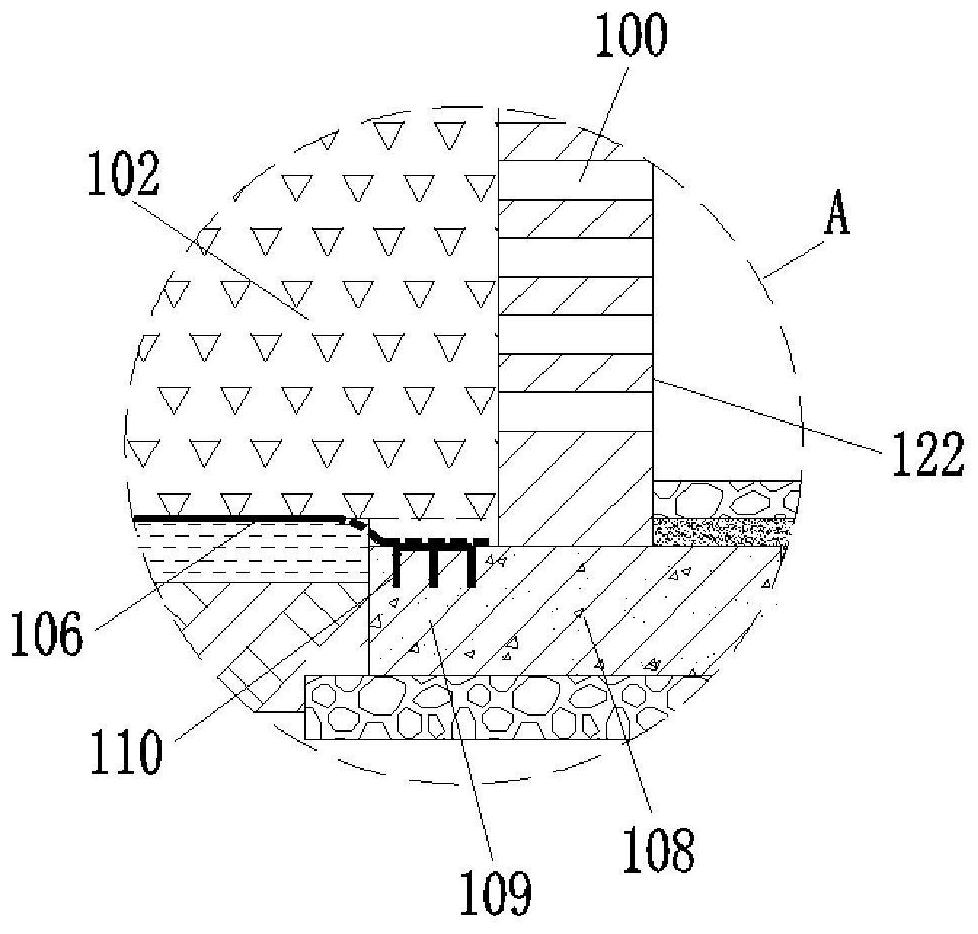

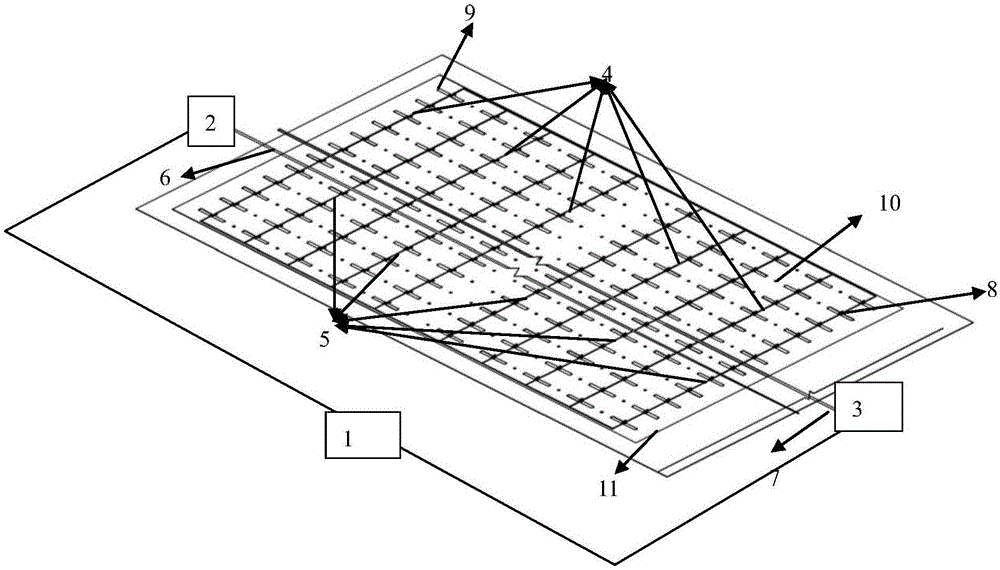

Intelligent-control type antiblockage artificial wetland rain and sewage enhanced disposal system and method based on solar power

ActiveCN108558124AFight cloggingReduce influent SS concentrationWater treatment parameter controlTreatment using aerobic processesConstructed wetlandSolar power

The invention discloses an intelligent-control type antiblockage artificial wetland rain and sewage enhanced disposal system and method based on solar power. The system includes a solar power supply intelligent control system and a sewage disposal main system; the sewage disposal main system consists of an artificial wetland system, an aeration filler system and a filtering, sand settling and heating system which are arranged from inside to outside in sequence. The filtering, sand settling and heating system includes a first box body, a bidirectional water distribution pipeline used for waterdistribution in a filtering area and a heating component; the area between the first box body and the aeration filler system is separated into the filtering area on the upper portion and a preheatingsand settling area on the lower portion, and the preheating sand settling area is communicated with the interior of the aeration filler system. The heating component is used for heating sewage in theartificial wetland system in the preheating sand settling area, and the solar power supply intelligent control system supplies power to the heating component and controls the heating component. By means of the intelligent-control type antiblockage artificial wetland rain and sewage enhanced disposal system and method, energy consumption for running of artificial wetlands is reduced, blockage is prevented, the hydraulic retention time is shortened, the effect is enhanced at the same time, and a great running effect under low temperature is ensured.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

