Method and system for performing atomization deodorization by utilizing plant extracting solution

A plant extract and liquid storage tank technology, which is applied in chemical instruments and methods, separation methods, atomized substances, etc., can solve the problem of impurity collection and rapid removal that are inconvenient to filter, plant extracts are prone to flocculation, and atomization nozzles are blocked Damage and other problems, to achieve the effect of easy collection and quick removal, improve filtration efficiency and stability, and meet the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

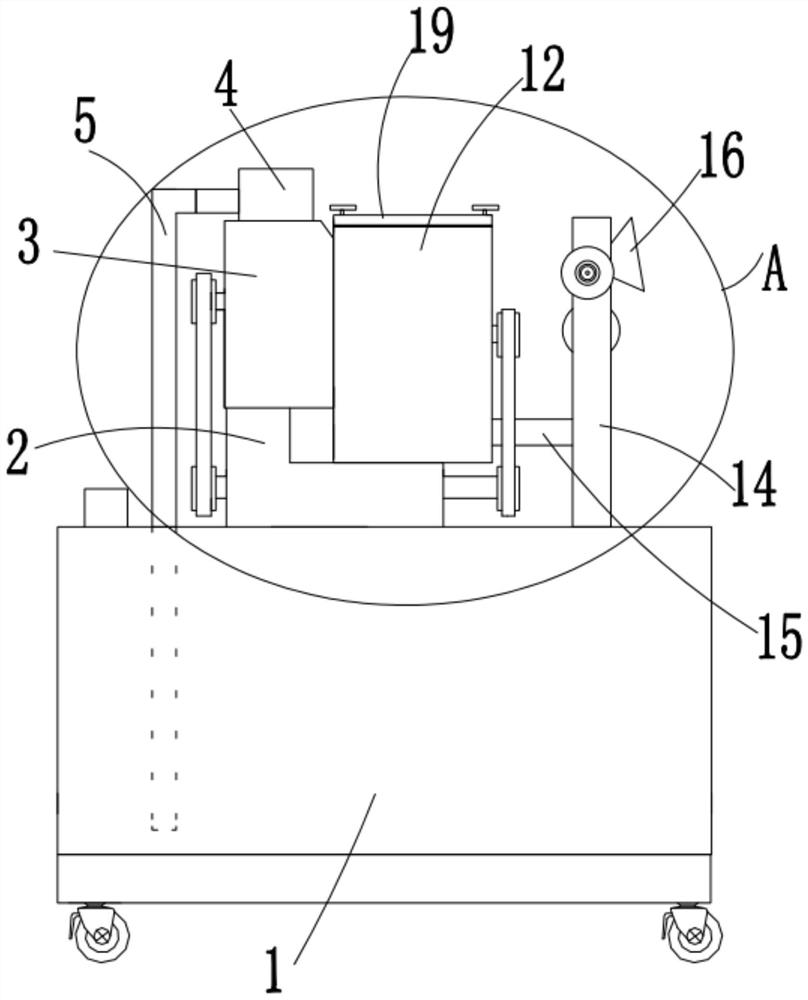

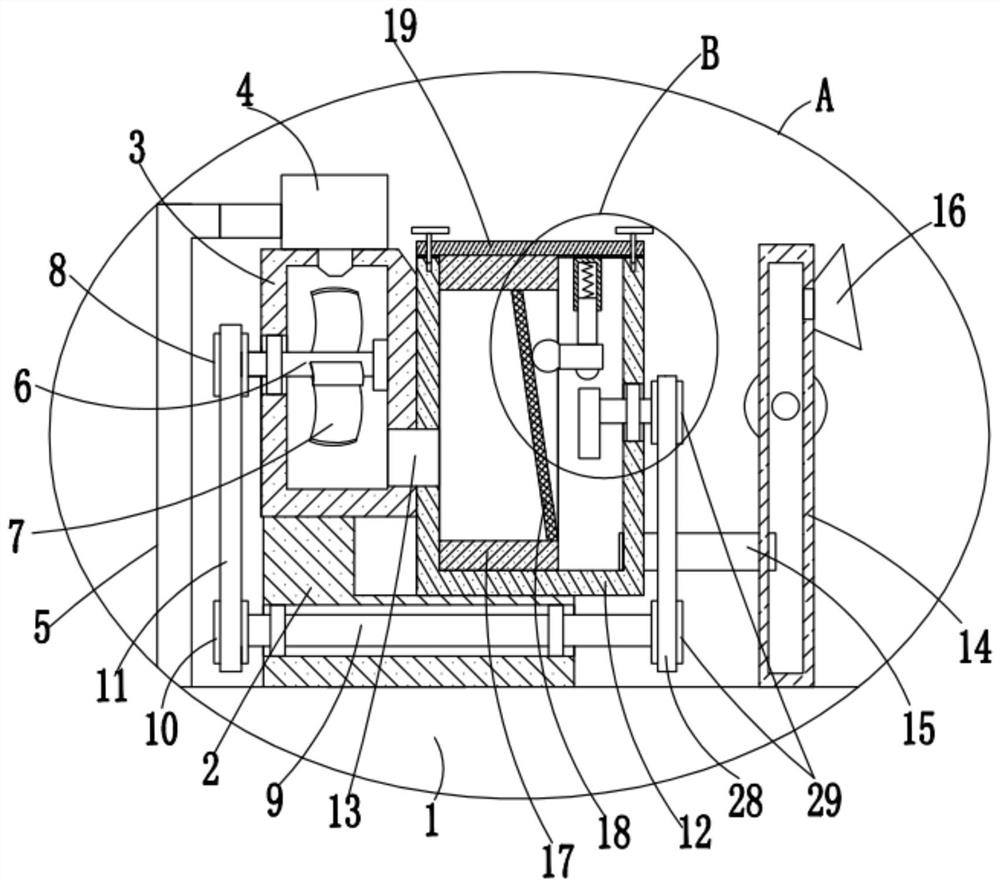

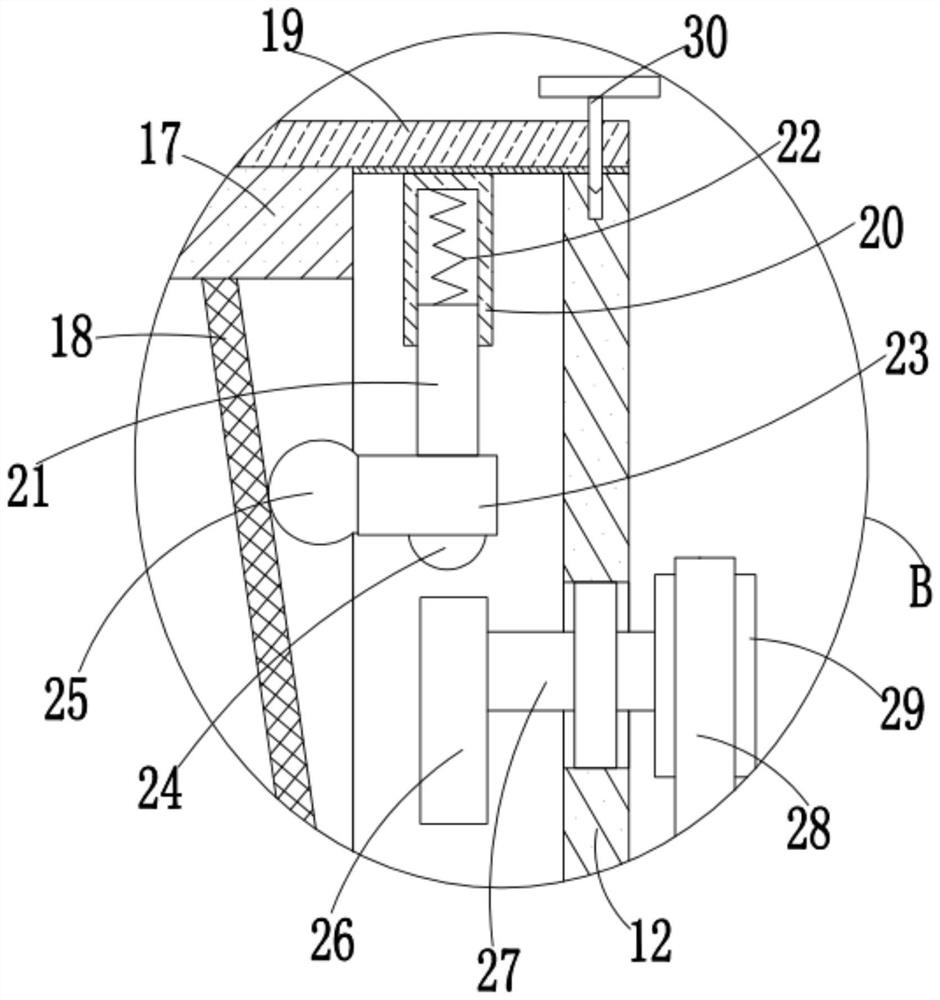

[0031]ReferFigure 1-4In this embodiment, the present embodiment proposes a system using a plant extract, including a reservoir 1, and the bottom of the reservoir 1 fixes a bottom plate, and the bottom ferrous portion of the bottom plate is rotated, and there is a row wheel, the liquid storage The top portion of the box 1 is fixedly mounted, and the top of the L-shaped support 2 is fixedly mounted, and the top of the hydraulic driving box 3 is fixedly mounted, and the water pump 4 in the high pressure water pump 4 is connected. And the bottom end of the L-shaking pipe 5, the L-shaped water pipe 5 extends into the reservoir 1, and the inlet port of the high pressure water pump 4 extends into the hydraulic drive case 3, and the upper right side of the hydraulic drive case 3 is fixed to the top. The filter box 12 provided for the opening is inserted with the left side of the hydraulic cassette 12 and fixedly provided with the same water pipe 13, and the bottom portion of the filter box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com