Functional master batch, preparation method thereof and application of functional master batch in preparation of polyester monofilament

A functional, masterbatch technology, applied in the field of monofilament, can solve the problem of viscosity drop of polyester monofilament, and achieve the effect of high yield, smooth surface and good weaving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

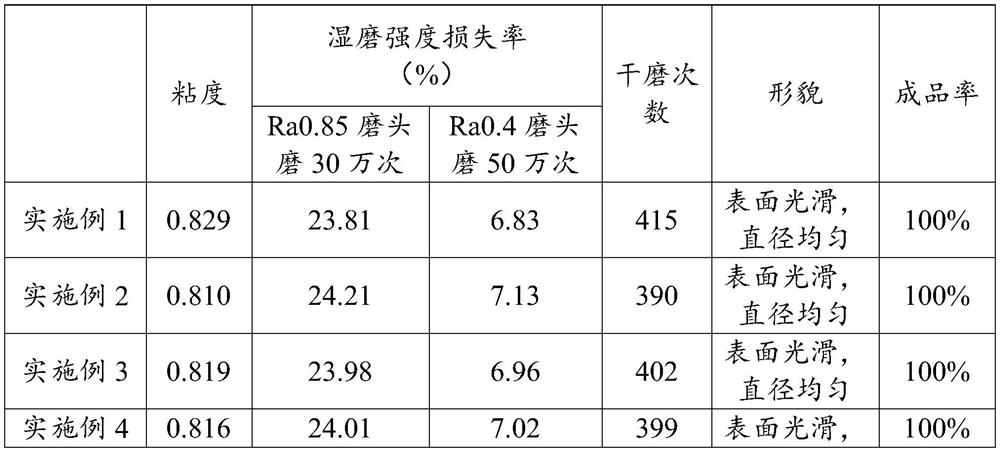

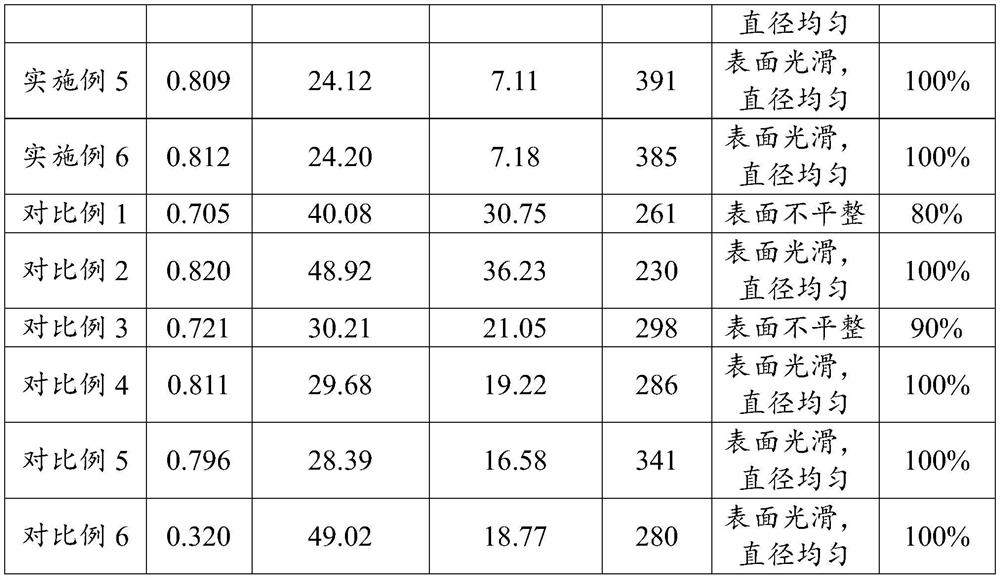

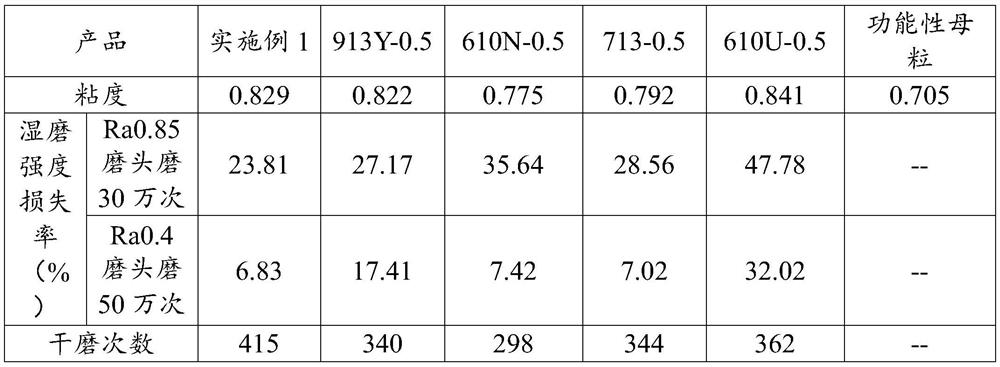

Examples

Embodiment 1

[0035] The wear-resistant polyester monofilament described in this embodiment includes the following raw materials by weight: 15 parts by weight of functional masterbatches and 85 parts by weight of high-viscosity polyester chips; wherein, the functional masterbatches include the following parts by weight of raw materials for preparation : 100 parts by weight of high-viscosity polyester chips, 2.5 parts by weight of ethylene methyl acrylate copolymer, 5 parts by weight of linear polyethylene, 12 parts by weight of titanium dioxide, 0.5 parts by weight of white oil, 1 part by weight of antihydrolysis agent and 0.3 parts by weight of antioxidant share.

[0036] The preparation method of described functional masterbatch, concrete steps are as follows:

[0037] After mixing high-viscosity polyester chips, ethylene methyl acrylate copolymer, linear polyethylene, titanium dioxide, white oil, anti-hydrolysis agent and antioxidant, put it into a screw extruder for melt extrusion at 25...

Embodiment 2

[0043]The high-strength wear-resistant polyester monofilament described in this embodiment includes the following raw materials in parts by weight: 30 parts by weight of functional masterbatches and 70 parts by weight of high-viscosity polyester chips; wherein, the functional masterbatches include the following parts by weight of Preparation raw materials: 100 parts by weight of high-viscosity polyester chips, 2.5 parts by weight of ethylene methyl acrylate copolymer, 5 parts by weight of linear polyethylene, 12 parts by weight of titanium dioxide, 0.5 parts by weight of white oil, 1 part by weight of anti-hydrolysis agent and antioxidant 0.3 parts by weight.

[0044] The preparation method of the functional masterbatch and the preparation method of the wear-resistant polyester monofilament are the same as in Example 1.

Embodiment 3

[0046] The high-strength wear-resistant polyester monofilament described in this embodiment includes the following raw materials in parts by weight: 15 parts by weight of functional masterbatches and 85 parts by weight of high-viscosity polyester chips; wherein, the functional masterbatches include the following parts by weight of Production raw materials: 100 parts by weight of high-viscosity polyester chips, 2 parts by weight of ethylene methyl acrylate copolymer, 4 parts by weight of linear polyethylene, 10 parts by weight of titanium dioxide, 0.1 part by weight of white oil, 0.5 parts by weight of anti-hydrolysis agent and antioxidant 0.2 parts by weight.

[0047] The preparation method of the functional masterbatch and the preparation method of the wear-resistant polyester monofilament are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com