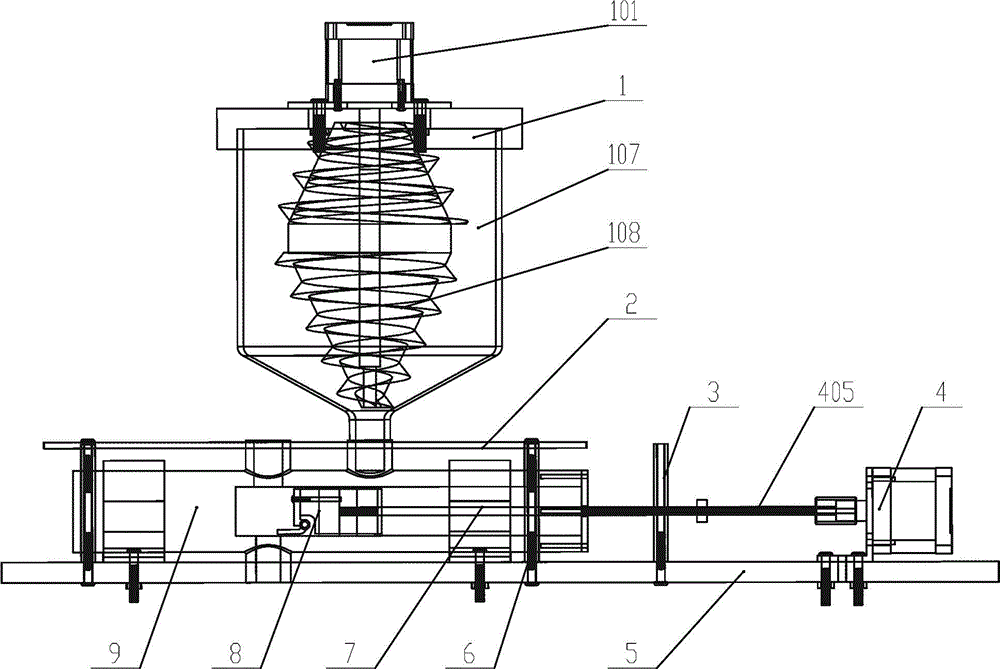

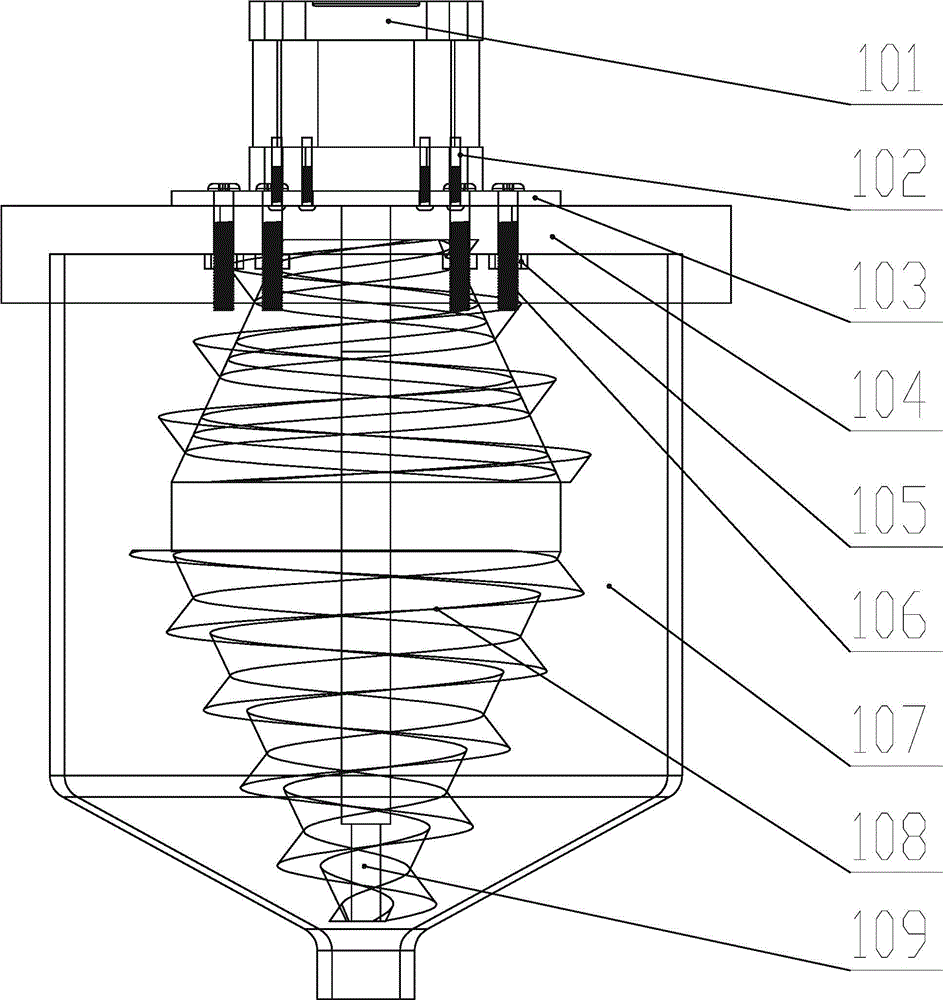

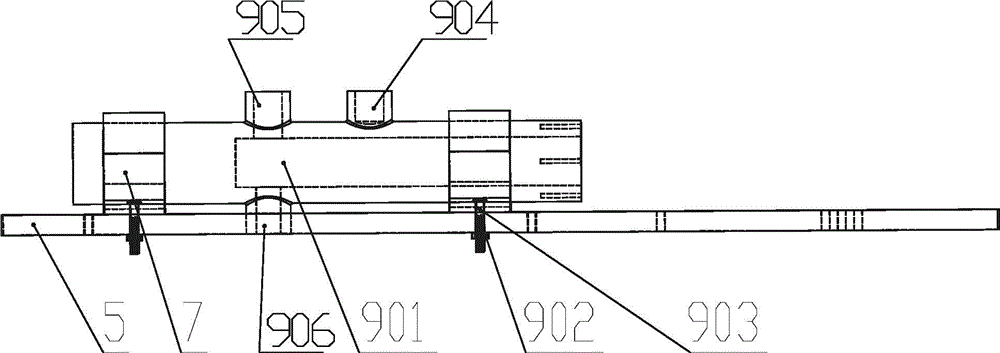

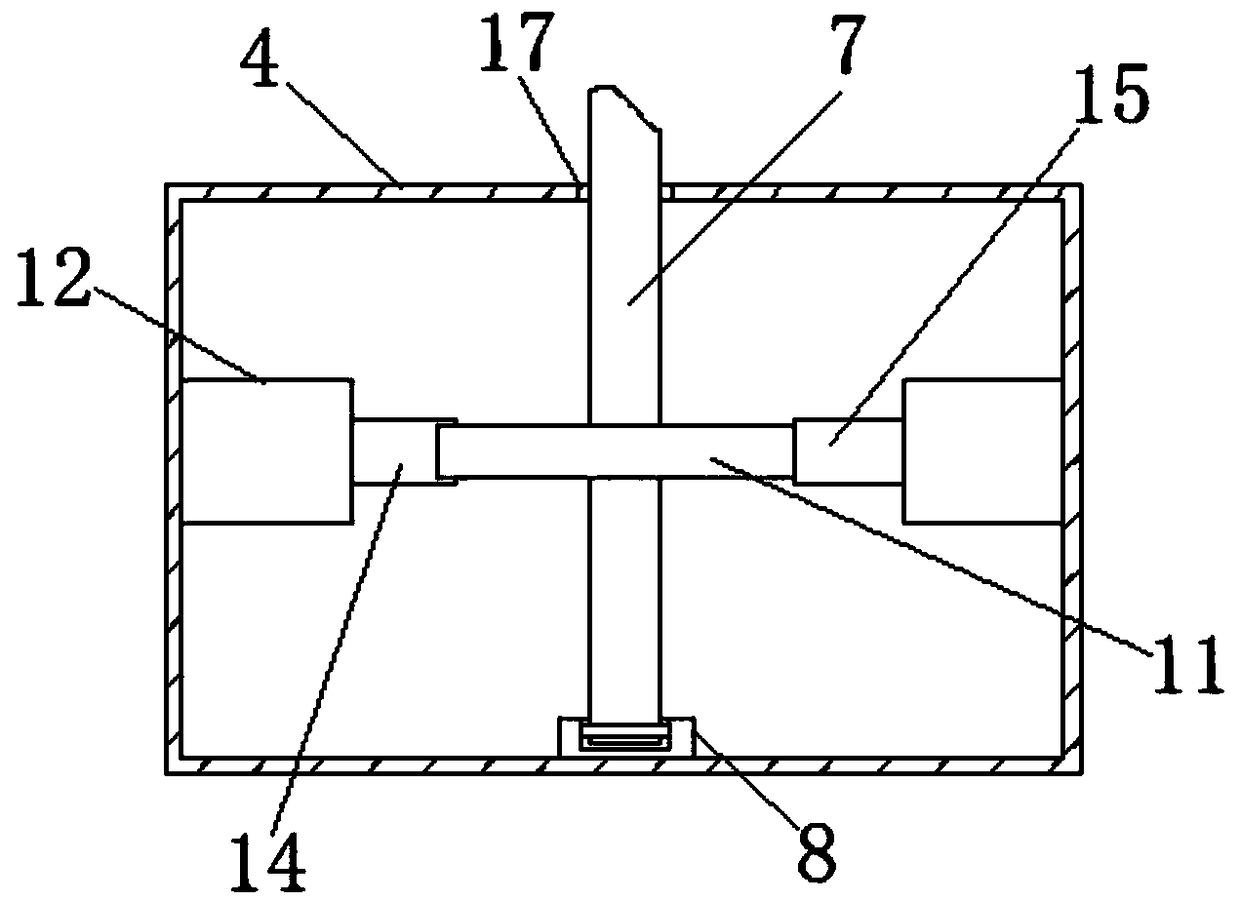

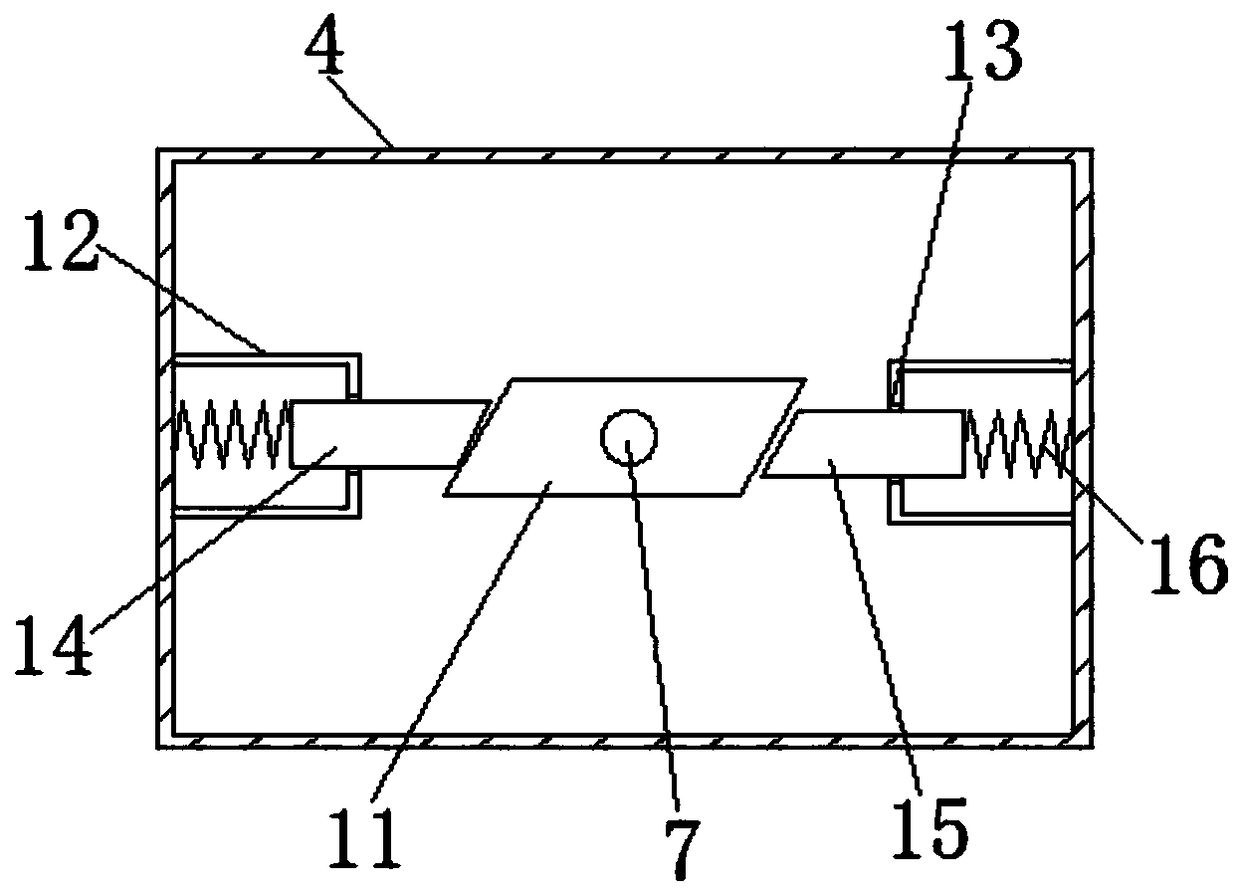

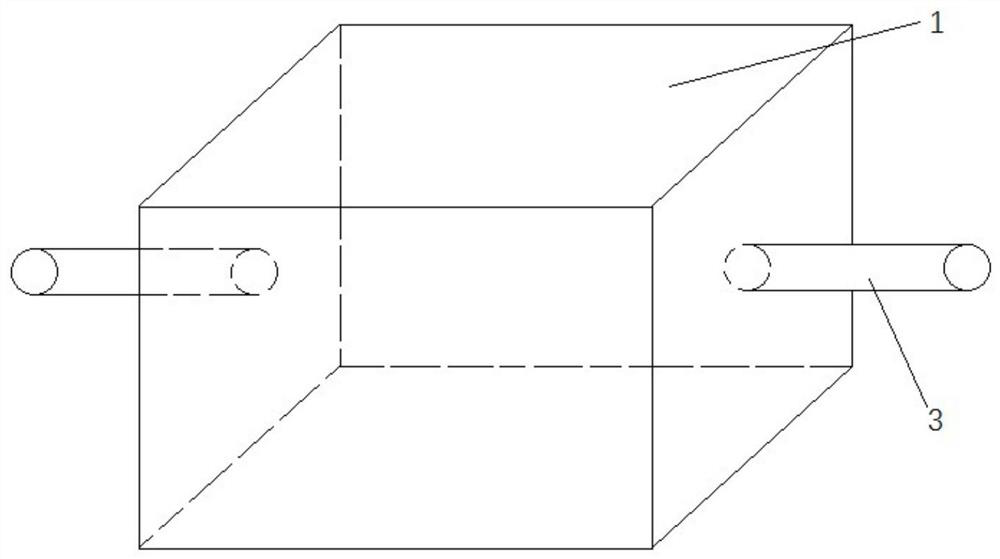

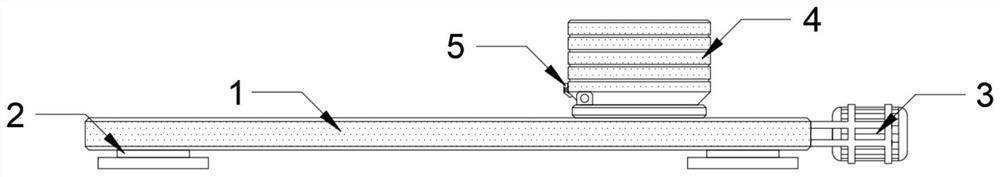

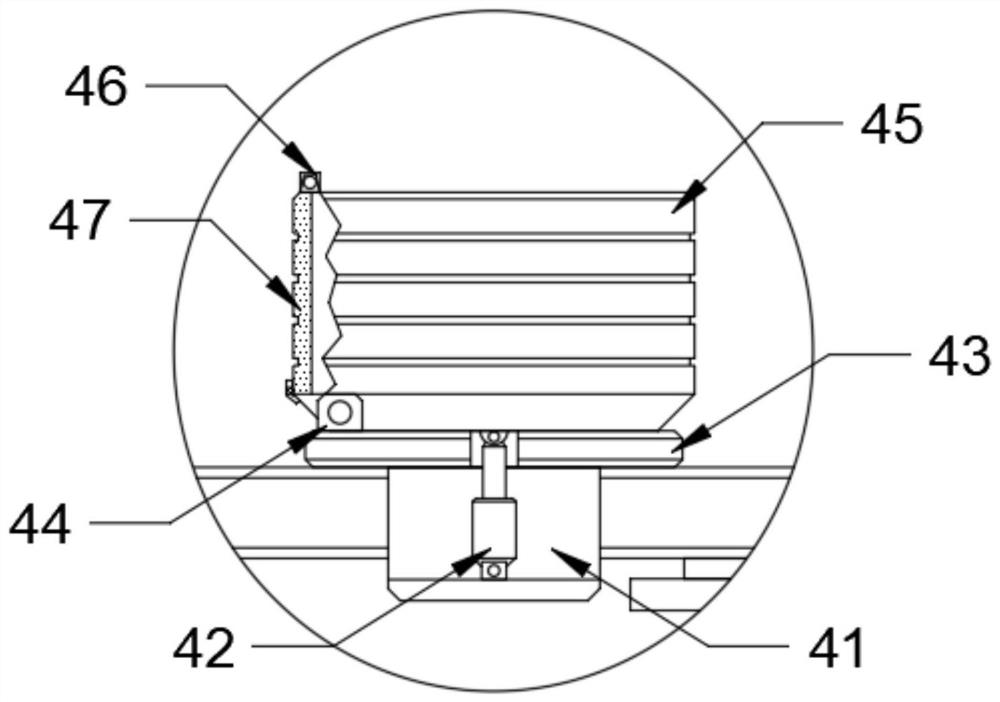

Functional gradient powder material feeding mechanism and operation method

ActiveCN105347042AMeet the requirements of conveying accuracyRelieve cloggingBulk conveyorsInterference fitAir pump

The invention discloses a functional gradient powder material feeding mechanism and an operation method. Two cylinder body fixing pieces are fixedly connected with the left side of a bottom board device of the mechanism through bolts; the cylinder body fixing pieces are used for fixing a cylinder body assembly to the bottom board device of the mechanism in an interference fit manner; a left limiting copper post is fixedly connected with the middle of the bottom board device of the mechanism; a transmission mechanism is fixedly connected with the right side of the bottom board device of the mechanism through a bolt; the transmission mechanism is connected with a sliding block in a cylinder through a threaded rod; the upper portion of the cylinder body assembly is connected with an upper supporting board in a clearance fit manner; the cylinder body assembly is fixedly connected between a supporting board and the bottom board device through four copper posts; a powder material storage bin is mounted at the upper portion of the supporting board; and the powder material storage bin is composed of a first stepping motor, a powder material barrel and a stirrer. The powder feeding mechanism can convey functional gradient powder materials accurately through back and forth movement of the transmission mechanism, intermittent rotation of the stirrer and air injection of an air pump.

