Spinning stoste of cellulose derivative and its preparation and use

A technology of cellulose derivatives and spinning dope, which is applied to the spinning dope of cellulose ethers and esters and its preparation and application. The spinning dope of cellulose derivatives and its preparation and application can solve the problem of fiber spinning Unfavorable effects on molding and structural properties, inability to produce cellulose ether and ester ultrafine fibers, and uneven fiber diameters, etc., to achieve the effects of low price, strong adsorption, and uniform diameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Using cellulose acetate butyrate (CAB) as raw material, first prepare the CAB spinning stock solution, the solvent is a mixed solvent of acetic acid and acetone, acetic acid: acetone = 1: 2 (volume ratio), and the cationic surfactant is hexadecane Trimethylammonium bromide (CTAB), wherein, the CAB powder content is 50wt%, and the addition amount of CTAB surfactant is 1wt%, is stirred evenly under the temperature condition of 25 ℃, obtains uniform CAB after static defoaming spinning dope.

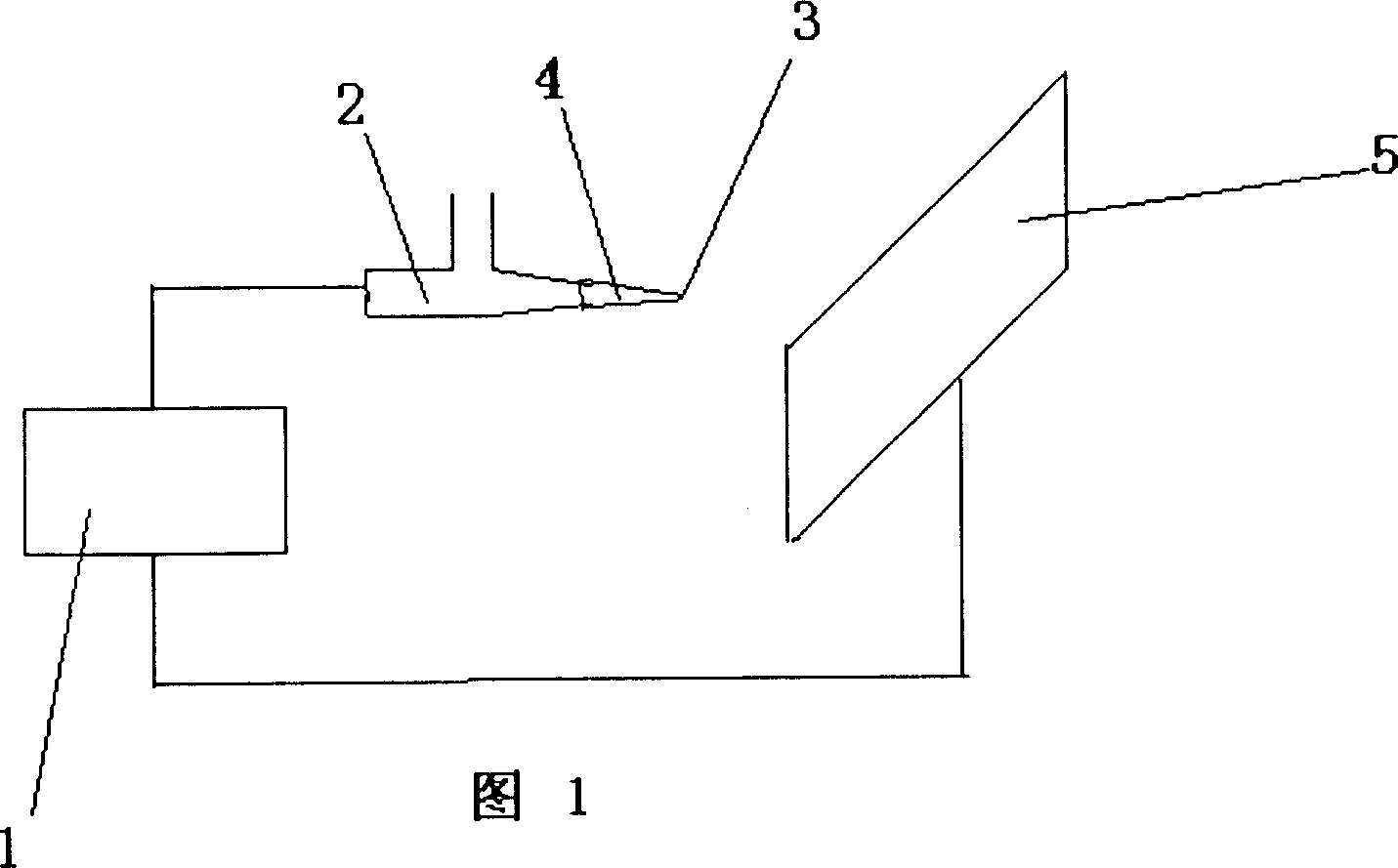

[0016] Referring to accompanying drawing 1, inject the prepared CAB spinning dope into the dope container 2, the spinning temperature is about 25°C, the output voltage of the high voltage power supply 1 is 10KV, and the distance between the receiving screen 5 and the spinneret 3 is 20cm , The receiving screen is aluminum foil. Take off the CAB superfine fibers collected on the receiving screen, the diameter is 500±50nm, smooth and uniform in thickness.

Embodiment 2

[0018] Using cellulose acetate propionate (CAP) as raw material, first prepare the CAP spinning stock solution, the solvent is acetone, and the nonionic surfactant is polyethylene glycol (PEG), wherein the CAB powder content is 40wt%, PEG polymerized The temperature is 20,000, the addition amount is 2wt%, the mixture is stirred evenly under the temperature condition of 50° C., and a uniform CAP spinning stock solution is obtained after standing for defoaming.

[0019] Referring to accompanying drawing 1, inject the prepared CAP spinning dope into the dope container 2, the spinning temperature is about 80°C, the output voltage of the high voltage power supply 1 is 25KV, and the distance between the receiving screen 5 and the spinneret 3 is 30cm , The receiving screen is copper mesh. Take off the CAP superfine fiber collected on the receiving screen, its diameter is 600±50nm, and it is smooth and uniform in thickness.

Embodiment 3

[0021] Using hydroxyethyl cellulose (HEC) as raw material, first prepare the HEC spinning stock solution, the solvent is water, the anionic surfactant is sodium dodecylsulfonate, wherein the HEC powder content is 30wt%, and the surfactant is added The amount is 2.5wt%, and it is evenly stirred on a magnetic stirrer at 30° C., and a uniform HEC spinning stock solution is obtained after standing for defoaming.

[0022] Referring to accompanying drawing 1, inject the obtained HEC spinning dope into the dope container 2, the spinning temperature is about 20°C, the output voltage of the high-voltage power supply 1 is 30KV, and the distance between the receiving screen 5 and the spinneret 3 is 10cm , The receiving screen is copper mesh. Take off the HEC superfine fiber collected on the receiving screen, its diameter is 300±50nm, and it is smooth and uniform in thickness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com