Owner:CHINA THREE GORGES UNIV

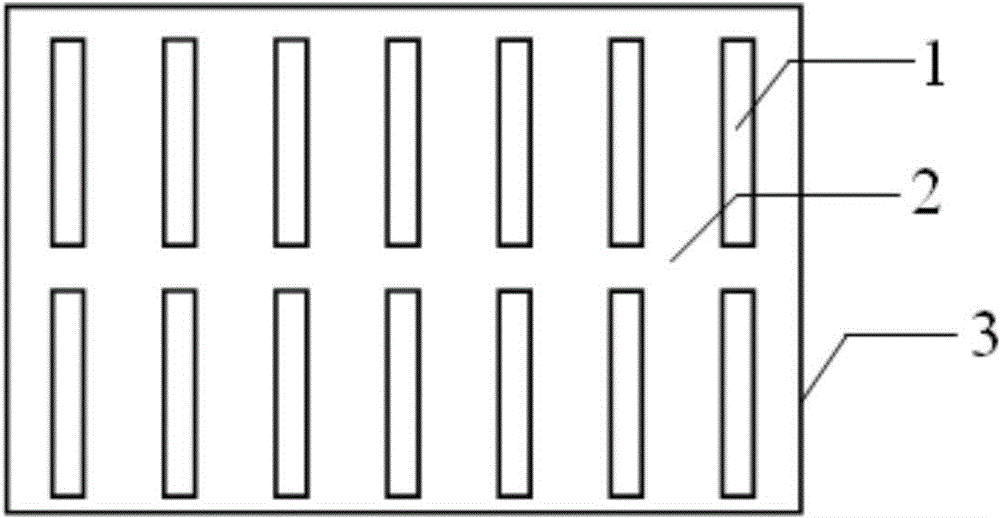

Dust removal filter screen plate for waste heat recovery boiler

InactiveCN104606979ALarge amount of waterRelieve cloggingDispersed particle filtrationSlagPulp and paper industry

The invention relates to a dust removal filter screen plate for a waste heat recovery boiler. The dust removal filter screen plate comprises a screen plate outer frame and a screen plate body arranged in the screen plate outer frame, wherein strip-shaped holes are uniformly formed in the screen plate body. After passing through the filter screen of three slag baths, most of the remainder coal slags are irregularly granular and liable to block small holes in the screen plate; after the open holes in the dust removal filter screen plate for the waste heat recovery boiler disclosed by the invention are changed into the strip-shaped holes, the blocking phenomenon can be effectively alleviated, in addition, the water yield of dust removal water can also be increased and the maintenance period can be prolonged.

Owner:SHANGHAI DAZHONG XIANGYUAN POWER SUPPLY

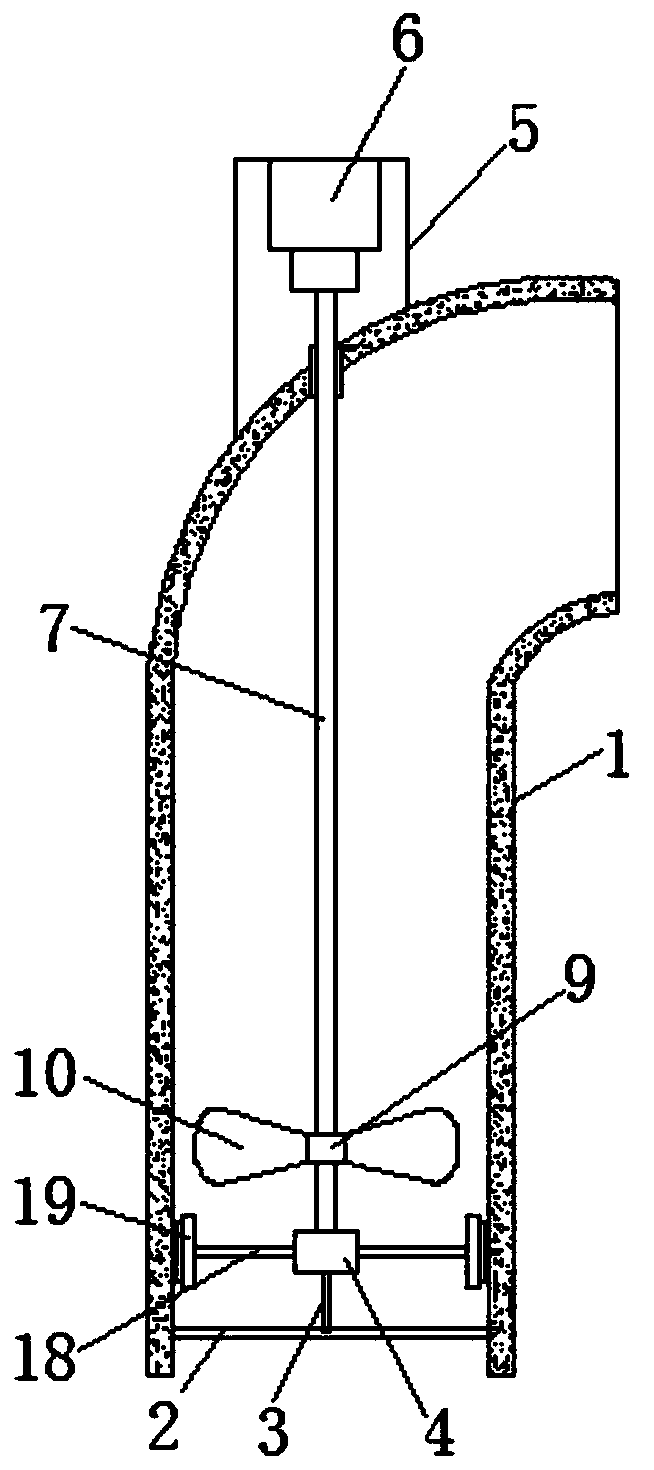

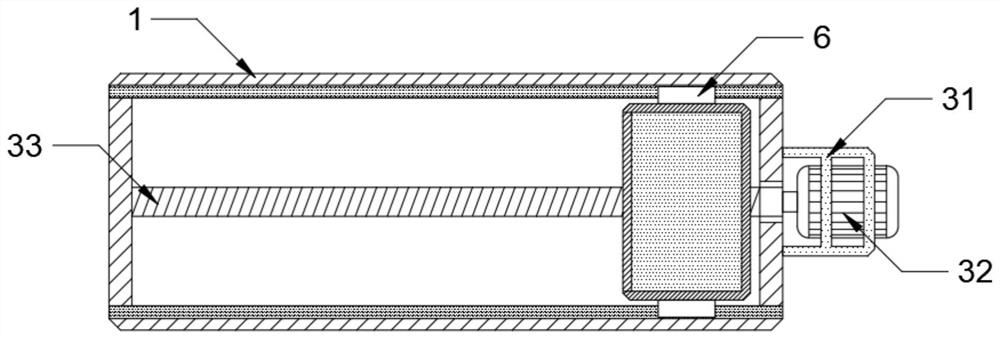

Axial flow pump for sewage treatment equipment

InactiveCN108843581ARelieve cloggingImprove work efficiencyPump componentsPump installationsAxial-flow pumpCoupling

The invention discloses an axial flow pump for sewage treatment equipment. The axial flow pump comprises an axial flow pump body, wherein one and the same fixing rod is fixedly mounted on the inner walls of two sides of the axial flow pump; a rotating rod is rotationally mounted on the top side of the fixing rod; a placing frame is fixedly mounted at the top end of the rotating rod; a fixing frameis fixedly mounted on the top side of the axial flow pump body; a rotating motor is fixedly mounted on the inner wall of the top side of the fixing frame; a rotating shaft is fixedly mounted on an output shaft of the rotating motor through a coupling; the bottom end of the rotating shaft extends into the placing frame positioned in the axial flow pump body; a rotating groove is formed in the inner wall of the bottom side of the placing frame; and the bottom end of the rotating shaft is rotationally mounted in the rotating groove. The axial flow pump disclosed by the invention is reasonable instructural design and convenient to use; pollutant accumulating on the inner walls of two sides of the axial flow pump can be cleared; the blockage phenomenon of the axial flow pump can be effectively relieved; and accordingly, the working efficiency of the axial flow pump can be improved and the usage demand of a user can be met.

Owner:浙江兴辰机械科技有限公司

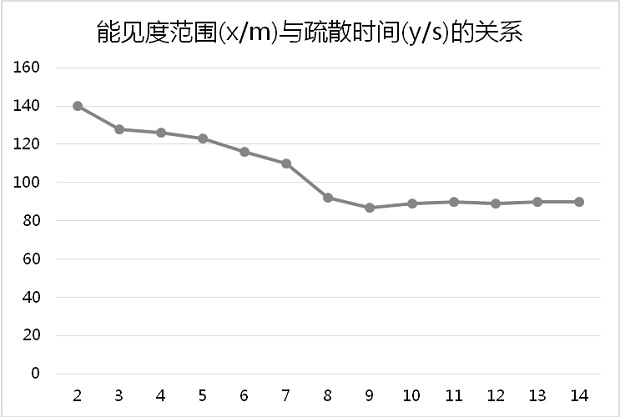

Crowd evacuation method in low-visibility environment

InactiveCN111651886ARelieve cloggingEnsure safetyDesign optimisation/simulationSpecial data processing applicationsPanicSimulation

The invention provides a crowd evacuation method in a low-visibility environment. The crowd evacuation method comprises the following steps: firstly, establishing an initial model of social force by virtue of a Newton second law; secondly, defining an acting force in an exponential form, representing the attraction of the leader to a common individual within the influence range, and selecting theexpected speed direction of the individual according to the familiarity degree of the individual to the surrounding environment; and finally, adding panic factors and visual influence factors, and thevisibility range, and studying the number and positions of leaders and the influence of the panic factors on the crowd evacuation efficiency. The model can effectively improve the evacuation efficiency and reduce crowd congestion and trampling phenomena, and has practical significance.

Owner:NANJING UNIV OF POSTS & TELECOMM

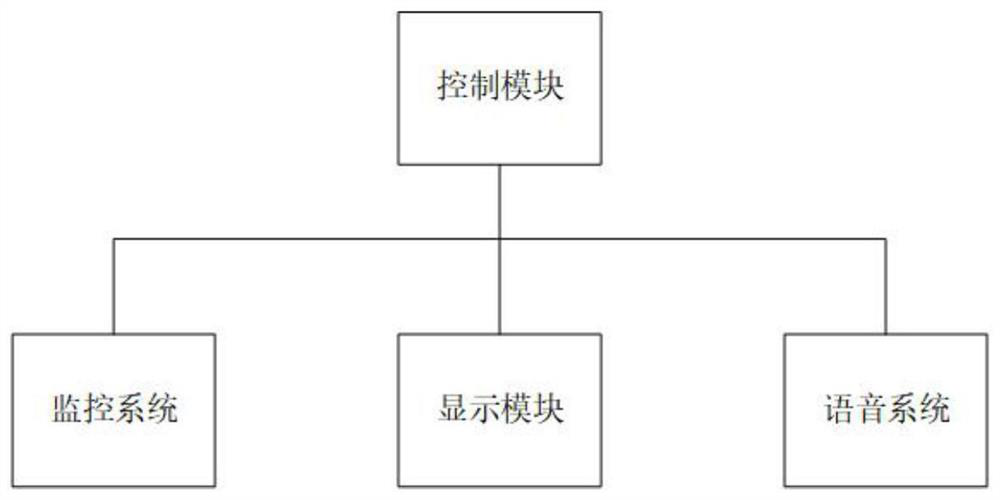

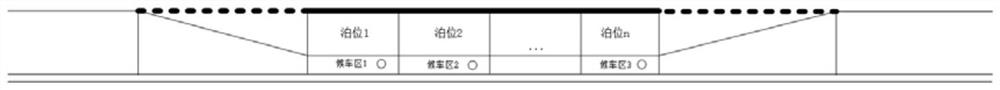

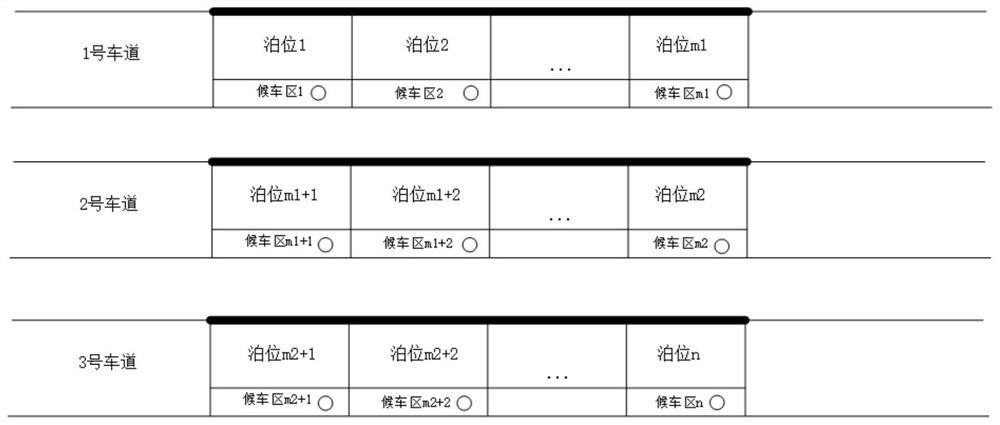

An intelligent bus platform system

ActiveCN110164177BSolve the problem of random parking in the pitShort stayIndication of parksing free spacesDisplay deviceTransit bus

The invention discloses an intelligent bus stop system, which includes a platform, a stop sign and a bus shelter. A monitoring system and a voice system are installed in the bus shelter. The monitoring system includes a camera and an image processing device. The camera captures images of the bus stop area; images The processing device processes the captured images, extracts parking space free information and parked vehicle information, and transmits the results to the control terminal in the platform. The control terminal extracts the bus length information sent by the command center and the historical data of the bus's stay time at the previous platform. And the information from the image processing device uses the Markov stochastic model to calculate the possible dwell time to allocate parking spaces to the buses. There is a display device in the stop sign. The voice system and the display device are connected to the control terminal of the platform. After the control terminal completes an assignment, the voice prompts the bus parking information, displays the vehicle that is about to park at the parking lot, and guides passengers and bus drivers to the designated parking space. go ahead.

Owner:HEFEI UNIV OF TECH

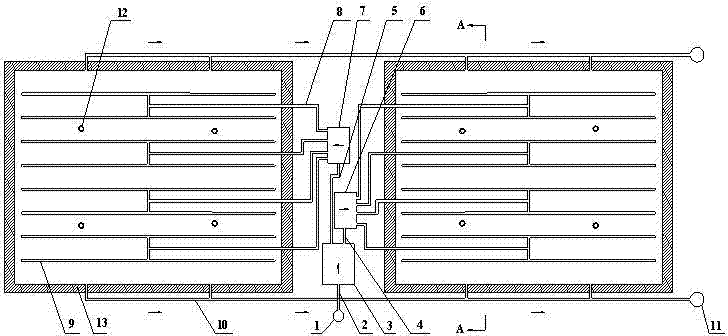

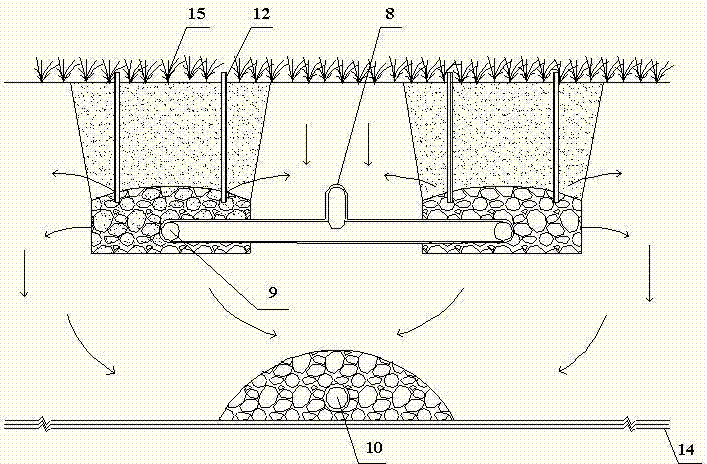

Scattered sewage subsurface infiltration ecological processing system

InactiveCN102092853BPlay a decontamination roleEven distribution of waterBiological water/sewage treatmentCold seasonDistribution system

The invention relates to a scattered sewage subsurface infiltration ecological processing system which comprises a plurality of subsurface infiltration regions, wherein an artificial substrate is filled around pipelines inside the subsurface infiltration regions; a water distribution system is arranged between every two subsurface infiltration regions, and comprises a water distribution well, a primary distribution tank and two secondary distribution tanks; water collection pipes are distributed on both sides of each subsurface infiltration region; one end of each water collection pipe penetrates through the tank wall of the subsurface infiltration region and enters the subsurface infiltration region, and the other end is connected with a water collection well; and a plurality of observation wells are arranged in each subsurface infiltration region. On one hand, the invention provides an ecological subsurface infiltration sewage processing system for scattered regions, such as sanatoria, holiday villages, villa areas, suburb apartment type villages and the like, and can meet the environmental protection requirements for scattered sewage processing and recycling; and on the other hand, the system has the advantages of uniform water distribution, low blocking tendency, high load and the like, and can still stably operate in cold seasons.

Owner:SHENYANG UNIV

Household floor heating circulating water system inorganic composite micro-particle protective agent and preparation method of protective agent

InactiveCN110217901ANot corrosiveEasy to prepareSpecific water treatment objectivesTreatment using complexing/solubilising chemicalsFiltrationCarbon nanotube

The invention discloses a household floor heating circulating water system inorganic composite micro-particle protective agent and a preparation method of the protective agent. The preparation methodcomprises the following steps: first adding carbon nanotubes into a mixed acid, performing stirring and refluxing, performing filtering, performing vacuum drying to obtain acidified carbon nanotubes,dispersing the acidified carbon nanotubes into dimethylformamide, dropwise adding thionyl chloride, continuously carrying out a reaction, adding tetrahydrofuran, performing centrifugal separation, performing vacuum drying to obtain acyl chlorination carbon nanotubes, adding the acyl chlorination carbon nanotubes into a diamine, adding a condensing agent and continuously carrying out a reaction, performing washing, performing filtering, performing vacuum drying to obtain aminated carbon nanotubes, then dissolving silver nitrate, ammonia water and anhydrous glucose into water, performing uniformstirring, adding the aminated carbon nanotubes for a reaction, and performing filtration, washing, drying, sintering, and grinding to obtain the aminated carbon nanotube nano silver composite material. The preparation process is simple, and can be industrially produced, and the prepared inorganic composite micro-particle protective agent has multiple effects of scale inhibition, corrosion inhibition, bacteriostasis and anti-clogging.

Owner:成都纳海川环境工程有限公司

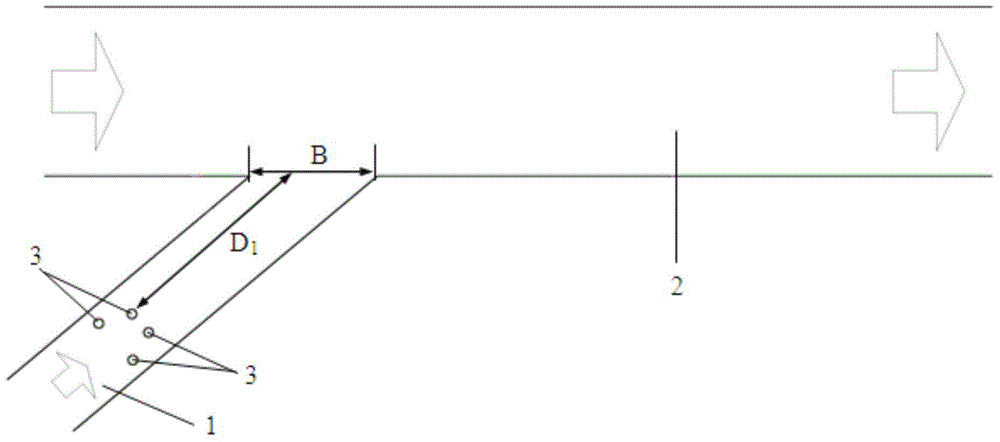

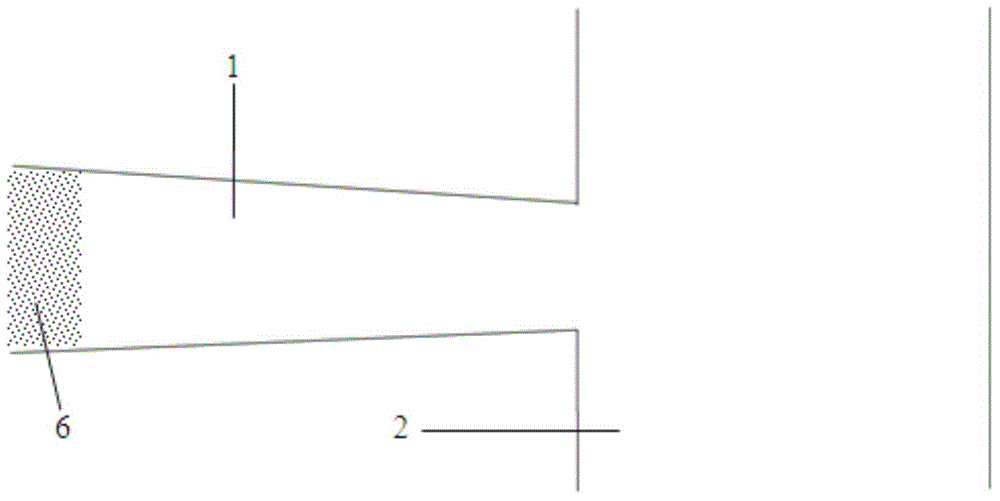

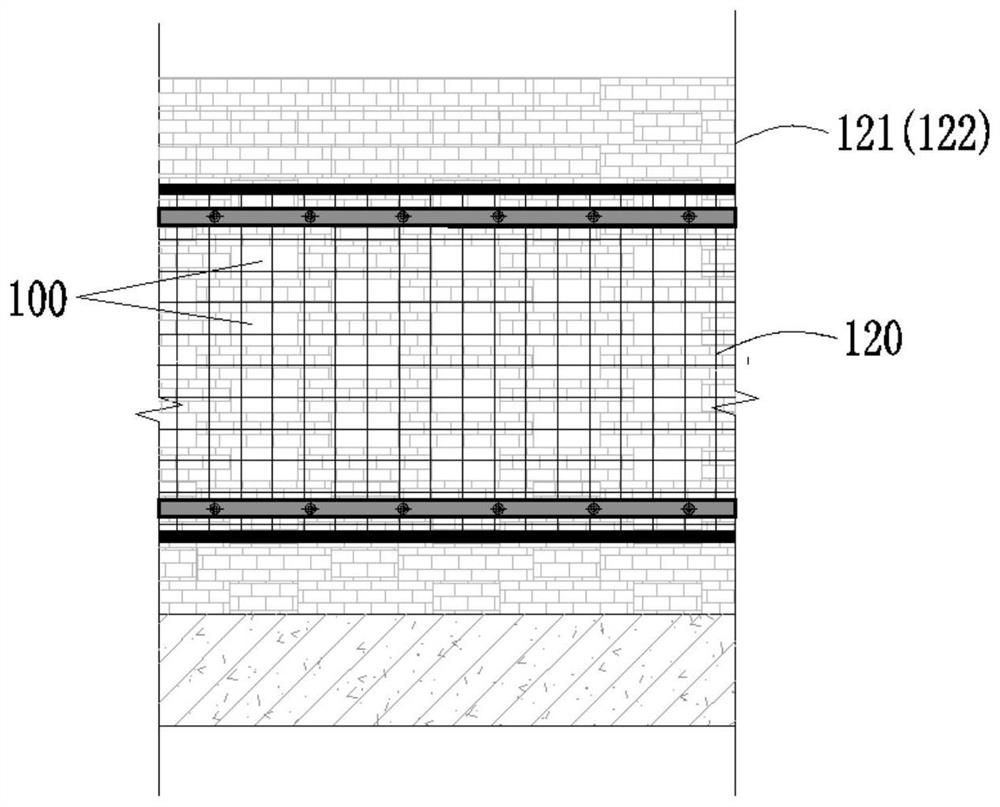

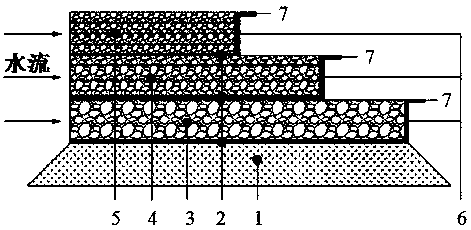

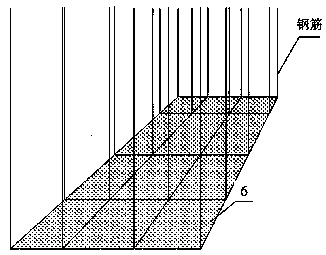

Method for mitigating silt blockage of confluence of main stream and tributary of mountain river

The invention belongs to the technical field of water and sediment movement disaster reduction for mountain rivers, and provides a method for mitigating the silt blockage of the confluence of a main stream and a tributary of a mountain river. The steps are as follows: (1) the position of the concentrated flow route of the tributary meeting the main stream is surveyed when the tributary is in the normal water level period, and the position of the concentrated flow route of the tributary meeting the main stream and the maximum siltation thickness of the silt of the confluence of the main stream and the tributary after flood subsidence are surveyed when the tributary is in the flood period; (2) according to the surveys of step 1, at least two rows of water-blocking piers are arranged in the tributary, at least three water-blocking piers are arranged, and the position of each water-blocking pier needs to meet the following conditions: each water-blocking pier is located outside the position of the concentrated flow route of the tributary when the tributary is in the normal water level period, and each water-blocking pier is located within the position of the concentrated flow route of the tributary when the tributary is in the flood period. The method described by the invention can mitigate the adverse influence of the forced silt discharge phenomenon of the tributary on the flood carrying safety of the riverway and the configuration of the riverway, thus increasing the flood carrying safety of the riverway of the mountain river.

Owner:SICHUAN UNIV

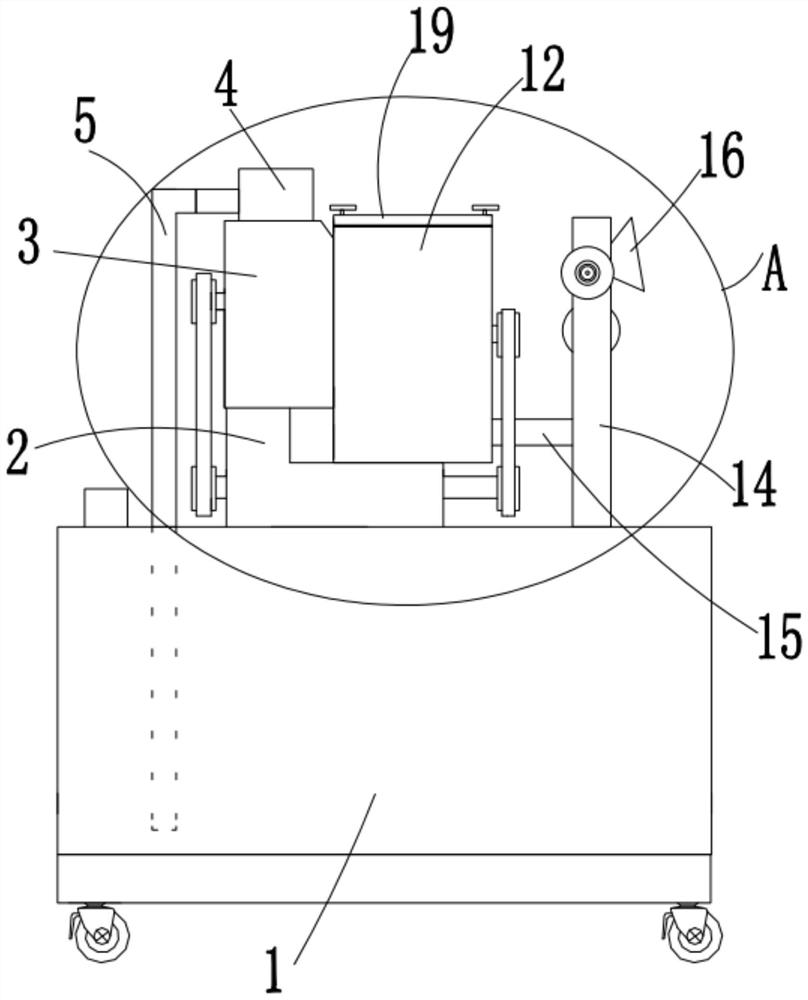

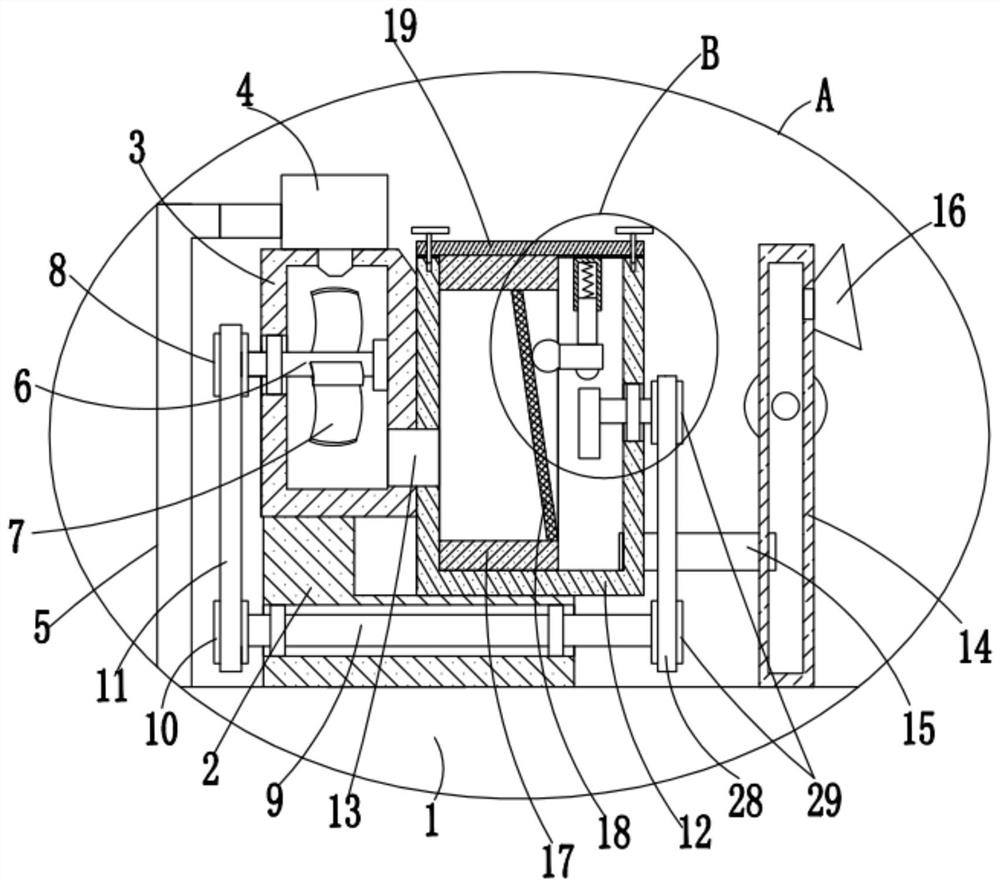

Anti-blocking heat exchanging device for pulverized coal boiler air pre-heater

PendingCN111981501AIncrease temperatureRelieve cloggingCombustion processIndirect carbon-dioxide mitigationEngineeringMechanical engineering

The invention discloses an anti-blocking heat exchanging device for a pulverized coal boiler air pre-heater. The anti-blocking heat exchanging device for the pulverized coal boiler air pre-heater comprises a main body. Pipes are arranged at two ends of the main body. The pipes are connected with a dust collector and an induced draft fan. The interior of the main body is divided into a plurality ofheat exchanger unit modules. Each heat exchanger unit module comprises an outer frame which is a cube or cuboid structure. Two ends of each outer frame are flues. A hollow cylinder is arranged insideeach outer frame. The forming direction of flues at two ends of each outer frame are identical with the installing direction of the pipes. The installing direction of each hollow cylinder is perpendicular to the installing direction of the pipes. Two ends of each hollow cylinder are connected respectively with an air feeder and an air pre-heater. By means of the anti-blocking heat exchanging device for the pulverized coal boiler air pre-heater, the flue gas temperature at the outlet of the air pre-heater is improved; the blocking phenomenon of the air pre-heater caused by hydrogen ammonium sulfate can be effectively mitigated; heat exchange is conducted at the inlet of the induced draught fan; the flue gas temperature entering the boiler smoke window is lowered; and the boiler efficiencyis improved.

Owner:NORTHWEST BRANCH OF CHINA DATANG CORP SCI & TECH RES INST

Method and system for performing atomization deodorization by utilizing plant extracting solution

PendingCN112675350AReasonable designRelieve cloggingAtomized substancesStationary filtering element filtersProcess engineeringLiquid storage tank

The invention discloses a method and system for performing atomization deodorization by utilizing a plant extracting solution. The system for performing atomization deodorization comprises a liquid storage tank, wherein a bottom plate is fixedly connected to the bottom of the liquid storage tank, walking wheels are rotatably mounted at four corners of the bottom of the bottom plate, and an L-shaped support is fixedly mounted at the top of the liquid storage tank; and a hydraulic driving box is fixedly mounted at the top of the L-shaped support, a high-pressure water pump is fixedly mounted at the top of the hydraulic driving box, and a water inlet of the high-pressure water pump communicates with and is fixedly provided with an L-shaped water suction pipe. The system is reasonable in design, a mixed solution formed by a plant extracting solution and water can be atomized, sprayed out and deodorized, impurities can be automatically vibrated and filtered when the mixed solution is sprayed, the device can be effectively prevented from being statically accumulated and covered by a large quantity of particle impurities through vibration force generated by a filter screen, a blocking phenomenon is relieved, the filtering efficiency and stability are improved, impurities can be conveniently collected and rapidly taken out, the use requirement is met, and use is facilitated.

Owner:厦门良航叮咚科技股份有限公司

Spinning stoste of cellulose derivative and its preparation and use

InactiveCN1314846CSolve the spinnabilityRelieve cloggingMonocomponent cellulose artificial filamentAcetic acidFiltration

Owner:SUZHOU UNIV

Subsurface coupled wetland for nitrogen and phosphorus removal

InactiveCN112851031APrevents the problem of large amounts of waterAchieve self-regulationWater contaminantsTreatment involving filtrationRiver routingStream flow

The invention discloses a subsurface coupled wetland for nitrogen and phosphorus removal. The subsurface coupled wetland comprises a water inlet channel, a wetland main body and a water outlet channel which are sequentially arranged along a water inlet direction, wherein the wetland main body comprises a water inlet distribution lattice wall, a water outlet distribution lattice wall and a filler area arranged between the water inlet distribution lattice wall and the water outlet distribution lattice wall, the filler area is filled with a phosphorus removal filter material, the water inlet distribution lattice wall is arranged at the joint of the water inlet channel and the wetland main body, the water outlet distribution lattice wall is arranged at the joint of the wetland main body and the water outlet channel, and the water inlet distribution lattice wall and the water outlet distribution lattice wall are respectively provided with a plurality of rows of water through holes. According to the invention, the subsurface coupled wetland is used for river channel water quality treatment, shows horizontal subsurface flow at low flow, has good pollutant removal capacity, ensures effluent quality, takes surface flow as a main part and subsurface flow as an auxiliary part at high flow, prevents suspended matters from entering a filter bed to cause blockage, and prolongs the service life of a wetland; and the water distribution lattice walls are respectively arranged at the water inlet end and the water outlet end of the wetland main body, so that self-regulation of flow is realized, surface flow / subsurface flow can be automatically regulated according to the water level, and manual control regulation is not needed.

Owner:HANGZHOU QINLIN ECOLOGICAL TECH CO LTD

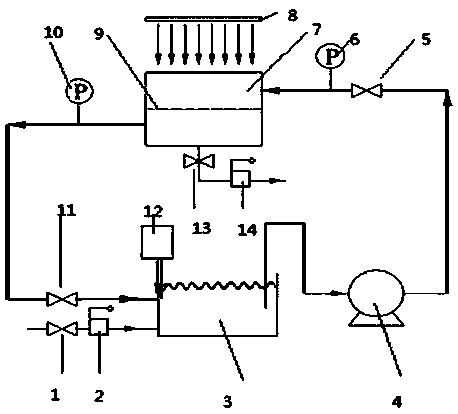

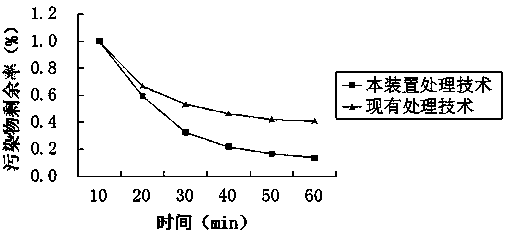

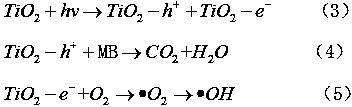

An ultrasonic photocatalytic combined sewage treatment device and its treatment process

ActiveCN106186269BSimple operation and managementEasy maintenanceWater/sewage treatment by irradiationWater treatment compoundsPeristaltic pumpPhotocatalytic reaction

Owner:江苏海壹环境科技有限公司

Vacuum prepressing method having alternating type air exhaust

InactiveCN106759237APostpone gatheringDelayed clogging timeSoil preservationEngineeringElectrical and Electronics engineering

The invention discloses a vacuum prepressing method having alternating type air exhaust. Each drain board is connected with corresponding drain branch pipes through bowknots, wherein all the drain branch pipes are arranged side by side; a first row of the drain branch pipes is set to be 1, a second row of the drain branch pipes is set to be 2, and the rest can be done in the same manner. The vacuum prepressing method is characterized in that two main pipes arranged side by side are adopted, wherein one of the main pipes is a first main pipe, and the other one is a second main pipe; the drain branch pipes in an odd number are connected with the first main pipe; the drain branch pipes in an even number are connected with the second main pipe; and two main pipes are respectively connected with different jet pumps, so that the situation of alternating type air exhaust of two jet pumps is realized through utilizing a controller. According to the vacuum prepressing method disclosed by the invention, the situation that the drain boards are silted untimely can be avoided.

Owner:TIANJIN UNIV

A kind of antibacterial plastic production device and using method thereof

The invention discloses an antibacterial plastic production device, comprising a workbench and a backing plate. The backing plate is fixedly installed at the bottom four corners of the worktable, and the backing plate is fixedly installed on the top of the work surface, and one end of the workbench is fixed A stable moving mechanism is installed, the output end of the stable moving mechanism is engaged and connected with a fast feeding mechanism, the low end of the fast feeding mechanism is symmetrically and fixedly installed with a convenient limit mechanism, and the backing plate includes Contact plate and fixed plate, four of the contact plates are evenly fixed and installed on the bottom four corners of the workbench, and the bottom of the contact plates are fixedly installed with fixed plates. This antibacterial plastic production device has a simple structure, convenient operation, and ease of processing equipment. The working pressure at the feed of the processing raw materials prevents clogging in the feeding link, and has high practicability.

Owner:NINGBO COLLEGE OF HEALTH SCI

Ecological filter dam used for small and medium river channel treatment

PendingCN109371904AImprove stabilityExtended functional periodDamsBarrages/weirsEnvironmental engineeringGabion

The invention provides an ecological filter dam used for small and medium river channel treatment. The ecological filter dam comprises a filter dam body, the filter dam body is sequentially composed of a dam base and filter layers in sequence from bottom to top, anti-seepage layers are arranged between the dam base and the filter layers, water fenders are arranged on the two sides and the rear ends of the filter layers, and a water extension plate is arranged at the upper end of the water fender on the rear end of the filter layers. Two to five filter layers are arranged, the anti-seepage layers are arranged between the filter layers, the permeating coefficients of the filter layers are sequentially reduced from bottom to top, and gabion boxes are adopted by the filter layers, and are filled with biological filler. Compared with the prior art, the ecological filter dam has the advantages that the dam base, the filter layers, the anti-seepage layers, the water fenders and the water extension plate are of a whole component splicing structure, the good integrality and stability are achieved, the service life is longer, the purification capacity of polluted water is higher, and the good drop reoxygenation capacity is achieved.

Owner:JIANGXI THERMAL POWER CONSTR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com